check oil MERCEDES-BENZ ML320 1997 Complete Manual PDF

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML320, Model: MERCEDES-BENZ ML320 1997Pages: 4133, PDF Size: 88.89 MB

Page 2096 of 4133

16

Remove poly V-belt (8)

Installation:

Lock tensioning device with

a drift or pin (diameter 5 mm).

Model 163.154 /157 /172.

AR13.22-P-1202B

Model 163.174 /175.

AR13.22-P-1202BA

17

Detach the coolant line (16) at the cylinder

head on the left

6 mm socket hexagon

*WH58.30-Z-1001-06A

7 mm socket hexagon

*WH58.30-Z-1002-06A

18.1

Remove fender liner (9)

Only with engine 113.113.942 /965 / 981.

AR88.10-P-1300GH

19.1

Remove shield (10)

Only with engine 113.942 /965 /981.

20.1

Remove exhaust bracket (11)

Only with engine 113.942 /965 /981.

Support exhaust system.

21

Detach exhaust system at exhaust manifold

Installation:

On vehicles with engine

damage, the exhaust system must be

examined for swarfs before assembling and

any swarfs present must be removed, in order

to avoid consequential damage.

*BA14.10-P-1002-01B

22

Position crankshaft to 40° after ignition TDC

on cylinder 1

The engine must not be turned back;

otherwise the timing chain can get jammed.

AR05.10-P-6858V

Rotate engine at the crankshaft in running

direction until scribe mark 40° on pulley/

vibration damper corresponds with scribe

mark on timing case.

The grooves on the camshafts must be

pointing toward the inner V.

23

Lock camshafts with locating plates

Locating plate

*112589003200

Locating plate

*112589013200

24

Remove chain tensioner (17)

Model 163.154 /157 with engine 112.942/

970, model 163.172 with engine 113.942.

AR05.10-P-7800C

Model 163.174 /175 with engine 113.981/ 965.

AR05.10-P-7800CA

25.1

Remove oil filter housing (18) together with oil-

water heat exchanger

Engine 113.942.

AR18.20-P-3471B

Engine 112.942/970.

AR18.20-P-3471BA

26

Unscrew camshaft sprockets (19)

If camshaft sprockets are removed,

engine must no longer be cranked, otherwise

timing chain might jam.

Engine 113.942 /965 /981:

#

Tie timing chain tight on both camshaft

sprockets with tie straps.

Engine 112.942 /970:

#

Right-hand camshaft sprocket:

Tie timing chain tight on camshaft sprocket

with tie strap.

Left-hand camshaft sprocket:

Mark camshaft sprocket to timing chain and

remove camshaft sprocket.

It is not possible for the timing chain to

jump across at the crankshaft and balancing

shaft.

After installation:

#

Inspect basic position of camshafts.

AR05.10-P-6858V

If necessary after checking:

#

Set the basic position of camshafts

AR05.20-P-6020AU

Open-end wrench

*112589000100

Insertion tool

*112589010300

Torque wrench

*001589722100

*BA05.20-P-1001-01B

27

Remove camshaft bearing bridges (28)

Pay attention to slackening and tightening

pattern!

AR05.20-P-7103AU

28

Unscrew bolts, cylinder head

!

timing case

cover (20)

*BA01.40-P-1002-01C

Copyright DaimlerChrysler AG 20.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 4

Page 2097 of 4133

29

Slacken cylinder head bolts (21) in stages,

unscrew

Loosen cylinder head bolts according to

loosening schematic only after engine has

cooled down to prevent cylinder head from

distorting.

AR01.30-P-5800-09B

Installation:

Observe tightening pattern

and tightening instructions of cylinder head

bolts.

Oil thread and head contact surface of

cylinder head bolts.

AR01.30-P-5800-07B

Screwdriver insert

*000589031000

Screwdriver insert

*000589041000

*BA01.30-P-1001-01D

30

Remove cylinder head

Installation:

On Engine 112/113 observe

porous points in the left and right cylinder

head. If porous points are present, sealant

must be applied to the cylinder head gasket.

Notes on application of sealant to cylinder

head gasket.

Engine 112, 113

AH01.30-P-1000-04VA

The sealant must be applied within

10 minutes.

Loctite 5900 sealant.

*BR00.45-Z-1015-01A

31

Inspect version of cylinder head gasket

Assignment of cylinder head gasket

Information for assigning the cylinder head

gaskets

Engine 112, 113

AH01.30-P-1000-06V

32

Check cylinder head bolts (21)

AR01.30-P-5800-03B

*BE01.30-P-1001-04B

33

Clean sealing surfaces, inspect for cracks,

shrink holes and flatness, clean threaded

holes.

Pay attention to dowel sleeves (26) for

locating the cylinder head.

Sealing surfaces of crankcase and

cylinder head are provided with an 0.8 mm

thick silicone layer during series production.

At the time of repair installation, silicone

sealant is applied to the sealing area only in

case of any shrink holes.

The sealant must be applied within

10 minutes.

Loctite 5900 sealant.

*BR00.45-Z-1015-01A

34

Install in the reverse order

Danger!

Risk of accident

caused by vehicle starting

off by itself when engine is running.

Risk of

injury

caused by contusions and burns when

working in engine during starting procedure

Secure vehicle to prevent it from moving.

Wear closed and snug-fitting work clothes.

Do not grasp hot or rotating parts.

AS00.00-Z-0005-01A

35

Run engine and inspect for leaks

36

Inspect cooling system for leaks

Warm up engine to operating temperature

and then inspect cooling system or leaks.

AR20.00-P-1010HA

37

Read out and erase fault memory

Stored faults which can result from cables

being disconnected or from simulation during

removal and installation or test work, have to

be processed and erased in the fault

memories after completing the work:

#

Diagnosis Manual Volume 2 Index 0:

Connecting and using test equipment.

