engine MERCEDES-BENZ ML320 1997 Complete Repair Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML320, Model: MERCEDES-BENZ ML320 1997Pages: 4133, PDF Size: 88.89 MB

Page 2877 of 4133

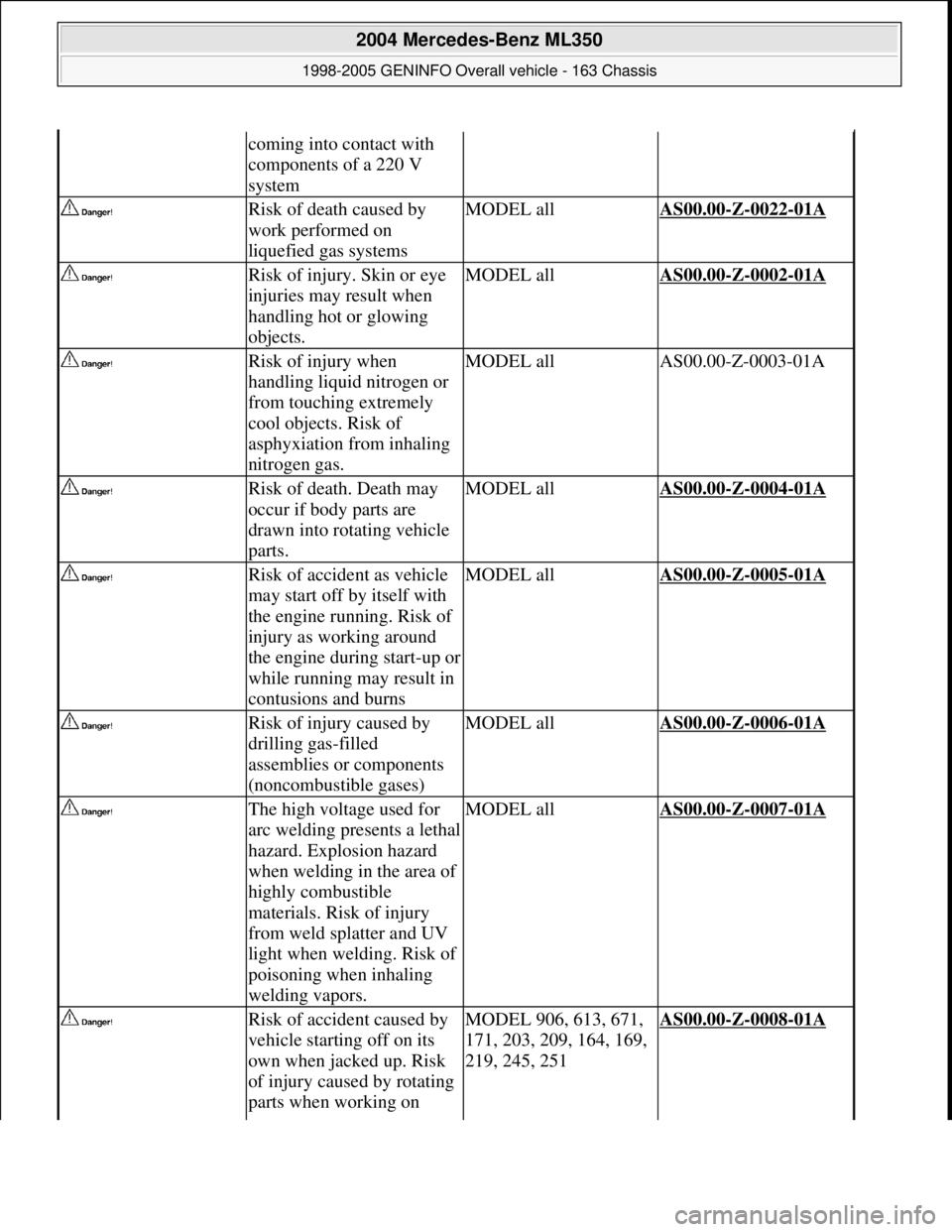

coming into contact with

components of a 220 V

system

Risk of death caused by

work performed on

liquefied gas systemsMODEL allAS00.00-Z-0022-01A

Risk of injury. Skin or eye

injuries may result when

handling hot or glowing

objects.MODEL allAS00.00-Z-0002-01A

Risk of injury when

handling liquid nitrogen or

from touching extremely

cool objects. Risk of

asphyxiation from inhaling

nitrogen gas.MODEL allAS00.00-Z-0003-01A

Risk of death. Death may

occur if body parts are

drawn into rotating vehicle

parts.MODEL allAS00.00-Z-0004-01A

Risk of accident as vehicle

may start off by itself with

the engine running. Risk of

injury as working around

the engine during start-up or

