ECO mode MERCEDES-BENZ ML320 1997 Complete Owner's Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML320, Model: MERCEDES-BENZ ML320 1997Pages: 4133, PDF Size: 88.89 MB

Page 377 of 4133

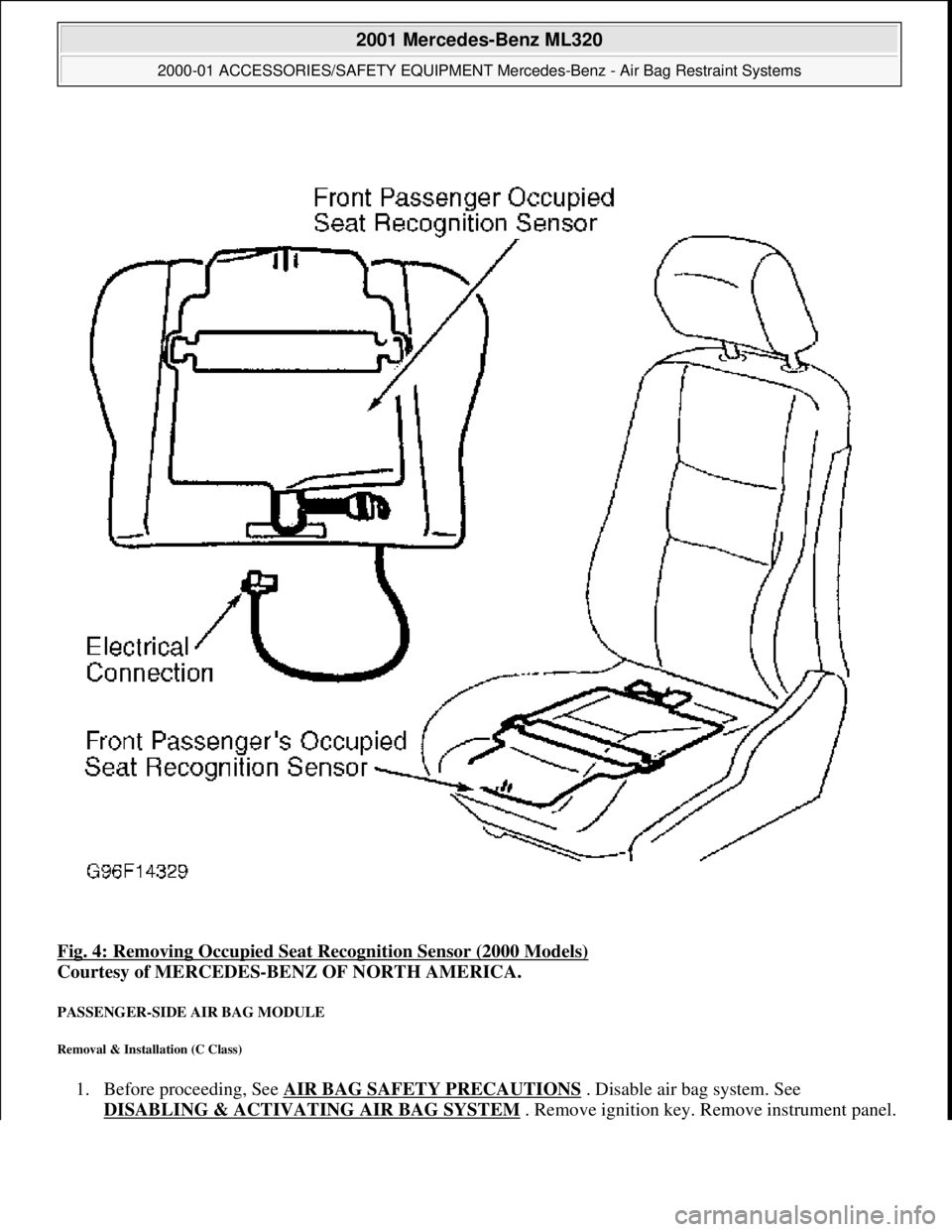

Fig. 4: Removing Occupied Seat Recognition Sensor (2000 Models)

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

PASSENGER-SIDE AIR BAG MODULE

Removal & Installation (C Class)

1. Before proceeding, See AIR BAG SAFETY PRECAUTIONS . Disable air bag system. See

DISABLING & ACTIVATI NG AIR BAG SYSTEM

. Remove ignition key. Remove instrument panel.

2001 Mercedes-Benz ML320

2000-01 ACCESSORIES/SAFETY EQUIPMENT Merc edes-Benz - Air Bag Restraint Systems

me

Saturday, October 02, 2010 3:44:45 PMPage 13 © 2006 Mitchell Repair Information Company, LLC.