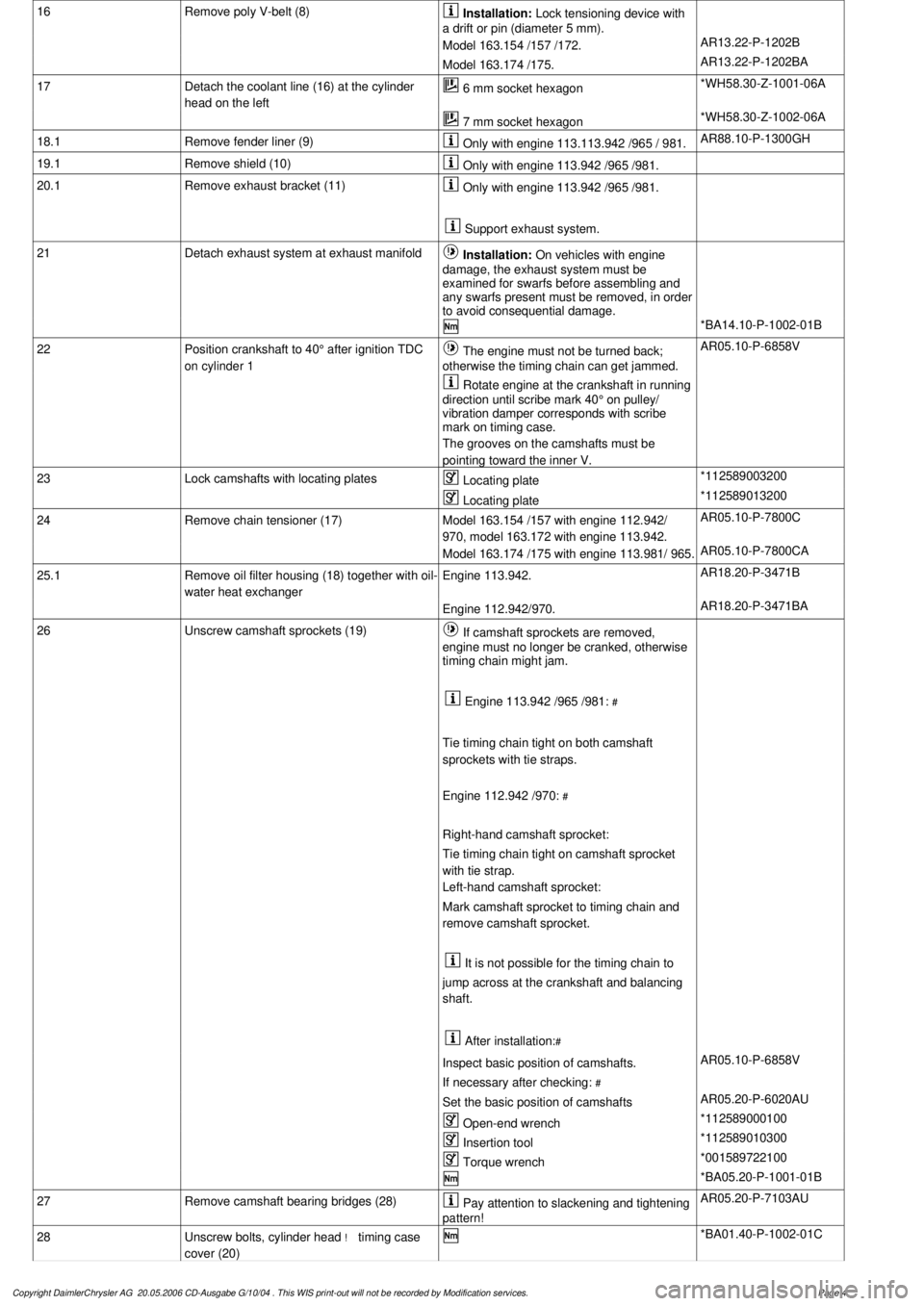

Cylinder head/cylinder head bolts

Number

Designation

Engine

112.910/911/912/

913/914/915/

916/917/920/

921/922/923/

940/941/942/

943/944/945/

946/947/949/

951/953/954/

955/960/961/

970/972/973/975

Engine

113.940/941/

942/943/944/

945/946/948/

960/961/962/

963/965/966/

967/968/969/

980/981/982/

984/986/987/

988/990/991/

992/993

BE01.30-P-1001-04B

Cylinder head bolt

Thread diameter

M

1111

Length (L) when new

mm

141.5141.5

Length (L)

mm

T

144.5

T

144.5

Copyright DaimlerChrysler AG 20.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 5