while running may result in

contusions and burnsMODEL allAS00.00-Z-0005-01A

Risk of injury caused by

drilling gas-filled

assemblies or components

(noncombustible gases)MODEL allAS00.00-Z-0006-01A

The high voltage used for

arc welding presents a lethal

hazard. Explosion hazard

when welding in the area of

highly combustible

materials. Risk of injury

from weld splatter and UV

light when welding. Risk of

poisoning when inhaling

welding vapors.MODEL allAS00.00-Z-0007-01A

Risk of accident caused by

vehicle starting off on its

own when jacked up. Risk

of injury caused by rotating

parts when working on MODEL 906, 613, 671,

171, 203, 209, 164, 169,

219, 245, 251AS00.00-Z-0008-01A

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:48 PMPage 232 © 2006 Mitchell Repair Information Company, LLC.

Page 2878 of 4133

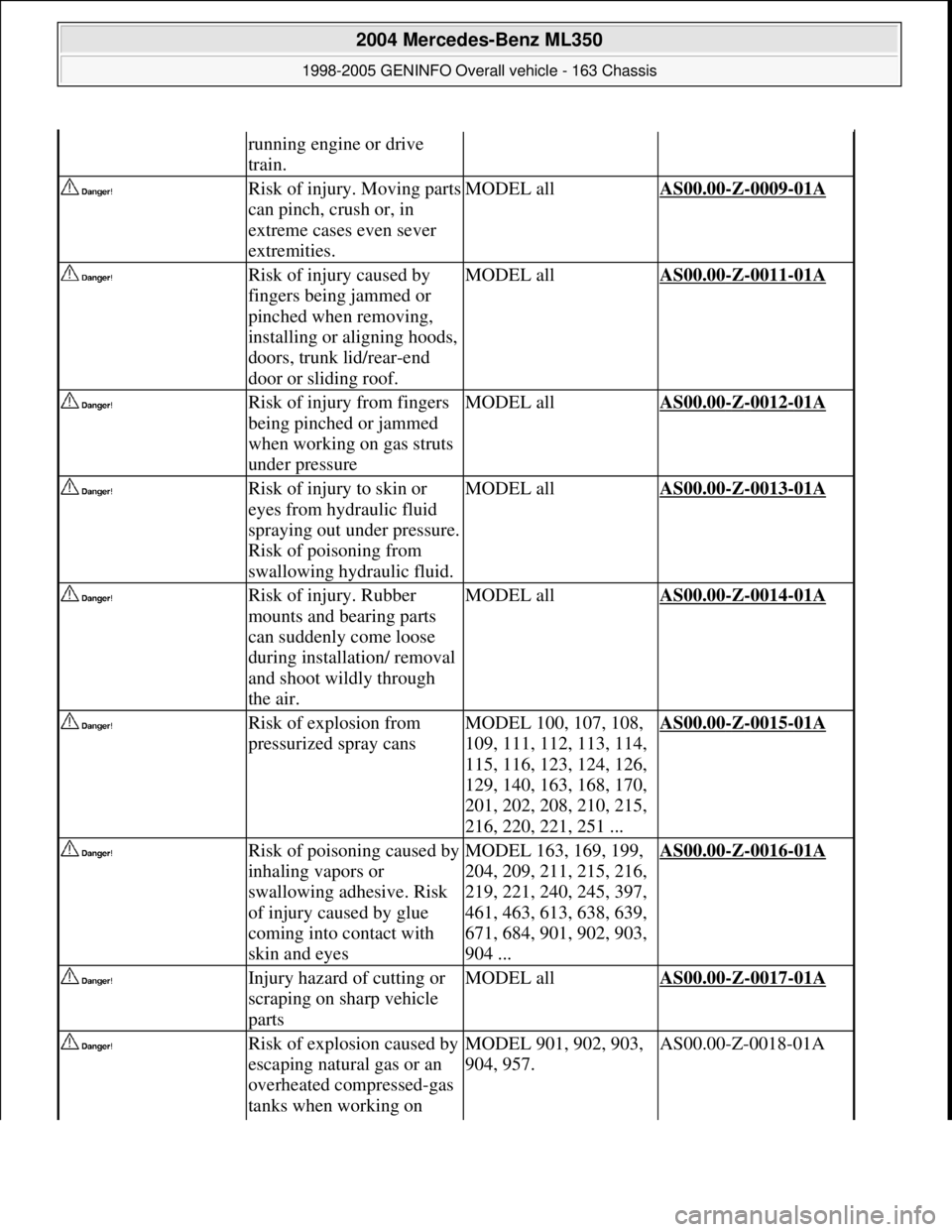

running engine or drive

train.

