engine oil MERCEDES-BENZ ML500 1997 Complete Manual Online

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML500, Model: MERCEDES-BENZ ML500 1997Pages: 4133, PDF Size: 88.89 MB

Page 1132 of 4133

328 IndexK

Key

Global locking 89

Global unlocking 89

Loss of 90

Positions in steering lock 33

Remote control with folding key 88

Unlocking liftgate 89

Unlocking the driver’s door, fuel filler

flap 89

Key positions in steering lock 33

Key, Mechanical 261

Key, Remote control

Unlocking with 32

Kickdown 123, 313

L

Labels, identification 292

Lamp bulbs, exterior 266

Lamps, exterior

Front 266

Rear 267Lamps, indicator and warning

4-ETS 251, 252

ABS 242

Adjustable steering column 253

AIRBAG OFF 63, 243

BAS 78, 245, 246, 247

Battery indicator lamp 254

Brake pad wear 254

Brakes 244

CHECK ENGINE 248

Coolant 249

EBP 245

Engine diagnostics 248

ESP 245, 246, 247, 251

Front fog lamps 253

Fuel reserve 252

Low engine oil level 253

LOW RANGE 252

Low washer system fluid level 253

Seat belts 253

Service indicator 232

SRS 255

Turn signals 25LATCH child seat anchors 72

LATCH child seat mounts 72

Layout of poly-V-belt drive 293

Leather upholstery

Cleaning 239

Lever

For cruise control 150

License plate lamps

Replacing bulbs 267, 271

Liftgate

Closing 92

Opening 89, 91

Opening from inside 91

Opening from outside 91

Light alloy wheels

Cleaning 238

Lighter

Rear center console 169

Lighter see cigarette lighter 168

Page 1133 of 4133

329 Index

Lighting 107

Automatic headlamp mode 108

Cargo compartment 114

Combination switch 110

Daytime running lamp mode 109

Door entry lamps 113

Front fog lamps 111

High beam flasher 110

High beams 110

Instrument cluster illumination 116

Interior 112

Locator lighting 110

Night security illumination 109

Limiting the gear range 121

Limp Home Mode 124

Line of fall 313

Loading 157

Cargo area cover blind* 161

Cargo floor plates 162

Cargo tie-down rings 158

Hooks 159

Instructions 157, 158

Partition net* 159

Roof rack 163Split rear bench seat 99

Trailer 208

Locator lighting 110

Lock button 313

Locking 88

Automatic while driving 93

Centrally from inside 94

Fuel filler flap 214

Global 89

Vehicle in an emergency 262

Locking knobs 32

Loss of keys 90

Loss of Service and Warranty Information