Page 2114 of 4133

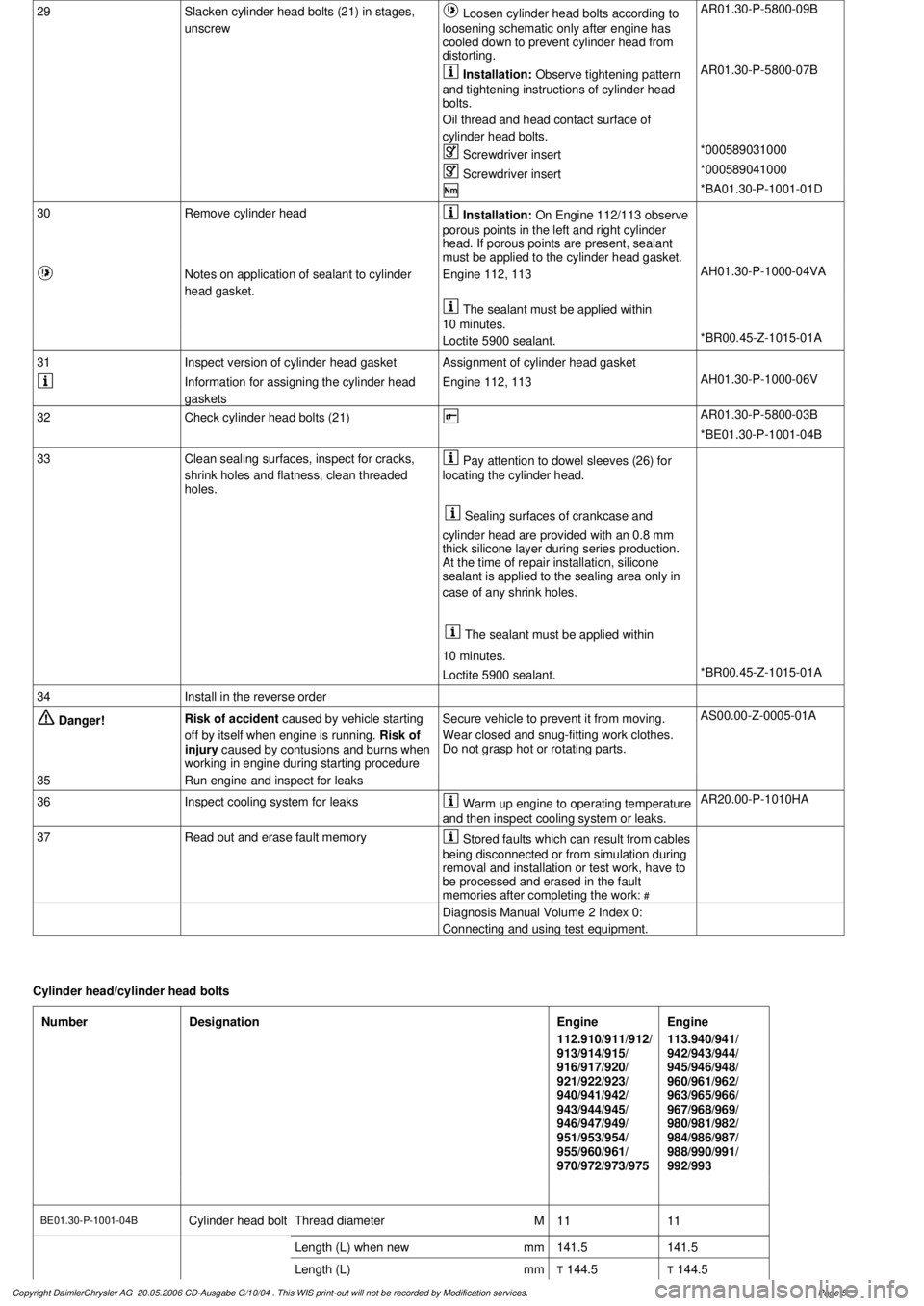

AR72.10-P-1000GH

Remove/install front door liner

11.2.97

MODEL

163.113 /128 /136 /154 /157 /172 /174 /175

P72.10-2161-06

1

Door liner

2

Door handle cover

3

Bolt

4

Cover

5

Clips

6

Bowden cable

7

Sheet metal clip nuts

8

Door foil

9

Entrance lamp

10

Bolt

Remove/install

1

Open crank window

2

Remove cover for door handle (2)

Press cover off using assembly wedge at

bottom.

Assembly wedge

*110589035900

3

Unscrew bolts (3)

4.1

Unclip SRS panel and unscrew screw (10)

As of vehicle identification number

A145273, X708319.

5

Remove cover (4) with installation wedge

Assembly wedge

*110589035900

6

Press door liner (1) off of inner door panel at

bottom, front and rear with assembly wedge

Position assembly wedge directly next to

clips (5).

Assembly wedge

*110589035900

7

Lift door liner (1) up and out

8

Unhook control cable (6) from inner door

actuation

9.1

Remove entrance lamp (9)

As of vehicle identification number

A145273, X708319.

10

Lay down door liner

11

Check sheet metal clip nuts (7) on inner door

panel

Replace damaged sheet metal clip nuts.

12

Check door foil (8) on inner door panel and

clips (5) on door

Replace damaged door foil Replace all

clips.

13

Install in the reverse order

Assembly wedge

110 589 03 59 00

Copyright DaimlerChrysler AG 09.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 2124 of 4133