Risk of injury. Moving parts

can pinch, crush or, in

extreme cases even sever

extremities.MODEL allAS00.00-Z-0009-01A

Risk of injury caused by

fingers being jammed or

pinched when removing,

installing or aligning hoods,

doors, trunk lid/rear-end

door or sliding roof.MODEL allAS00.00-Z-0011-01A

Risk of injury from fingers

being pinched or jammed

when working on gas struts

under pressureMODEL allAS00.00-Z-0012-01A

Risk of injury to skin or

eyes from hydraulic fluid

spraying out under pressure.

Risk of poisoning from

swallowing hydraulic fluid.MODEL allAS00.00-Z-0013-01A

Risk of injury. Rubber

mounts and bearing parts

can suddenly come loose

during installation/ removal

and shoot wildly through

the air.MODEL allAS00.00-Z-0014-01A

Risk of explosion from

pressurized spray cansMODEL 100, 107, 108,

109, 111, 112, 113, 114,

115, 116, 123, 124, 126,

129, 140, 163, 168, 170,

201, 202, 208, 210, 215,

216, 220, 221, 251 ...AS00.00-Z-0015-01A

Risk of poisoning caused by

inhaling vapors or

swallowing adhesive. Risk

of injury caused by glue

coming into contact with

skin and eyesMODEL 163, 169, 199,

204, 209, 211, 215, 216,

219, 221, 240, 245, 397,

461, 463, 613, 638, 639,

671, 684, 901, 902, 903,

904 ...AS00.00-Z-0016-01A

Injury hazard of cutting or

scraping on sharp vehicle

partsMODEL allAS00.00-Z-0017-01A

Risk of explosion caused by

escaping natural gas or an

overheated compressed-gas

tanks when working on MODEL 901, 902, 903,

904, 957.AS00.00-Z-0018-01A

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:48 PMPage 233 © 2006 Mitchell Repair Information Company, LLC.

