Sensor MERCEDES-BENZ ML500 1997 Complete Repair Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML500, Model: MERCEDES-BENZ ML500 1997Pages: 4133, PDF Size: 88.89 MB

Page 3777 of 4133

AR40.10-P-1030A

Replace tire

27.1.95

MODELS

124, 129, 140, 163, 168, 170, 171, 202, 203, 208, 209, 210, 211, 215, 220, 230, 240

MODEL

414

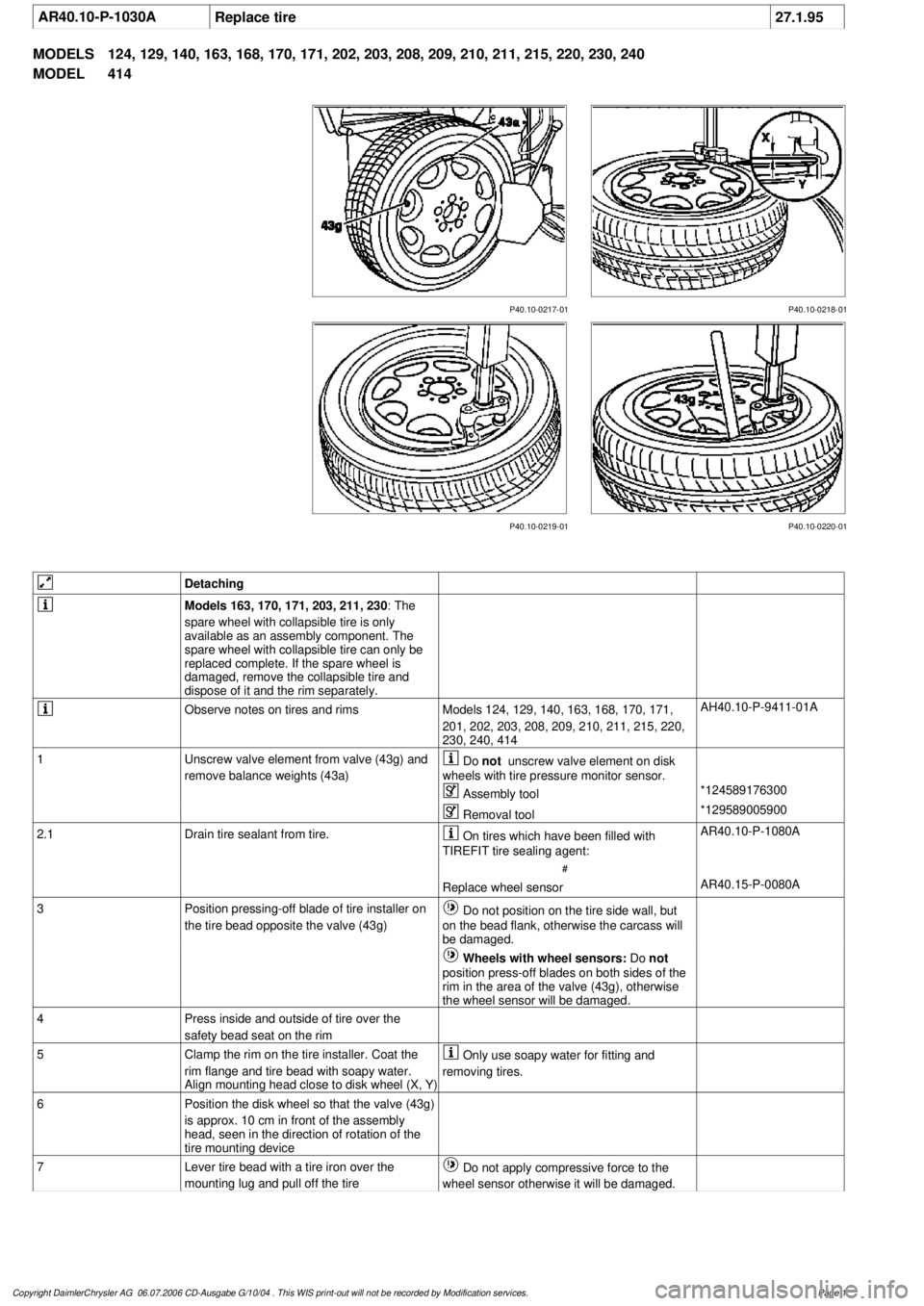

P40.10-0218-01

P40.10-0217-01

P40.10-0219-01 P40.10-0220-01

Detaching

Models 163, 170, 171, 203, 211, 230

: The

spare wheel with collapsible tire is only

available as an assembly component. The

spare wheel with collapsible tire can only be

replaced complete. If the spare wheel is

damaged, remove the collapsible tire and

dispose of it and the rim separately.

Observe notes on tires and rims

Models 124, 129, 140, 163, 168, 170, 171,

201, 202, 203, 208, 209, 210, 211, 215, 220,

230, 240, 414

AH40.10-P-9411-01A

1

Unscrew valve element from valve (43g) and

remove balance weights (43a)

Do

not

unscrew valve element on disk

wheels with tire pressure monitor sensor.

Assembly tool

*124589176300

Removal tool

*129589005900

2.1

Drain tire sealant from tire.

On tires which have been filled with

TIREFIT tire sealing agent:

#

AR40.10-P-1080A

Replace wheel sensor

AR40.15-P-0080A

3

Position pressing-off blade of tire installer on

the tire bead opposite the valve (43g)

Do not position on the tire side wall, but

on the bead flank, otherwise the carcass will

be damaged.

Wheels with wheel sensors:

Do

not

position press-off blades on both sides of the

rim in the area of the valve (43g), otherwise

the wheel sensor will be damaged.

4

Press inside and outside of tire over the

safety bead seat on the rim

5

Clamp the rim on the tire installer. Coat the

rim flange and tire bead with soapy water.

Align mounting head close to disk wheel (X, Y)

Only use soapy water for fitting and

removing tires.

6

Position the disk wheel so that the valve (43g)

is approx. 10 cm in front of the assembly

head, seen in the direction of rotation of the

tire mounting device

7

Lever tire bead with a tire iron over the

mounting lug and pull off the tire

Do not apply compressive force to the

wheel sensor otherwise it will be damaged.

Copyright DaimlerChrysler AG 06.07.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3778 of 4133

8.1

Check wheel sensor, valve body and sealing

rubber for damage

Vehicles with tire pressure monitor (code 475)

Do not remove wheel sensor for this.