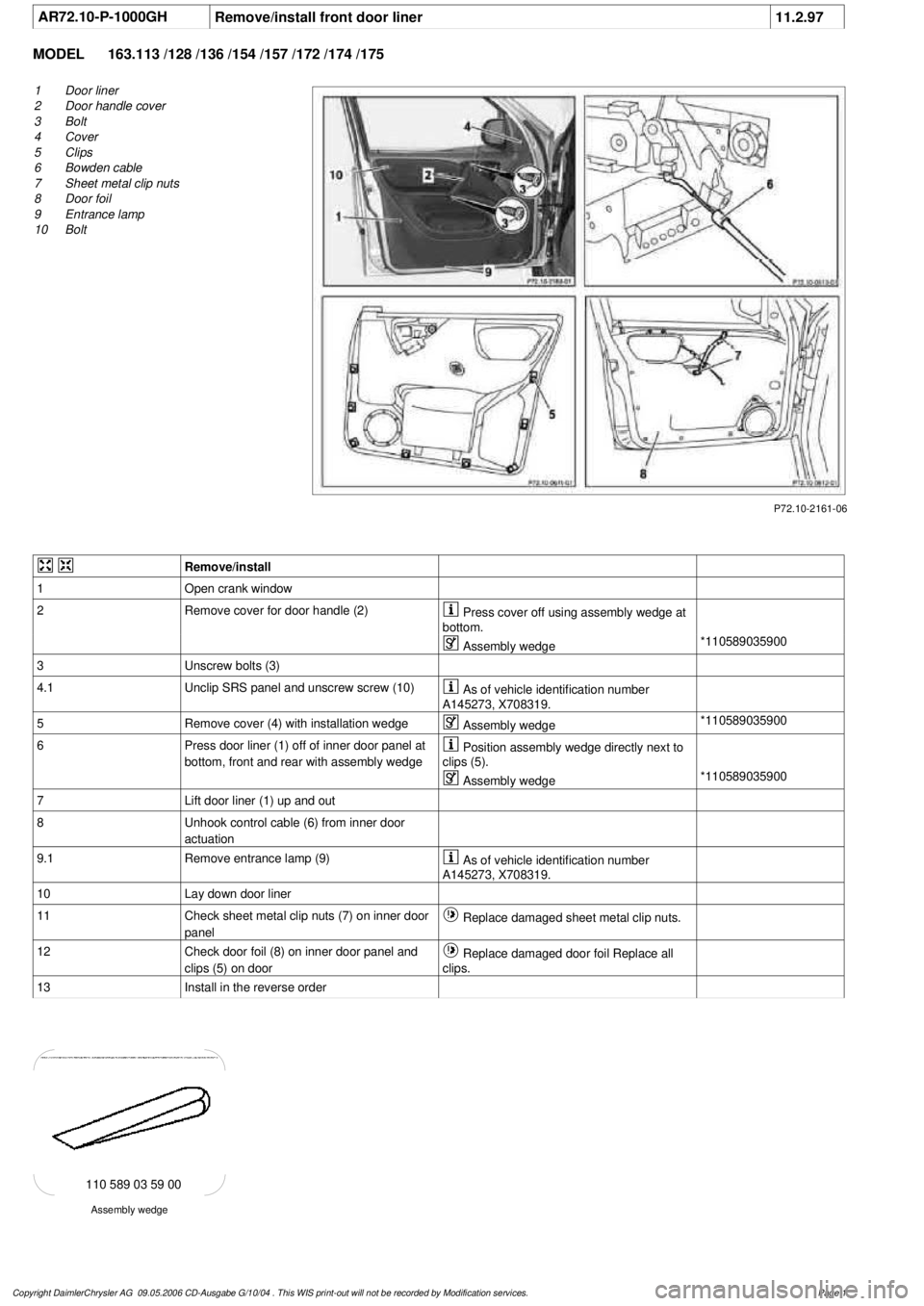

AR72.12-P-1010GH

Remove/install rear door liner

18.2.97

MODEL

163.113 /128 /136 /154 /157 /172 /174 /175

P72.12-2061-09

1

Door handle cover

2

Bolt

3

Door liner

7

Assembly wedge

8

Entrance lamp

9

Bolt

4

Bowden cable

5

Inner lock

6

Clips

Remove/install

1

Open crank window

2

Remove cover for door handle (1)

3

Unscrew screw (2)

4.1

Unclip SRS panel and unscrew screw (9)

As of vehicle identification number

A145273, X708319.

5

Press door liner (3) off of bottom, front and

rear inner door panel with assembly wedge (7)

Position assembly wedge directly next to

clips

Assembly wedge

*110589035900

6

Lift door liner (3) up and out

7

Unhook control cable (4) on inner door

actuating mechanism

8

Unclip inner lock (5) on door liner (3)

9.1

Remove entrance lamp (8)

As of vehicle identification number

A145273, X708319.

10

Lay down door liner

11

Check foil and sheet metal clip nuts on inner

door panel

Replace damaged foil. Replace all clips.

12

Install in the reverse order

Assembly wedge

110 589 03 59 00

Copyright DaimlerChrysler AG 09.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 2156 of 4133

NOTES ON AVOIDING DAMAGE TO IGNITION SYSTEM - AH15.10-P-0002-01D

Engine 104, 111, 112, 113, 119, 120, 156, 271

To avoid damage to control unit connect and disconnect the two connectors on control unit only when

ignition is switched off.

Terminal 1 of ignition coils must not be short-circuited to GND, e.g. as anti-theft protection.

Install only original ignition system components.

Do not operate ignition system at starting speed unless all of the ignition cables are connected.

No tests such as holding ignition cable 4 at a distance to GND, unplugging a spark plug connector or

pulling cable 4 out of the ignition coils, may be performed at starting speed or when the engine is

running.

Every high voltage circuit must be loaded with at least 2 kohms (spark plug connector).

If it is necessary to test the ignition spark when providing roadside assistance, this must only be done with

a spark plug at a cylinder ignition cable. Ensure that the spark plug has good contact to ground.

Before working at cranking speed, e.g. checking compression pressure, switch off ignition and disconnect

connector "2" from control unit.

Engine 120 has two fuel injection and ignition systems.

Use of testers

Only connect and disconnect secondary measuring sensor to corresponding ignition cables when vertical

engine and ignition are switched off.

If the shot-circuit protection is operated (cylinder comparison) and the engine stays upright, it is not

possible to conduct the test with this test instrument.

Do not connect test lamp to ignition coil terminals 1 and 15.

NOTES ON IGNITION COIL CHARACTERISTICS OF IGNITION SYSTEMS - AH15.10-P-1001-01A

Engine 104, 111, 112, 113, 119, 120

In the case of the twin-spark ignition coil with kV pickup in ignition systems ME-SFI 2.1 and HFM-SFI, no

measurement facilit

y exists at the ignition coil using the kV pickup although a kV pickup is fitted. It is only

damage to ignition system

Notes on avoiding

damage to ignition systemENGINE 104, 111, 112, 113,

119, 120, 156, 271, 112 mit

Benzin-Einspritz- und

Zundsystem MEAH15.10-P-0002-01D

Notes for ceramic glow

plugsENGINE 646.8, 642AH15.20-P-0001-01A

2001 Mercedes-Benz ML320

1998-2005 ENGINE Electrical System - Engine - 163 Chassis

me

Saturday, October 02, 2010 3:18:54 PMPage 2 © 2006 Mitchell Repair Information Company, LLC.

Page 2171 of 4133

Engine load

Crankshaft position sensor

Camshaft Hall sensor

Coolant temperature sensor

Intake air temperature sensor/charge air.

Coil ignition: The ME control unit interrupts at the point of ignition timing at the ground end the ignition

coil primary circuit of the ignition coil.

ECI ignition system (engine 137): The ME control unit actuates the output stages in the ECI ignition

modules.

The ignition angle can only be checked with the HHT/STAR DIAGNOSIS.

