overheating MERCEDES-BENZ ML430 1997 Complete Owner's Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML430, Model: MERCEDES-BENZ ML430 1997Pages: 4133, PDF Size: 88.89 MB

Page 2665 of 4133

ASSESSMENT OF DAMAGE IN WIRING HARNESSES - AH00.19-P-1000-05A

Model 124, 126, 129, 140, 163, 164, 168, 169, 170, 171, 199, 202, 203, 208, 209, 210, 211, 215, 216, 219, 220,

221, 230, 240, 245, 251, 414, 461, 463

Always assess the damage thoroughly before repairing the wiring harnesses.

The following criteria must be observed:

Type of damage:

Damage caused by scorching/overheating, chafing, clamping, crushing, severing, fatigue, corrosion, cable

chewed by an animal, assembly fault.

Cause of damage:

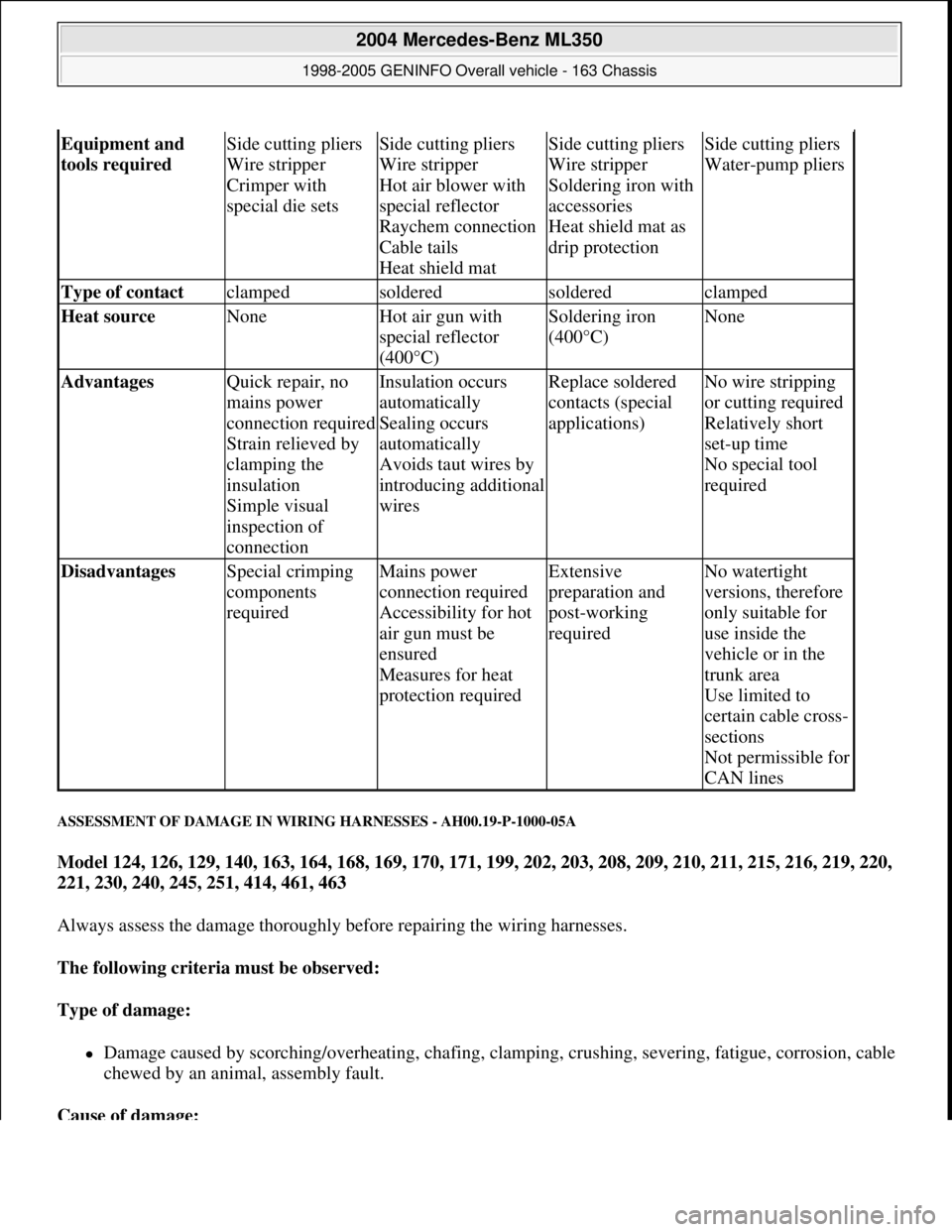

Equipment and

tools required Side cutting pliers

Wire stripper

Crimper with

special die setsSide cutting pliers

Wire stripper

Hot air blower with

special reflector

Raychem connection

Cable tails

Heat shield matSide cutting pliers

Wire stripper

Soldering iron with

accessories

Heat shield mat as

drip protectionSide cutting pliers

Water-pump pliers

Type of contact clampedsolderedsolderedclamped

Heat source NoneHot air gun with

special reflector

(400°C)Soldering iron

(400°C)None

Advantages Quick repair, no

mains power

connection required

Strain relieved by

clamping the

insulation

Simple visual

inspection of

connectionInsulation occurs

automatically

Sealing occurs

automatically

Avoids taut wires by

introducing additional

wiresReplace soldered

contacts (special

applications)No wire stripping

or cutting required

Relatively short

set-up time

No special tool

required

Disadvantages Special crimping

components

requiredMains power

connection required

Accessibility for hot

air gun must be

ensured

Measures for heat

protection requiredExtensive

preparation and

post-working

requiredNo watertight

versions, therefore

only suitable for

use inside the

vehicle or in the

trunk area

Use limited to

certain cable cross-

sections

Not permissible for

CAN lines

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:44 PMPage 20 © 2006 Mitchell Repair Information Company, LLC.

Page 2666 of 4133

The cause for the damage must be determined to ensure that the damage does not reoccur after the wiring

harness has been repaired.

Scope of the damage:

Which components are damaged, can the damage be identified exactly?

Can you be sure that no other components are damaged?

Repair options:

What are the options for repair?

Which replacement parts are available?

