flat tire MERCEDES-BENZ ML350 1997 Complete Workshop Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML350, Model: MERCEDES-BENZ ML350 1997Pages: 4133, PDF Size: 88.89 MB

Page 1677 of 4133

The date or the version of the currently stored software and the software on the CD appears in the

display.

By pressing the right knob the download is started. After some seconds the system changes to screen

"CD ROM software download".

On the download control module the main processor software is loaded first, then the graphic

processor software. Entire duration: approx. 40 minutes

The download progress is indicated by a bar graph.

In the event of errors an error message is indicated on the display.

When the download is completed, the display switches off for a short time. When it is switched back on

again the result of the download is displayed.

6. Remove download CD and reinsert navigation CD.

FAULT IN COMAND OPERATING AND DISPLAY SYSTEM - AF82.85-P-6000N

MODEL 163, 203, 208, 210, 215, 220, 463 with CODE (352a) COMAND operating and display system

with CODE (801) Model year 2001

MODEL 414 with CODE (EN4) Auto pilot system with TMC interface, large display with CODE (EN3)

Auto pilot system with GSM interface, large display

Modification notes

Operation no. of operation texts or standard texts and flat rates

26.11.01Supersedes AF82.85-P-

6000N dated 09.01.2002

Part numbers added and

changedAF82.85-P-6000-01B

CategoryOp. no.Operation textTimeAcc. no.Code

P829905PERFORMING SW

UPDATE FOR

RADIO/COMAND003 WU/0.3 h--

Damage codeCauseRemedy

Software error Error patterns for

COMAND update CD

10/2001.AF82.85-P-6000-01B

1 Perform COMAND

updateAF82.85-P-6000-04A

Update only

COMAND with the

following part numbers.

A 163 820 14 89

2001 Mercedes-Benz ML320

1998-2005 ACCESSORIES & BODY, CAB Electrical System - Body - 163 Chassis

me

Saturday, October 02, 2010 3:30:07 PMPage 182 © 2006 Mitchell Repair Information Company, LLC.

Page 3050 of 4133

SAFETY PRECAUTIONS FOR NEW VEHICLES THAT ARE BEING PUT IN STORAGE - AP00.70-P-1000ZZ

MODELS all

and rear axle

Frame

New vehicles in the

context of this description

are vehicles for which no

inspection has been carried

out to date. For other

vehicles, the instructions

in the Specifications for

Service Products apply

In areas in which

extremely high corrosive

attacks can be expected

from experience, the

measures given here are

not always sufficient even

for new vehiclesExport countries

In these cases, proceed in

accordance with

Specifications for Service

products.

Treatment of battery if

vehicle taken out of

service AR54.10-P-0006EA

Treatment of tire inflation

pressure if vehicle taken

out of serviceFor vehicles which will be

stored for longer than 2

months, the tire inflation

pressure should be

increased to approx. 4 bar

to prevent flattening of the

contact surface.

Treatment of break system

if vehicle taken out of

serviceWarm up service brake so

that adhering moisture at

the brake disks and the

brake pads evaporates.

This prevents the brake

pad from becoming stuck

to the brake disks.

Release parking brake.

The vehicle must be

secured by engaging a

gear/park pawl or by using

wedges.

Treatment of fuel system

if vehicle taken out of To protect the fuel tank

from corrosion, we

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:52 PMPage 405 © 2006 Mitchell Repair Information Company, LLC.

Page 3484 of 4133

AH40.10-P-9411-01A

Information on tires/rims

Model 124, 129, 140, 163, 168, 169,

170, 171, 199, 201, 202, 203, 208, 209,

210, 211, 215, 219, 220, 230, 240, 414,

450, 452,

639

Tires

D

For service conversions, the tire/disc wheel specifications and

dimensions should be compared with the entries in the

registration papers.

D

When mounting tires, the tires and rims must be carefully

matched in order to guarantee the concentricity of the wheel.

Identification of matching points on:

- Tires with a colored dot on the outside of the tire,

- Sheet steel disk wheel by a colored dot or punch mark on the

outside of the wheel,

- Perform this operation at the valve stem hole on light-alloy

disk wheels

With an additional paint spot or punch mark in the rim base

for the 140 Model Series.

D

Always replace the rubber valve.