Page 2879 of 4133

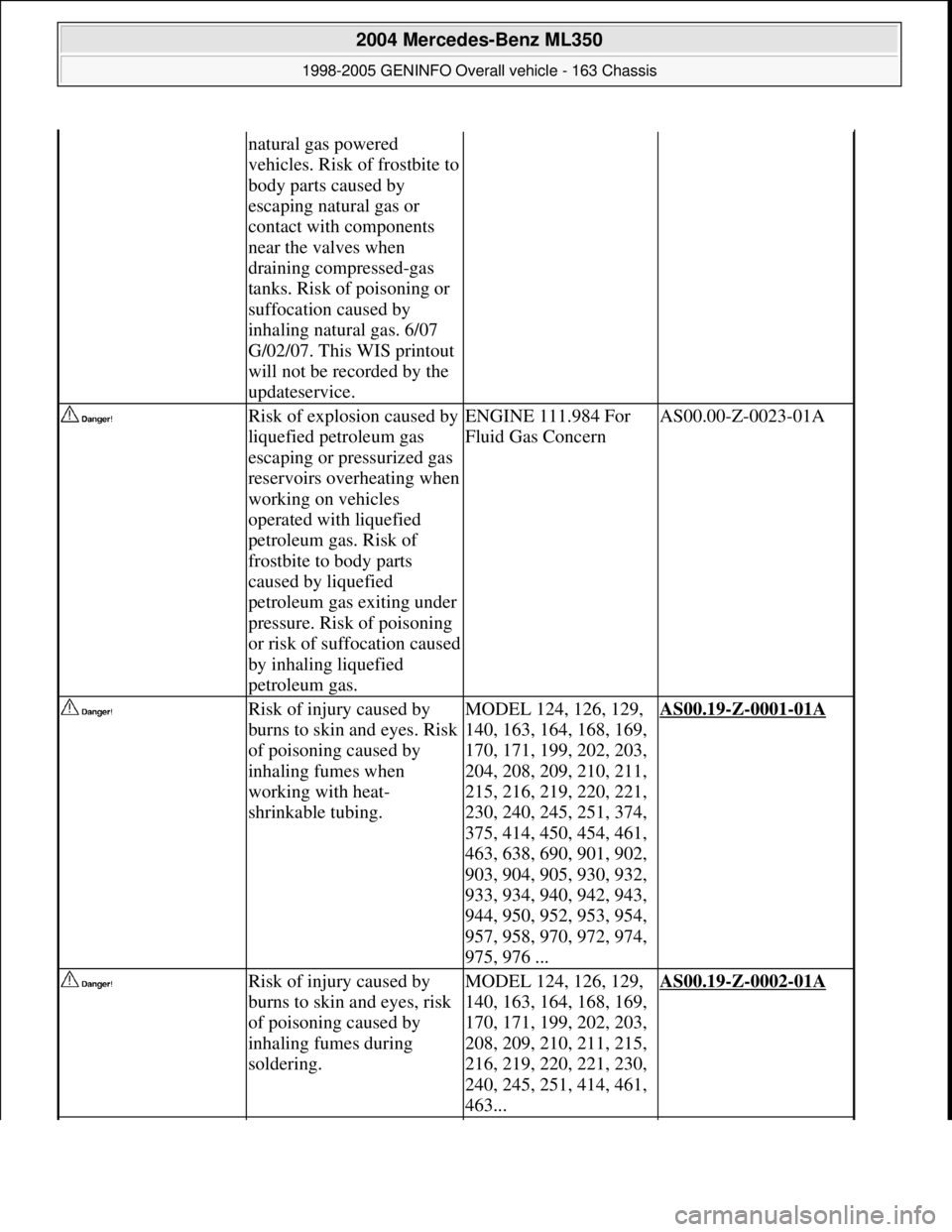

natural gas powered

vehicles. Risk of frostbite to

body parts caused by

escaping natural gas or

contact with components

near the valves when

draining compressed-gas

tanks. Risk of poisoning or

suffocation caused by

inhaling natural gas. 6/07

G/02/07. This WIS printout

will not be recorded by the

updateservice.

Risk of explosion caused by

liquefied petroleum gas

escaping or pressurized gas

reservoirs overheating when

working on vehicles

operated with liquefied

petroleum gas. Risk of

frostbite to body parts

caused by liquefied

petroleum gas exiting under

pressure. Risk of poisoning

or risk of suffocation caused

by inhaling liquefied

petroleum gas.ENGINE 111.984 For

Fluid Gas ConcernAS00.00-Z-0023-01A

Risk of injury caused by

burns to skin and eyes. Risk

of poisoning caused by

inhaling fumes when

working with heat-

shrinkable tubing.MODEL 124, 126, 129,

140, 163, 164, 168, 169,

170, 171, 199, 202, 203,

204, 208, 209, 210, 211,

215, 216, 219, 220, 221,

230, 240, 245, 251, 374,

375, 414, 450, 454, 461,

463, 638, 690, 901, 902,

903, 904, 905, 930, 932,

933, 934, 940, 942, 943,

944, 950, 952, 953, 954,

957, 958, 970, 972, 974,

975, 976 ...AS00.19-Z-0001-01A

Risk of injury caused by

burns to skin and eyes, risk

of poisoning caused by

inhaling fumes during

soldering.MODEL 124, 126, 129,

140, 163, 164, 168, 169,

170, 171, 199, 202, 203,

208, 209, 210, 211, 215,

216, 219, 220, 221, 230,

240, 245, 251, 414, 461,

463...AS00.19-Z-0002-01A

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:48 PMPage 234 © 2006 Mitchell Repair Information Company, LLC.

