hood open MERCEDES-BENZ ML320 1997 Complete Manual PDF

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML320, Model: MERCEDES-BENZ ML320 1997Pages: 4133, PDF Size: 88.89 MB

Page 3208 of 4133

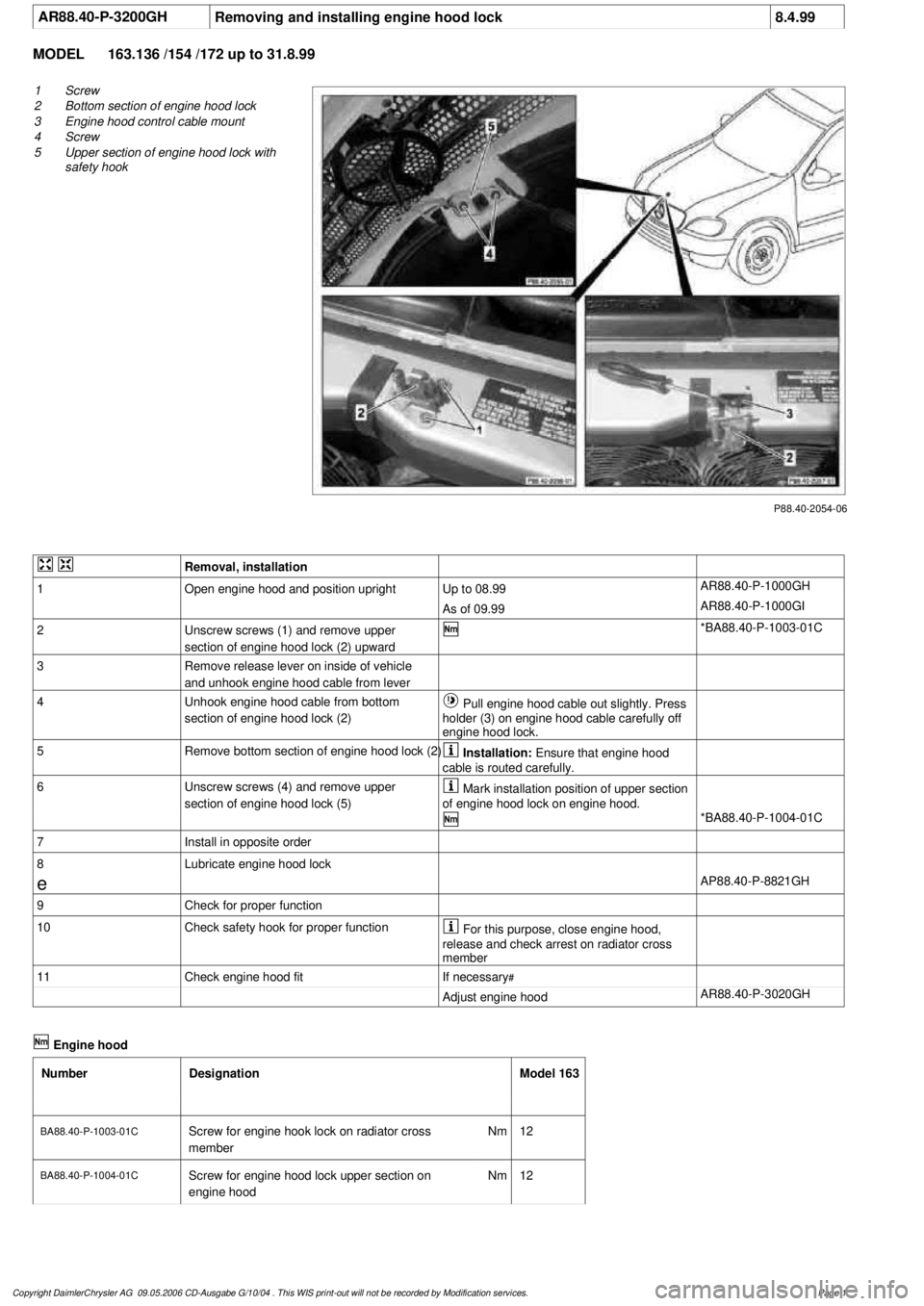

AR88.40-P-3200GH

Removing and installing engine hood lock

8.4.99

MODEL

163.136 /154 /172 up to 31.8.99

P88.40-2054-06

1

Screw

2

Bottom section of engine hood lock

3

Engine hood control cable mount

4

Screw

5

Upper section of engine hood lock with

safety hook

Removal, installation

1

Open engine hood and position upright

Up to 08.99

AR88.40-P-1000GH

As of 09.99

AR88.40-P-1000GI

2

Unscrew screws (1) and remove upper

section of engine hood lock (2) upward

*BA88.40-P-1003-01C

3

Remove release lever on inside of vehicle

and unhook engine hood cable from lever

4

Unhook engine hood cable from bottom

section of engine hood lock (2)

Pull engine hood cable out slightly. Press

holder (3) on engine hood cable carefully off

engine hood lock.

5

Remove bottom section of engine hood lock (2)

Installation:

Ensure that engine hood

cable is routed carefully.

6

Unscrew screws (4) and remove upper

section of engine hood lock (5)

Mark installation position of upper section

of engine hood lock on engine hood.