Do not use compressed air, solvents or

detergents to clean the wheel sensor. Wipe

off dirt with a clean, lint-free cloth only.

Do not retighten the female torx bolt and

union nut.

Replace all valve components of wheel

electronics if:

D

The wheel sensor mounting bolt or union

nut is visibly loose.

Replace the wheel sensor if:

D

The wheel sensor is obviously damaged.

D

Tire sealant was used.

Install new wheel sensors:

#

Replace wheel sensor.

AR40.15-P-0080A

8.2

Install new valve (43g).

Vehicles without tire pressure monitor (code

475)

9

Checking condition of rim

AR40.10-P-1010-01A

Mounting

10

Moisten rim flange and tire beads with soapy

water and align assembly head at a small

distance (X, Y) to the disk wheel

Only use soapy water for fitting and

removing tires.

11

Place tire obliquely on the rim and pull on

over the rim flange using the tire installer

Position wheels with wheel sensors so

that the wheel sensor is approximately 180°

opposite the mounting head.

Do not apply compressive force to the wheel

sensor otherwise it will be damaged.

Observe the running direction on tires with

specified running direction.

Put as little stress as possible on bead

area.

12

Align the match points of the tire and disk

wheel with each other and remove the disk

wheel with tire from the tire mounting device

13

Inflate tires without valve element up to max.

3 bar

Do

not

unscrew valve element on disk

wheels with tire pressure monitor sensor.

The tire must slide evenly over the safety

shoulders of the disk wheel, otherwise coat

the tire beads with soapy water again.

14

Screw the valve element into the valve (43g)

and adjust the tire inflation pressure to the

specified value

Observe the tire pressure information in

the fuel filler flap of the vehicle.

15

Balance wheel

AR40.10-P-1040A

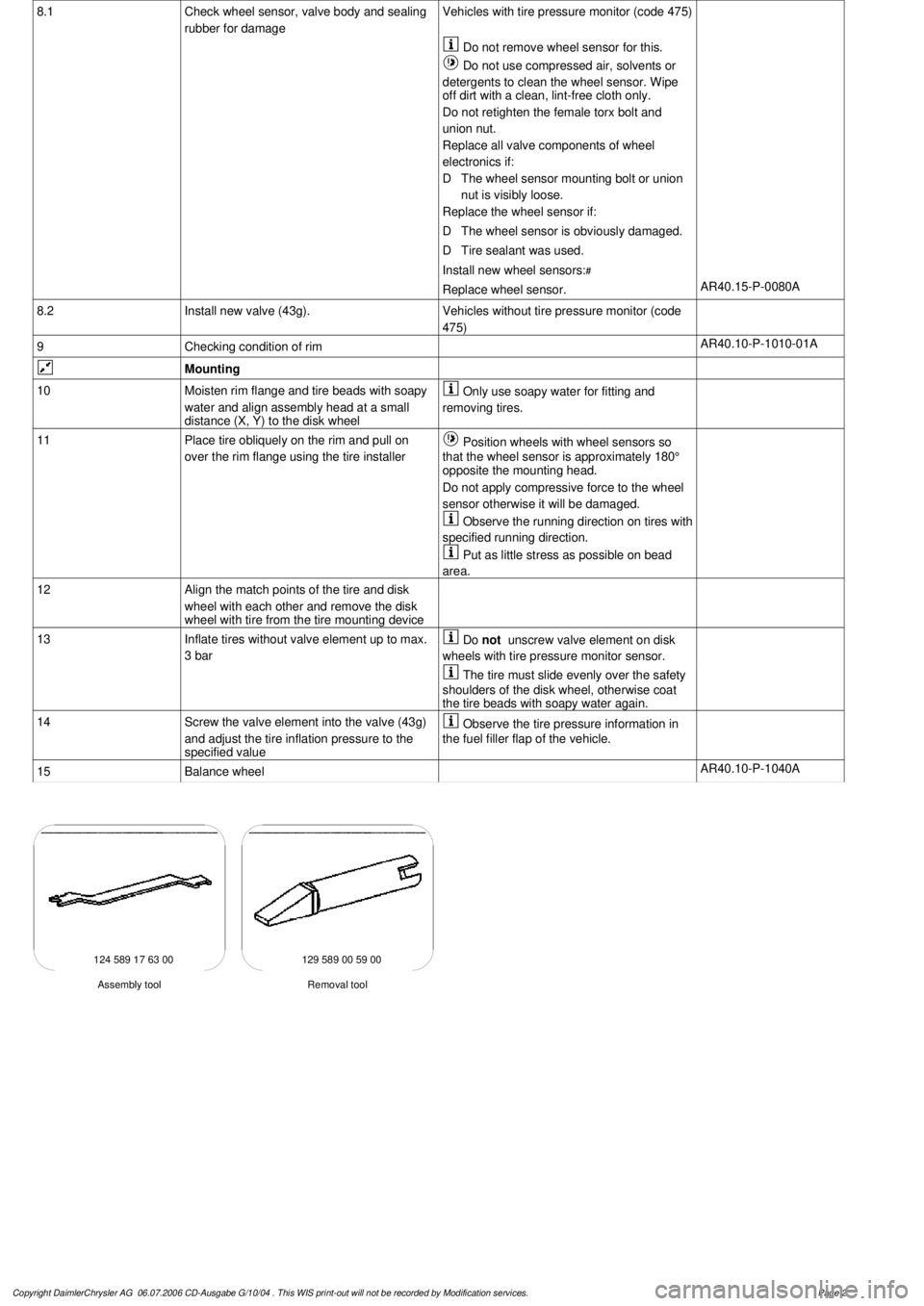

124 589 17 63 00 129 589 00 59 00

Removal tool

Assembly tool

Copyright DaimlerChrysler AG 06.07.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 2