2.Ignition angle adaptation

2.1 Catalytic converter heating-up (warming-up)

The ignition angle is continuously retarded for about 20 seconds in order to more rapidly warm up the catalytic

converter to its operating temperature if:

coolant temperature at start > 15 °C and < 40 °C

Selector lever position P or N

At the same time idle speed is increased by the idle speed control.

2.2 Idle speed

To assist the idle speed control, the ignition angle can be retarded by as much as 36° crank angle or advanced by

as much as 20° crank angle.

Altering the ignition angle provides a more rapid control than altering the position of the throttle valve (idle

speed control).

2.3 Deceleration fuel shutoff

The ignition angle is briefly retarded when combustion is resumed (fuel injectors actuated) in order to prevent a

sudden increase in torque.

2.4 Intake air temperature/coolant temperature

The ignition angle is retarded under load, as a function of the intake air temperature and coolant temperature, in

order to prevent an

y knocking tendency at high intake air and coolant temperatures. The ignition angle is

2001 Mercedes-Benz ML320

1998-2005 ENGINE Electrical System - Engine - 163 Chassis

me

Saturday, October 02, 2010 3:18:54 PMPage 17 © 2006 Mitchell Repair Information Company, LLC.

Page 2226 of 4133

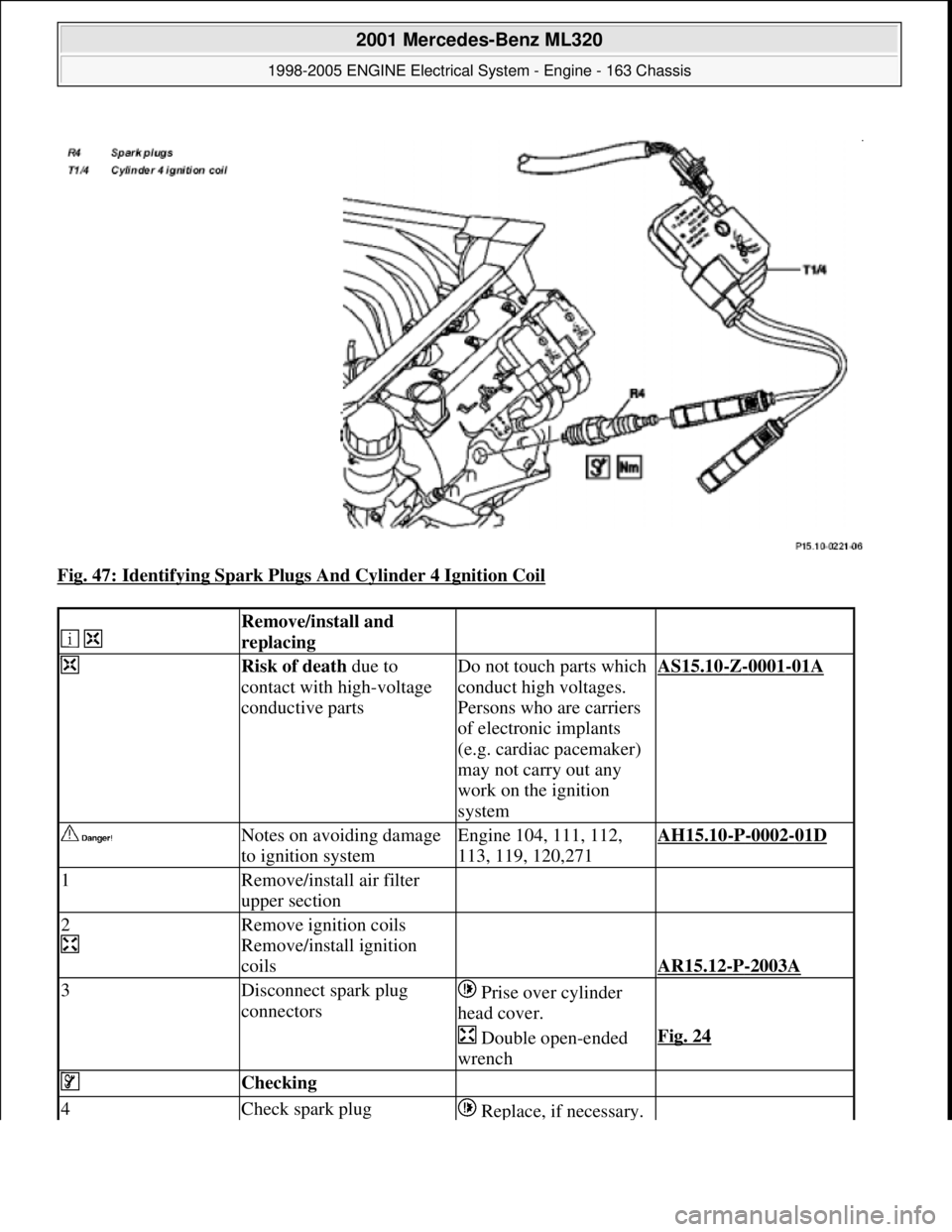

Fig. 47: Identifying Spark Plugs And Cylinder 4 Ignition Coil

Remove/install and

replacing

Risk of death due to

contact with high-voltage

conductive partsDo not touch parts which

conduct high voltages.

Persons who are carriers

of electronic implants

(e.g. cardiac pacemaker)

may not carry out any

work on the ignition

systemAS15.10-Z-0001-01A

Notes on avoiding damage

to ignition systemEngine 104, 111, 112,

113, 119, 120,271AH15.10-P-0002-01D

1Remove/install air filter

upper section

2

Remove ignition coils

Remove/install ignition

coils

AR15.12-P-2003A

3Disconnect spark plug

connectors Prise over cylinder

head cover.

Double open-ended

wrenchFig. 24

Checking

4Check spark plug Replace, if necessary.

2001 Mercedes-Benz ML320

1998-2005 ENGINE Electrical System - Engine - 163 Chassis

me

Saturday, October 02, 2010 3:18:55 PMPage 72 © 2006 Mitchell Repair Information Company, LLC.