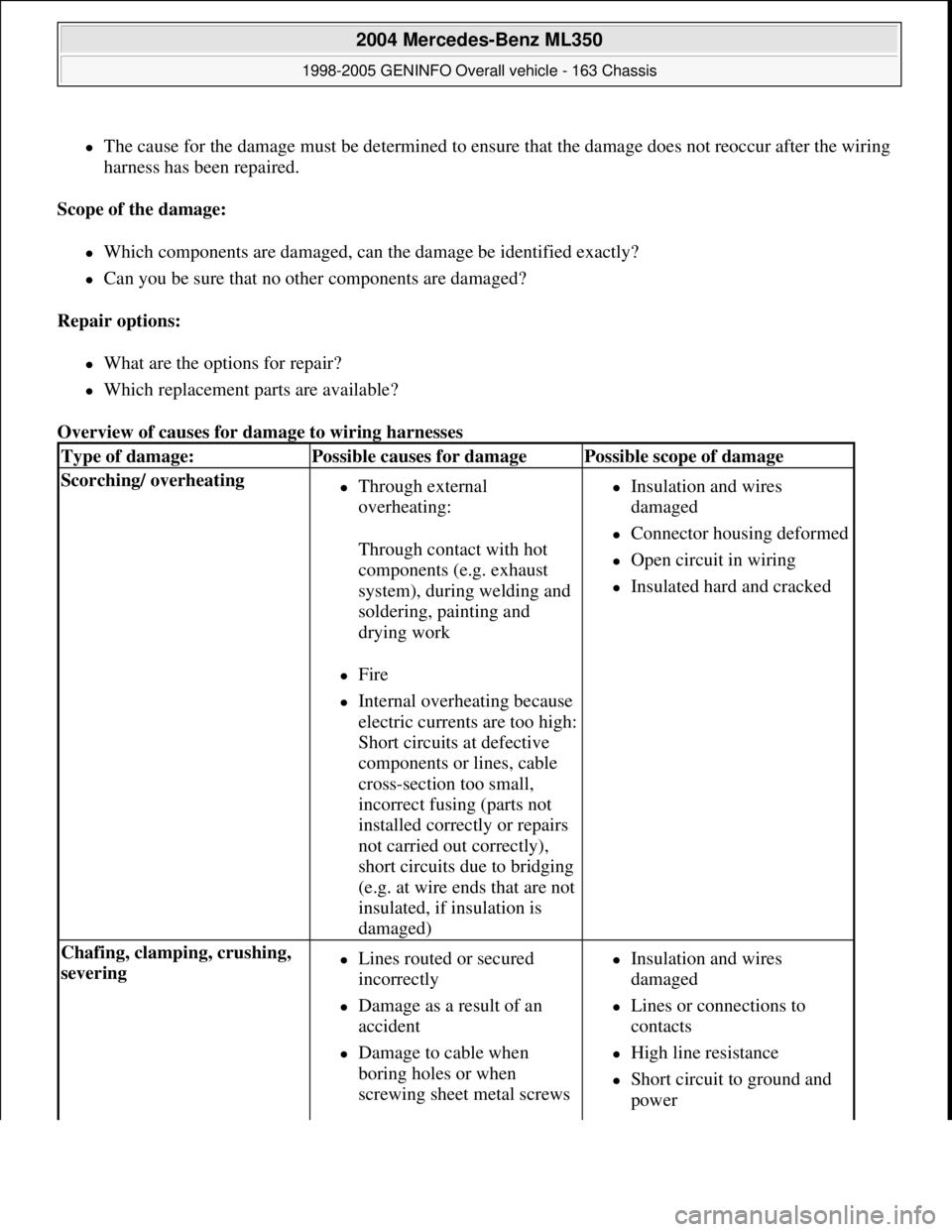

Overview of causes for damage to wiring harnesses

Type of damage:Possible causes for damagePossible scope of damage

Scorching/ overheating Through external

overheating:

Through contact with hot

components (e.g. exhaust

system), during welding and

soldering, painting and

drying work

Fire

Internal overheating because

electric currents are too high:

Short circuits at defective

components or lines, cable

cross-section too small,

incorrect fusing (parts not

installed correctly or repairs

not carried out correctly),

short circuits due to bridging

(e.g. at wire ends that are not

insulated, if insulation is

damaged)

Insulation and wires

damaged

Connector housing deformed

Open circuit in wiring

Insulated hard and cracked

Chafing, clamping, crushing,

severing Lines routed or secured

incorrectly

Damage as a result of an

accident

Damage to cable when

boring holes or when

screwing sheet metal screws

Insulation and wires

damaged

Lines or connections to

contacts

High line resistance

Short circuit to ground and

power

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:44 PMPage 21 © 2006 Mitchell Repair Information Company, LLC.