Page 3843 of 4133

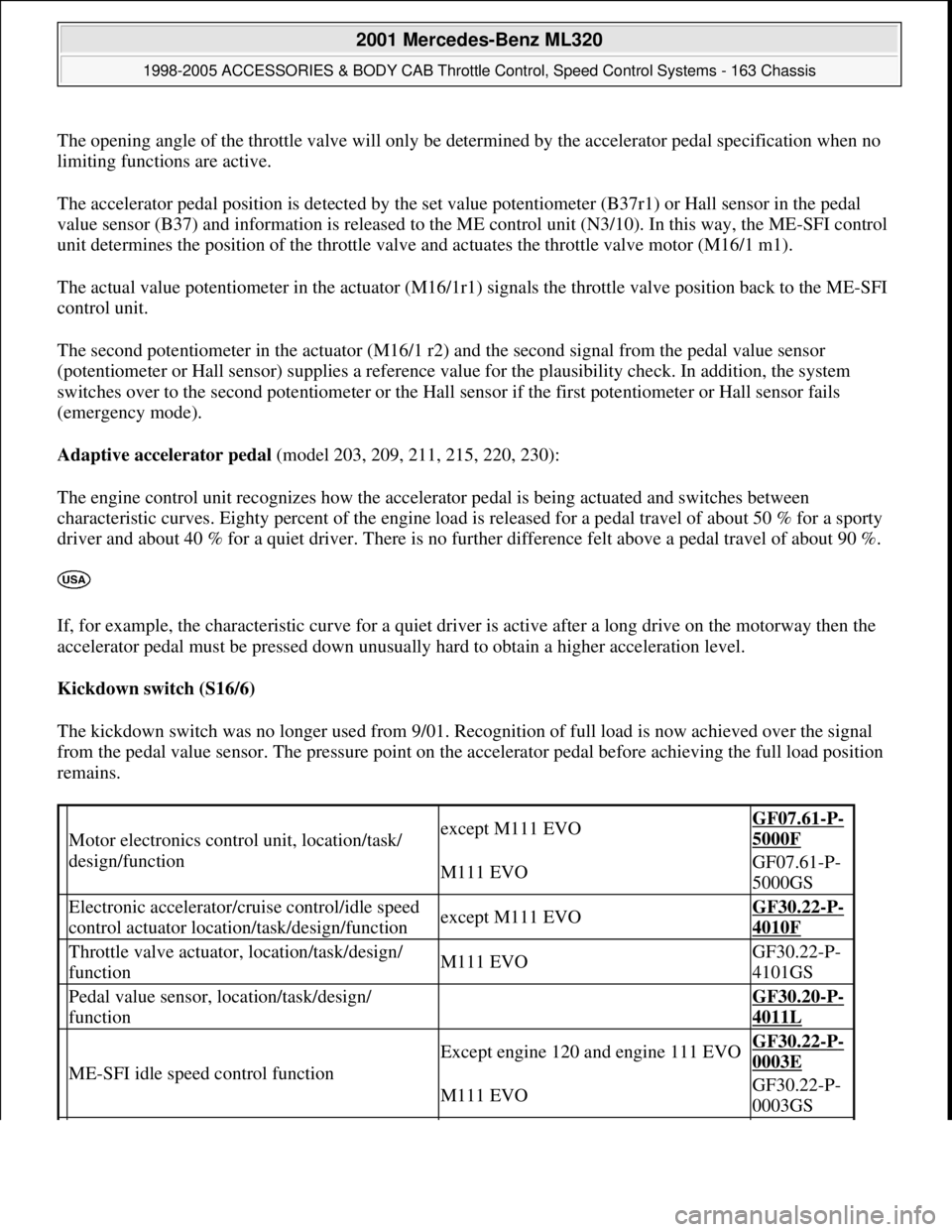

The opening angle of the throttle valve will only be determined by the accelerator pedal specification when no

limiting functions are active.

The accelerator pedal position is detected by the set value potentiometer (B37r1) or Hall sensor in the pedal

value sensor (B37) and information is released to the ME control unit (N3/10). In this way, the ME-SFI control

unit determines the position of the throttle valve and actuates the throttle valve motor (M16/1 m1).

The actual value potentiometer in the actuator (M16/1r1) signals the throttle valve position back to the ME-SFI

control unit.

The second potentiometer in the actuator (M16/1 r2) and the second signal from the pedal value sensor

(potentiometer or Hall sensor) supplies a reference value for the plausibility check. In addition, the system

switches over to the second potentiometer or the Hall sensor if the first potentiometer or Hall sensor fails

(emergency mode).

Adaptive accelerator pedal (model 203, 209, 211, 215, 220, 230):

The engine control unit recognizes how the accelerator pedal is being actuated and switches between

characteristic curves. Eighty percent of the engine load is released for a pedal travel of about 50 % for a sporty

driver and about 40 % for a quiet driver. There is no further difference felt above a pedal travel of about 90 %.

If, for example, the characteristic curve for a quiet driver is active after a long drive on the motorway then the

accelerator pedal must be pressed down unusually hard to obtain a higher acceleration level.

Kickdown switch (S16/6)

The kickdown switch was no longer used from 9/01. Recognition of full load is now achieved over the signal

from the pedal value sensor. The pressure point on the accelerator pedal before achieving the full load position

remains.

Motor electronics control unit, location/task/

design/functionexcept M111 EVOGF07.61-P-

5000F

M111 EVOGF07.61-P-

5000GS

Electronic accelerator/cruise control/idle speed

control actuator location/task/design/functionexcept M111 EVOGF30.22-P-

4010F

Throttle valve actuator, location/task/design/

functionM111 EVOGF30.22-P-

4101GS

Pedal value sensor, location/task/design/

function GF30.20-P-

4011L

ME-SFI idle speed control function

Except engine 120 and engine 111 EVOGF30.22-P-

0003E

M111 EVOGF30.22-P-

0003GS

2001 Mercedes-Benz ML320

1998-2005 ACCESSORIES & BODY CAB Throttle Control, Speed Control Systems - 163 Chassis

me

Saturday, October 02, 2010 3:36:27 PMPage 3 © 2006 Mitchell Repair Information Company, LLC.

