Drive Mode MERCEDES-BENZ ML320 1997 Complete Repair Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML320, Model: MERCEDES-BENZ ML320 1997Pages: 4133, PDF Size: 88.89 MB

Page 1 of 4133

AIR BAG RESTRAINT SYSTEM

1998 AIR BAG RESTRAINT SYSTEMS Mercedes-Benz

DESCRIPTION & OPERATION

All models are equipped with Supplemental Restraint System (SRS). The main components of SRS are a driver

air bag module, passenger air bag module, control unit, SRS warning light, driver knee bolster, passenger knee

bolster, and Emergency Tensioning Retractor (ETR) seat belt assembly. Additionally, all vehicles provide

driver-side and passenger-side impact protection by side air bags which are mounted in the driver-side and

passenger-side doors. Each of the door mounted side air bags utilize sensors which recognize lateral

acceleration durin

g side impact and signal this to the control module. See Fig. 1. NOTE: Information on ML320 is not available. For WIRING DIAGRAMS, See Fig. 32

.

WARNING:To avoid injury from accidental air bag deployment, read and carefully

follow all WARNINGS and SERVICE PRECAUTIONS

.

1998 Mercedes-Benz ML320

AIR BAG RESTRAINT SYSTEM 1998 AIR BAG RESTRAINT SYSTEMS Mercedes-Benz

1998 Mercedes-Benz ML320

AIR BAG RESTRAINT SYSTEM 1998 AIR BAG RESTRAINT SYSTEMS Mercedes-Benz

me

Saturday, October 02, 2010 3:33:13 PMPage 1 © 2006 Mitchell Repair Information Company, LLC.

me

Saturday, October 02, 2010 3:33:18 PMPage 1 © 2006 Mitchell Repair Information Company, LLC.

Page 3 of 4133

Fig. 1: Locating Restraint System Components (E Class Shown; Others Are Similar)

Courtesy of MERCEDES-BENZ OF NORTH AMERICA

Both SRS and ETR are electronically activated by a single control unit if a moderately severe to severe frontal

collision occurs. There are 2 thresholds which must be exceeded to trigger an ETR action, air bag deployment,

or both. If a moderately severe frontal collision occurs exceeding first triggering threshold where protection

from safety belt is sufficient, only Emergency Tensioning Retractor (ETR) is activated if safety belt is buckled.

If a moderately severe frontal collision occurs exceeding first triggering threshold where protection from safety

belt is sufficient, but safety belt is not buckled, air bag is deployed and EAR is not activated.

If a severe frontal collision occurs exceeding second triggering threshold where protection from safety belt is

insufficient, air bag is deployed. EAR is activated if safety belt is buckled. If safety belt is not buckled, ETR is

not activated when second triggering threshold is reached. Passenger air bag will deploy even if passenger seat

is not occupied when a triggering threshold is exceeded. If during a severe frontal collision the power supply is

interrupted, the driver and passenger air bag can still be deployed, but ETR cannot be activated.

The side air bag on the driver-side deploys whenever the driver-side air bag module is deployed and when there

is a substantial side impact crash. The air bag on the passenger-side will activate only when a sensor (Occupied

Seat Recognition Sensor) in the passenger seat sends a signal to the control module that the passenger-side seat

is occupied. During a collision, the side air bag will then deploy.

SERVICING

SRS AIR BAG label on driver-side door latch post indicates SRS replacement date for driver and passenger air

bag units. All SRS components must be thoroughly inspected, including wiring harness. Before component

replacement, check for SRS fault codes by performing system operation check. See SYSTEM OPERATION

CHECK . SRS service life is 10 years from manufactured date, or 10 years from SRS replacement date after

accident related repairs are completed.

POST-COLLISION INSPECTION

When a vehicle has been involved in a collision, certain components of the passive restraint system must be

inspected or replaced. See PASSIVE RESTRAINT SYSTEM INSPECTION article in the GENERAL

INFORMATION section for post-collision inspection information.

ADJUSTMENTS

If fixing screws were not used during clockspring removal or clockspring was rotated during removal, turn

clockspring clockwise until resistance is detectable. Turn clockspring counterclockwise 2-2.5 turns until fixing

screws can be unscrewed holding clockspring in this position.

DISPOSAL PROCEDURES

WARNING:An undeployed air bag module or ETR should never be disposed of

without first being deployed. See SCRAPPED VEHICLE

. If deployment is

not possible, contact vehicle manufacturer for further instructions.

1998 Mercedes-Benz ML320

AIR BAG RESTRAINT SYSTEM 1998 AIR BAG RESTRAINT SYSTEMS Mercedes-Benz

me

Saturday, October 02, 2010 3:33:13 PMPage 3 © 2006 Mitchell Repair Information Company, LLC.