Page 2892 of 4133

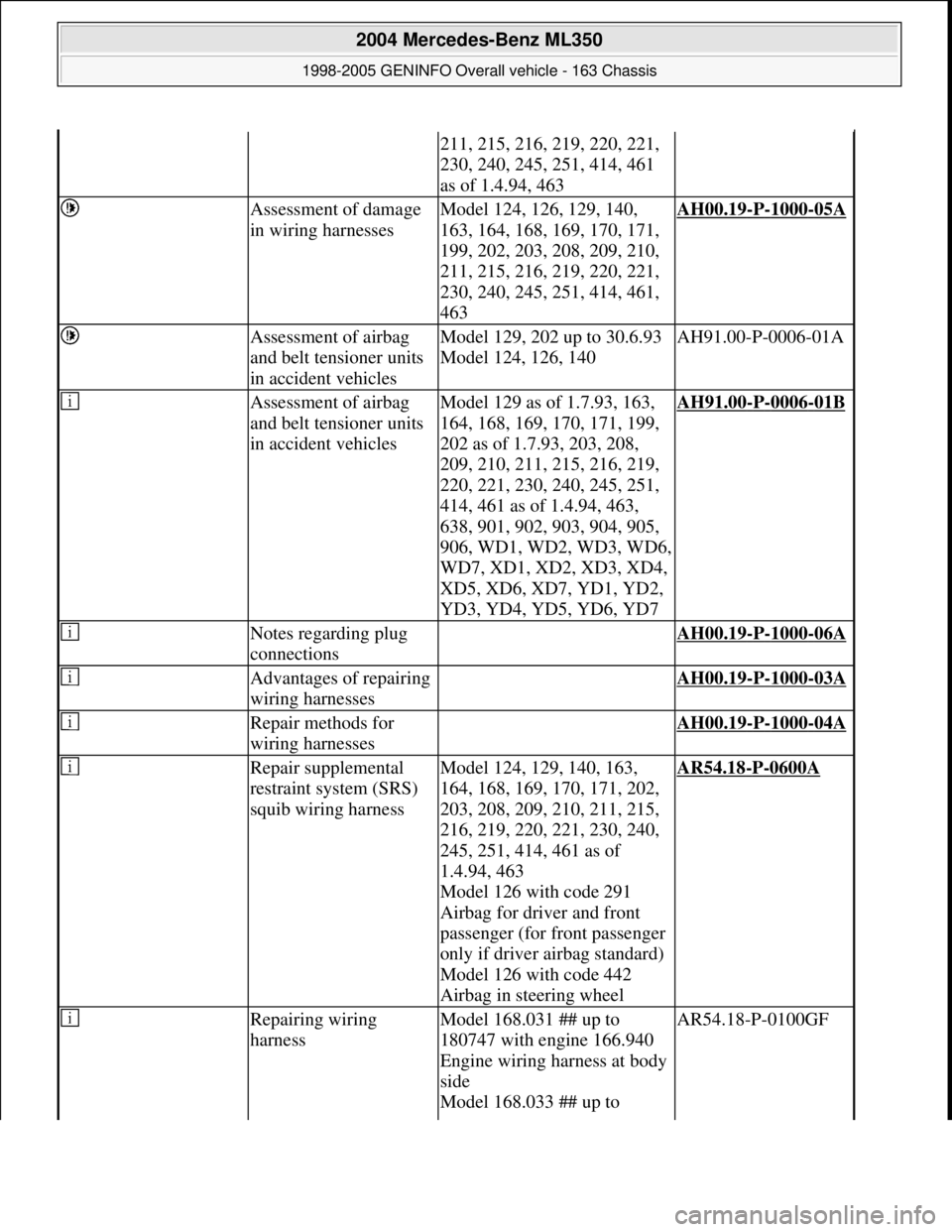

211, 215, 216, 219, 220, 221,

230, 240, 245, 251, 414, 461

as of 1.4.94, 463

Assessment of damage

in wiring harnessesModel 124, 126, 129, 140,

163, 164, 168, 169, 170, 171,

199, 202, 203, 208, 209, 210,

211, 215, 216, 219, 220, 221,

230, 240, 245, 251, 414, 461,

463AH00.19-P-1000-05A

Assessment of airbag

and belt tensioner units

in accident vehiclesModel 129, 202 up to 30.6.93

Model 124, 126, 140AH91.00-P-0006-01A

Assessment of airbag

and belt tensioner units

in accident vehiclesModel 129 as of 1.7.93, 163,

164, 168, 169, 170, 171, 199,

202 as of 1.7.93, 203, 208,

209, 210, 211, 215, 216, 219,

220, 221, 230, 240, 245, 251,

414, 461 as of 1.4.94, 463,

638, 901, 902, 903, 904, 905,

906, WD1, WD2, WD3, WD6,

WD7, XD1, XD2, XD3, XD4,

XD5, XD6, XD7, YD1, YD2,

YD3, YD4, YD5, YD6, YD7AH91.00-P-0006-01B

Notes regarding plug

connections AH00.19-P-1000-06A

Advantages of repairing

wiring harnesses AH00.19-P-1000-03A

Repair methods for

wiring harnesses AH00.19-P-1000-04A

Repair supplemental

restraint system (SRS)

squib wiring harnessModel 124, 129, 140, 163,

164, 168, 169, 170, 171, 202,

203, 208, 209, 210, 211, 215,

216, 219, 220, 221, 230, 240,

245, 251, 414, 461 as of

1.4.94, 463

Model 126 with code 291

Airbag for driver and front

passenger (for front passenger

only if driver airbag standard)

Model 126 with code 442

Airbag in steering wheelAR54.18-P-0600A

Repairing wiring

harnessModel 168.031 ## up to

180747 with engine 166.940

Engine wiring harness at body

side

Model 168.033 ## up to AR54.18-P-0100GF

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:48 PMPage 247 © 2006 Mitchell Repair Information Company, LLC.

Page 2893 of 4133

180747 with engine 166.960

Engine wiring harness at body

side

Repairing wiring

harnessModel 168.007 with engine

668.941

Engine wiring harness at body

side

Model 168.008 with engine

668.940

Engine wiring harness at body

sideAR54.18-P-0100GD

Repairing wiring

harnessModel 168.007 with engine

668.941

Engine wiring harness

Model 168.008 with engine

668.940

Engine wiring harnessAR54.18-P-0100GC

Install left front repair

wiring harnessModel

168.007/008/031/032/033

Only vehicles with one-piece

wiring harnessAR54.18-P-0700GC

Install right front repair

wiring harnessModel

168.007/008/031/032/033

Only vehicles with one-piece

wiring harnessAR54.18-P-0701GC

Install left rear repair

wiring harnessModel

168.007/008/031/032/033

Only vehicles with one-piece

wiring harnessAR54.18-P-0702GC

Install right rear repair

wiring harnessModel

168.007/008/031/032/033

Only vehicles with one-piece

wiring harnessAR54.18-P-0703GC

General repair method

for wiring harness. AR00.19-P-0100A

Checking wiring harness AR54.18-P-0600-01A

Electrical connection setFig. 336

126-pin socket boxFig. 337

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:48 PMPage 248 © 2006 Mitchell Repair Information Company, LLC.