Page 3844 of 4133

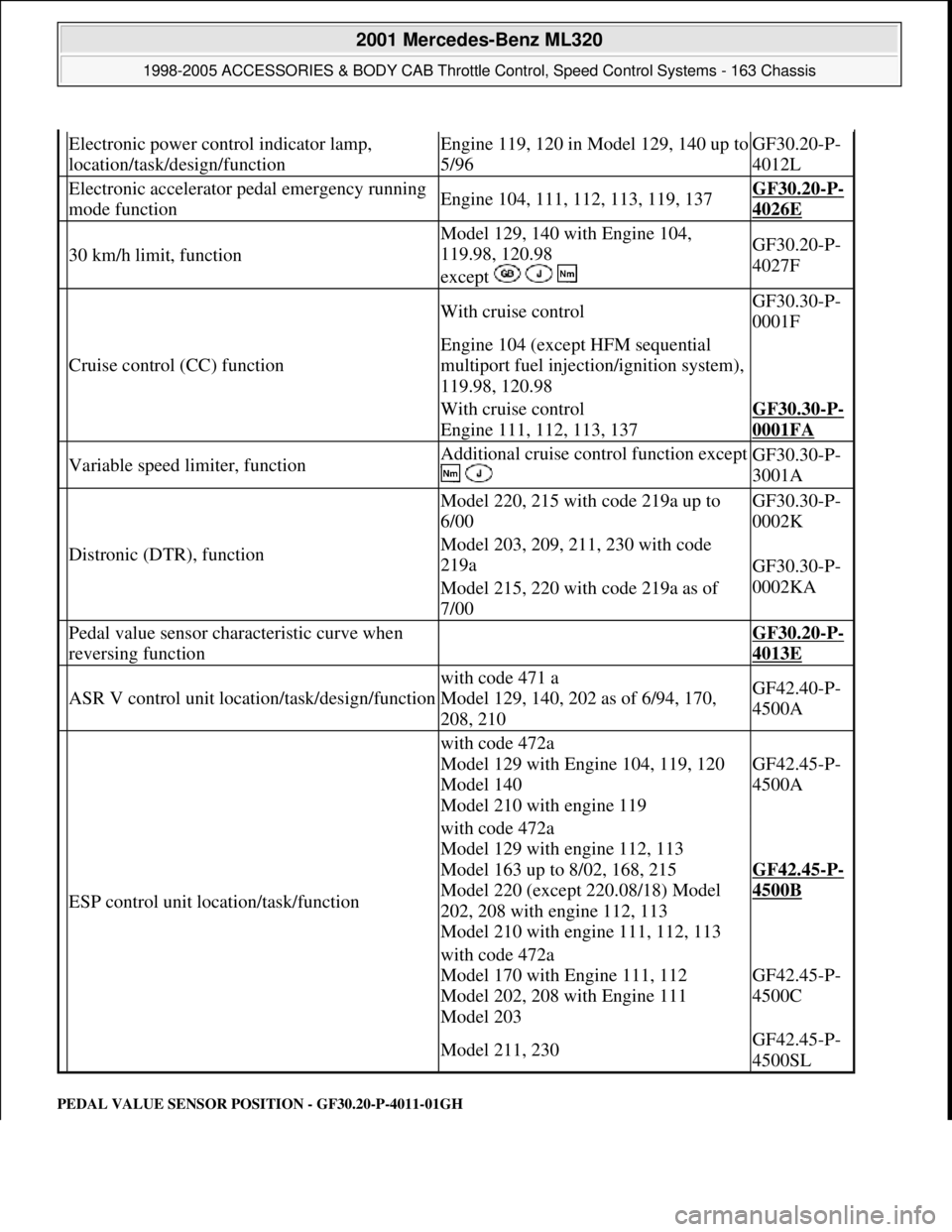

PEDAL VALUE SENSOR PO SITION - GF30.20-P-4011-01GH

Electronic power control indicator lamp,

location/task/design/functionEngine 119, 120 in Model 129, 140 up to

5/96GF30.20-P-

4012L

Electronic accelerator pe dal emergency running

mode functionEngine 104, 111, 112, 113, 119, 137GF30.20-P-

4026E

30 km/h limit, function

Model 129, 140 with Engine 104,

119.98, 120.98

except GF30.20-P-

4027F

Cruise control (CC) function

With cruise controlGF30.30-P-

0001F

Engine 104 (except HFM sequential

multiport fuel injection/ignition system),

119.98, 120.98

With cruise control

Engine 111, 112, 113, 137GF30.30-P-

0001FA

Variable speed limiter, functionAdditional cruise control function except

GF30.30-P-

3001A

Distronic (DTR), function

Model 220, 215 with code 219a up to

6/00GF30.30-P-

0002K

Model 203, 209, 211, 230 with code

219a

GF30.30-P-

0002KA

Model 215, 220 with code 219a as of

7/00

Pedal value sensor characteristic curve when

reversing function GF30.20-P-

4013E

ASR V control unit location/task/design/function

with code 471 a

Model 129, 140, 202 as of 6/94, 170,

208, 210GF42.40-P-

4500A

ESP control unit location/task/function

with code 472a

Model 129 with Engine 104, 119, 120

Model 140

Model 210 with engine 119

GF42.45-P-

4500A

with code 472a

Model 129 with engine 112, 113

Model 163 up to 8/02, 168, 215

Model 220 (except 220.08/18) Model

202, 208 with engine 112, 113

Model 210 with engine 111, 112, 113

GF42.45-P-

4500B

with code 472a

Model 170 with Engine 111, 112

Model 202, 208 with Engine 111

Model 203

GF42.45-P-

4500C

Model 211, 230GF42.45-P-

4500SL

2001 Mercedes-Benz ML320

1998-2005 ACCESSORIES & BODY CAB Throttle Control, Speed Control Systems - 163 Chassis

me

Saturday, October 02, 2010 3:36:27 PMPage 4 © 2006 Mitchell Repair Information Company, LLC.

