change key battery MERCEDES-BENZ ML320 1997 Complete Repair Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML320, Model: MERCEDES-BENZ ML320 1997Pages: 4133, PDF Size: 88.89 MB

Page 320 of 4133

270 Remote control

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

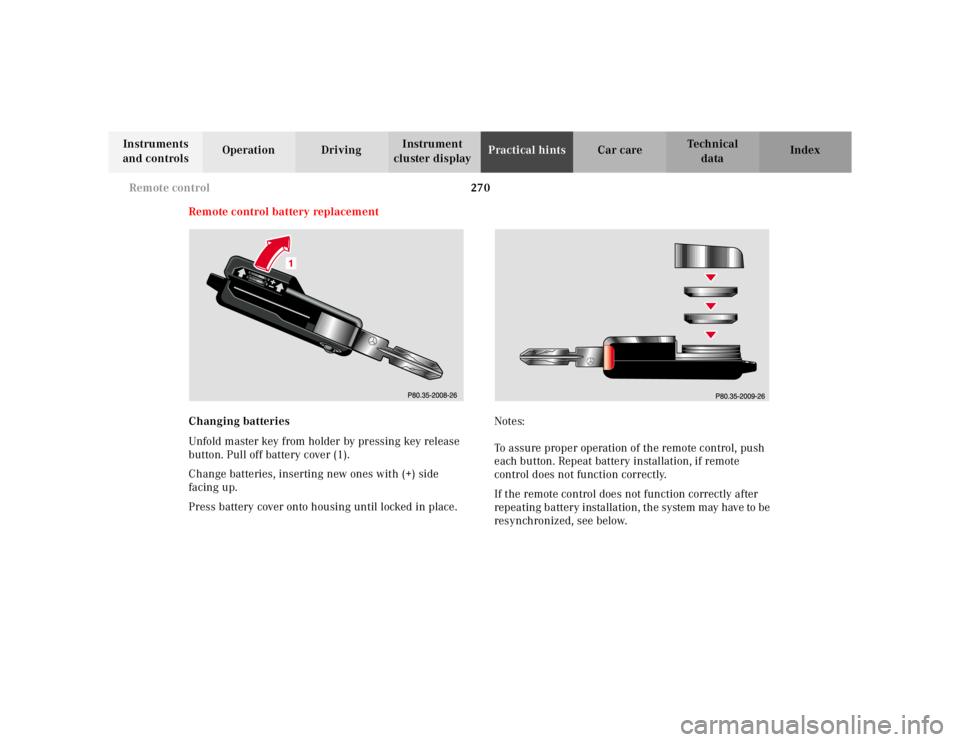

Remote control battery replacement

Changing batteries

Unfold master key from holder by pressing key release

button. Pull off battery cover (1).

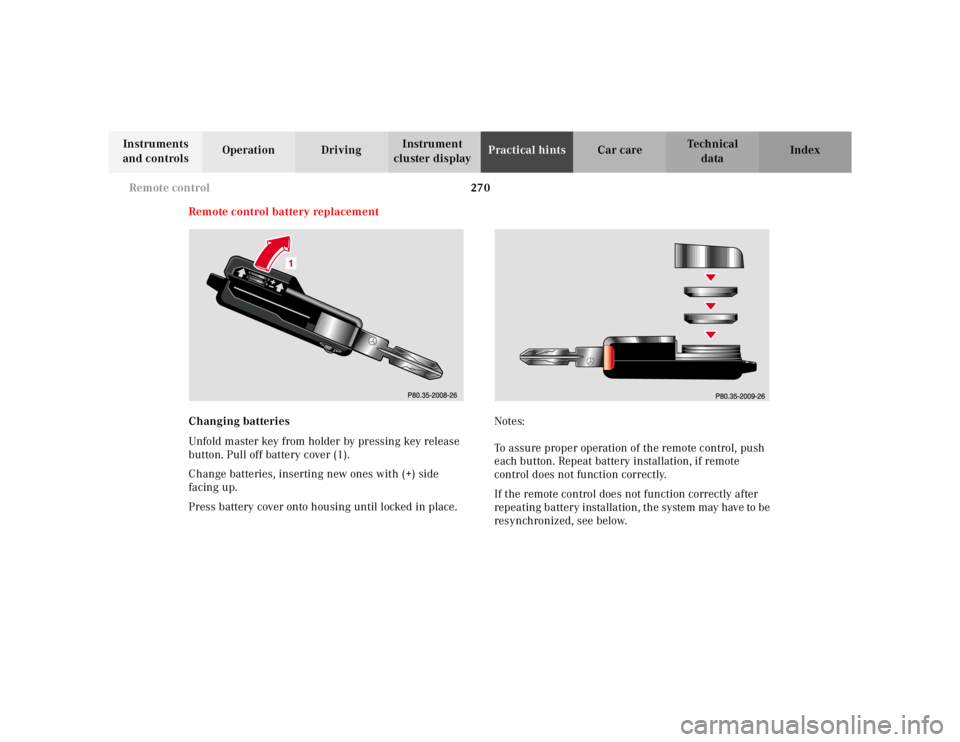

Change batteries, inserting new ones with (+) side

facing up.