Page 384 of 4133

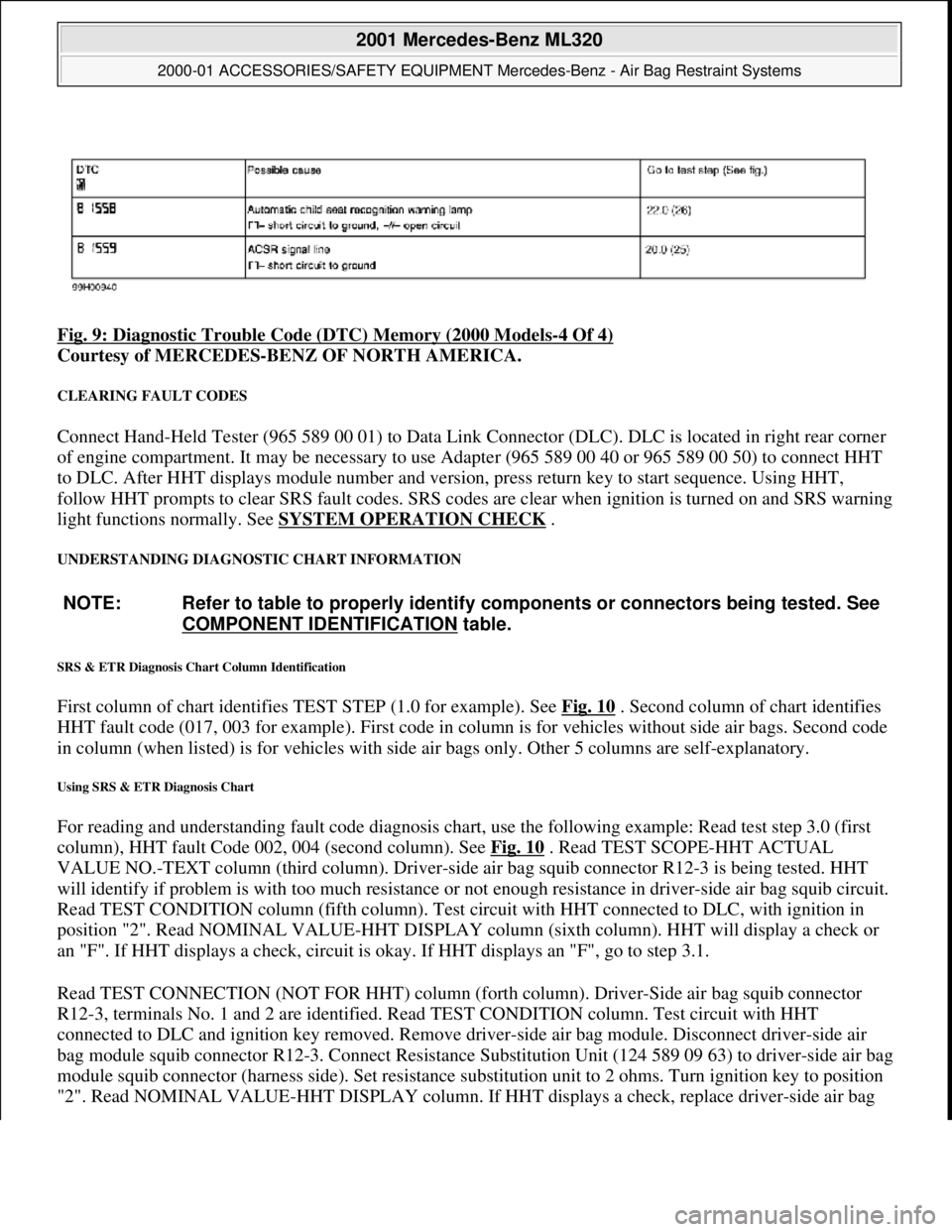

Fig. 9: Diagnostic Trouble Code (DTC) Memory (2000 Models-4 Of 4)

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

CLEARING FAULT CODES

Connect Hand-Held Tester (965 589 00 01) to Data Link Connector (DLC). DLC is located in right rear corner

of engine compartment. It may be necessary to use Adapter (965 589 00 40 or 965 589 00 50) to connect HHT

to DLC. After HHT displa ys module number and version, press return key to start sequence. Using HHT,

follow HHT prompts to clear SRS faul t codes. SRS codes are clear when ignition is turned on and SRS warning

light functions normally. See SYSTEM OPERATION CHECK

.

UNDERSTANDING DIAGNOSTIC CHART INFORMATION

SRS & ETR Diagnosis Chart Column Identification

First column of chart identifies TEST STEP (1.0 for example). See Fig. 10 . Second column of chart identifies

HHT fault code (017, 003 for example). First code in column is for ve hicles without side air bags. Second code

in column (when listed) is for ve hicles with side air bags only. Ot her 5 columns are self-explanatory.

Using SRS & ETR Diagnosis Chart

For reading and understanding fault code diagnosis chart, use the following example: Read test step 3.0 (first

column), HHT fault Code 002, 004 (second column). See Fig. 10

. Read TEST SCOPE-HHT ACTUAL

VALUE NO.-TEXT column (third column). Driver-side air bag squib connector R12-3 is being tested. HHT

will identify if problem is with too much resistance or not enough resistance in driver-side air bag squib circuit.