Page 3845 of 4133

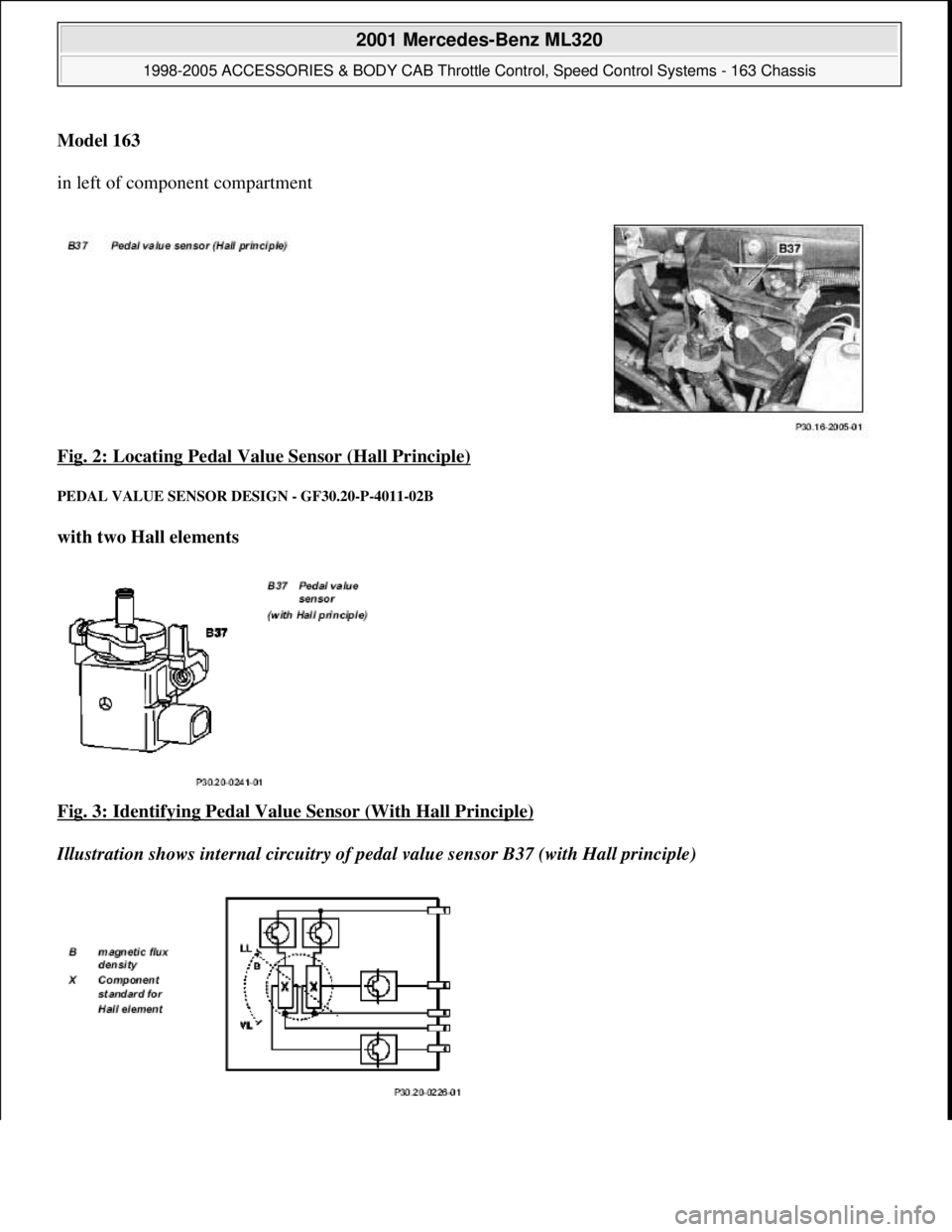

Model 163

in left of component compartment

Fig. 2: Locating Pedal Valu e Sensor (Hall Principle)

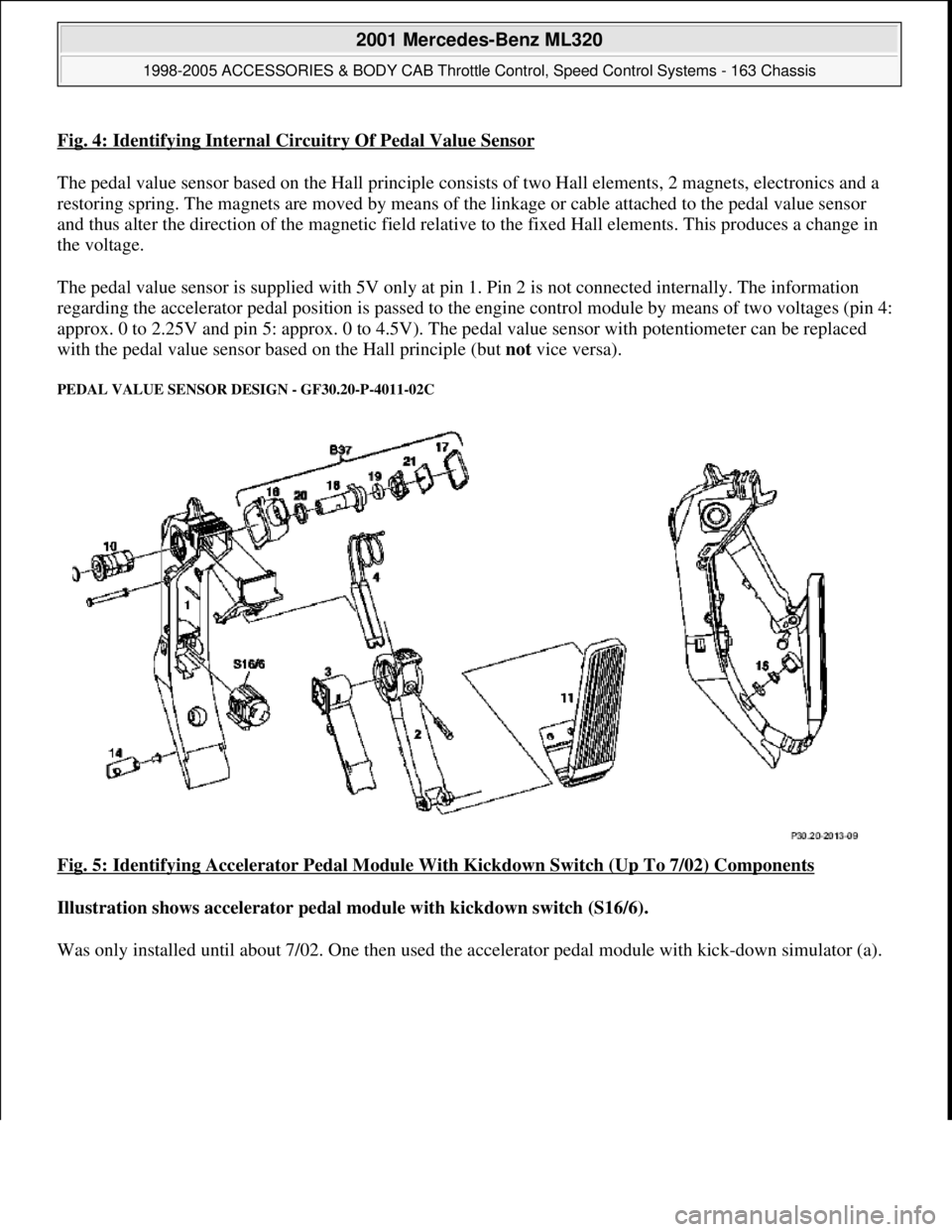

PEDAL VALUE SENSOR DE SIGN - GF30.20-P-4011-02B

with two Hall elements

Fig. 3: Identifying Pedal Value Sensor (With Hall Principle)

Illustration shows internal circuitry of pedal value sensor B37 (with Hall principle)

2001 Mercedes-Benz ML320

1998-2005 ACCESSORIES & BODY CAB Throttle Control, Speed Control Systems - 163 Chassis

me

Saturday, October 02, 2010 3:36:27 PMPage 5 © 2006 Mitchell Repair Information Company, LLC.