Page 2879 of 4133

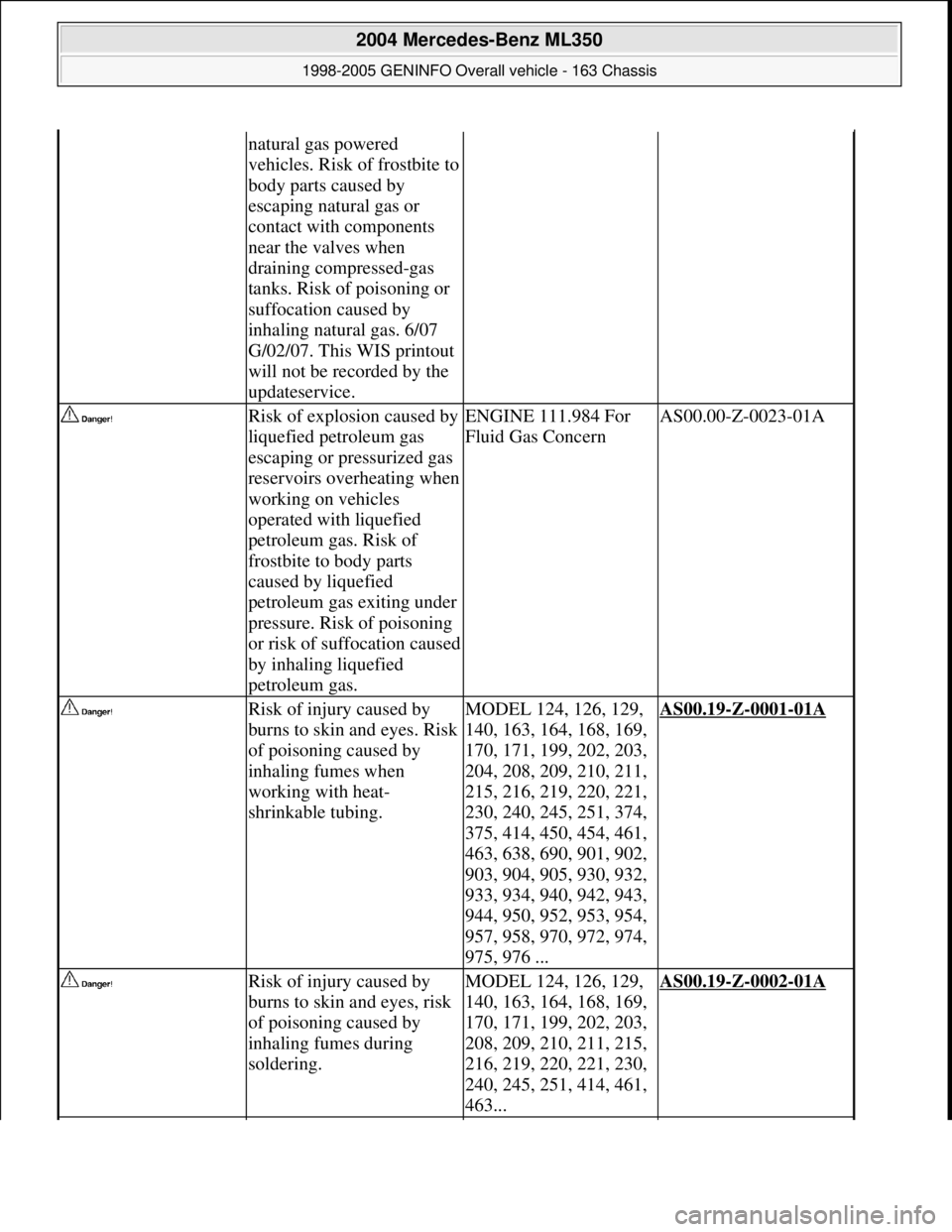

natural gas powered

vehicles. Risk of frostbite to

body parts caused by

escaping natural gas or

contact with components

near the valves when

draining compressed-gas

tanks. Risk of poisoning or

suffocation caused by

inhaling natural gas. 6/07

G/02/07. This WIS printout

will not be recorded by the

updateservice.

Risk of explosion caused by

liquefied petroleum gas

escaping or pressurized gas

reservoirs overheating when

working on vehicles

operated with liquefied

petroleum gas. Risk of

frostbite to body parts

caused by liquefied

petroleum gas exiting under

pressure. Risk of poisoning

or risk of suffocation caused

by inhaling liquefied

petroleum gas.ENGINE 111.984 For

Fluid Gas ConcernAS00.00-Z-0023-01A

Risk of injury caused by

burns to skin and eyes. Risk

of poisoning caused by

inhaling fumes when

working with heat-

shrinkable tubing.MODEL 124, 126, 129,

140, 163, 164, 168, 169,

170, 171, 199, 202, 203,

204, 208, 209, 210, 211,

215, 216, 219, 220, 221,

230, 240, 245, 251, 374,

375, 414, 450, 454, 461,

463, 638, 690, 901, 902,

903, 904, 905, 930, 932,

933, 934, 940, 942, 943,

944, 950, 952, 953, 954,

957, 958, 970, 972, 974,

975, 976 ...AS00.19-Z-0001-01A

Risk of injury caused by

burns to skin and eyes, risk

of poisoning caused by

inhaling fumes during

soldering.MODEL 124, 126, 129,

140, 163, 164, 168, 169,

170, 171, 199, 202, 203,

208, 209, 210, 211, 215,

216, 219, 220, 221, 230,

240, 245, 251, 414, 461,

463...AS00.19-Z-0002-01A

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:48 PMPage 234 © 2006 Mitchell Repair Information Company, LLC.

Page 2881 of 4133

Risk of injury

When working with heat-shrinkable tubing, excessive temperatures may cause burns to skin and eye.

