run flat MERCEDES-BENZ ML320 1997 Complete Repair Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML320, Model: MERCEDES-BENZ ML320 1997Pages: 4133, PDF Size: 88.89 MB

Page 299 of 4133

249 Tires, Wheels

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

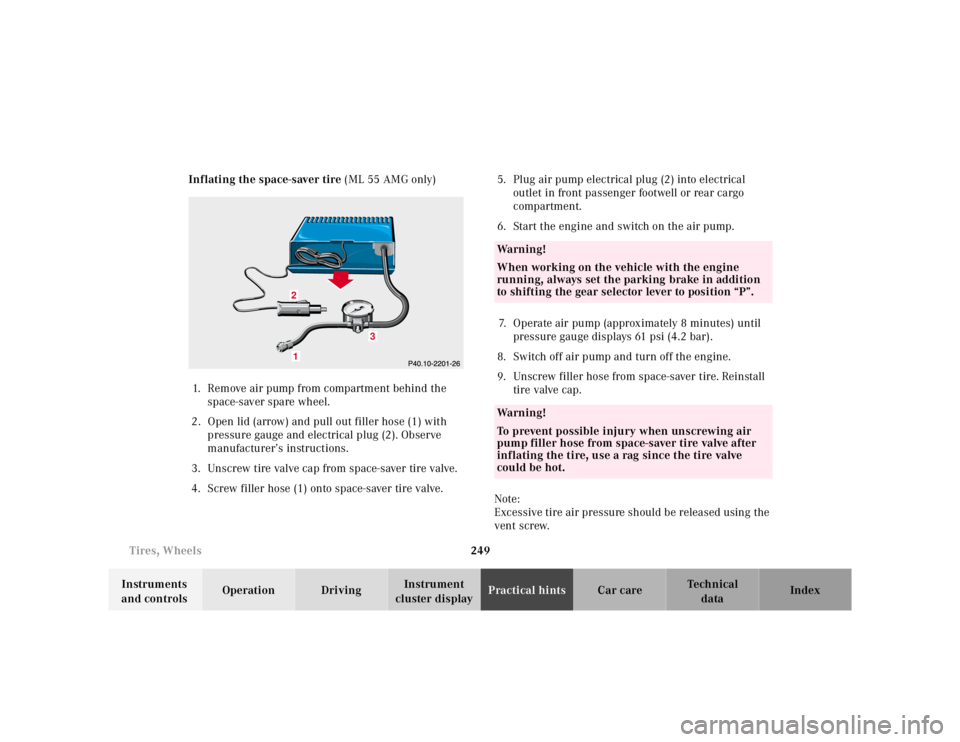

cluster displayPractical hintsCar care Index Inflating the space-saver tire (ML 55 AMG only)

1. Remove air pump from compartment behind the

space-saver spare wheel.

2. Open lid (arrow) and pull out filler hose (1) with

pressure gauge and electrical plug (2). Observe

manufacturer’s instructions.

3. Unscrew tire valve cap from space-saver tire valve.

4. Screw filler hose (1) onto space-saver tire valve.5. Plug air pump electrical plug (2) into electrical

outlet in front passenger footwell or rear cargo

compartment.

6. Start the engine and switch on the air pump.

7. Operate air pump (approximately 8 minutes) until

pressure gauge displays 61 psi (4.2 bar).

8. Switch off air pump and turn off the engine.

9. Unscrew filler hose from space-saver tire. Reinstall

tire valve cap.

Note:

Excessive tire air pressure should be released using the

vent screw.

3

12

Wa r n i n g !

When working on the vehicle with the engine

running, always set the parking brake in addition

to shifting the gear selector lever to position “P”.Wa r n i n g !

To prevent possible injury when unscrewing air

pump filler hose from space-saver tire valve after

inflating the tire, use a rag since the tire valve

could be hot.

Page 360 of 4133

310 Index

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hints Car careIndex

Tires

Driving instructions ................................................. 177

Rims and tires ...........................................................288

Rotating wheels ......................................................... 241

Tire inflation pressure .............................................250

Tire replacement .......................................................240

Winter driving instructions .................................... 180

Tow-away alarm ................................................................ 36

Switching off ................................................................ 36

Towing the vehicle .........................................................255

Stranded vehicle .......................................................259

Transmission selector lever, manually unlocking 259

Trailer operation ............................................................ 198

Trailer towing ................................................................. 190

Transmission .................................................................. 165

Transmission control - LOW RANGE mode ...............209

Transmission fluid level ...............................................234

Transmission selector lever, manually unlocking ....259

Traveling abroad ............................................................ 182

Trip computer ................................................................... 83

Trip odometer ................................................................... 80

Trunk ................................................................................. 34

Opening ........................................................................ 28

Trunk lamp ...................................................................... 111Turn signal failure ........................................................... 91

Turn signal lamp, side .................................................. 266

Turn signals ......................................................................90

UUnlocking the vehicle ...................................................... 27VVanity mirrors ................................................................ 113

Vehicle jack .................................................................... 237

Vehicle keys ......................................................................24

Ve h i c l e t o o l s

Screwdriver ............................................................... 237WWarranty coverage ........................................................ 284

Washing the vehicle ..................................................... 280

What you should know at the gas station .................. 212

Wheel bolt wrench ........................................................ 237

Wheels ............................................................................ 240