Page 9 of 4133

Fig. 2: Removing Side Air Bag Unit

Courtesy of MERCEDES-BENZ OF NORTH AMERICA

SIDE AIR BAG SENSOR - DRIVER-SIDE & PASSENGER-SIDE

Removal & Installation

1. Before proceeding, see SERVICE PRECAUTIONS . Disable air bag system. See DISABLING &

ACTIVATING AIR BAG SYSTEM . Remove ignition key. On SLK 230, remove door sill moulding.

On all models, remove front seat. Fold floor covering in area toward rear. Unclip connector on side bag

sensor. Remove 2 mounting screws. Remove sensor from vehicle.

2. To install, reverse removal procedure. Ensure that arrow on sensor points toward outside. Perform system

operation check to ensure system is functioning properly. See SYSTEM OPERATION CHECK

.

1998 Mercedes-Benz ML320

AIR BAG RESTRAINT SYSTEM 1998 AIR BAG RESTRAINT SYSTEMS Mercedes-Benz

me

Saturday, October 02, 2010 3:33:14 PMPage 9 © 2006 Mitchell Repair Information Company, LLC.

Page 20 of 4133

with HHT connected to DLC and ignition key removed. Remove driver-side air bag module. Disconnect

driver-side air bag module squib connector R12/3. Connect Resistance Substitution Unit (124 589 09 63)

to driver-side air bag module squib connector (harness side). Set resistance substitution unit to 2 ohms.

Turn ignition key to position "2". Read NOMINAL VALUE/HHT DISPLAY column. If HHT displays a

check, replace driver-side air bag module. If HHT displays an "F", go to step 3.2.

Read TEST CONNECTION (NOT FOR HHT) column. Horn/air bag clockspring connector A45x1,

terminals No. 1 and 2 are identified. Read TEST CONDITION column. Test circuit with HHT connected

to DLC. Remove ignition key. Connect Resistance Substitution Unit (124 589 09 63 00) to horn/air bag

clockspring connector A45x1. Set resistance substitution unit to 2 ohms. Read NOMINAL VALUE/HHT

DISPLAY column. If HHT displays a check, check horn/air bag clockspring for continuity. Replace

horn/air bag clockspring as necessary. If HHT displays an "F", go to step 3.4.

MODEL IDENTIFICATION

COMPONENT IDENTIFICATION

DIAGNOSTIC TESTS NOTE: Some testing is identified by model number. To identify models by model

number see MODEL IDENTIFICATION

table.

Model NumberModel

129SL Class

140S Class

170SLK 230

202C Class

208CLK 320

210E Class

ComponentManufacturer's Designation

A45Horn/Air Bag Clockspring

A53Driver-Side Air Bag Sensor

A54Passenger-Side Air Bag Sensor

B41/1Passenger-Side Seat Occupied Recognition Sensor

N2/2Control Module

R12/1Driver-Side ETR Squib Connector

R12/2Passenger-Side ETR Squib Connector

R12/3Driver-Side Air Bag Squib Connector

R12/8Passenger-Side Air Bag Squib Connector

R12/9Side Air Bag (Driver-Side)Squib Connector

R12/10Side Air Bag (Passenger-Side) Squib Connector

S68/3Driver-Side Belt Buckle Switch

S68/4Passenger-Side Belt Buckle Switch

W26Control Module Ground

X11/4Data Link Connector

1998 Mercedes-Benz ML320

AIR BAG RESTRAINT SYSTEM 1998 AIR BAG RESTRAINT SYSTEMS Mercedes-Benz

me

Saturday, October 02, 2010 3:33:14 PMPage 20 © 2006 Mitchell Repair Information Company, LLC.

Page 69 of 4133

19 Instruments and controls

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hints Car care Index For more detailed descriptions see index on page 300.

For adjustment of air outlets, refer to climate control,

see page 98.

1Cup holder, see page 114

2Parking brake release, see page 173

3Parking brake pedal, see page 173

4Steering wheel adjustment lever, see page 70

5Headlamp washer switch, see page 94

6Exterior lamp switch, see page 90

7Cruise control switch, see page 196

8Instrument cluster, see page 76

9Hazard warning flasher switch, see page 94

10Horn (with key in steering lock position 1 or 2),

Driver airbag, see page 56

11Steering lock with ignition / starter switch, see

page 162

12Switch for exterior rear view mirrors, electrically

folding, see page 75

13Windshield wiper / washer switch, see page 9514Transmission control – LOW RANGE mode, see

page 209

15Indicator lamp for antitheft alarm system

16Auxiliary front fog lamp / rear fog lamp switch, see

page 92

17MCS (Optional Modular Control System), see

separate operator’s manual

18Front passenger airbag, see page 56

19Glove box (illuminated with key in steering lock

position 1 or 2)