Read TEST CONDITION column (fifth column). Test ci rcuit with HHT connected to DLC, with ignition in

position "2". Read NOMINAL VALUE-HHT DISPLAY column (sixth column). HHT will display a check or

an "F". If HHT displays a check, circuit is okay. If HHT displays an "F", go to step 3.1.

Read TEST CONNECTION (NOT FOR HHT) column (fort h column). Driver-Side air bag squib connector

R12-3, terminals No. 1 and 2 are id entified. Read TEST CONDITION column. Test circuit with HHT

connected to DLC and igni tion key removed. Remove driver-side air bag module. Disconnect driver-side air

bag module squib connector R12-3. Conn ect Resistance Substitution Unit (124 589 09 63) to driver-side air bag

module squib connector (harness side). Set resistance substitution unit to 2 ohms. Turn ignition key to position

"2". Read NOMINAL VALUE-HHT DISPLAY column. If HHT displa

ys a check, replace driver-side air bag

NOTE: Refer to table to properly identify components or connectors being tested. See

COMPONENT IDENTIFICATION

table.

2001 Mercedes-Benz ML320

2000-01 ACCESSORIES/SAFETY EQUIPMENT Merc edes-Benz - Air Bag Restraint Systems

me

Saturday, October 02, 2010 3:44:46 PMPage 20 © 2006 Mitchell Repair Information Company, LLC.

Page 385 of 4133

module. If HHT displays an "F", go to step 3.2.

Read TEST CONNECTION (NOT FOR HHT) column. Horn -air bag clockspring connector A45x1, terminals

No. 1 and 2 are identified. Read TEST CONDITION column. Test circuit with HHT connected to DLC.

Remove ignition key. Connect Resist ance Substitution Unit (124 589 09 63 00) to horn-air bag clockspring

connector A45x1. Set resistance s ubstitution unit to 2 ohms. Read NOMINAL VALUE-HHT DISPLAY

column. If HHT displays a check, check horn-air ba g clockspring for continuity. Replace horn-air bag

clockspring as necessary. If HHT displays an "F", go to step 3.4.