Press battery cover onto housing until locked in place.Notes:

To assure proper operation of the remote control, push

each button. Repeat battery installation, if remote

control does not function correctly.

If the remote control does not function correctly after

repeating battery installation, the system may have to be

resynchronized, see below.

Page 737 of 4133

270

Remote control

Te ch n ica l

data

Instruments

and controls Operation Driving

Instrument

cluster display Practical hints

Car care Index

Remote control battery replacement

Changing batteries

Unfold master key from holder by pressing key release

button. Pull off battery cover (1).

Change batteries, inserting new ones with (+) side

facing up.

Press battery cover onto housing until locked in place. Notes:

To assure proper operation of the remote control, push

each button. Repeat battery installation, if remote

control does not function correctly.

If the remote control does not function correctly after

repeating battery installation, the system may have to be

resynchronized, see below.

Page 3185 of 4133

AD54.30-P-2000-02GC

Notes on HHT previous knowledge diagnosis

IC

HHT :

The instrument cluster and active service system (ASSYST) sub-

function are checked with HHT, there being the choice of the

following functions for this:

1. Control module version

2. Fault memory

3. Actual values

4. Actuations

5. Control module adaptation

Additional information on test items 2, 3 and 5 can be called up using

the INPUT key

Control module adaptation

The following alternatives are available in the HHT under control

module adaptation:

1.)

Read out coding and transfer to new instrument cluster. IC and

ASSYST.

2.)

Read out/change codings e.g.:

Engine and national variants,

version of fuel tank,

special equipment etc.

3.)

Settings:

1

Clock

2

Put forward kilometer reading

3

Put back kilometer reading

4

Oil change

5

Reset oil change initiated inadvertently

6

Active Service System

7

Enter times with battery disconnected

8

Set minimum oil warning

Before replacing a defective instrument cluster, readout the existing

variant codings (driving data and instrument cluster data) and store in

the HHT on an interim basis. Read in the values stored on an interim

basis again after installing the new instrument cluster.

If it is not possible to read out the stored variant coding, all variant

codings must be input manually (menu-assistance in HHT).

When installing an instrument cluster on an experimental basis, do

not put forward the kilometer reading as it cannot be put back later.

Copyright DaimlerChrysler AG 05.06.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3397 of 4133

OFF . To this end the system uses the residual heat of the engine. The residual engine heat is dissipated to the

coolant and routed through the heat exchanger with the aid of the heating water circulation pump. The air drawn

in by the blower motor is routed around the heat exchanger, whereby it is then warmed up. The heated air is

then routed over the air outlets into the passenger compartment.

The residual engine heat utilization system can only be used when the ignition is switched OFF.

Once the Rest push-button ( ) on the AAC push-button control module (N22) has been pressed the

following program sequence is run:

Blending air flaps are automatically controlled

Heating water circulation pump ON

The blower's control voltage is limited to a maximum value of 5 Volt.

End of program

Pressing the Rest push-button ( )

Timeout of 30 minutes period (repeated operation possible)

Protection against undervoltage at a battery voltage of less than 11 V (LED flashes)

Ignition ON

During the residual engine heat utilization function no function keys are accepted apart from the Rest push-

button ( ) and the set point adjusters.

SAFETY PRECAUTIONS

RISK OF EXPLOSION CAUSED BY WELDING OR SOLDERING WORK ON CLOSED AIR CONDITIONING SYSTEM.

RISK OF POISONING CAUSED BY INHALING OVERHEATED REFRIGERANT VAPORS. RISK OF INJURY TO SKIN AND

EYES CAUSED BY CONTACT WITH LIQUID REFRIGERANT. - AS83.00-Z-0001-01A

Never perform welding work on or near a closed air conditioning system. No smoking or open flames.

Wear safety glasses and protective gloves. Work only in well ventilated areas. Carry out repair work on

the air conditioning system circuit only after the system has been discharged.

Potential risks

Risk of explosion

When closed air conditionin

g systems (charged or empty) become heated, high pressures are produced that can

Rest push-button, location/task/function GF83.40-P-2148GI

Heating water circulation pump, location/task/ function GF83.20-P-2109GI

Heating system heat exchanger, location/ purpose/function GF83.20-P-2108GC

Blower motor, location/task/design/function GF83.10-P-2170GI

Blending air flap actuator, location/task/function GF83.57-P-2112GI

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:17 PMPage 153 © 2006 Mitchell Repair Information Company, LLC.