*BA88.40-P-1004-01C

7

Install in opposite order

8

Lubricate engine hood lock

e

AP88.40-P-8821GH

9

Check for proper function

10

Check safety hook for proper function

For this purpose, close engine hood,

release and check arrest on radiator cross

member

11

Check engine hood fit

If necessary

#

Adjust engine hood

AR88.40-P-3020GH

Engine hood

Number

Designation

Model 163

BA88.40-P-1003-01C

Screw for engine hook lock on radiator cross

member

Nm

12

BA88.40-P-1004-01C

Screw for engine hood lock upper section on

engine hood

Nm

12

Copyright DaimlerChrysler AG 09.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3209 of 4133

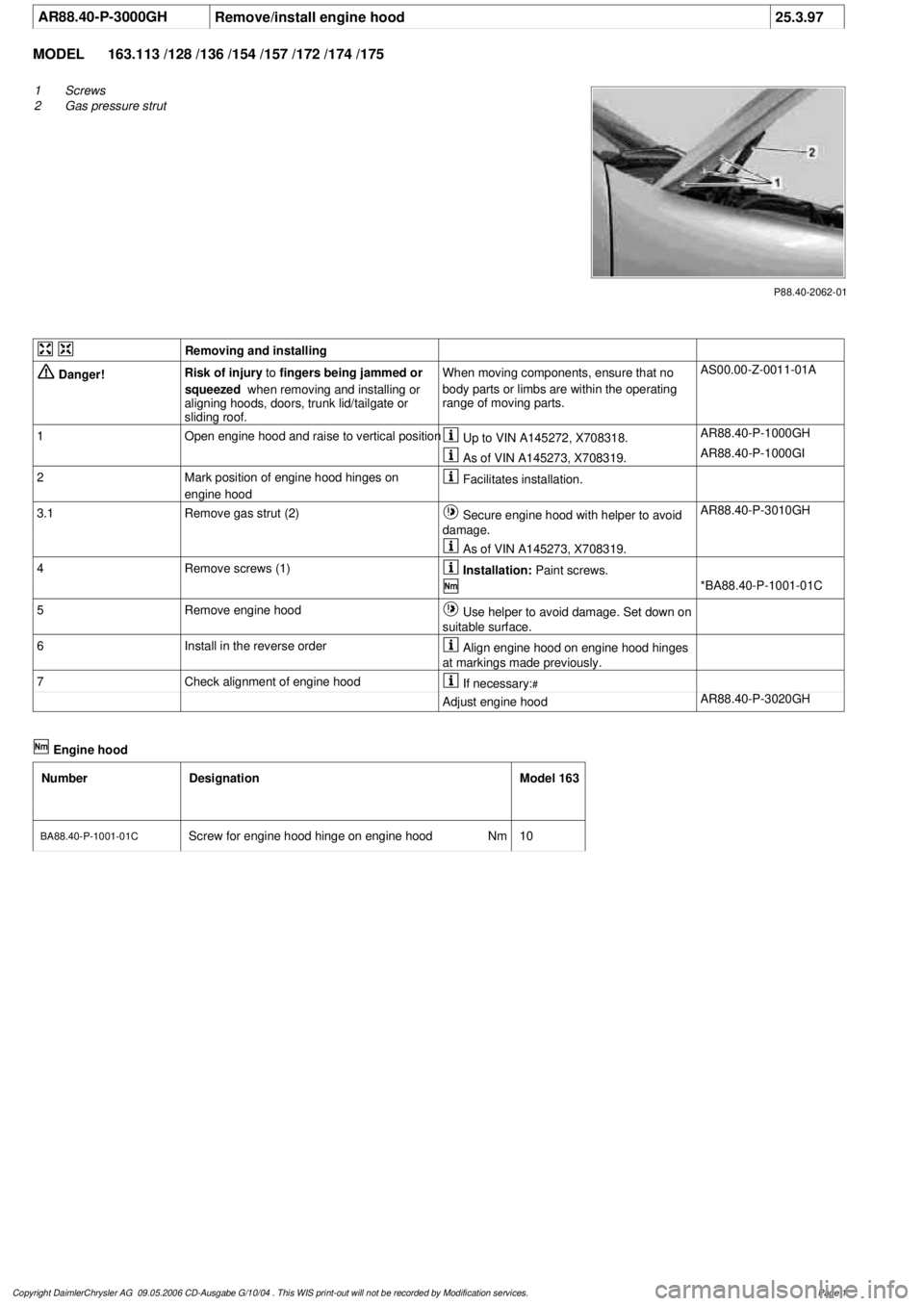

AR88.40-P-3000GH

Remove/install engine hood

25.3.97

MODEL

163.113 /128 /136 /154 /157 /172 /174 /175

P88.40-2062-01

1

Screws

2

Gas pressure strut

Removing and installing

Danger!

Risk of injury

to

fingers being jammed or

squeezed

when removing and installing or

aligning hoods, doors, trunk lid/tailgate or

sliding roof.

When moving components, ensure that no

body parts or limbs are within the operating

range of moving parts.

AS00.00-Z-0011-01A

1

Open engine hood and raise to vertical position

Up to VIN A145272, X708318.

AR88.40-P-1000GH

As of VIN A145273, X708319.

AR88.40-P-1000GI

2

Mark position of engine hood hinges on

engine hood

Facilitates installation.

3.1

Remove gas strut (2)

Secure engine hood with helper to avoid

damage.

AR88.40-P-3010GH

As of VIN A145273, X708319.

4

Remove screws (1)

Installation:

Paint screws.

*BA88.40-P-1001-01C

5

Remove engine hood

Use helper to avoid damage. Set down on

suitable surface.

6

Install in the reverse order

Align engine hood on engine hood hinges

at markings made previously.