-----------------------------------------------------------------------------------------

D

Damaged and defective tires must always be replaced. The

repair methods employed in the tire trade are not approved by

Mercedes-Benz. Small nicks (<0.8mm) on the tire's sidewall do

not usually pose a cause for concern, and continued use of

such tires is approved

D When replacing just one tire, install it on the front of the vehicle.

This does not apply to vehicles with different tires of varying

specifications on the front and rear wheels.

D

Only use tires listed in the valid Service Information bulletins

and repair instructions.

D

If the permissible maximum speed of an M+S tire is below the

maximum speed of the vehicle, an appropriate adhesive plate

must be attached in the driver's field of view.

-----------------------------------------------------------------------------------------

D

Tires permissible for higher speeds may be used.

D

Always fit all rims with tires of the same design, make and

version.

-----------------------------------------------------------------------------------------

D

Run in new tires for approx. 100 km at moderate speed.

D

Handed tires must be installed according to the arrow on the

side wall of the tire.

D

Tires are subject to an aging process with negative effects on

the properties of the tire. In order to ensure optimum

effectiveness in winter, M+S tires should not be used for longer

than 3 years.

-----------------------------------------------------------------------------------------

Tire pressure

(For specified values see tire pressure table in the fuel filler flap, on

the Vaneo BM 414 see B-pillar on the passenger side).

Too low tire pressure increases the rolling resistance and increases

the flexing energy of the tire. This causes the critical temperature limit

to be exceeded (carcass detachment) and destroys the tire. Respond

to loss of tire pressure by determining the source and replacing the

tire as indicated.

Cleaning

Using a spray wand with high-pressure nozzles to clean the wheel

can lead to tire damage. Such damage occurs especially on the tire

side walls. The following should be observed when using flat jet

nozzles:

D

Maintain a minimum distance of 300 mm

D

Do not direct the water jet at a single point on the surface of the

tire for any length of time.

-----------------------------------------------------------------------------------------

Mounting in bearings

Before putting into storage, clean tires thoroughly and check for

damage and adequate tread depth. Mark the position and running

direction of the tires with chalk. Do not store tires outdoors. Under the

influence of sunlight, heat, moving air and ozone the rubber looses

elasticity and strength, ages more quickly and becomes cracked.

Storage areas should be dry, cool and dark. Avoid drafts by keeping

doors and windows closed as much as possible. Do not bring tires

into contact with gasoline, oil or other greases as they dissolve the

rubber.

Disposal

Collection, storage and disposal should be performed in accordance

with the legal requirements and the company's own regulations.

-----------------------------------------------------------------------------------------

Copyright DaimlerChrysler AG 06.07.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3778 of 4133

8.1

Check wheel sensor, valve body and sealing

rubber for damage

Vehicles with tire pressure monitor (code 475)

Do not remove wheel sensor for this.

Do not use compressed air, solvents or

detergents to clean the wheel sensor. Wipe

off dirt with a clean, lint-free cloth only.

Do not retighten the female torx bolt and

union nut.

Replace all valve components of wheel

electronics if:

D

The wheel sensor mounting bolt or union

nut is visibly loose.

Replace the wheel sensor if:

D

The wheel sensor is obviously damaged.

D

Tire sealant was used.

Install new wheel sensors:

#

Replace wheel sensor.

AR40.15-P-0080A

8.2

Install new valve (43g).

Vehicles without tire pressure monitor (code

475)

9

Checking condition of rim

AR40.10-P-1010-01A

Mounting

10

Moisten rim flange and tire beads with soapy

water and align assembly head at a small

distance (X, Y) to the disk wheel

Only use soapy water for fitting and

removing tires.

11

Place tire obliquely on the rim and pull on

over the rim flange using the tire installer

Position wheels with wheel sensors so

that the wheel sensor is approximately 180°

opposite the mounting head.

Do not apply compressive force to the wheel

sensor otherwise it will be damaged.

Observe the running direction on tires with

specified running direction.

Put as little stress as possible on bead

area.

12

Align the match points of the tire and disk

wheel with each other and remove the disk

wheel with tire from the tire mounting device

13

Inflate tires without valve element up to max.

3 bar

Do

not

unscrew valve element on disk

wheels with tire pressure monitor sensor.

The tire must slide evenly over the safety

shoulders of the disk wheel, otherwise coat

the tire beads with soapy water again.