Changing wheels ...................................................... 245

Page 716 of 4133

249

Tires, Wheels

Te ch n ica l

data

Instruments

and controls Operation Driving

Instrument

cluster display Practical hints

Car care Index

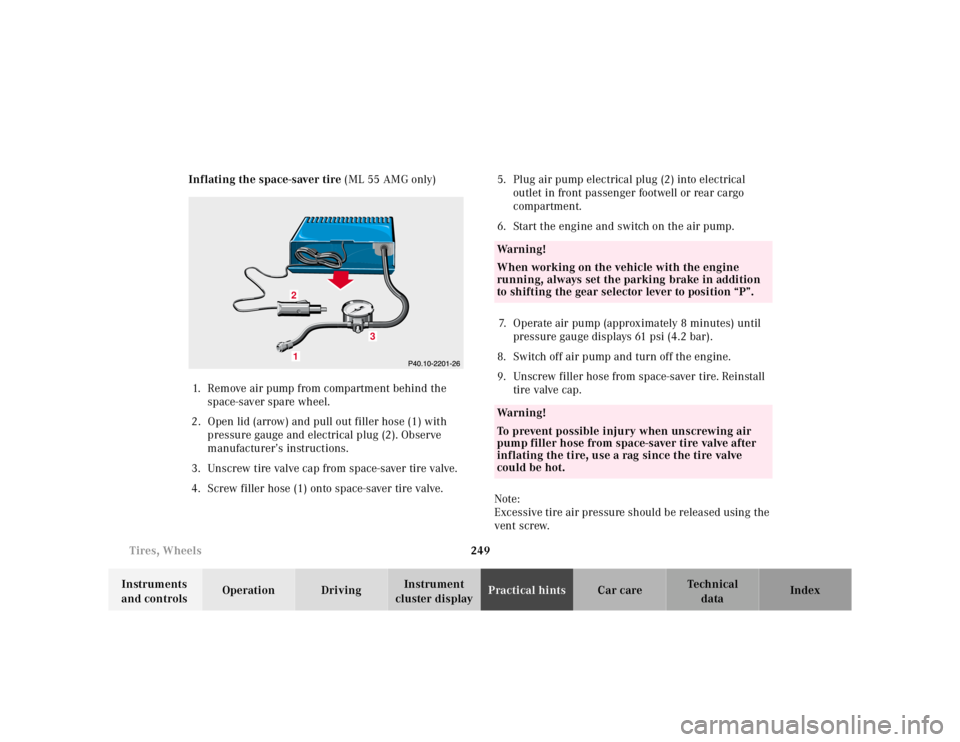

Inflating the space-saver tire

(ML 55 AMG only)

1. Remove air pump from compartment behind the space-saver spare wheel.

2. Open lid (arrow) and pull out filler hose (1) with pressure gauge and electrical plug (2). Observe

manufacturer’s instructions.

3. Unscrew tire valve cap from space-saver tire valve.

4. Screw filler hose (1) onto space-saver tire valve. 5. Plug air pump electrical plug (2) into electrical

outlet in front passenger footwell or rear cargo

compartment.

6. Start the engine and switch on the air pump.

7. Operate air pump (approximately 8 minutes) until pressure gauge displays 61 psi (4.2 bar).

8. Switch off air pump and turn off the engine.

9. Unscrew filler hose from space-saver tire. Reinstall tire valve cap.

Note:

Excessive tire air pressure should be released using the

vent screw.

3

12

Wa r n i n g !

When working on the vehicle with the engine

running, always set the parking brake in addition

to shifting the gear selector lever to position “P”.Wa r n i n g !

To prevent possible injury when unscrewing air

pump filler hose from space-saver tire valve after

inflating the tire, use a rag since the tire valve

could be hot.

Page 777 of 4133

310

Index

Te ch n ica l

data

Instruments

and controls Operation Driving

Instrument

cluster display Practical hints Car care

Index

Tires Driving instructions ................................................. 177

Rims and tires ...........................................................288

Rotating wheels ......................................................... 241

Tire inflation pressure .............................................250

Tire replacement .......................................................240

Winter driving instructions .................................... 180

Tow-away alarm ................................................................ 36 Switching off ................................................................ 36

Towing the vehicle .........................................................255

Stranded vehicle .......................................................259

Transmission selector lever, manually unlocking 259

Trailer operation ............................................................ 198

Trailer towing ................................................................. 190

Transmission .................................................................. 165

Transmission control - LOW RANGE mode ...............209

Transmission fluid level ...............................................234

Transmission selector lever, manually unlocking ....259

Traveling abroad ............................................................ 182

Trip computer ................................................................... 83

Trip odometer ................................................................... 80

Trunk ................................................................................. 34

Opening ........................................................................ 28

Trunk lamp ...................................................................... 111 Turn signal failure ........................................................... 91

Turn signal lamp, side .................................................. 266

Turn signals ......................................................................90

UUnlocking the vehicle ...................................................... 27VVanity mirrors ................................................................ 113

Vehicle jack .................................................................... 237

Vehicle keys ......................................................................24

Ve h i c l e t o o l s

Screwdriver ............................................................... 237WWarranty coverage ........................................................ 284

Washing the vehicle ..................................................... 280

What you should know at the gas station .................. 212

Wheel bolt wrench ........................................................ 237

Wheels ............................................................................ 240 Changing wheels ...................................................... 245