7

Check alignment of engine hood

If necessary:

#

Adjust engine hood

AR88.40-P-3020GH

Engine hood

Number

Designation

Model 163

BA88.40-P-1001-01C

Screw for engine hood hinge on engine hood

Nm

10

Copyright DaimlerChrysler AG 09.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

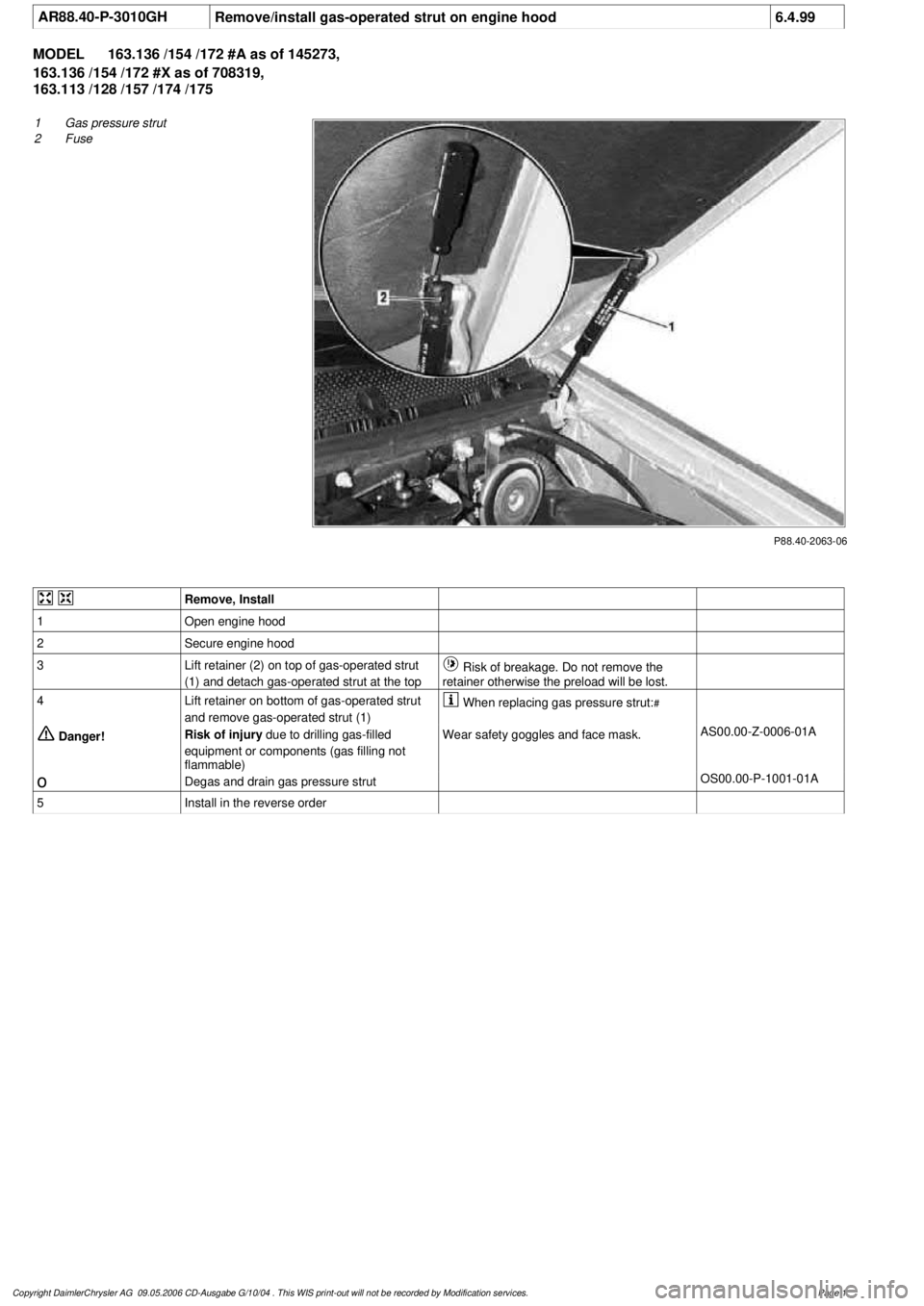

Page 3211 of 4133

AR88.40-P-3010GH

Remove/install gas-operated strut on engine hood

6.4.99

MODEL

163.136 /154 /172 #A as of 145273,

163.136 /154 /172 #X as of 708319,

163.113 /128 /157 /174 /175

P88.40-2063-06

1

Gas pressure strut

2

Fuse

Remove, Install

1

Open engine hood

2

Secure engine hood

3

Lift retainer (2) on top of gas-operated strut

(1) and detach gas-operated strut at the top

Risk of breakage. Do not remove the

retainer otherwise the preload will be lost.

4

Lift retainer on bottom of gas-operated strut

and remove gas-operated strut (1)

When replacing gas pressure strut:

#

Danger!

Risk of injury

due to drilling gas-filled

equipment or components (gas filling not

flammable)

Wear safety goggles and face mask.

AS00.00-Z-0006-01A

o

Degas and drain gas pressure strut

OS00.00-P-1001-01A

5

Install in the reverse order

Copyright DaimlerChrysler AG 09.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3236 of 4133

Fig. 9: Replacing Intake Air Dust Filter

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

RECEIVER-DRIER

Removal & Installation

1. Discharge A/C system, using approved refrigerant recovery/recycling equipment. Remove headlight

units. Remove headlight units. Remove upper frame crossmember, release hood release control cable and

remove crossmember. See Fig. 6

.

2. Remove bolts from receiver-drier refrigerant lines. See Fig. 5

. Disconnect refrigerant lines from receiver-

drier. Plug exposed openings to protect A/C system from debris and moisture. Discard "O" rings. Loosen

receiver-drier clamp bolt. Remove receiver-drier. To install, reverse removal procedure.