Risk of poisoning

When working with heat-shrinkable tubing, vapors may be produced which lead to symptoms of poisoning such

as coughing, headaches, dizziness and nausea. Moreover, irritation may occur to the respiratory paths and eyes.

Safety precautions/instructions

Work only in well ventilated rooms.

Avoid overheating the heat-shrinkable tubing.

Stop heat-shrinking immediately if the shrink hose becomes blistered or charred or shows other signs of

damage.

Do not inhale the vapors.

Avoid contact with melted shrink tubing.

Wear safety glasses with side protection and protective gloves.

First aid measures

When eyes or skin come in contact with melted shrink tubing

Flush the affected area immediately with plenty of water for approx. 15 minutes.

Treat affected areas like burn wounds. Do not remove any burned parts.

Contact physician or medical service.

When vapor is inhaled:

Take victim to fresh air.

Keep victim calm and cover with a blanket.

Contact physician or medical service.

Fire protection measures

Suitable extinguishing agents

Water mist, general-purpose foam, powder, carbon dioxide

Protective equipment for firefighters (compressed air equipment, oxygen apparatus, chemical resistant

protective clothing)

RISK OF INJURY & RISK OF POISONING - AS00.19-Z-0002-01A

Wear protective gloves, protective clothing and safety glasses. Ensure that the work area is adequately

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:48 PMPage 236 © 2006 Mitchell Repair Information Company, LLC.

Page 3169 of 4133

provide reliable cooling system protection. In special cases (commercial-vehicle engines, no antifreeze

specification) coolant additives can be used that are primarily corrosion protection additives. In this case

item 2.3 is valid.

As an exception, if neither anticorrosion/antifreeze agent conforming to Sheet 325.0 nor coolant additives

without addition of antifreeze conforming to Sheet 312.0 are available, proceed according to point 2.4

(exception: OM 500 and OM 900). The systems described under items 2.2/2.3/2.4 are not compatible

with each other. It is recommended to mix the entire coolant quantity outside the engine.

2.1 Anticorrosion/antifreeze agent for passenger-car engines

Alongside the correct constitution of the cooling water (point 1.2.2), care must be taken to ensure that

only anticorrosion/antifreeze agents as approved for all engines in accordance with Sheet 325.0 are used.

These products serve to guarantee that, in particular, an effective protection against corrosion is provided

for all light-alloy parts in the cooling system and they are also specified for all passenger-car engines.

In order to ensure that the protection against corrosion is effective, the anticorrosion/antifreeze agent must

remain in the cooling system throughout the year - including when in tropical climates - and regardless of

the operating conditions. In countries with high outside temperatures this is also important in terms of

raising the boiling point.

In the event that these regulations are not observed the cooling system may suffer from damage by

corrosion. As a consequence of corrosion deposits there is a danger that ducts in the radiators (engine

overheating) and heat exchangers (poor heat output) get plugged up thus causing damage to the engine.

As a result of the optimizations we have carried out on the system of engine/coolant/cooling system, in

the majority of our newer passenger cars, a replacement of coolant is not necessary until reaching 15

operating years or 250,000 km (whichever comes first). This may not apply to some models; in these

cases the maintenance booklet will stipulate another regulation.

2.2 Anticorrosion/antifreeze agent for commercial-vehicle engines (normal case)

(not: BR 600, BR 100 and BR 200)

The coolant in commercial-vehicle engines is made up of both water and anticorrosion/antifreeze agent

(refer to item 1.1.1) and as such offers ideal protection against corrosion and cavitation.

All the approved products on the Sheets 325.2, 325.3 or 325.0 which are part of the Specifications for

Operating Fluids can be used to select an anticorrosion/antifreeze agent. However, it should be noted that

passenger vehicle engines built into commercial vehicles must be filled like passenger vehicles (e.g. OM

601 in T1), i.e. a product conforming to Sheet 325.0 and 326.0 must be used.

Products that are not listed in Sheets 325.0 and 326.0, or 325.2 and 326.2, or 325.3 and 326.3 are not

approved and are therefore not to be used under any circumstances.

Anticorrosion/antifreeze agents or coolants conforming to Sheet 325.3 or 326.3 may be used for

longer than other products due to their composition. The change interval is set at 5 years (refer to

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:57 PMPage 524 © 2006 Mitchell Repair Information Company, LLC.