20Cup holder, see page 114

21Storage compartment

22Air recirculation switch, see page 98

23Air conditioner on /off switch, see page 98

24Air volume control switch

25Temperature selector switch

26Air distribution switch

27Electrical outlet, see page 230

Page 90 of 4133

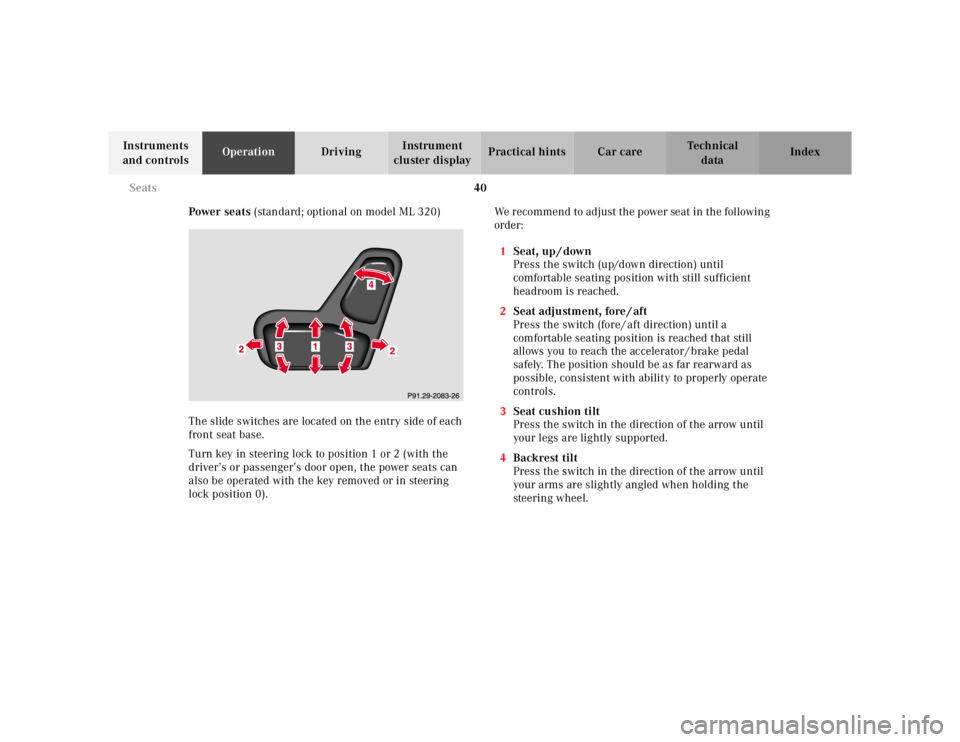

40 Seats

Te ch n ica l

data Instruments

and controlsOperationDrivingInstrument

cluster displayPractical hints Car care Index

Power seats (standard; optional on model ML 320)

The slide switches are located on the entry side of each

front seat base.

Turn key in steering lock to position 1 or 2 (with the

driver’s or passenger’s door open, the power seats can

also be operated with the key removed or in steering

lock position 0).We recommend to adjust the power seat in the following

order:

1Seat, up / down

Press the switch (up/down direction) until

comfortable seating position with still sufficient

headroom is reached.

2Seat adjustment, fore / aft

Press the switch (fore / aft direction) until a

comfortable seating position is reached that still

allows you to reach the accelerator / brake pedal

safely. The position should be as far rearward as

possible, consistent with ability to properly operate

controls.

3Seat cushion tilt

Press the switch in the direction of the arrow until

your legs are lightly supported.

4Backrest tilt

Press the switch in the direction of the arrow until

your arms are slightly angled when holding the

steering wheel.

Page 108 of 4133

58 Restraint systems

Te ch n ica l

data Instruments

and controlsOperationDrivingInstrument

cluster displayPractical hints Car care Index

out after approximately 5 seconds; after the lamp goes

out, the system continues to monitor the components

and circuitry of the airbag system and will indicate a

malfunction by coming on again. If the lamp does not

come on at all or if it fails to extinguish after

approximately 5 seconds or if it comes on thereafter,

a malfunction in the system has been detected.

The following system components are monitored or

undergo a self-check: crash-sensor(s), airbag ignition

circuits, front seat belt buckles, emergency tensioning

retractors, seat sensor.

Initially, when the key is turned from steering lock

position 0 to positions 1 or 2, malfunctions in the

crash-sensor are detected and indicated (the “SRS”

indicator lamp stays on longer than 5 seconds or does

not come on).

Have the system checked at your authorized

Mercedes-Benz Light Truck Center immediately.In the operational mode, after the indicator lamp has

gone out following the initial check, interruptions or

short circuits in the airbag ignition circuit and in the

driver and front passenger seat belt buckle harnesses,

and low voltage in the entire system are detected and

indicated.

Wa r n i n g !