3. When installing a new receiver-drier, add 0.34 ounce of NEW refrigerant oil to receiver-drier. Use NEW

"O" rings. Tighten refrigerant line bolts to specification. See TORQUE SPECIFICATIONS

.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

WIRING DIAGRAMS

ApplicationFt. Lbs. (N.m)

Compressor Mounting Bolts15 (20)

Refrigerant Line-To-Compressor Bolt15 (20)

Refrigerant Line-To-Condenser Bolt15 (20)

Steering Column Bolt15 (20)

Steering Column Nut13 (18)

INCH Lbs. (N.m)

Expansion Valve Self-Locking Nut89 (10)

Refrigerant Line-To-Receiver-Drier Bolt89 (10)

2001 Mercedes-Benz ML320

2000-01 MANUAL A/C-HEATER SYSTEMS ML 320, ML 430 & ML 55

me

Saturday, October 02, 2010 3:25:10 PMPage 25 © 2006 Mitchell Repair Information Company, LLC.

Page 3752 of 4133

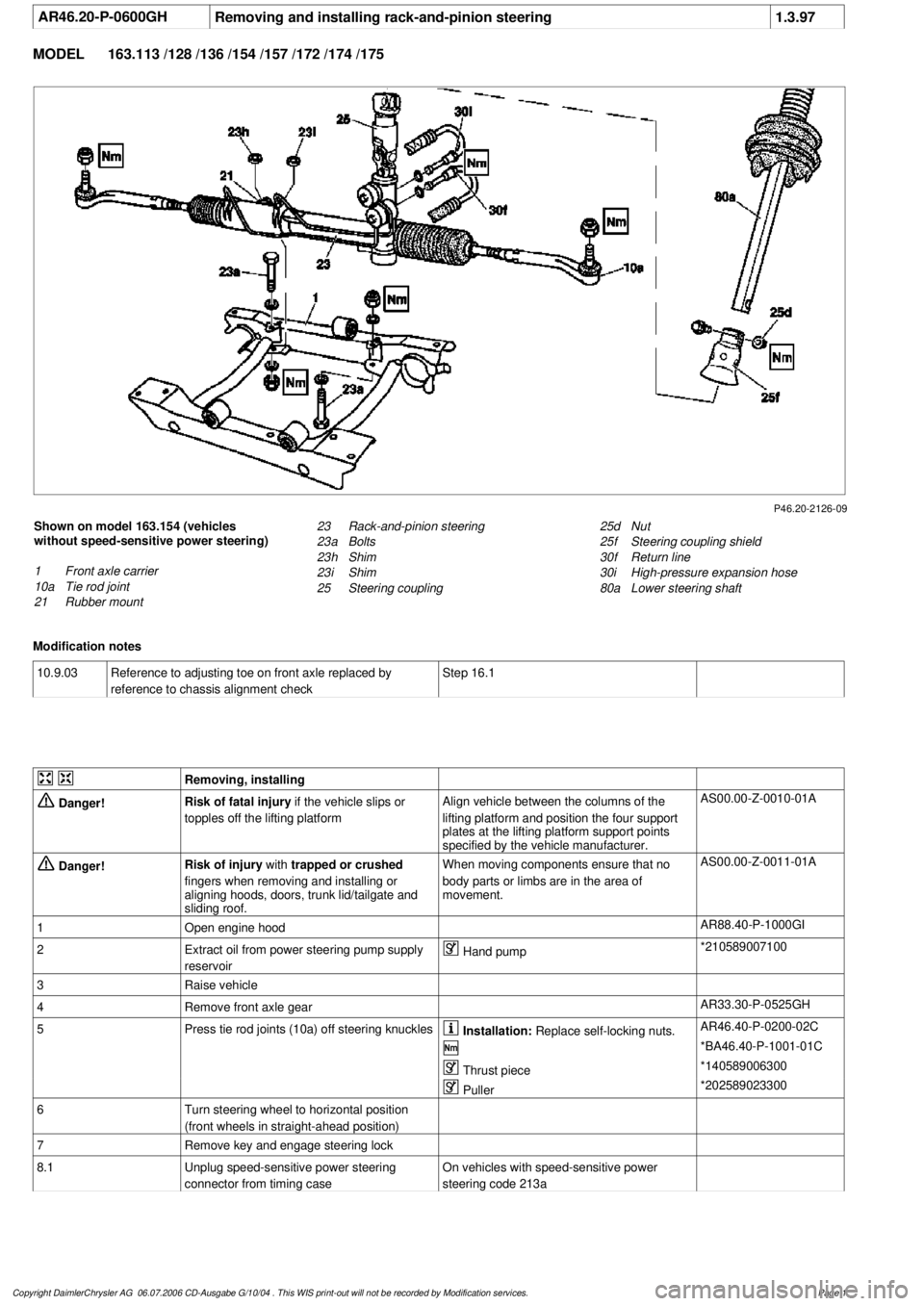

AR46.20-P-0600GH

Removing and installing rack-and-pinion steering

1.3.97

MODEL

163.113 /128 /136 /154 /157 /172 /174 /175

P46.20-2126-09

Shown on model 163.154 (vehicles

without speed-sensitive power steering)

1

Front axle carrier

10a

Tie rod joint

21

Rubber mount

25d

Nut

25f

Steering coupling shield

30f

Return line

30i

High-pressure expansion hose

80a

Lower steering shaft

23

Rack-and-pinion steering

23a

Bolts

23h

Shim

23i

Shim

25

Steering coupling

Modification notes

10.9.03

Reference to adjusting toe on front axle replaced by

reference to chassis alignment check

Step 16.1

Removing, installing

Danger!