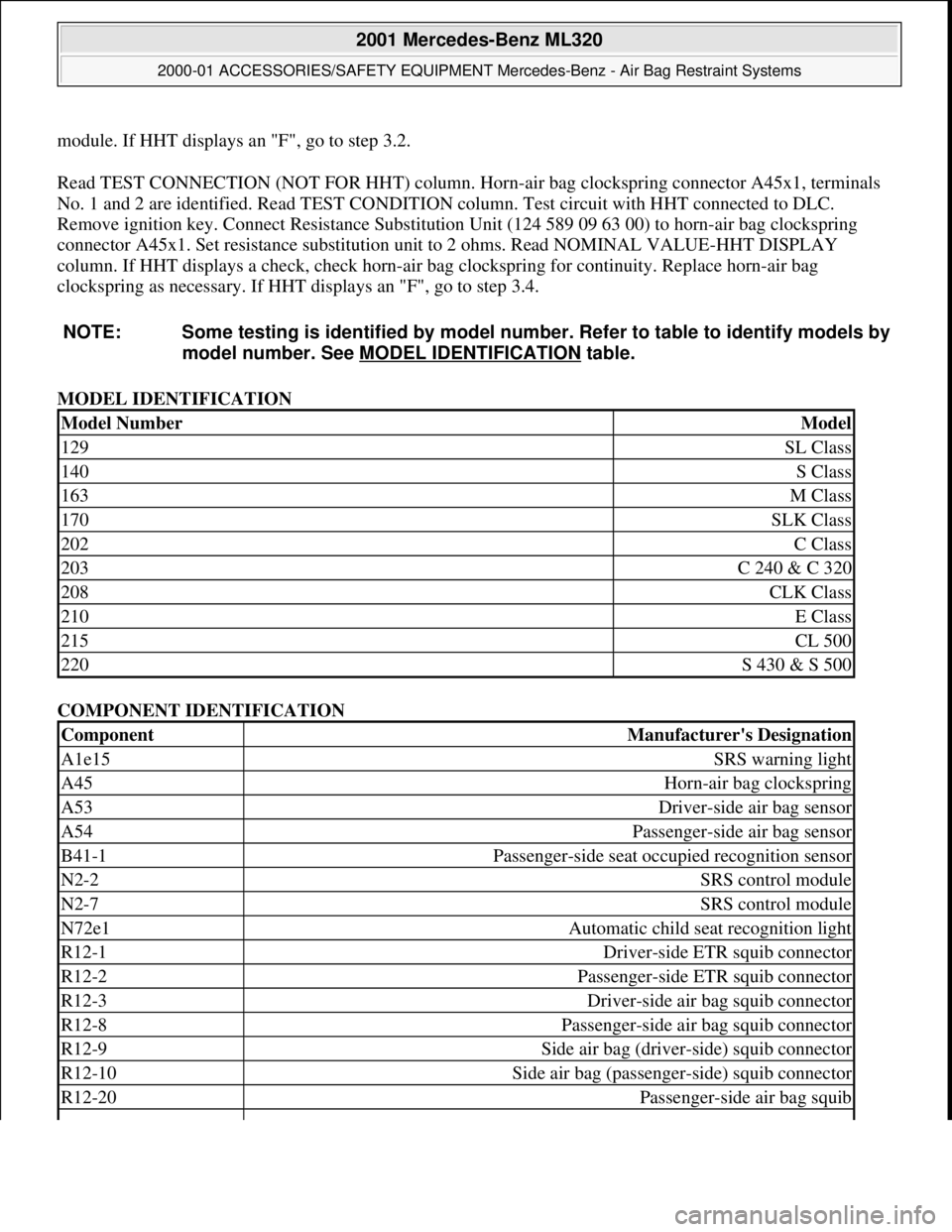

MODEL IDENTIFICATION

COMPONENT IDENTIFICATION

NOTE: Some testing is identified

by model number. Refer to table to identify models by

model number. See MO DEL IDENTIFICATION

table.

Model NumberModel

129SL Class

140S Class

163M Class

170SLK Class

202C Class

203C 240 & C 320

208CLK Class

210E Class

215CL 500

220S 430 & S 500

ComponentManufacturer's Designation

A1e15SRS warning light

A45Horn-air bag clockspring

A53Driver-side air bag sensor

A54Passenger-side air bag sensor

B41-1Passenger-side seat occupied recognition sensor

N2-2SRS control module

N2-7SRS control module

N72e1Automatic child seat recognition light

R12-1Driver-side ETR squib connector

R12-2Passenger-side ETR squib connector

R12-3Driver-side air bag squib connector

R12-8Passenger-side air bag squib connector

R12-9Side air bag (driver-side) squib connector

R12-10Side air bag (passenge r-side) squib connector

R12-20Passenger-side air bag squib

2001 Mercedes-Benz ML320

2000-01 ACCESSORIES/SAFETY EQUIPMENT Merc edes-Benz - Air Bag Restraint Systems

me

Saturday, October 02, 2010 3:44:46 PMPage 21 © 2006 Mitchell Repair Information Company, LLC.