Page 2921 of 4133

Fig. 394: Wrapping Insulating Tape Around Corrugated Hose At Both Ends

PROTECT REPAIR AREA AFTER CABLE REPAIRS - AR00.19-P-0100-08C

Protect repair area by wrapping fabric tape around it.

1. Wrap fabric tape around repair area as per original condition.

Fabric tape restores the appearan ce of the repair area and provides pr otection from chafing. In parts of

vehicle subject to high levels of st ress (e.g. engine compartment) fabric tape should only be used together

with other (watertight) protective measures.

REPAIRING WIRING HARN ESS USING SOLDER CONNECTORS - AR00.19-P-0100-09A

Fig. 395: Identifying New Passe nger Vehicle Wiring Harness Repair Kit (220 589 04 99 00)

Fig. 396: Identifying Wiring Harness Repair Kit, Basic (000 589 13 99 00)

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:49 PMPage 276 © 2006 Mitchell Repair Information Company, LLC.

Page 3041 of 4133

the side jacking points.

Fig. 639: Identifyin g Lifting At Rear

RAISING, JACKING UP VEHICLE - AR00.60-P-1000GH

MODEL 163

Fig. 640: Raising, Jacking Up Vehicle

Fig. item, etc.Work instructions

Lethal injuries are

possible if vehicle slips

off of lifting platformAlign vehicle between the

four lifting platform pillars

and position the four

support plates at the hoist

mounting points specified

by the vehicle

manufacturer.AS00.00-Z-0010-01A

Danger of accident

through self-acting

movement of the vehicle

when jacked up Risk of

injury through intrusion

into engine compartment

or driveline where rotating

parts pose a serious

hazard.Make sure that the jack

stands are securely

positioned. Authorized

person should occupy

driver's seat. Wear closed

and close-fitting work

clothes. Do not grasp hot

or rotating parts.AS00.00-Z-0008-01A

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:52 PMPage 396 © 2006 Mitchell Repair Information Company, LLC.

Page 3044 of 4133

These instructions are to be read carefully and complied with in full In order to rule out any risk of personal

injury, to avoid impairing the reliability and safety of the vehicle, and to prevent damage to the vehicle as a

result of work improperly carried out.

It is therefore not possible for DaimlerChrysler AG to evaluate in the last consequence every situation which

might present a risk of injury for the operative. It is therefore an urgent necessity that everyone who carries out

repair work on Mercedes-Benz passenger cars by applying his professional knowledge satisfies himself that his

own safety is not at risk and that the vehicle will not suffer any negative effects, in particular of a safety

engineering nature, as a result of the repair procedure adopted.

It is therefore expressly pointed out that all work for the operations described must be carried out in compliance

with valid directives and instructions from the responsible local authorities and those relating to health, work

safety and environmental protection.

ADDITIONAL DESIGNATION FOR MODELS AND COMPONENTS - AP00.20-P-0000-03A

Models and components, in addition to their 3 to 6-figure designation (e.g. 124 or 124.028), may have different

versions, dates and work procedures. These differences are indicated b

y the following additional designations:

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:52 PMPage 399 © 2006 Mitchell Repair Information Company, LLC.