Risk of fatal injury

if the vehicle slips or

topples off the lifting platform

Align vehicle between the columns of the

lifting platform and position the four support

plates

at the lifting platform support points

specified by the vehicle manufacturer.

AS00.00-Z-0010-01A

Danger!

Risk of injury

with

trapped or crushed

fingers when removing and installing or

aligning hoods, doors, trunk lid/tailgate and

sliding roof.

When moving components ensure that no

body parts or limbs are in the area of

movement.

AS00.00-Z-0011-01A

1

Open engine hood

AR88.40-P-1000GI

2

Extract oil from power steering pump supply

reservoir

Hand pump

*210589007100

3

Raise vehicle

4

Remove front axle gear

AR33.30-P-0525GH

5

Press tie rod joints (10a) off steering knuckles

Installation:

Replace self-locking nuts.

AR46.40-P-0200-02C

*BA46.40-P-1001-01C

Thrust piece

*140589006300

Puller

*202589023300

6

Turn steering wheel to horizontal position

(front wheels in straight-ahead position)

7

Remove key and engage steering lock

8.1

Unplug speed-sensitive power steering

connector from timing case

On vehicles with speed-sensitive power

steering code 213a

Copyright DaimlerChrysler AG 06.07.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3759 of 4133

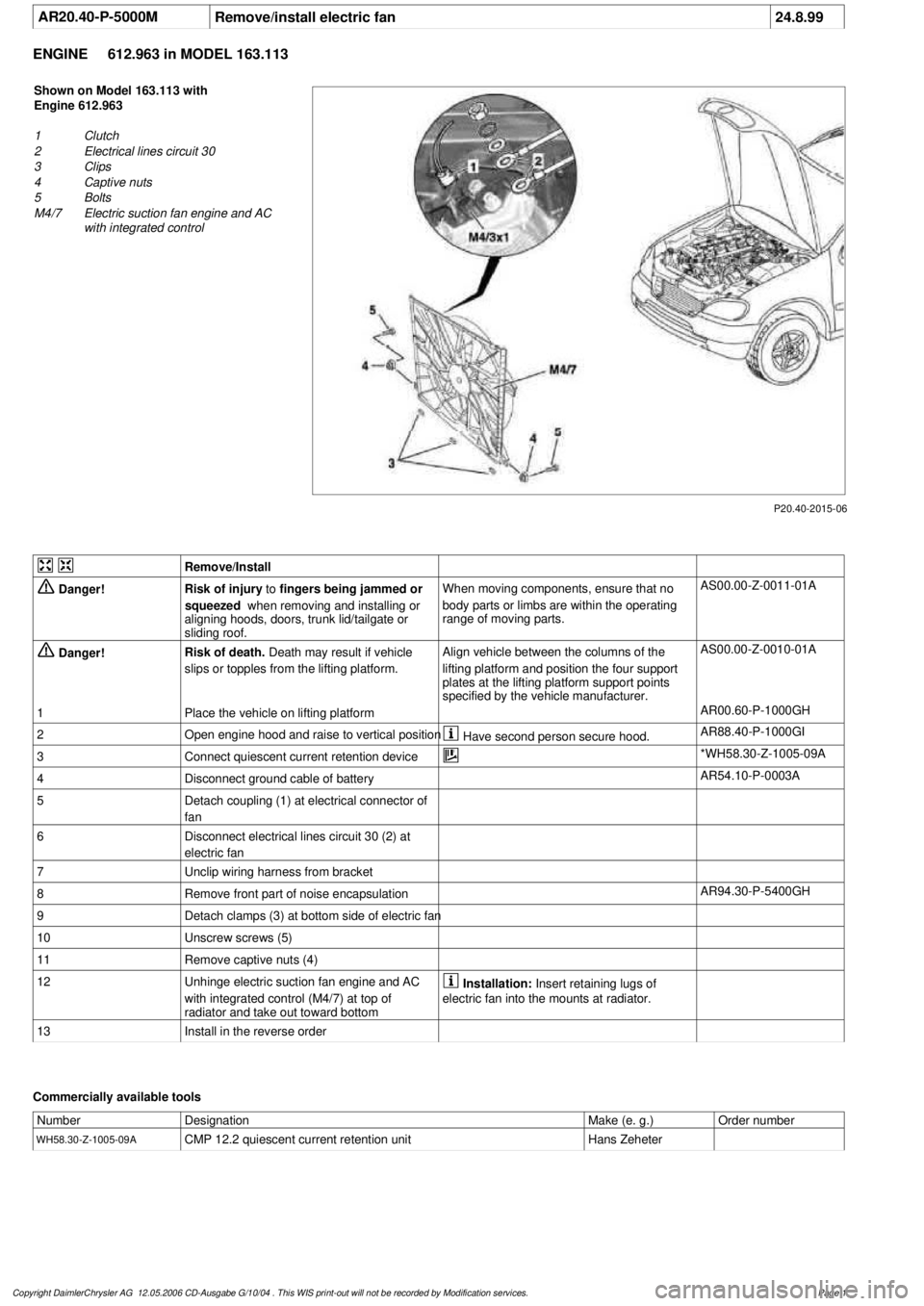

AR20.40-P-5000M

Remove/install electric fan

24.8.99

ENGINE

612.963 in MODEL 163.113

P20.40-2015-06

Shown on Model 163.113 with

Engine 612.963

1

Clutch

2

Electrical lines circuit 30

3

Clips

4

Captive nuts

5

Bolts

M4/7

Electric suction fan engine and AC

with integrated control

Remove/Install

Danger!

Risk of injury

to

fingers being jammed or

squeezed

when removing and installing or

aligning hoods, doors, trunk lid/tailgate or

sliding roof.

When moving components, ensure that no

body parts or limbs are within the operating

range of moving parts.