Page 386 of 4133

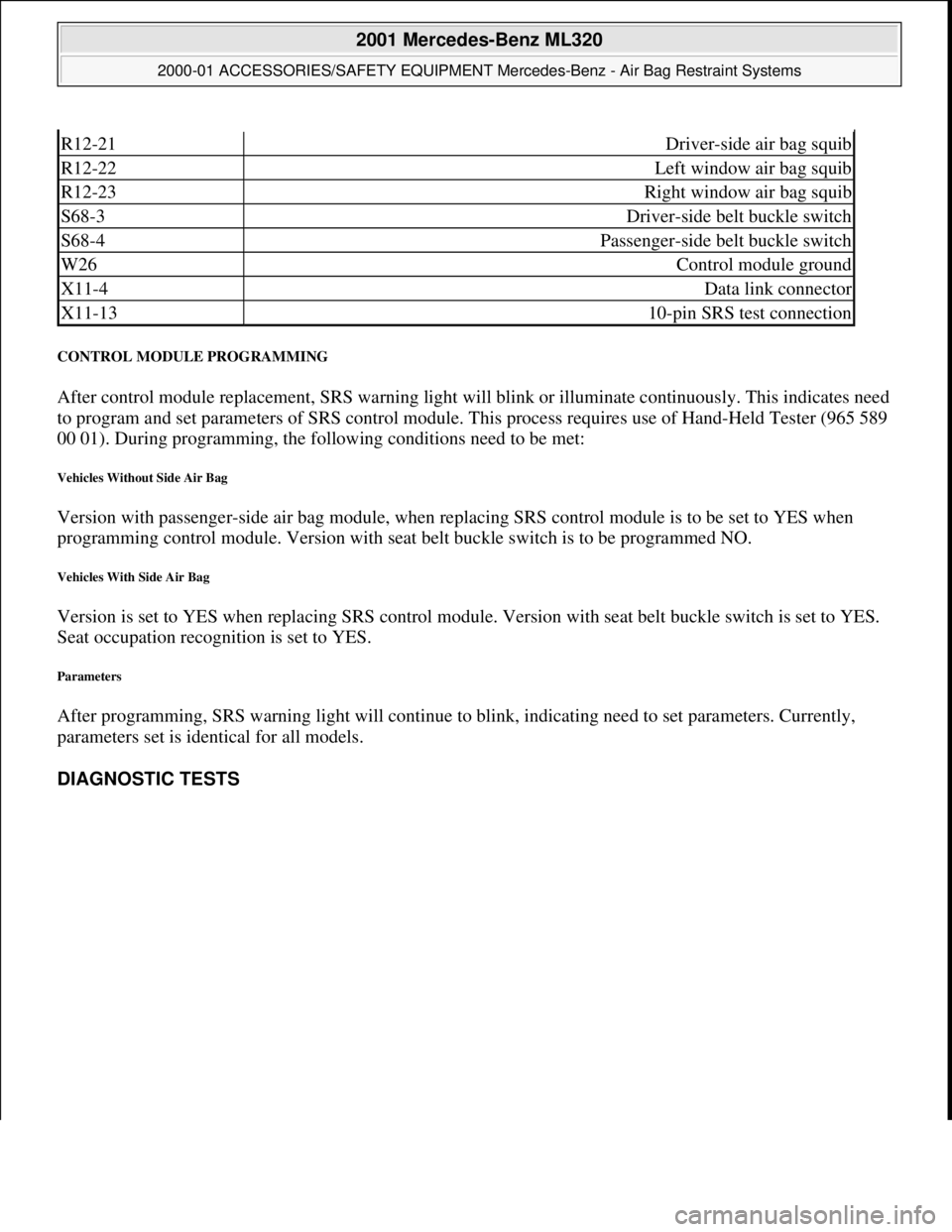

CONTROL MODULE PROGRAMMING

After control module replacement, SRS warning light will blink or illuminate continuously. This indicates need

to program and set paramete rs of SRS control module. This process requires use of Hand-Held Tester (965 589

00 01). During programming, the follow ing conditions need to be met:

Vehicles Without Side Air Bag

Version with passenger-side air bag module, when replac ing SRS control module is to be set to YES when

programming control module. Version with seat belt buckle switch is to be programmed NO.

Vehicles With Side Air Bag

Version is set to YES when replacing SRS control module. Version with seat belt buckle switch is set to YES.

Seat occupation recogni tion is set to YES.

Parameters

After programming, SRS warning light wi ll continue to blink, indicating need to set parameters. Currently,

parameters set is identical for all models.

DIAGNOSTIC TESTS

R12-21Driver-side air bag squib

R12-22Left window air bag squib

R12-23Right window air bag squib

S68-3Driver-side belt buckle switch

S68-4Passenger-side belt buckle switch

W26Control module ground

X11-4Data link connector

X11-1310-pin SRS test connection

2001 Mercedes-Benz ML320

2000-01 ACCESSORIES/SAFETY EQUIPMENT Merc edes-Benz - Air Bag Restraint Systems

me

Saturday, October 02, 2010 3:44:46 PMPage 22 © 2006 Mitchell Repair Information Company, LLC.