Page 1840 of 4133

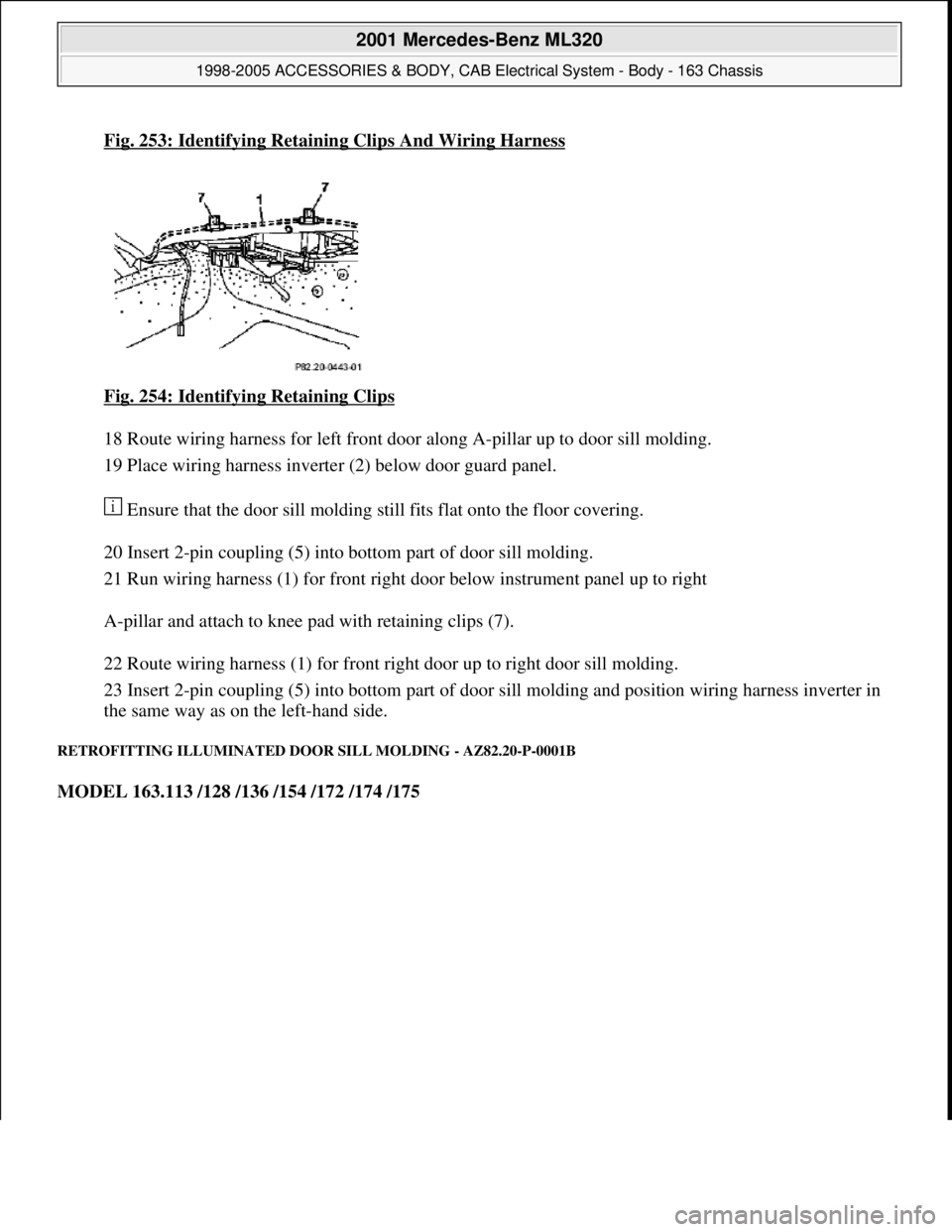

Fig. 253: Identifying Retaining Clips And Wiring Harness

Fig. 254: Identifying Retaining Clips

18 Route wiring harness for left front door along A-pillar up to door sill molding.

19 Place wiring harness inverter (2) below door guard panel.

Ensure that the door sill molding still fits flat onto the floor covering.

20 Insert 2-pin coupling (5) into bottom part of door sill molding.

21 Run wiring harness (1) for front right door below instrument panel up to right

A-pillar and attach to knee pad with retaining clips (7).

22 Route wiring harness (1) for front right door up to right door sill molding.

23 Insert 2-pin coupling (5) into bottom part of door sill molding and position wiring harness inverter in

the same way as on the left-hand side.

RETROFITTING ILLUMINATED DOOR SILL MOLDING - AZ82.20-P-0001B

MODEL 163.113 /128 /136 /154 /172 /174 /175

2001 Mercedes-Benz ML320

1998-2005 ACCESSORIES & BODY, CAB Electrical System - Body - 163 Chassis

me

Saturday, October 02, 2010 3:30:11 PMPage 345 © 2006 Mitchell Repair Information Company, LLC.