14

Screw the valve element into the valve (43g)

and adjust the tire inflation pressure to the

specified value

Observe the tire pressure information in

the fuel filler flap of the vehicle.

15

Balance wheel

AR40.10-P-1040A

124 589 17 63 00 129 589 00 59 00

Removal tool

Assembly tool

Copyright DaimlerChrysler AG 06.07.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 2

Page 3948 of 4133

AH40.10-P-0001-01A

TIREFIT tire sealant

MODEL 163, 168, 169, 170, 171, 199,

203, 209, 211,215, 219, 230, 240, 414,

639

P40.10-0311-01

Note

TIREFIT tire sealant has a shelf life of 3 or 4 years depending on the version, measured from the

date of manufacture marked on the container. The TIREFIT tire sealant must be replaced after

this date.

Application

TIREFIT tire sealant can be used at the roadside to seal minor punctures, in particular in the

tread. After this the tire will be finitely operational.

F

Tires which have been treated with TIREFIT tire sealant must not be repaired. The should

be replaced with new tires of the same type and specifications from the same manufacturer.

F

To prevent odor emission by TIREFIT tire sealant, deflate tire outdoors.

F

The TIREFIT tire sealant must not come into contact with skin,

eyes or clothing. If tire sealant comes into contact with skin,

eyes or clothing, rinse immediately with clean water.

Call a physician immediately if allergic reactions occur.

Keep the TIREFIT tire sealant away from children. If TIREFIT

tire sealant is swallowed, induce vomiting and call a physician

immediately.

Regulations for disposal

Dispose of used or obsolete TIREFIT in a container designed for

paint shop waste (see Workshop Equipment Manual Volume 2,

Chapter U, Group 00 (22), Subject 2.3).

When using TIREFIT always avoid fire, open flames and smoking,

avoid arcing, and avoid inhaling the fumes fro the product.

Copyright DaimlerChrysler AG 06.07.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3993 of 4133