Page 430 of 4133

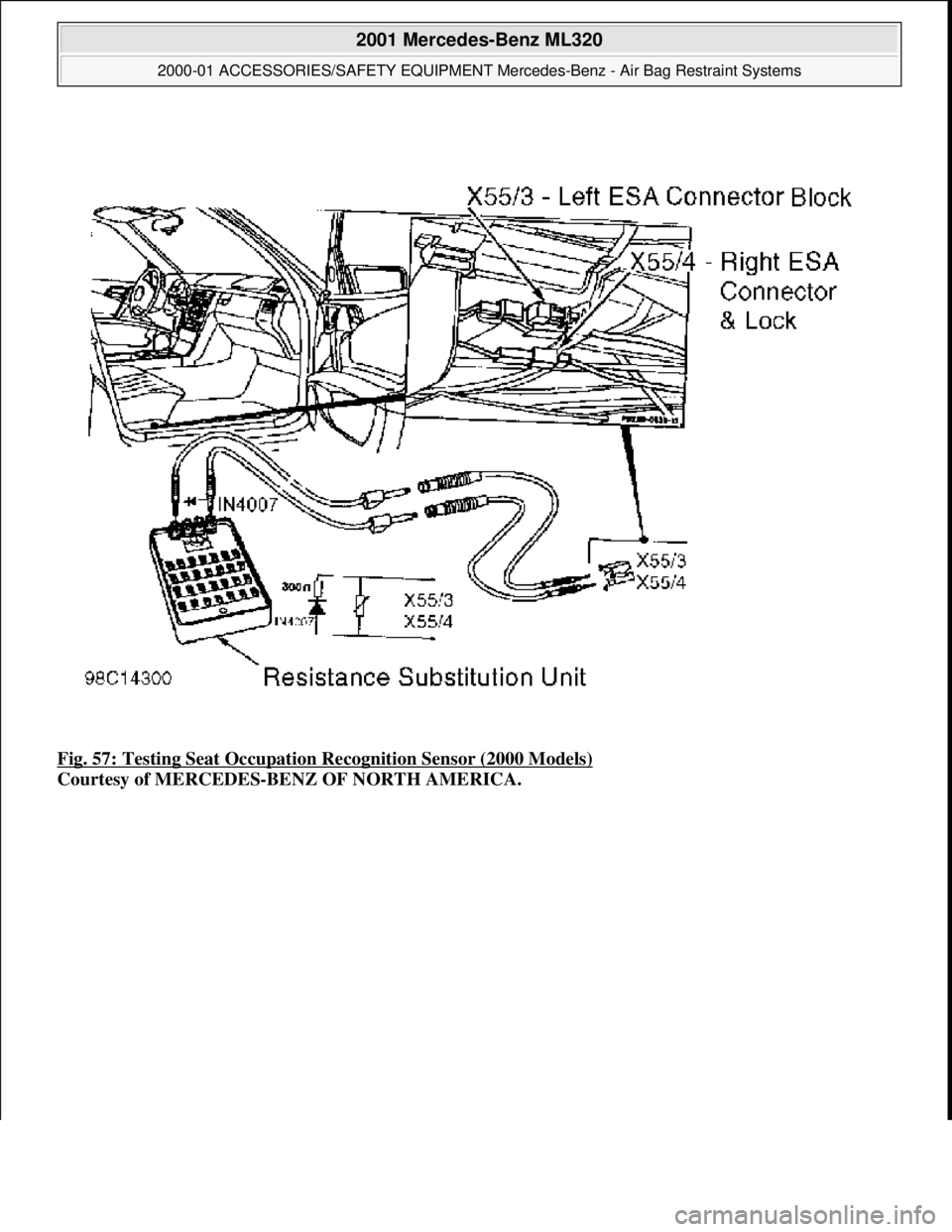

Fig. 57: Testing Seat Occupation Recognition Sensor (2000 Models)

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

2001 Mercedes-Benz ML320

2000-01 ACCESSORIES/SAFETY EQUIPMENT Merc edes-Benz - Air Bag Restraint Systems

me

Saturday, October 02, 2010 3:44:46 PMPage 66 © 2006 Mitchell Repair Information Company, LLC.

Page 431 of 4133

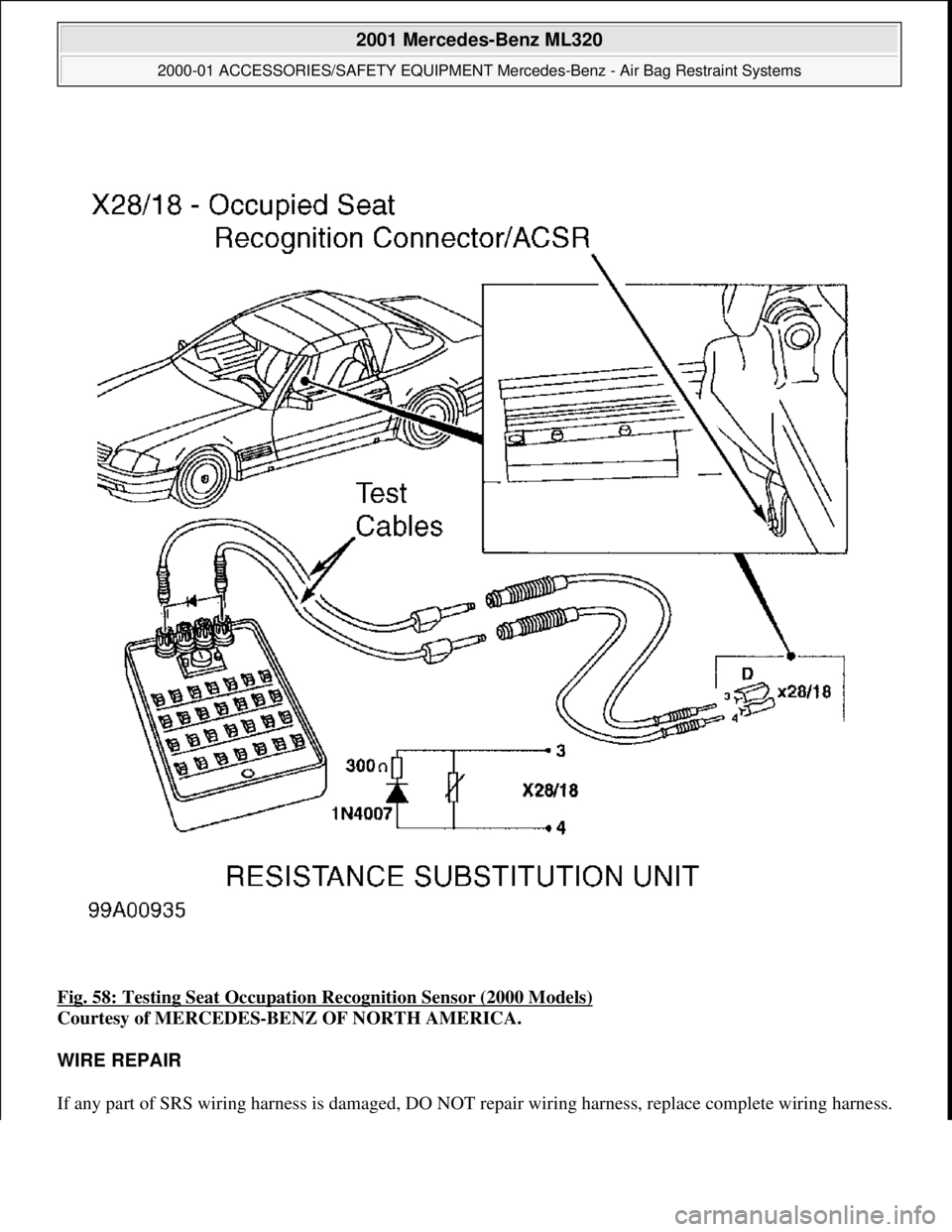

Fig. 58: Testing Seat Occupation Recognition Sensor (2000 Models)