Page 3846 of 4133

Fig. 4: Identifying Internal Circuitry Of Pedal Value Sensor

The pedal value sensor based on the Hall principle consists of two Hall elements, 2 magnets, electronics and a

restoring spring. The magnets are moved by means of the linkage or cable attached to the pedal value sensor

and thus alter the direction of the magnetic field relative to the fixed Hall elements. This produces a change in

the voltage.

The pedal value sensor is supplied with 5V only at pin 1. Pin 2 is not connected internally. The information

regarding the accelerator pedal position is passed to the engine control module by means of two voltages (pin 4:

approx. 0 to 2.25V and pin 5: approx. 0 to 4.5V). The pedal value sensor with potentiometer can be replaced

with the pedal value sensor based on the Hall principle (but not vice versa).

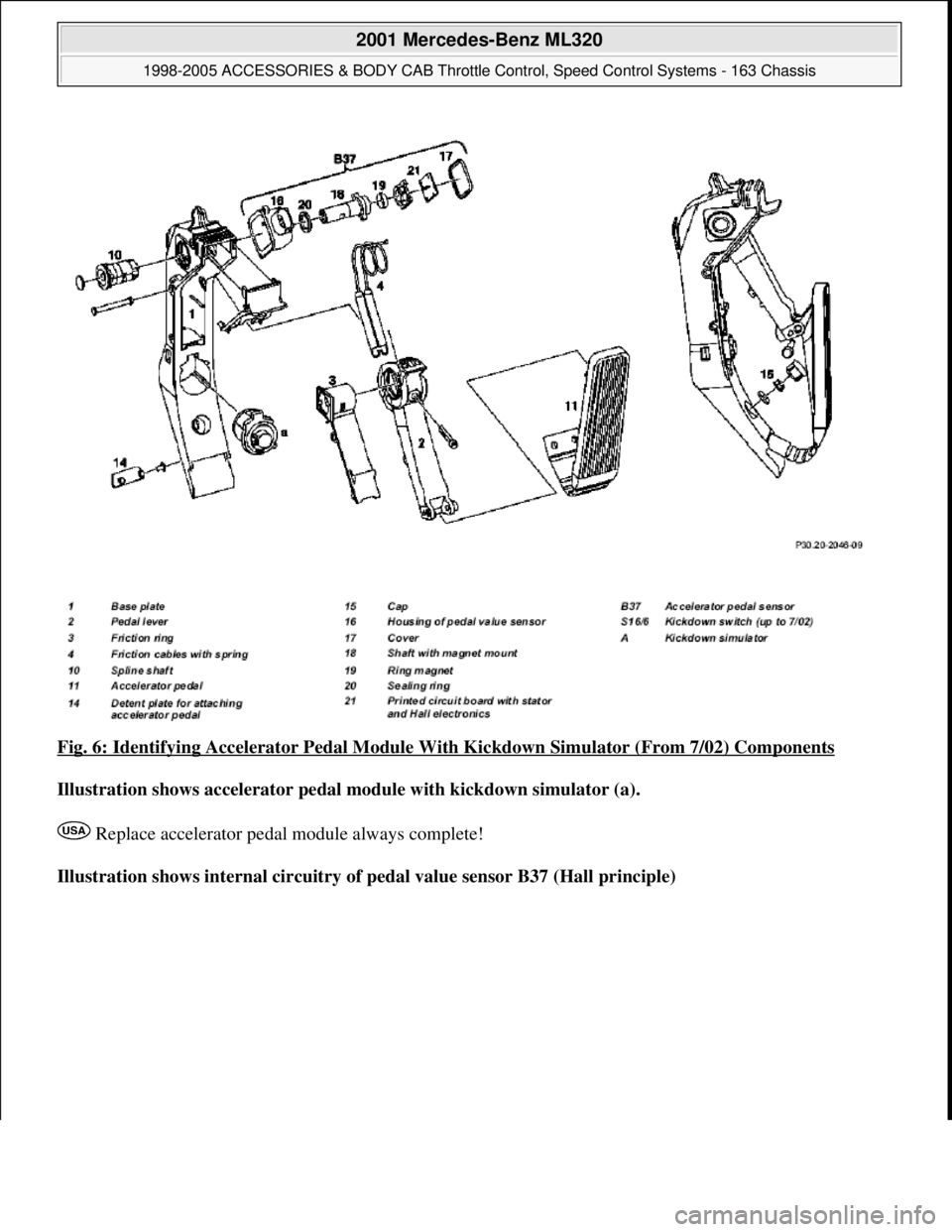

PEDAL VALUE SENSOR DESIGN - GF30.20-P-4011-02C

Fig. 5: Identifying Accelerator Pedal Module With Kickdown Switch (Up To 7/02) Components

Illustration shows accelerator pedal module with kickdown switch (S16/6).

Was onl

y installed until about 7/02. One then used the accelerator pedal module with kick-down simulator (a).

2001 Mercedes-Benz ML320

1998-2005 ACCESSORIES & BODY CAB Throttle Control, Speed Control Systems - 163 Chassis

me

Saturday, October 02, 2010 3:36:27 PMPage 6 © 2006 Mitchell Repair Information Company, LLC.

Page 3847 of 4133

Fig. 6: Identifying Accelerator Pedal Module With Kickdown Simulator (From 7/02) Components

Illustration shows accelerator pedal module with kickdown simulator (a).

Replace accelerator pedal module always complete!