Page 2233 of 4133

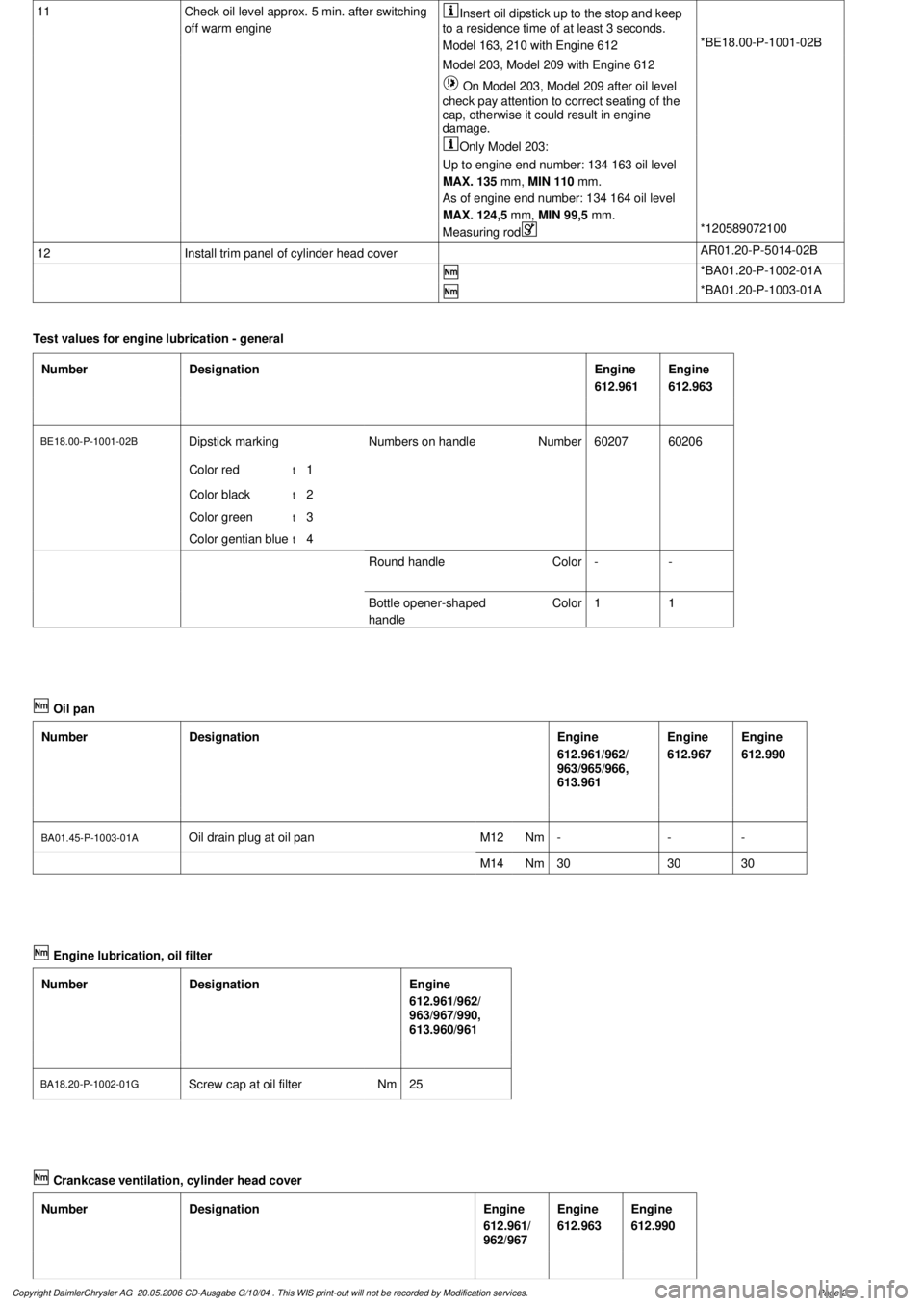

11

Check oil level approx. 5 min. after switching

off warm engine

Insert oil dipstick up to the stop and keep

to a residence time of at least 3 seconds.

Model 163, 210 with Engine 612

*BE18.00-P-1001-02B

Model 203, Model 209 with Engine 612

On Model 203, Model 209 after oil level

check pay attention to correct seating of the

cap, otherwise it could result in engine

damage.

Only Model 203:

Up to engine end number: 134 163 oil level

MAX. 135

mm,

MIN 110

mm.

As of engine end number: 134 164 oil level

MAX. 124,5

mm,

MIN 99,5

mm.

Measuring rod

*120589072100

12

Install trim panel of cylinder head cover

AR01.20-P-5014-02B

*BA01.20-P-1002-01A

*BA01.20-P-1003-01A

Test values for engine lubrication - general

Number

Designation

Engine

612.961

Engine

612.963

BE18.00-P-1001-02B

Dipstick marking

Color red

t

1

Color black

t

2

Color green

t

3

Color gentian blue

t

4

Numbers on handle

Number

6020760206

Round handle

Color

--

Bottle opener-shaped

handle

Color

11

Designation

Engine

612.961/962/

963/965/966,

613.961

Engine

612.967

Engine

612.990

BA01.45-P-1003-01A

Oil drain plug at oil pan

M12

Nm

---

M14

Nm

303030

Engine lubrication, oil filter

Number

Designation

Engine

612.961/962/

963/967/990,

613.960/961

BA18.20-P-1002-01G

Screw cap at oil filter

Nm

25

Crankcase ventilation, cylinder head cover

Number

Designation

Engine

612.961/

962/967

Engine

612.963

Engine

612.990

Copyright DaimlerChrysler AG 20.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 2