Page 2030 of 4133

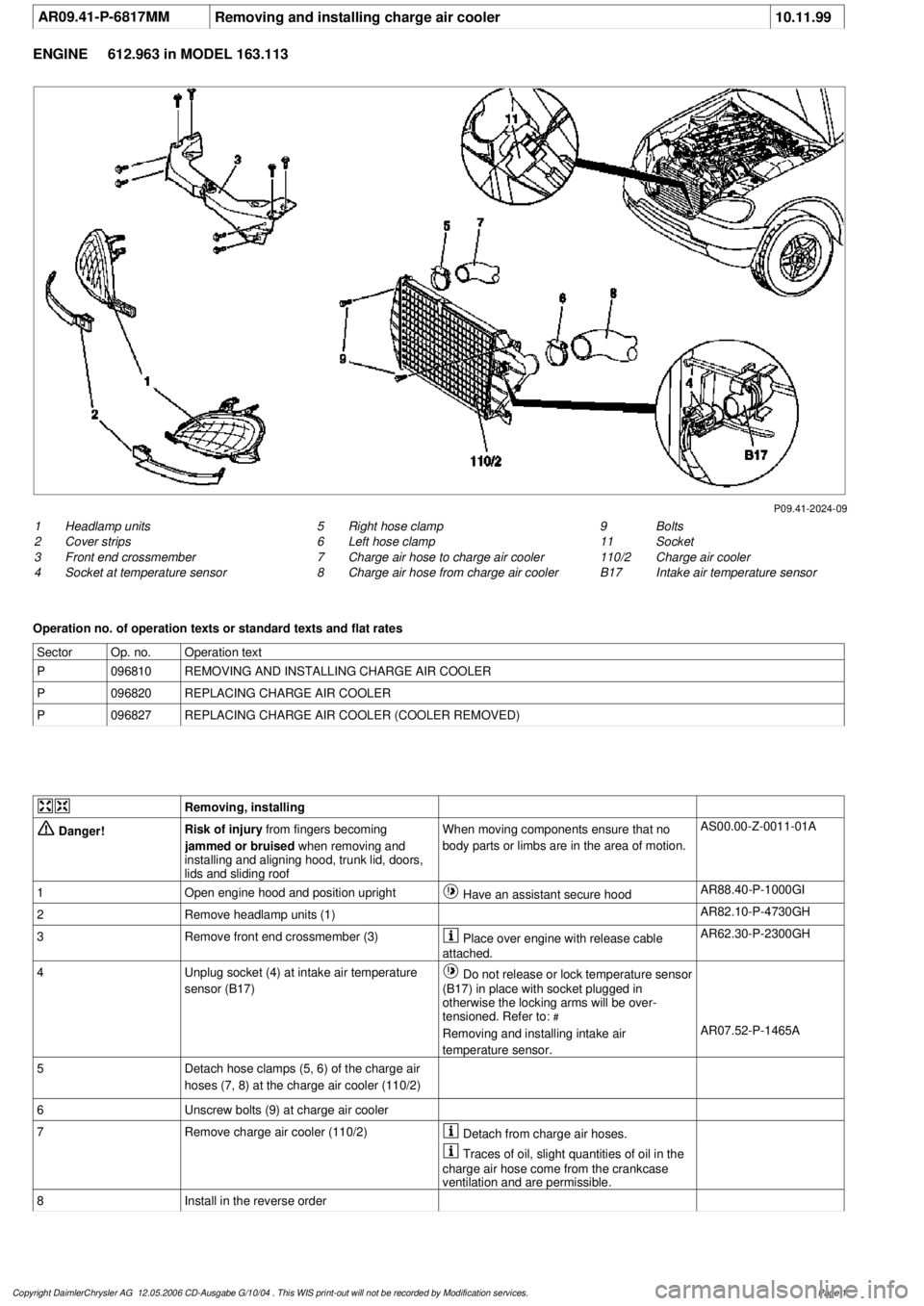

AR09.41-P-6817MM

Removing and installing charge air cooler

10.11.99

ENGINE

612.963 in MODEL 163.113

P09.41-2024-09

1

Headlamp units

2

Cover strips

3

Front end crossmember

4

Socket at temperature sensor

9

Bolts

11

Socket

110/2

Charge air cooler

B17

Intake air temperature sensor

5

Right hose clamp

6

Left hose clamp

7

Charge air hose to charge air cooler

8

Charge air hose from charge air cooler

Operation no. of operation texts or standard texts and flat rates

Sector

Op. no.

Operation text

P

096810

REMOVING AND INSTALLING CHARGE AIR COOLER

P

096820

REPLACING CHARGE AIR COOLER

P

096827

REPLACING CHARGE AIR COOLER (COOLER REMOVED)

Removing, installing

Danger!

Risk of injury

from fingers becoming

jammed or bruised

when removing and

installing and aligning hood, trunk lid, doors,

lids and sliding roof

When moving components ensure that no

body parts or limbs are in the area of motion.

AS00.00-Z-0011-01A

1

Open engine hood and position upright

Have an assistant secure hood

AR88.40-P-1000GI

2

Remove headlamp units (1)

AR82.10-P-4730GH

3

Remove front end crossmember (3)

Place over engine with release cable

attached.

AR62.30-P-2300GH

4

Unplug socket (4) at intake air temperature

sensor (B17)

Do not release or lock temperature sensor

(B17) in place with socket plugged in

otherwise the locking arms will be over-

tensioned. Refer to:

#

Removing and installing intake air

temperature sensor.

AR07.52-P-1465A

5

Detach hose clamps (5, 6) of the charge air

hoses (7, 8) at the charge air cooler (110/2)

6

Unscrew bolts (9) at charge air cooler

7

Remove charge air cooler (110/2)

Detach from charge air hoses.

Traces of oil, slight quantities of oil in the

charge air hose come from the crankcase

ventilation and are permissible.

8

Install in the reverse order

Copyright DaimlerChrysler AG 12.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 2032 of 4133