In the event a malfunction of the “SRS” is indicated

as outlined above, the “SRS” may not be

operational. For your safety, we strongly

recommend that you visit an authorized

Mercedes-Benz Light Truck Center immediately to

have the system checked; otherwise the “SRS” may

not be activated when needed in an accident, which

could result in serious or fatal injury, or it might

deploy unexpectedly and unnecessarily which

could also result in injury.

Page 136 of 4133

86 Trip computer

Te ch n ica l

data Instruments

and controlsOperationDrivingInstrument

cluster displayPractical hints Car care Index

To calibrate the compass:

If the vehicle was exposed to a significant magnetic

zone, such as high voltage power lines, the compass

may have to be calibrated.

Calibration of the compass should be done in an area

free of steel superstructures and power lines. All

electrical consumers (e.g. exterior lamps, climate

control, etc.) should be switched off, doors and liftgate

closed. Do not open or close the roof. An open door or

liftgate triggers the display “–––”.

1. Start and run the engine.

2. Press MODE key repeatedly until the compass

display appears in the trip computer display.

3. Press RESET key to select the compass zone display.

4. Press RESET repeatedly until the correct zone, as

determined from the zone map (see page 85), is

shown in the display.

5. Press MODE key, “CAL–” appears in the display.

6. Press and hold RESET for a minimum of 2 seconds.7. Without interruption drive two or more full circles

at a speed between 3 mph (5 km / h) and 7 mph

(10 km / h) during which the message “CAL” is

replaced with a compass bearing (e.g. N, SW etc.),

immediately followed by three full circles at the

same speed, with only the rear window defroster

switched on. The defroster can be switched off

again. The calibration of the compass is now

complete.

•Stop watch –

Press RESET key to start the count. Press again to

stop the count. Press and hold RESET key to reset

sto p watch.

•Average fuel consumption –

Press RESET key to delete present reading.

•Language –

Press RESET key to set the language used in the

display.

Page 195 of 4133

145 Contents - Driving

Te ch n ica l

data Instruments

and controlsOperationDrivingInstrument

cluster displayPractical hints Car care Index

DrivingControl and operation of

radio transmitters ..................... 146

The first 1 000 miles

(1 500 km) ................................. 147

Maintenance ................................... 147

Tele Aid ........................................... 148

Catalytic converter ........................ 160

Emission control ............................ 161

Steering lock ................................... 162

Starting and turning off

the engine .................................. 164

Automatic transmission ............... 165

Parking brake ................................. 173Driving instructions .......................174

Drive sensibly – save fuel .........174

Drinking and driving .................174

Pedals ...........................................174

Power assistance ........................ 175

Brakes .......................................... 175

Driving off .................................... 176

Parking ......................................... 176

Tires ............................................. 177

Snow chains ............................... 179

Winter driving instructions ......180

Deep water ...................................181

Passenger compartment ............182

Traveling abroad .........................182Off-Road driving ............................. 183

Trailer towing ................................. 190

Cruise control ................................. 196

Brake assist system (BAS) ............ 199

Antilock brake system (ABS) ....... 201

Four-wheel electronic

traction system (4-ETS+) ..........203

Electronic brake

proportioning (EBP) ..................204

Electronic stability program

(ESP) ...........................................205

Transmission control –

LOW RANGE mode ...................209

What you should know

at the gas station ....................... 212

Check regularly and

before a long trip ...................... 215

Page 197 of 4133

147 The first 1 000 miles

Te ch n ica l

data Instruments

and controlsOperationDrivingInstrument

cluster displayPractical hints Car care Index The first 1 000 miles (1 500 km)

The more cautiously you treat your vehicle during the

break-in period, the more satisfied you will be with its

performance later on. Therefore, drive your vehicle

during the first 1 000 miles (1 500 km) at moderate

vehicle and engine speeds.

During this period, avoid heavy loads (full throttle

driving) and excessive engine speeds.

Avoid accelerating by kickdown. It is not recommended

to brake the vehicle by manually shifting to a lower gear.

We recommend that you select positions “3”, “2” or “1”

only at moderate speeds (for hill driving).

After 1 000 miles (1 500 km) speeds may be gradually

increased to the permissible maximum.Maintenance

Approximately 30 days or 2 000 miles

(Canada: 2000 km) prior to the next recommended

service, the remaining distance or days are displayed in

the multifunction indicator. See Flexible Service System

(FSS) on page 87.

We strongly recommend that you have your vehicle

serviced by your authorized Mercedes-Benz Light Truck

Center, in accordance with the Service Booklet at the

times called for by the FSS.

Failure to have the vehicle maintained in accordance

with the Service Booklet at the designated times /

mileage may result in vehicle damage not covered by

the Mercedes-Benz Limited Warranty.

Check regularly and before a long trip, see page 215.