AS00.00-Z-0011-01A

Danger!

Risk of death.

Death may result if vehicle

slips or topples from the lifting platform.

Align vehicle between the columns of the

lifting platform and position the four support

plates

at the lifting platform support points

specified by the vehicle manufacturer.

AS00.00-Z-0010-01A

1

Place the vehicle on lifting platform

AR00.60-P-1000GH

2

Open engine hood and raise to vertical position

Have second person secure hood.

AR88.40-P-1000GI

3

Connect quiescent current retention device

*WH58.30-Z-1005-09A

4

Disconnect ground cable of battery

AR54.10-P-0003A

5

Detach coupling (1) at electrical connector of

fan

6

Disconnect electrical lines circuit 30 (2) at

electric fan

7

Unclip wiring harness from bracket

8

Remove front part of noise encapsulation

AR94.30-P-5400GH

9

Detach clamps (3) at bottom side of electric fan

10

Unscrew screws (5)

11

Remove captive nuts (4)

12

Unhinge electric suction fan engine and AC

with integrated control (M4/7) at top of

radiator and take out toward bottom

Installation:

Insert retaining lugs of

electric fan into the mounts at radiator.

13

Install in the reverse order

Commercially available tools

Number

Designation

Make (e. g.)

Order number

WH58.30-Z-1005-09A

CMP 12.2 quiescent current retention unit

Hans Zeheter

Copyright DaimlerChrysler AG 12.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3761 of 4133

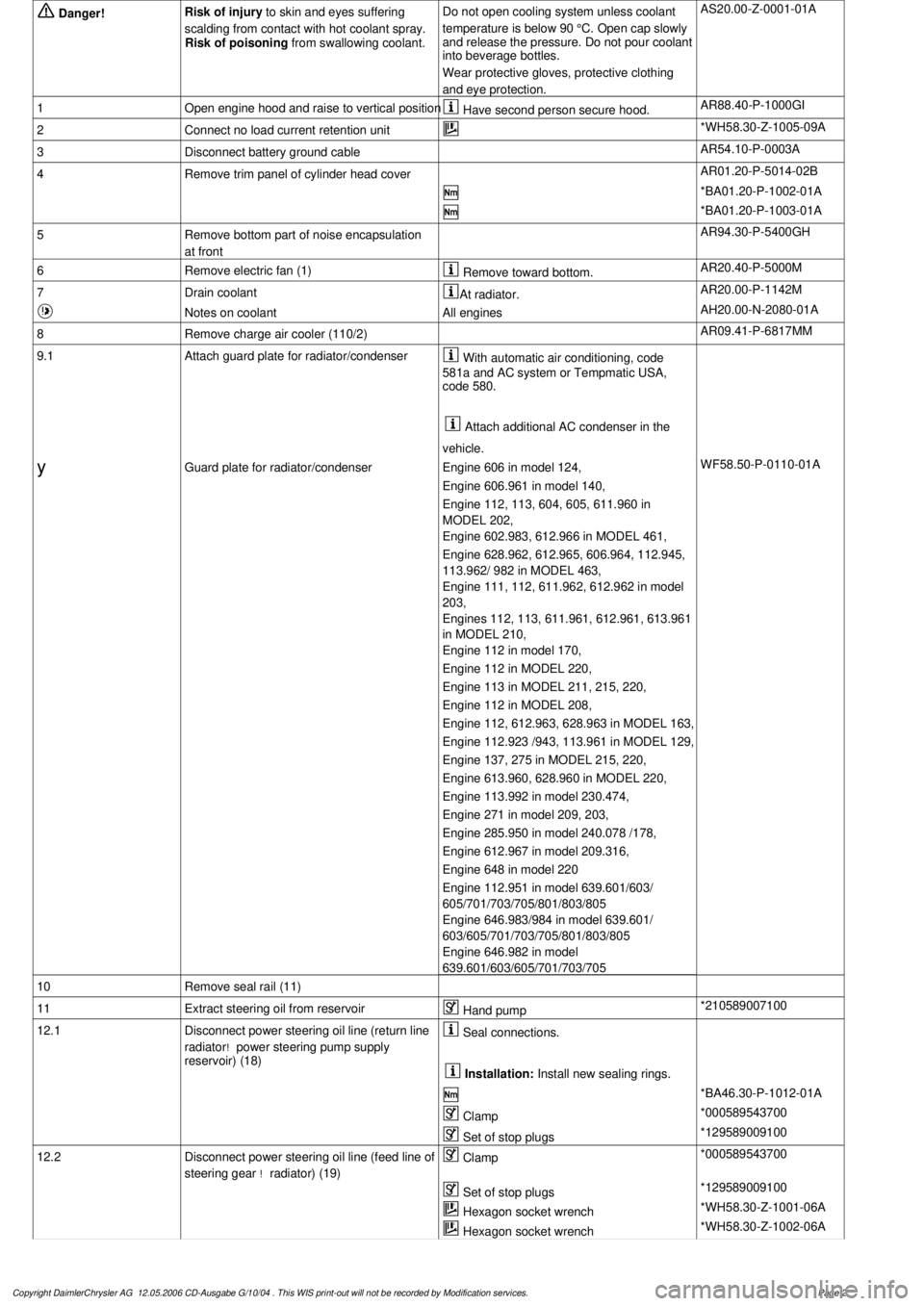

Danger!

Risk of injury

to skin and eyes suffering

scalding from contact with hot coolant spray.

Risk of poisoning

from swallowing coolant.

Do not open cooling system unless coolant

temperature is below 90 °C. Open cap slowly

and release the pressure. Do not pour coolant

into beverage bottles.