Illustration shows internal circuitry of pedal value sensor B37 (Hall principle)

2001 Mercedes-Benz ML320

1998-2005 ACCESSORIES & BODY CAB Throttle Control, Speed Control Systems - 163 Chassis

me

Saturday, October 02, 2010 3:36:27 PMPage 7 © 2006 Mitchell Repair Information Company, LLC.

Page 3848 of 4133

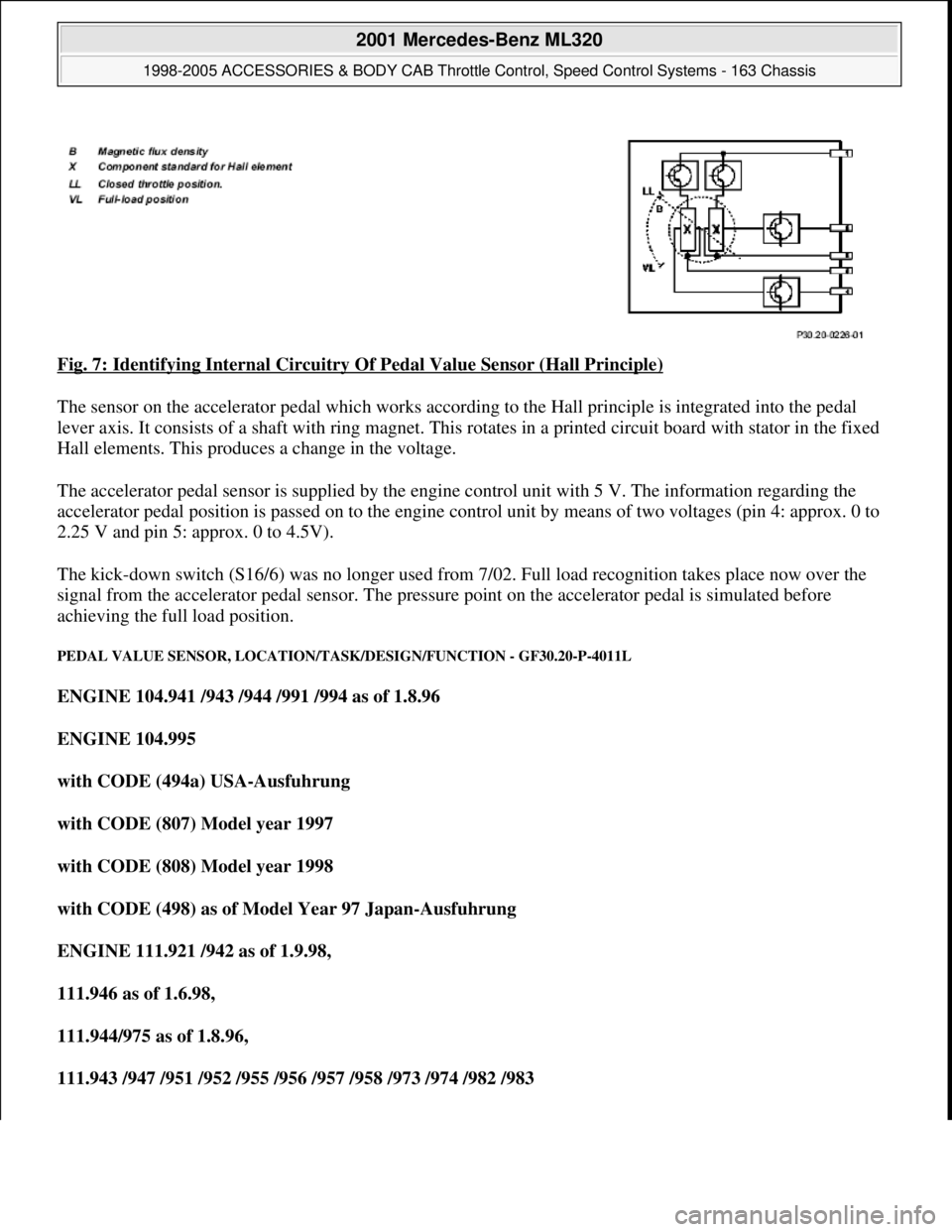

Fig. 7: Identifying Internal Circuitry Of Pedal Value Sensor (Hall Principle)

The sensor on the accelerator pedal which works according to the Hall principle is integrated into the pedal

lever axis. It consists of a shaft with ring magnet. This rotates in a printed circuit board with stator in the fixed

Hall elements. This produces a change in the voltage.

The accelerator pedal sensor is supplied by the engine control unit with 5 V. The information regarding the

accelerator pedal position is passed on to the engine control unit by means of two voltages (pin 4: approx. 0 to

2.25 V and pin 5: approx. 0 to 4.5V).

The kick-down switch (S16/6) was no longer used from 7/02. Full load recognition takes place now over the

signal from the accelerator pedal sensor. The pressure point on the accelerator pedal is simulated before

achieving the full load position.

PEDAL VALUE SENSOR, LOCATION/TASK/DESIGN/FUNCTION - GF30.20-P-4011L

ENGINE 104.941 /943 /944 /991 /994 as of 1.8.96

ENGINE 104.995

with CODE (494a) USA-Ausfuhrung

with CODE (807) Model year 1997

with CODE (808) Model year 1998

with CODE (498) as of Model Year 97 Japan-Ausfuhrung

ENGINE 111.921 /942 as of 1.9.98,

111.946 as of 1.6.98,

111.944/975 as of 1.8.96,

111.943 /947 /951 /952 /955 /956 /957 /958 /973 /974 /982 /983

2001 Mercedes-Benz ML320

1998-2005 ACCESSORIES & BODY CAB Throttle Control, Speed Control Systems - 163 Chassis

me

Saturday, October 02, 2010 3:36:27 PMPage 8 © 2006 Mitchell Repair Information Company, LLC.