Page 2239 of 4133

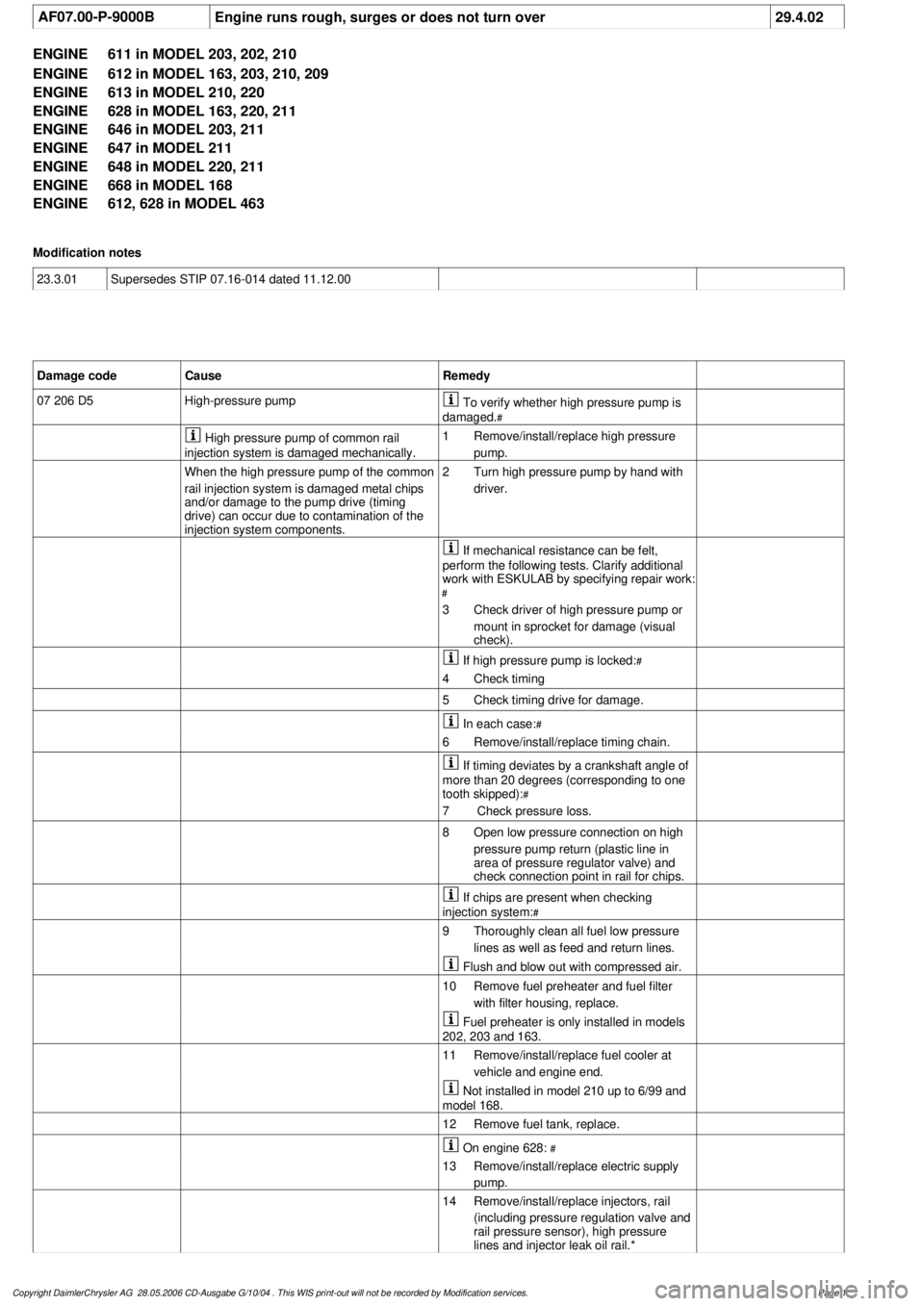

AF07.00-P-9000B

Engine runs rough, surges or does not turn over

29.4.02

ENGINE

611 in MODEL 203, 202, 210

ENGINE

612 in MODEL 163, 203, 210, 209

ENGINE

613 in MODEL 210, 220

ENGINE

628 in MODEL 163, 220, 211

ENGINE

646 in MODEL 203, 211

ENGINE

647 in MODEL 211

ENGINE

648 in MODEL 220, 211

ENGINE

668 in MODEL 168

ENGINE

612, 628 in MODEL 463

Modification notes

23.3.01

Supersedes STIP 07.16-014 dated 11.12.00

Damage code

Cause

Remedy

07 206 D5

High-pressure pump

To verify whether high pressure pump is

damaged.

#

High pressure pump of common rail

injection system is damaged mechanically.

1

Remove/install/replace high pressure

pump.

When the high pressure pump of the common

rail injection system is damaged metal chips

and/or damage to the pump drive (timing

drive) can occur due to contamination of the

injection system components.

2

Turn high pressure pump by hand with

driver.

If mechanical resistance can be felt,

perform the following tests. Clarify additional

work with ESKULAB by specifying repair work:

#

3

Check driver of high pressure pump or

mount in sprocket for damage (visual

check).

If high pressure pump is locked:

#

4

Check timing

5

Check timing drive for damage.

In each case:

#

6

Remove/install/replace timing chain.

If timing deviates by a crankshaft angle of

more than 20 degrees (corresponding to one

tooth skipped):

#

7

Check pressure loss.

8

Open low pressure connection on high

pressure pump return (plastic line in

area of pressure regulator valve) and

check connection point in rail for chips.

If chips are present when checking

injection system:

#

9

Thoroughly clean all fuel low pressure

lines as well as feed and return lines.

Flush and blow out with compressed air.

10

Remove fuel preheater and fuel filter

with filter housing, replace.

Fuel preheater is only installed in models

202, 203 and 163.

11

Remove/install/replace fuel cooler at

vehicle and engine end.

Not installed in model 210 up to 6/99 and

model 168.

12

Remove fuel tank, replace.

On engine 628:

#

13

Remove/install/replace electric supply

pump.