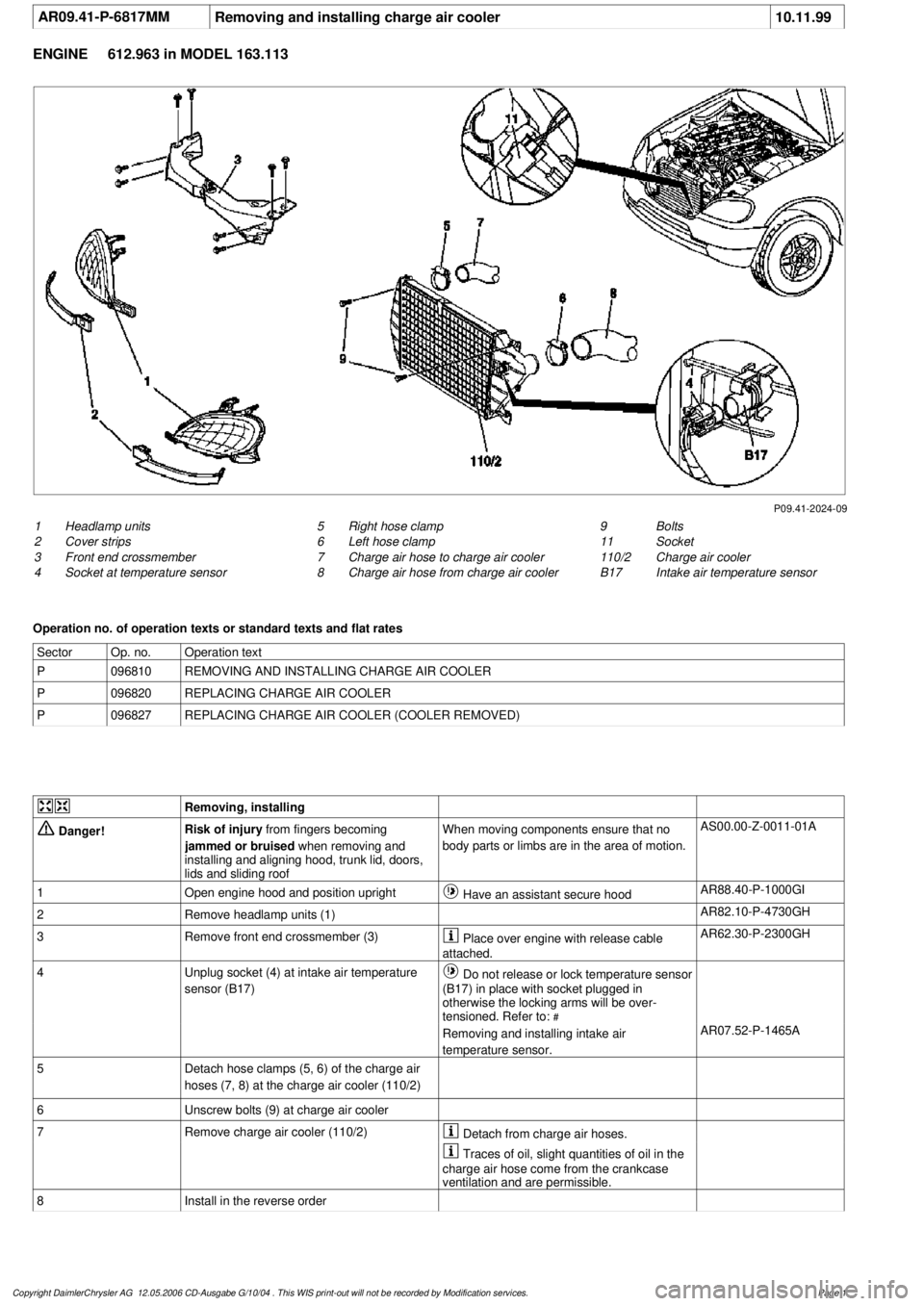

AR09.41-P-6817MM

Removing and installing charge air cooler

10.11.99

ENGINE

612.963 in MODEL 163.113

P09.41-2024-09

1

Headlamp units

2

Cover strips

3

Front end crossmember

4

Socket at temperature sensor

9

Bolts

11

Socket

110/2

Charge air cooler

B17

Intake air temperature sensor

5

Right hose clamp

6

Left hose clamp

7

Charge air hose to charge air cooler

8

Charge air hose from charge air cooler

Operation no. of operation texts or standard texts and flat rates

Sector

Op. no.

Operation text

P

096810

REMOVING AND INSTALLING CHARGE AIR COOLER

P

096820

REPLACING CHARGE AIR COOLER

P

096827

REPLACING CHARGE AIR COOLER (COOLER REMOVED)

Removing, installing

Danger!

Risk of injury

from fingers becoming

jammed or bruised

when removing and

installing and aligning hood, trunk lid, doors,

lids and sliding roof

When moving components ensure that no

body parts or limbs are in the area of motion.

AS00.00-Z-0011-01A

1

Open engine hood and position upright

Have an assistant secure hood

AR88.40-P-1000GI

2

Remove headlamp units (1)

AR82.10-P-4730GH

3

Remove front end crossmember (3)

Place over engine with release cable

attached.

AR62.30-P-2300GH

4

Unplug socket (4) at intake air temperature

sensor (B17)

Do not release or lock temperature sensor

(B17) in place with socket plugged in

otherwise the locking arms will be over-

tensioned. Refer to:

#

Removing and installing intake air

temperature sensor.

AR07.52-P-1465A

5

Detach hose clamps (5, 6) of the charge air

hoses (7, 8) at the charge air cooler (110/2)

6

Unscrew bolts (9) at charge air cooler

7

Remove charge air cooler (110/2)

Detach from charge air hoses.

Traces of oil, slight quantities of oil in the

charge air hose come from the crankcase

ventilation and are permissible.

8

Install in the reverse order

Copyright DaimlerChrysler AG 12.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 2089 of 4133