Page 3046 of 4133

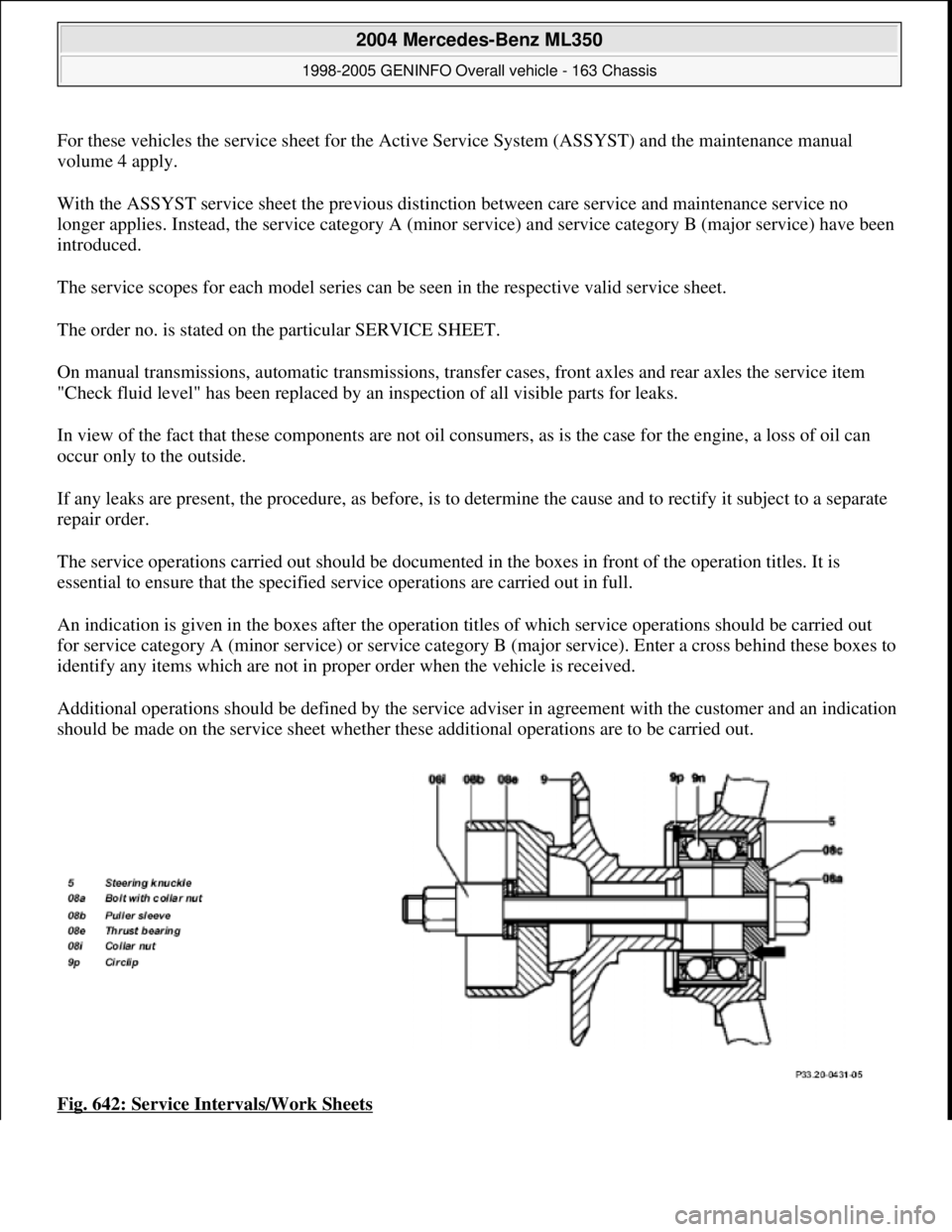

For these vehicles the service sheet for the Active Service System (ASSYST) and the maintenance manual

volume 4 apply.

With the ASSYST service sheet the previous distinction between care service and maintenance service no

longer applies. Instead, the service category A (minor service) and service category B (major service) have been

introduced.

The service scopes for each model series can be seen in the respective valid service sheet.

The order no. is stated on the particular SERVICE SHEET.

On manual transmissions, automatic transmissions, transfer cases, front axles and rear axles the service item

"Check fluid level" has been replaced by an inspection of all visible parts for leaks.

In view of the fact that these components are not oil consumers, as is the case for the engine, a loss of oil can

occur only to the outside.

If any leaks are present, the procedure, as before, is to determine the cause and to rectify it subject to a separate

repair order.

The service operations carried out should be documented in the boxes in front of the operation titles. It is

essential to ensure that the specified service operations are carried out in full.

An indication is given in the boxes after the operation titles of which service operations should be carried out

for service category A (minor service) or service category B (major service). Enter a cross behind these boxes to

identify any items which are not in proper order when the vehicle is received.

Additional operations should be defined by the service adviser in agreement with the customer and an indication

should be made on the service sheet whether these additional operations are to be carried out.

Fig. 642: Service Intervals/Work Sheets

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:52 PMPage 401 © 2006 Mitchell Repair Information Company, LLC.

Page 3048 of 4133

Run in gently, but briskly.

Avoid high load, high rpm and high speed.

Automatic transmissions: do not use kick-down and do not brake the vehicle by shifting down manually.

After 1 500 km

Gradually bring the vehicle up to its full road and engine speeds.