14

Remove/install/replace injectors, rail

(including pressure regulation valve and

rail pressure sensor), high pressure

lines and injector leak oil rail.*

Copyright DaimlerChrysler AG 28.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 2296 of 4133

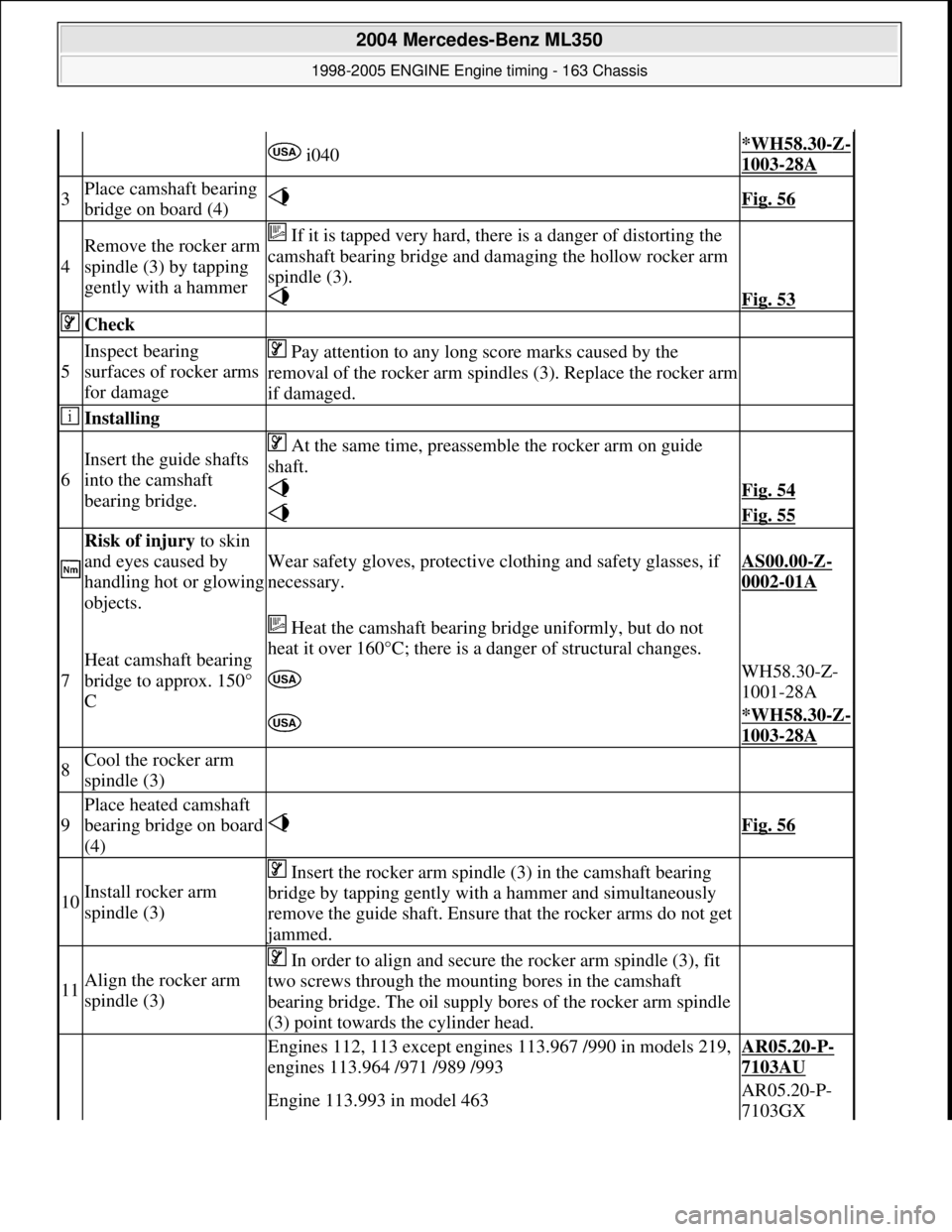

i040*WH58.30-Z-

1003-28A

3Place camshaft bearing

bridge on board (4) Fig. 56

4

Remove the rocker arm

spindle (3) by tapping

gently with a hammer If it is tapped very hard, th ere is a danger of distorting the

camshaft bearing bridge and da maging the hollow rocker arm

spindle (3).

Fig. 53

Check

5

Inspect bearing

surfaces of rocker arms

for damage Pay attention to any long score marks caused by the

removal of the rocker arm spindl es (3). Replace the rocker arm

if damaged.

Installing

6

Insert the guide shafts

into the camshaft

bearing bridge. At the same time, preassemble the rocker arm on guide

shaft.

Fig. 54

Fig. 55

Risk of injury to skin

and eyes caused by

handling hot or glowing

objects.

Wear safety gloves, protective cl othing and safety glasses, if

necessary.AS00.00-Z-

0002-01A

7

Heat camshaft bearing

bridge to approx. 150°

C

Heat the camshaft bearing bridge uniformly, but do not

heat it over 160°C; there is a danger of structural changes.

WH58.30-Z-

1001-28A

*WH58.30-Z-

1003-28A

8Cool the rocker arm

spindle (3)

9

Place heated camshaft

bearing bridge on board

(4) Fig. 56

10Install rocker arm

spindle (3)

Insert the rocker arm spindle (3) in the camshaft bearing

bridge by tapping gently with a hammer and simultaneously

remove the guide shaft. Ensure that the rocker arms do not get

jammed.

11Align the rocker arm

spindle (3)

In order to align and secure the rocker arm spindle (3), fit

two screws through the mount ing bores in the camshaft

bearing bridge. The oil supply bores of the rocker arm spindle

(3) point towards the cylinder head.

Engines 112, 113 except engines 113.967 /990 in models 219,

engines 113.964 /971 /989 /993AR05.20-P-

7103AU

Engine 113.993 in model 463AR05.20-P-

7103GX

2004 Mercedes-Benz ML350

1998-2005 ENGINE Engine timing - 163 Chassis

me

Saturday, October 02, 2010 3:39:38 PMPage 55 © 2006 Mitchell Repair Information Company, LLC.