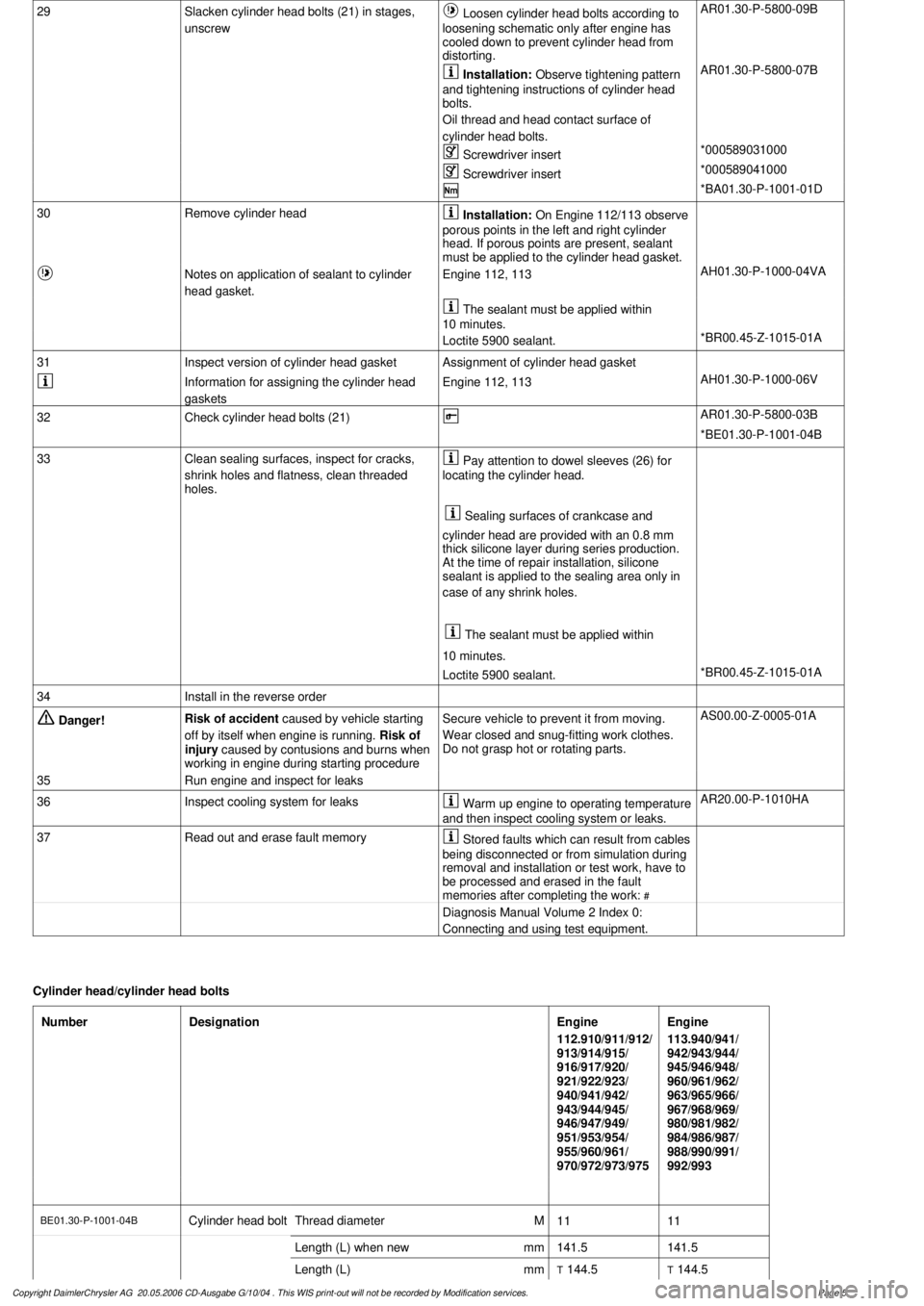

29

Slacken cylinder head bolts (21) in stages,

unscrew

Loosen cylinder head bolts according to

loosening schematic only after engine has

cooled down to prevent cylinder head from

distorting.

AR01.30-P-5800-09B

Installation:

Observe tightening pattern

and tightening instructions of cylinder head

bolts.

Oil thread and head contact surface of

cylinder head bolts.

AR01.30-P-5800-07B

Screwdriver insert

*000589031000

Screwdriver insert

*000589041000

*BA01.30-P-1001-01D

30

Remove cylinder head

Installation:

On Engine 112/113 observe

porous points in the left and right cylinder

head. If porous points are present, sealant

must be applied to the cylinder head gasket.

Notes on application of sealant to cylinder

head gasket.

Engine 112, 113

AH01.30-P-1000-04VA

The sealant must be applied within

10 minutes.

Loctite 5900 sealant.

*BR00.45-Z-1015-01A

31

Inspect version of cylinder head gasket

Assignment of cylinder head gasket

Information for assigning the cylinder head

gaskets

Engine 112, 113

AH01.30-P-1000-06V

32

Check cylinder head bolts (21)

AR01.30-P-5800-03B

*BE01.30-P-1001-04B

33

Clean sealing surfaces, inspect for cracks,

shrink holes and flatness, clean threaded

holes.

Pay attention to dowel sleeves (26) for

locating the cylinder head.

Sealing surfaces of crankcase and

cylinder head are provided with an 0.8 mm

thick silicone layer during series production.

At the time of repair installation, silicone

sealant is applied to the sealing area only in

case of any shrink holes.

The sealant must be applied within

10 minutes.

Loctite 5900 sealant.

*BR00.45-Z-1015-01A

34

Install in the reverse order

Danger!

Risk of accident

caused by vehicle starting

off by itself when engine is running.

Risk of

injury

caused by contusions and burns when

working in engine during starting procedure

Secure vehicle to prevent it from moving.

Wear closed and snug-fitting work clothes.

Do not grasp hot or rotating parts.

AS00.00-Z-0005-01A

35

Run engine and inspect for leaks

36

Inspect cooling system for leaks

Warm up engine to operating temperature

and then inspect cooling system or leaks.

AR20.00-P-1010HA

37

Read out and erase fault memory

Stored faults which can result from cables

being disconnected or from simulation during

removal and installation or test work, have to

be processed and erased in the fault

memories after completing the work:

#

Diagnosis Manual Volume 2 Index 0:

Connecting and using test equipment.