Wear protective gloves, protective clothing

and eye protection.

AS20.00-Z-0001-01A

1

Open engine hood and raise to vertical position

Have second person secure hood.

AR88.40-P-1000GI

2

Connect no load current retention unit

*WH58.30-Z-1005-09A

3

Disconnect battery ground cable

AR54.10-P-0003A

4

Remove trim panel of cylinder head cover

AR01.20-P-5014-02B

*BA01.20-P-1002-01A

*BA01.20-P-1003-01A

5

Remove bottom part of noise encapsulation

at front

AR94.30-P-5400GH

6

Remove electric fan (1)

Remove toward bottom.

AR20.40-P-5000M

7

Drain coolant

At radiator.

AR20.00-P-1142M

Notes on coolant

All engines

AH20.00-N-2080-01A

8

Remove charge air cooler (110/2)

AR09.41-P-6817MM

9.1

Attach guard plate for radiator/condenser

With automatic air conditioning, code

581a and AC system or Tempmatic USA,

code 580.

Attach additional AC condenser in the

vehicle.

y

Guard plate for radiator/condenser

Engine 606 in model 124,

Engine 606.961 in model 140,

Engine 112, 113, 604, 605, 611.960 in

MODEL 202,

Engine 602.983, 612.966 in MODEL 461,

Engine 628.962, 612.965, 606.964, 112.945,

113.962/ 982 in MODEL 463,

Engine 111, 112, 611.962, 612.962 in model

203,

Engines 112, 113, 611.961, 612.961, 613.961

in MODEL 210,

Engine 112 in model 170,

Engine 112 in MODEL 220,

Engine 113 in MODEL 211, 215, 220,

Engine 112 in MODEL 208,

Engine 112, 612.963, 628.963 in MODEL 163,

Engine 112.923 /943, 113.961 in MODEL 129,

Engine 137, 275 in MODEL 215, 220,

Engine 613.960, 628.960 in MODEL 220,

Engine 113.992 in model 230.474,

Engine 271 in model 209, 203,

Engine 285.950 in model 240.078 /178,

Engine 612.967 in model 209.316,

Engine 648 in model 220

Engine 112.951 in model 639.601/603/

605/701/703/705/801/803/805

Engine 646.983/984 in model 639.601/

603/605/701/703/705/801/803/805

Engine 646.982 in model

639.601/603/605/701/703/705

WF58.50-P-0110-01A

10

Remove seal rail (11)

11

Extract steering oil from reservoir

Hand pump

*210589007100

12.1

Disconnect power steering oil line (return line

radiator

!

power steering pump supply

reservoir) (18)

Seal connections.

Installation:

Install new sealing rings.

*BA46.30-P-1012-01A

Clamp

*000589543700

Set of stop plugs

*129589009100

12.2

Disconnect power steering oil line (feed line of

steering gear

!

radiator) (19)

Clamp

*000589543700

Set of stop plugs

*129589009100

Hexagon socket wrench

*WH58.30-Z-1001-06A

Hexagon socket wrench

*WH58.30-Z-1002-06A

Copyright DaimlerChrysler AG 12.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 2