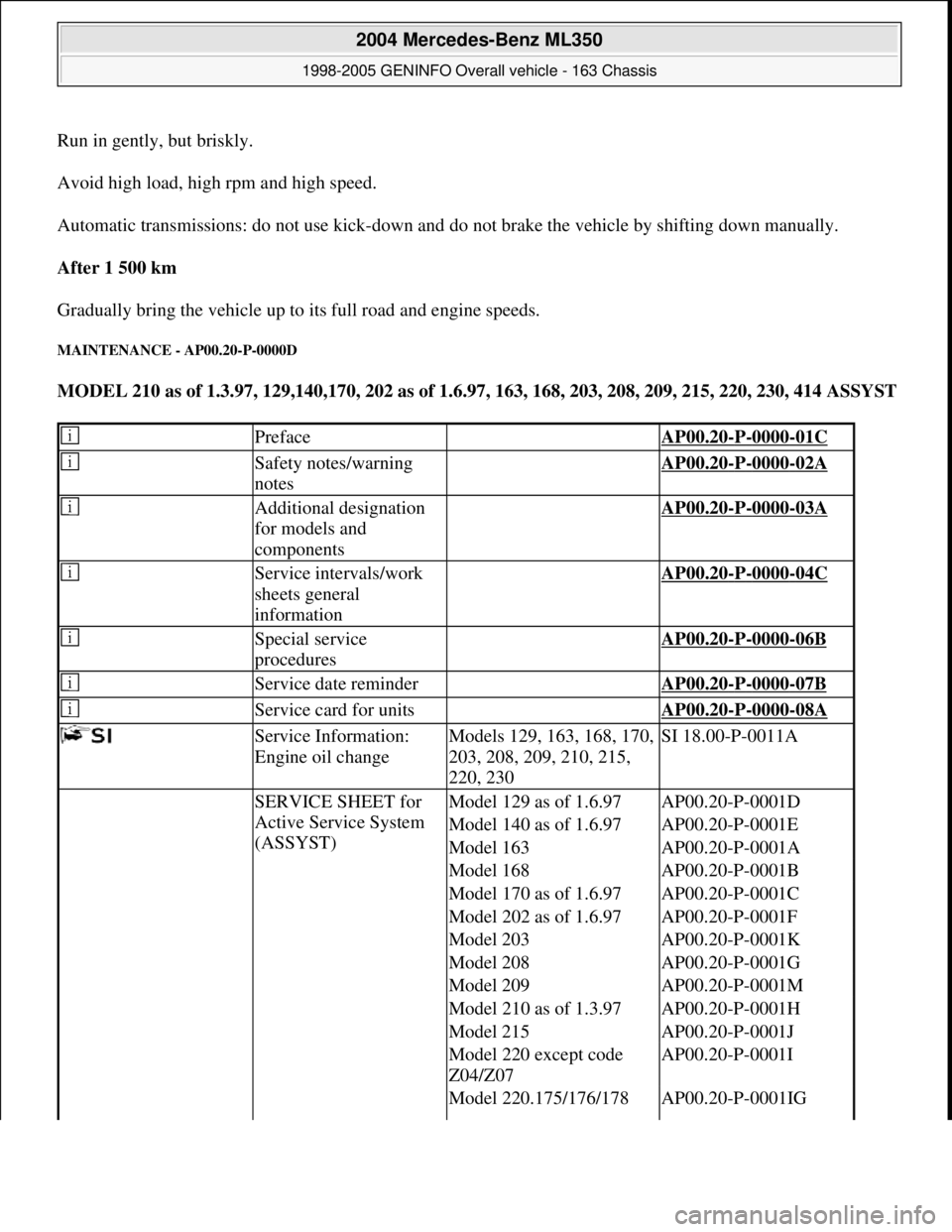

MAINTENANCE - AP00.20-P-0000D

MODEL 210 as of 1.3.97, 129,140,170, 202 as of 1.6.97, 163, 168, 203, 208, 209, 215, 220, 230, 414 ASSYST

Preface AP00.20-P-0000-01C

Safety notes/warning

notes AP00.20-P-0000-02A

Additional designation

for models and

components AP00.20-P-0000-03A

Service intervals/work

sheets general

information AP00.20-P-0000-04C

Special service

procedures AP00.20-P-0000-06B

Service date reminder AP00.20-P-0000-07B

Service card for units AP00.20-P-0000-08A

Service Information:

Engine oil changeModels 129, 163, 168, 170,

203, 208, 209, 210, 215,

220, 230SI 18.00-P-0011A

SERVICE SHEET for

Active Service System

(ASSYST)Model 129 as of 1.6.97AP00.20-P-0001D

Model 140 as of 1.6.97AP00.20-P-0001E

Model 163AP00.20-P-0001A

Model 168AP00.20-P-0001B

Model 170 as of 1.6.97AP00.20-P-0001C

Model 202 as of 1.6.97AP00.20-P-0001F

Model 203AP00.20-P-0001K

Model 208AP00.20-P-0001G

Model 209AP00.20-P-0001M

Model 210 as of 1.3.97AP00.20-P-0001H

Model 215AP00.20-P-0001J

Model 220 except code

Z04/Z07AP00.20-P-0001I

Model 220.175/176/178 AP00.20-P-0001IG

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:52 PMPage 403 © 2006 Mitchell Repair Information Company, LLC.