Page 3850 of 4133

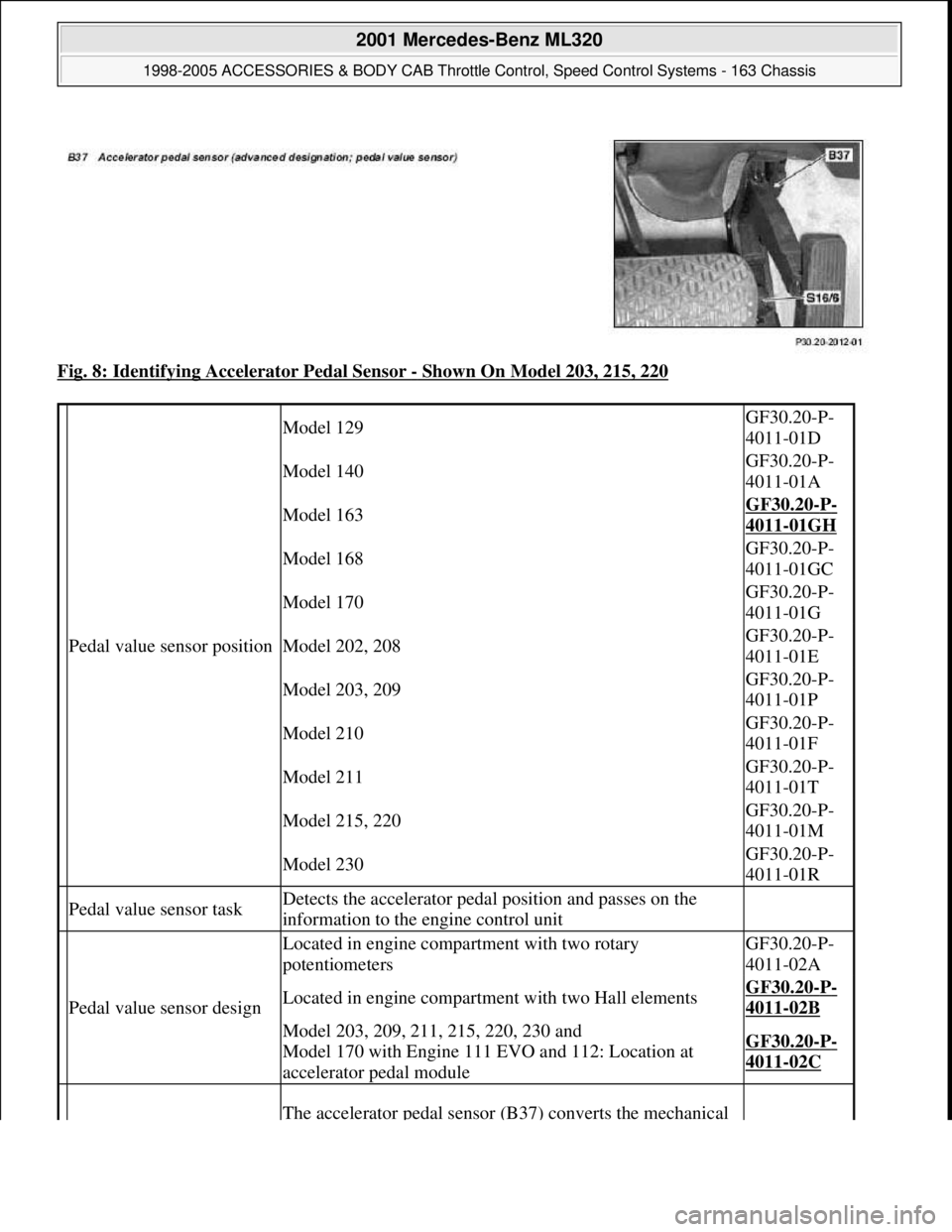

Fig. 8: Identifying Accelerator Pedal Sensor - Shown On Model 203, 215, 220

Pedal value sensor position

Model 129GF30.20-P-

4011-01D

Model 140GF30.20-P-

4011-01A

Model 163GF30.20-P-

4011-01GH

Model 168GF30.20-P-

4011-01GC

Model 170GF30.20-P-

4011-01G

Model 202, 208GF30.20-P-

4011-01E

Model 203, 209GF30.20-P-

4011-01P

Model 210GF30.20-P-

4011-01F

Model 211GF30.20-P-

4011-01T

Model 215, 220GF30.20-P-

4011-01M

Model 230GF30.20-P-

4011-01R

Pedal value sensor taskDetects the accelerator pedal position and passes on the

information to the engine control unit

Pedal value sensor design

Located in engine compartment with two rotary

potentiometersGF30.20-P-

4011-02A

Located in engine compartment with two Hall elementsGF30.20-P-

4011-02B

Model 203, 209, 211, 215, 220, 230 and

Model 170 with Engine 111 EVO and 112: Location at

accelerator pedal moduleGF30.20-P-

4011-02C

The accelerator pedal sensor (B37) converts the mechanical

2001 Mercedes-Benz ML320

1998-2005 ACCESSORIES & BODY CAB Throttle Control, Speed Control Systems - 163 Chassis

me

Saturday, October 02, 2010 3:36:27 PMPage 10 © 2006 Mitchell Repair Information Company, LLC.

Page 3851 of 4133

PEDAL VALUE SENSOR CHARACTERISTIC CURVE WHEN REVERSING FUNCTION - GF30.20-P-4013E

ENGINE 104.943 /944 /991 /994 as of 1.8.96

ENGINE 104.995

with CODE (494a) USA version

with CODE (807) Model year 1997

with CODE (808) Model year 1998

with CODE (498) as of Model year 97 Japanese version

ENGINE 104.941 as of 1.8.96

ENGINE 111.921 /942 as of 1.9.98,

111.946 as of 1.6.98,

111.944/975 as of 1.8.96,

111.943 /947 /951 /952 /955 /956 /957 /958 /973 /974 /982 /983

ENGINE 111.945

in MODEL 202.020 /080 as of 1.9.98,

208.335/435 as of 1.6.98

with CODE (494a) USA version

with CODE (807) Model year 1997

with CODE (808) Model year 1998

ENGINE

112.910 /911 /912 /913 /914 /916 /917 /920 /921 /922 /923 /940 /941 /942 /943 /944 /946 /947 /949 /953 /954 /9

5

ENGINE 113.940 /941 /942 /943 /948 /960 /961 /963 /965 /966 /967 /968 /969

Pedal value sensor functionactuation determined by the accelerator pedal into an

electrical signal according to the accelerator pedal position.

Pedal value sensor

characteristic curve when

reversing function

GF30.20-P-

4013E

2001 Mercedes-Benz ML320

1998-2005 ACCESSORIES & BODY CAB Throttle Control, Speed Control Systems - 163 Chassis

me

Saturday, October 02, 2010 3:36:27 PMPage 11 © 2006 Mitchell Repair Information Company, LLC.