Page 3771 of 4133

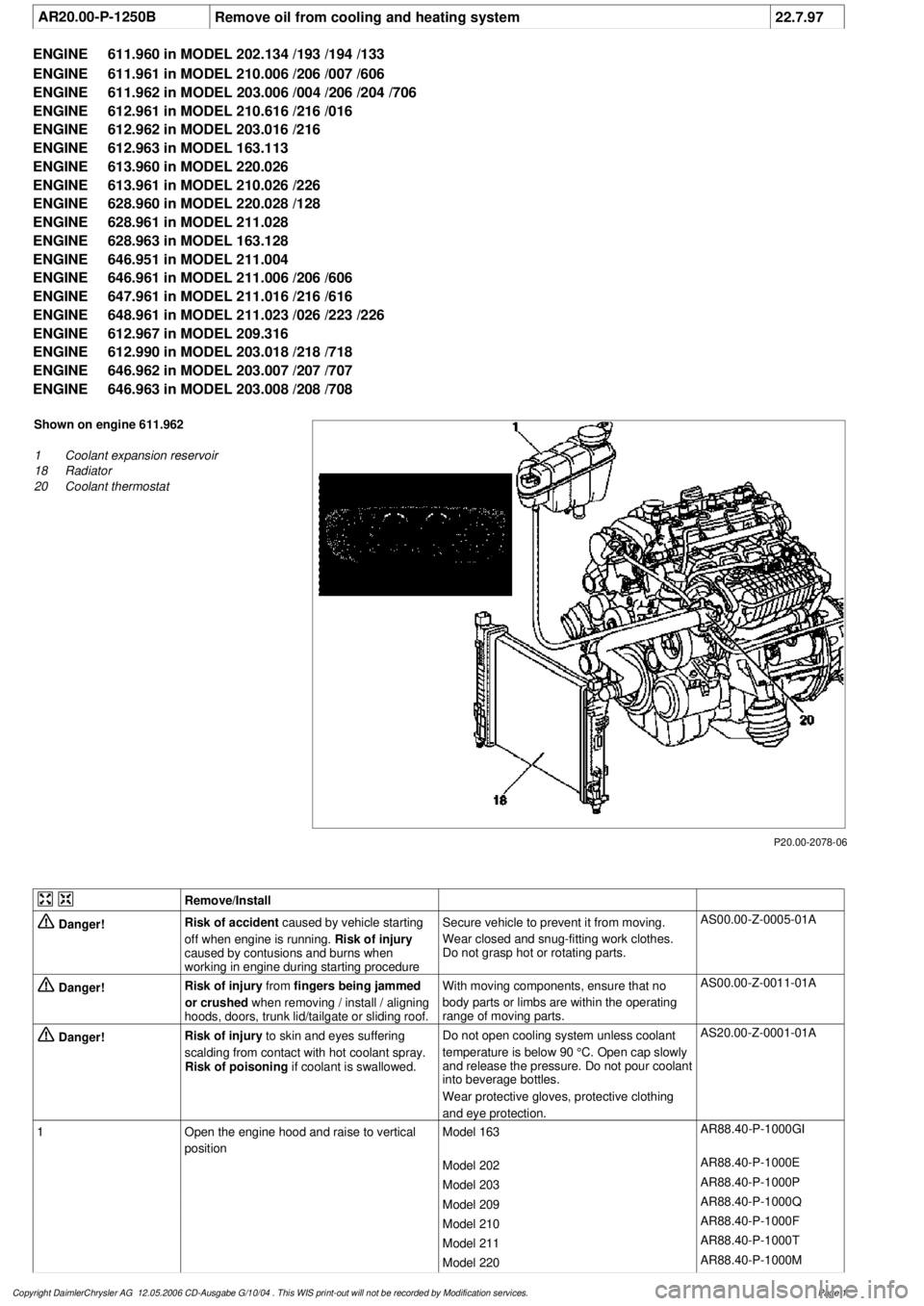

AR20.00-P-1250B

Remove oil from cooling and heating system

22.7.97

ENGINE

611.960 in MODEL 202.134 /193 /194 /133

ENGINE

611.961 in MODEL 210.006 /206 /007 /606

ENGINE

611.962 in MODEL 203.006 /004 /206 /204 /706

ENGINE

612.961 in MODEL 210.616 /216 /016

ENGINE

612.962 in MODEL 203.016 /216

ENGINE

612.963 in MODEL 163.113

ENGINE

613.960 in MODEL 220.026

ENGINE

613.961 in MODEL 210.026 /226

ENGINE

628.960 in MODEL 220.028 /128

ENGINE

628.961 in MODEL 211.028

ENGINE

628.963 in MODEL 163.128

ENGINE

646.951 in MODEL 211.004

ENGINE

646.961 in MODEL 211.006 /206 /606

ENGINE

647.961 in MODEL 211.016 /216 /616

ENGINE

648.961 in MODEL 211.023 /026 /223 /226

ENGINE

612.967 in MODEL 209.316

ENGINE

612.990 in MODEL 203.018 /218 /718

ENGINE

646.962 in MODEL 203.007 /207 /707

ENGINE

646.963 in MODEL 203.008 /208 /708

P20.00-2078-06

Shown on engine 611.962

1

Coolant expansion reservoir

18

Radiator

20

Coolant thermostat

Remove/Install

Danger!

Risk of accident

caused by vehicle starting

off when engine is running.

Risk of injury

caused by contusions and burns when

working in engine during starting procedure

Secure vehicle to prevent it from moving.

Wear closed and snug-fitting work clothes.

Do not grasp hot or rotating parts.

AS00.00-Z-0005-01A

Danger!

Risk of injury

from

fingers being jammed

or crushed

when removing / install / aligning

hoods, doors, trunk lid/tailgate or sliding roof.

With moving components, ensure that no

body parts or limbs are within the operating

range of moving parts.

AS00.00-Z-0011-01A

Danger!

Risk of injury

to skin and eyes suffering

scalding from contact with hot coolant spray.

Risk of poisoning

if coolant is swallowed.

Do not open cooling system unless coolant

temperature is below 90 °C. Open cap slowly

and release the pressure. Do not pour coolant

into beverage bottles.

Wear protective gloves, protective clothing

and eye protection.

AS20.00-Z-0001-01A

1

Open the engine hood and raise to vertical

position

Model 163

AR88.40-P-1000GI

Model 202

AR88.40-P-1000E

Model 203

AR88.40-P-1000P

Model 209

AR88.40-P-1000Q

Model 210

AR88.40-P-1000F

Model 211

AR88.40-P-1000T

Model 220

AR88.40-P-1000M

Copyright DaimlerChrysler AG 12.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3884 of 4133

Verify ground connection integrity between engine, body, battery and generator. Check for damaged wiring

harnesses and/or switches. Check fo r a broken or partially broken wire inside insulation, which could cause

system malfunction but prove good in a continuity/vol tage check with system disconnected. Ensure any

aftermarket electronic e quipment is properly installed. If fault is found, repair as necessary. If no fault is found,

check for conditions that might cause an intermittent situation.

SERVICE PRECAUTIONS

BATTERY DISCONNECT/CONNECT

Disconnect/Connect Procedures

1. Turn ignition off. Open engine hood. After opening ve hicle wait at least 4 minutes before disconnecting

battery or alarm wi ll be triggered.

2. Disconnect negative battery cable (1) and insulate cable lug to prevent unwanted contact with ground

point (W16/4). See Fig. 1

.

3. To connect, reverse disconnect procedur e. Tighten nut (5) to specification. See TORQUE

SPECIFICATIONS .

4. Perform basic programming, read Diagnostic Tr ouble Code (DTC) memory and erase DTCs from

memory. See BASIC PROGRAMMING

and RETRIEVING & ERASING DIAGNOSTIC

TROUBLE CODES .

NOTE: Numbers and letters in text refe

r to numbers and letters in figures.

2001 Mercedes-Benz ML320

2001-04 STARTING & CHARGING SYSTEMS Starters - 163 Chassis

me

Saturday, October 02, 2010 3:19:47 PMPage 2 © 2006 Mitchell Repair Information Company, LLC.