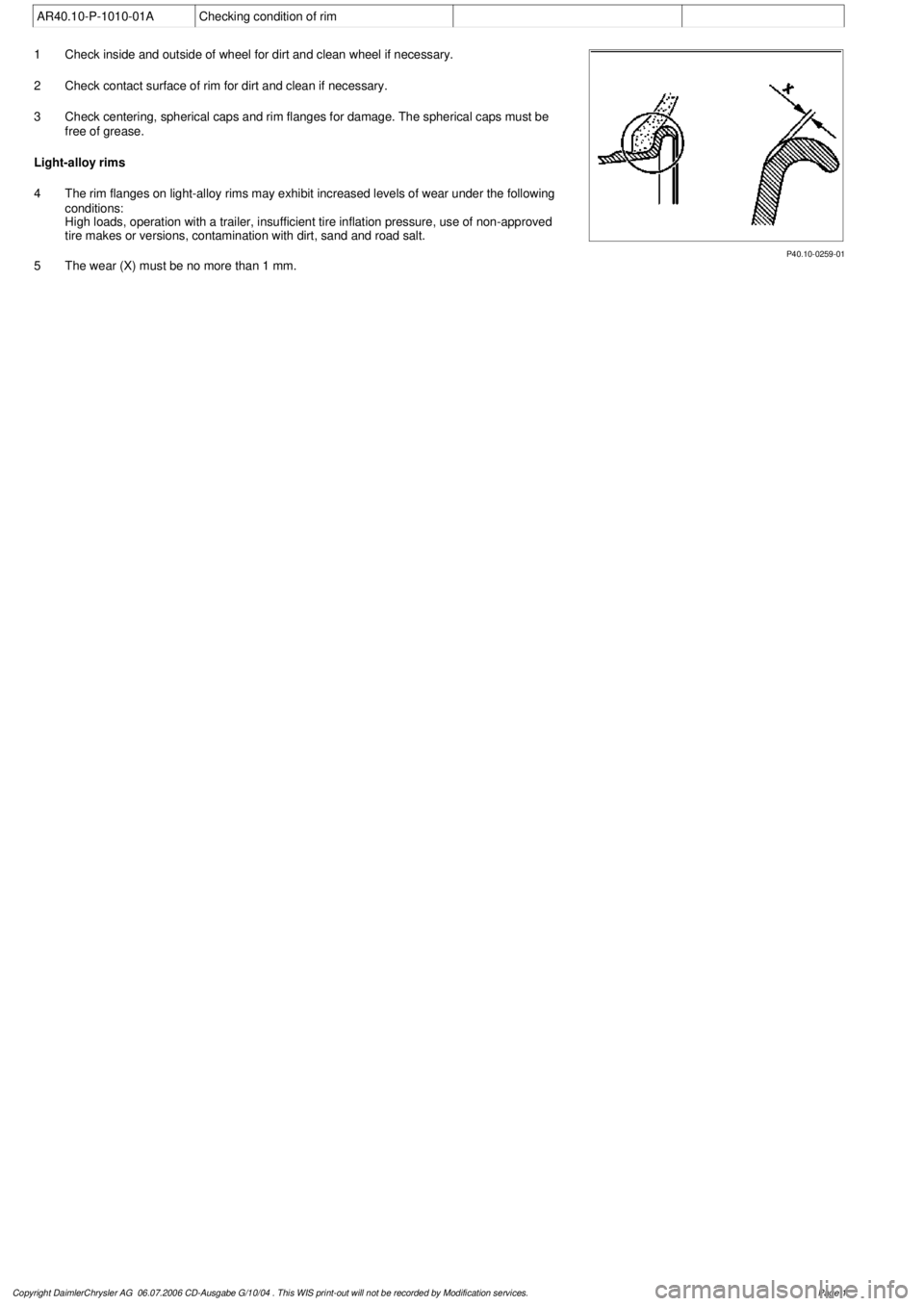

AR40.10-P-1010-01A

Checking condition of rim

P40.10-0259-01

1

Check inside and outside of wheel for dirt and clean wheel if necessary.

2

Check contact surface of rim for dirt and clean if necessary.

3

Check centering, spherical caps and rim flanges for damage. The spherical caps must be

free of grease.

Light-alloy rims

4

The rim flanges on light-alloy rims may exhibit increased levels of wear under the following

conditions:

High loads, operation with a trailer, insufficient tire inflation pressure, use of non-approved

tire makes or versions, contamination with dirt, sand and road salt.

5

The wear (X) must be no more than 1 mm.

Copyright DaimlerChrysler AG 06.07.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3994 of 4133

AP40.10-P-4050GH

Remove/install wheels, rotate if necessary

15.7.97

MODEL

163

1-5

Tightening sequence

P40.10-0004-01

P40.00-0208-01

Remove

Danger!

Lethal injuries

are possible if vehicle slips off

of lifting platform

Align vehicle between the columns of the

lifting platform and position the four support

plates

at the lifting platform support points

specified by the vehicle manufacturer.

AS00.00-Z-0010-01A

Comply with notes on tires / rims

AH40.10-P-9411-01A

1

Raise vehicle.

AS00.00-Z-0010-01A

2

Unscrew wheel bolts, remove wheels

3

Check wheel bolts

The round contact shoulders on the lug

bolts must be free of oil and grease.

Replace bolts that have a damaged thread,

worn dacromet coating at radius seat or

corroded radius seat.

4

Check tires for damage and wear - measure

depth of tread

AP40.10-P-4051Z

5

Check disk wheels

D

check for contamination,

D

check that spherical caps are free of oil

and grease,

D

check centering, spherical caps and rim

flanges for damage,

D

check corrosion of lay-on surface

6

Check front wheel hub, brake disk bowl at

attachment face for contamination and

corrosion

Clean corroded surfaces with a wire brush or

an emery cloth.

Install

7

Change wheels around if necessary retaining

the same running direction

This excludes vehicles with mixed tires at

the front and rear axle.

Between

5,000 and 10,000 km according to wear.

8

Fit wheels, tighten wheel bolts

Observe tightening sequence "1-5".

*BA40.10-P-1001-01A

*126589040900

9

Lower vehicle, correct tire inflation pressure

(including spare wheel)

In the case of loss of tire pressure,

determine cause and replace tire if necessary.

On versions with spare tire attached to

underside of vehicle, check tire inflation

pressure of spare tire before lowering the

vehicle.

c

Deletion of spare tire with model 163.174

with TIREFIT

AH40.10-P-0001-01A

Wheels

Number

Designation

Models

163.113/128/

136/154/157/

172/175

Model

163.174

Copyright DaimlerChrysler AG 06.07.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1