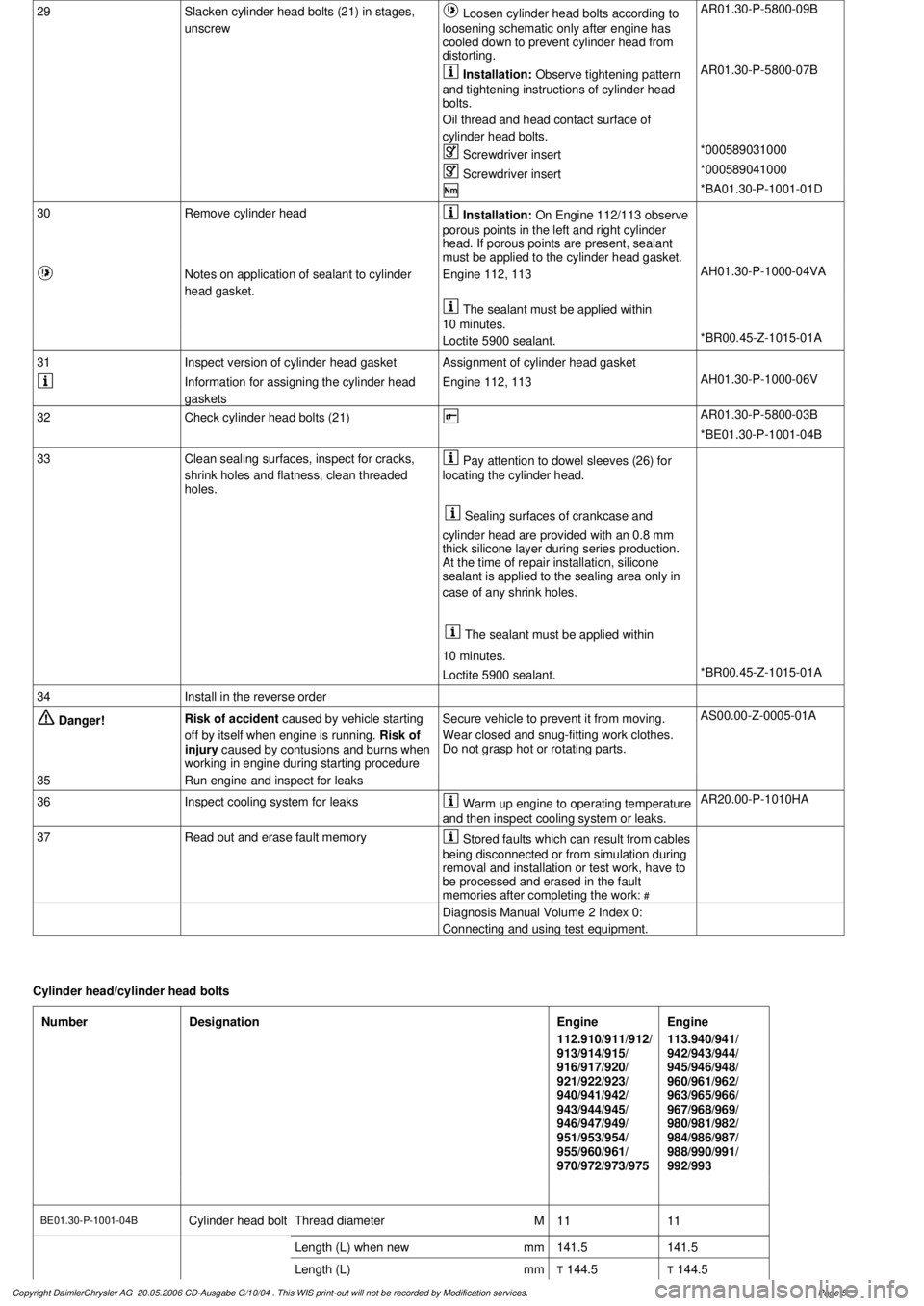

Cylinder head/cylinder head bolts

Number

Designation

Engine

112.910/911/912/

913/914/915/

916/917/920/

921/922/923/

940/941/942/

943/944/945/

946/947/949/

951/953/954/

955/960/961/

970/972/973/975

Engine

113.940/941/

942/943/944/

945/946/948/

960/961/962/

963/965/966/

967/968/969/

980/981/982/

984/986/987/

988/990/991/

992/993

BE01.30-P-1001-04B

Cylinder head bolt

Thread diameter

M

1111

Length (L) when new

mm

141.5141.5

Length (L)

mm

T

144.5

T

144.5

Copyright DaimlerChrysler AG 20.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 5

Page 2097 of 4133

29

Slacken cylinder head bolts (21) in stages,

unscrew

Loosen cylinder head bolts according to

loosening schematic only after engine has

cooled down to prevent cylinder head from

distorting.

AR01.30-P-5800-09B

Installation:

Observe tightening pattern

and tightening instructions of cylinder head

bolts.

Oil thread and head contact surface of

cylinder head bolts.

AR01.30-P-5800-07B

Screwdriver insert

*000589031000

Screwdriver insert

*000589041000

*BA01.30-P-1001-01D

30

Remove cylinder head

Installation:

On Engine 112/113 observe

porous points in the left and right cylinder

head. If porous points are present, sealant

must be applied to the cylinder head gasket.

Notes on application of sealant to cylinder

head gasket.

Engine 112, 113

AH01.30-P-1000-04VA

The sealant must be applied within

10 minutes.

Loctite 5900 sealant.

*BR00.45-Z-1015-01A

31

Inspect version of cylinder head gasket

Assignment of cylinder head gasket

Information for assigning the cylinder head

gaskets

Engine 112, 113

AH01.30-P-1000-06V

32

Check cylinder head bolts (21)

AR01.30-P-5800-03B

*BE01.30-P-1001-04B

33

Clean sealing surfaces, inspect for cracks,

shrink holes and flatness, clean threaded

holes.

Pay attention to dowel sleeves (26) for

locating the cylinder head.

Sealing surfaces of crankcase and

cylinder head are provided with an 0.8 mm

thick silicone layer during series production.

At the time of repair installation, silicone

sealant is applied to the sealing area only in

case of any shrink holes.

The sealant must be applied within

10 minutes.

Loctite 5900 sealant.

*BR00.45-Z-1015-01A

34

Install in the reverse order

Danger!

Risk of accident

caused by vehicle starting

off by itself when engine is running.

Risk of

injury

caused by contusions and burns when

working in engine during starting procedure

Secure vehicle to prevent it from moving.

Wear closed and snug-fitting work clothes.

Do not grasp hot or rotating parts.

AS00.00-Z-0005-01A

35

Run engine and inspect for leaks

36

Inspect cooling system for leaks

Warm up engine to operating temperature

and then inspect cooling system or leaks.

AR20.00-P-1010HA

37

Read out and erase fault memory

Stored faults which can result from cables

being disconnected or from simulation during

removal and installation or test work, have to

be processed and erased in the fault

memories after completing the work:

#

Diagnosis Manual Volume 2 Index 0:

Connecting and using test equipment.