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

WIRE REPAIR

If any part of SRS wiring harness is damaged, DO NOT repair wiring harness, replace complete wiring harness.

2001 Mercedes-Benz ML320

2000-01 ACCESSORIES/SAFETY EQUIPMENT Merc edes-Benz - Air Bag Restraint Systems

me

Saturday, October 02, 2010 3:44:46 PMPage 67 © 2006 Mitchell Repair Information Company, LLC.

Page 474 of 4133

7

Introduction Product information

Kindly observe the following in your own best interest:

We recommend using Mercedes-Benz original parts as well as conversion parts and accessories

explicitly approved by us for your vehicle model.

We have tested these parts to determine their reliability, safety and their special

suitability for Mercedes-Benz vehicles.

We are unable to make an assessment for other products and therefore cannot be held responsible

for them, even if in individual cases an official approval or authorization by governmental or other

agencies should exist. Use of such parts and accessories could adversely affect the safety,

performance or reliability of your vehicle. Please do not use them.

Mercedes-Benz original parts as well as conversion parts and accessories approved by us are available

at your authorized Mercedes-Benz Light Truck Center where you will receive comprehensive information, also on

permissible technical modifications, and where proper installation will be performed.

Page 503 of 4133

36

Tow-away protection

Te ch n ica l

data

Instruments

and controls Operation

Driving Instrument

cluster display Practical hints Car care Index

Tow-away alarm and glass breakage sensor

The switch is located in the overhead console.

The tow-away alarm and glass breakage sensor are part

of the antitheft alarm system.

Once the alarm system has been armed, the turn signal

lamps will flash rapidly and the horn will sound when

someone attempts to raise the vehicle, or breaks a

window and reaches into the passenger compartment. The alarm will last approximately 3 minutes in the form

of rapidly flashing turn signal lamps. At the same time

the horn will sound for approximately 30 seconds. The

alarm will stay on even if the vehicle is immediately

lowered.

If the alarm stays on for more than 20 seconds, an

emergency call is initiated automatically. See Tele Aid

on page 148.

To prevent triggering the tow-away alarm feature, switch

off the tow-away alarm and glass breakage sensor before

towing the vehicle, or when parking on a surface subject

to movement, such as a ferry or auto train.

To do so, turn key in steering lock to position 1, then

return it to position 0 and remove key from steering

lock.

Within 30 seconds, push left or right button. (On

vehicles equipped with optional trip computer, push

RESET or MODE button, display shows OFF.)

Exit vehicle, and lock vehicle with remote control.

The tow-away alarm and glass breakage sensor remain

switched off until the key is inserted in steering lock

and turned to position 1.

Page 507 of 4133

40

Seats

Te ch n ica l

data

Instruments

and controls Operation

Driving Instrument

cluster display Practical hints Car care Index

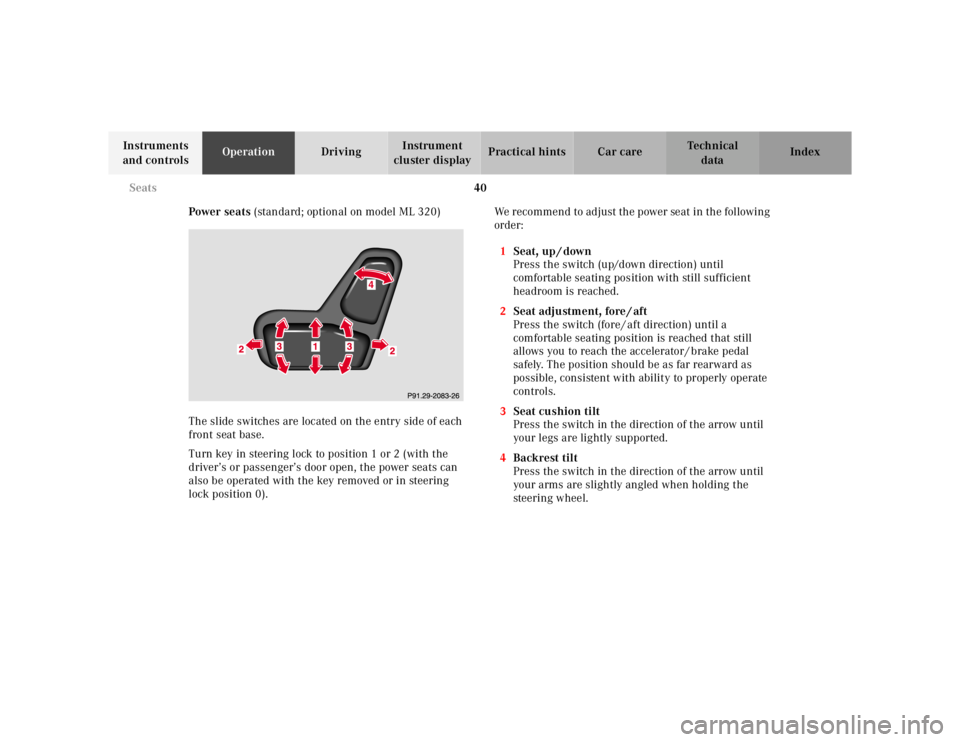

Power seats (standard; optional on model ML 320)

The slide switches are located on the entry side of each

front seat base.

Turn key in steering lock to position 1 or 2 (with the

driver’s or passenger’s door open, the power seats can

also be operated with the key removed or in steering

lock position 0). We recommend to adjust the power seat in the following

order:

1 Seat, up / down

Press the switch (up/down direction) until

comfortable seating position with still sufficient

headroom is reached.

2 Seat adjustment, fore / aft

Press the switch (fore / aft direction) until a

comfortable seating position is reached that still

allows you to reach the accelerator / brake pedal

safely. The position should be as far rearward as

possible, consistent with ability to properly operate

controls.

3 Seat cushion tilt

Press the switch in the direction of the arrow until

your legs are lightly supported.

4 Backrest tilt

Press the switch in the direction of the arrow until

your arms are slightly angled when holding the

steering wheel.

Page 509 of 4133

42

Seats

Te ch n ica l

data

Instruments

and controls Operation

Driving Instrument

cluster display Practical hints Car care Index

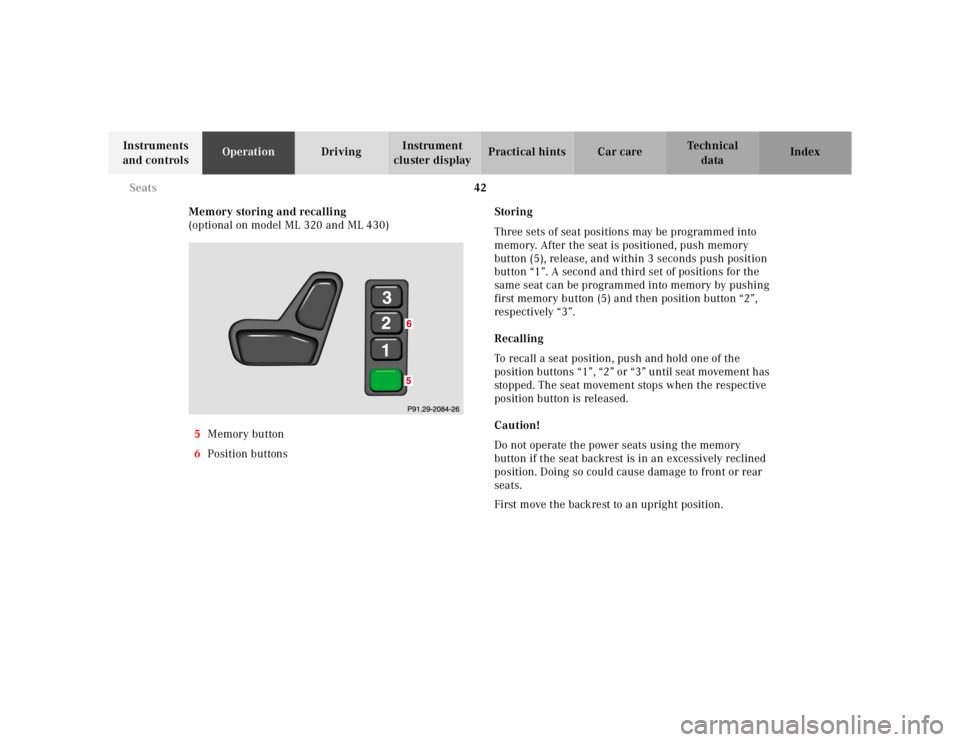

Memory storing and recalling

(optional on model ML 320 and ML 430)

5 Memory button

6 Position buttons Storing

Three sets of seat positions may be programmed into

memory. After the seat is positioned, push memory

button (5), release, and within 3 seconds push position

button “1”. A second and third set of positions for the

same seat can be programmed into memory by pushing

first memory button (5) and then position button “2”,

respectively “3”.

Recalling

To recall a seat position, push and hold one of the

position buttons “1”, “2” or “3” until seat movement has

stopped. The seat movement stops when the respective

position button is released.

Caution!

Do not operate the power seats using the memory

button if the seat backrest is in an excessively reclined

position. Doing so could cause damage to front or rear

seats.

First move the backrest to an upright position.