Cylinder head/cylinder head bolts

Number

Designation

Engine

112.910/911/912/

913/914/915/

916/917/920/

921/922/923/

940/941/942/

943/944/945/

946/947/949/

951/953/954/

955/960/961/

970/972/973/975

Engine

113.940/941/

942/943/944/

945/946/948/

960/961/962/

963/965/966/

967/968/969/

980/981/982/

984/986/987/

988/990/991/

992/993

BE01.30-P-1001-04B

Cylinder head bolt

Thread diameter

M

1111

Length (L) when new

mm

141.5141.5

Length (L)

mm

T

144.5

T

144.5

Copyright DaimlerChrysler AG 20.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 5

Page 2591 of 4133

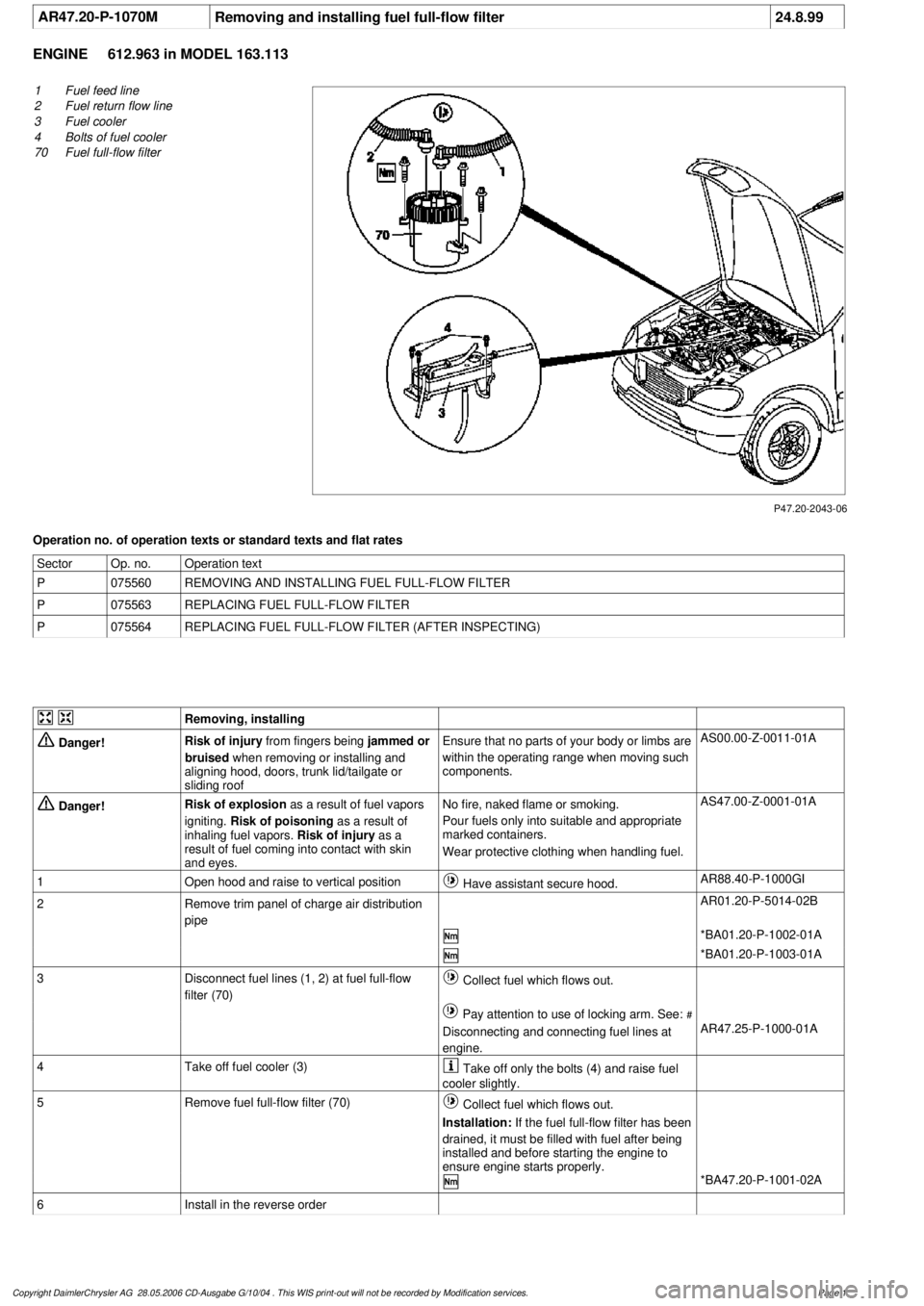

AR47.20-P-1070M

Removing and installing fuel full-flow filter

24.8.99

ENGINE

612.963 in MODEL 163.113

P47.20-2043-06

1

Fuel feed line

2

Fuel return flow line

3

Fuel cooler

4

Bolts of fuel cooler

70

Fuel full-flow filter

Operation no. of operation texts or standard texts and flat rates

Sector

Op. no.

Operation text

P

075560

REMOVING AND INSTALLING FUEL FULL-FLOW FILTER

P

075563

REPLACING FUEL FULL-FLOW FILTER

P

075564

REPLACING FUEL FULL-FLOW FILTER (AFTER INSPECTING)

Removing, installing

Danger!

Risk of injury

from fingers being

jammed or

bruised

when removing or installing and

aligning hood, doors, trunk lid/tailgate or

sliding roof

Ensure that no parts of your body or limbs are

within the operating range when moving such

components.

AS00.00-Z-0011-01A

Danger!

Risk of explosion

as a result of fuel vapors

igniting.

Risk of poisoning

as a result of

inhaling fuel vapors.

Risk of injury

as a

result of fuel coming into contact with skin

and eyes.

No fire, naked flame or smoking.

Pour fuels only into suitable and appropriate

marked containers.

Wear protective clothing when handling fuel.

AS47.00-Z-0001-01A

1

Open hood and raise to vertical position

Have assistant secure hood.

AR88.40-P-1000GI

2

Remove trim panel of charge air distribution

pipe

AR01.20-P-5014-02B

*BA01.20-P-1002-01A

*BA01.20-P-1003-01A

3

Disconnect fuel lines (1, 2) at fuel full-flow

filter (70)

Collect fuel which flows out.

Pay attention to use of locking arm. See:

#

Disconnecting and connecting fuel lines at

engine.

AR47.25-P-1000-01A

4

Take off fuel cooler (3)

Take off only the bolts (4) and raise fuel

cooler slightly.

5

Remove fuel full-flow filter (70)

Collect fuel which flows out.

Installation:

If the fuel full-flow filter has been

drained, it must be filled with fuel after being

installed and before starting the engine to

ensure engine starts properly.

*BA47.20-P-1001-02A

6

Install in the reverse order

Copyright DaimlerChrysler AG 28.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1