Booklet 291

Low beam headlamps

Replacing bulbs 266, 268

Switching on 48

Low engine oil level

Indicator lamp 253

LOW RANGE - 4-ETS 80

LOW RANGE - ABS 77LOW RANGE - ESP 81

LOW RANGE mode 125

Low washer system fluid level

Indicator lamp 253

Lowering

Vehicle 276

M

Main dimensions 298

Maintenance 12

Display messages 256

Manual operations

Fuel filler flap 263

Interior lighting control 113

Locking the vehicle 262

Sliding/pop-up roof* 265

Unlocking the driver’s door 261

Unlocking transmission selector

lever 264

Page 1141 of 4133

337 Index

Sun visor 132

Supplemental Restraint System

(SRS) 314

Switching off

Automatic climate control 137

ESP 81

Hazard warning flasher 112

Headlamps 54

Rapid seat heating 99

Transmission control – LOW RANGE

mode 125

Switching on

Automatic climate control 137

ESP 82

Front fog lamps 111

Front fog lamps, rear fog lamp 111

Hazard warning flasher 112

Headlamps 48

High beams 110

Rapid seat heating* 98

Seat heating* 98

Transmission control – LOW RANGE

mode 125

Trip computer* 186

Windshield wipers 49Synchronizing

ESP 246

Power windows 146

Remote control 263

Sliding/pop-up roof* 149

T

Tachometer 26, 118

Displaying gear range 121

Tail lamps 270

Cleaning 236

Replacing bulbs 267Tar stains 235

Technical data 302

Brake fluid 302

Coolants 304

Electrical system 297

Engine 294

Engine oil 302

Engine oil additives 302

Fuel requirements 303

Gasoline additives 303

Main dimensions 298

Premium unleaded gasoline 303

Rims and tires 295

Weights 299

Windshield and headlamp washer

system 307

Tele Aid System* 315

Page 1170 of 4133

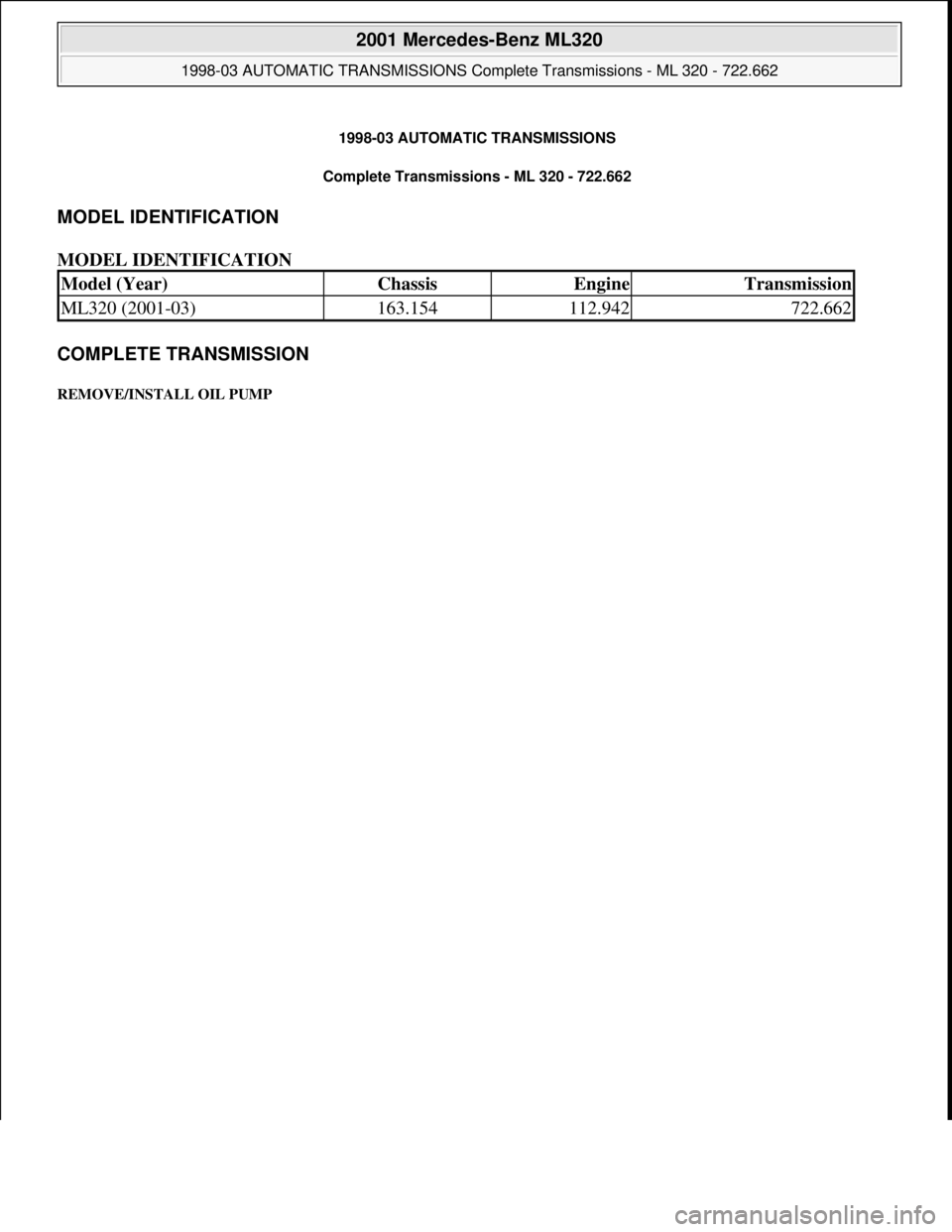

1998-03 AUTOMATIC TRANSMISSIONS

Complete Transmissions - ML 320 - 722.662

MODEL IDENTIFICATION

MODEL IDENTIFICATION

COMPLETE TRANSMISSION

REMOVE/INSTALL OIL PUMP

Model (Year)ChassisEngineTransmission

ML320 (2001-03)163.154112.942722.662

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMISSIONS Complete Transmissions - ML 320 - 722.662

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMISSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:25 PMPage 1 © 2006 Mitchell Repair Information Company, LLC.

me

Saturday, October 02, 2010 3:15:33 PMPage 1 © 2006 Mitchell Repair Information Company, LLC.

Page 1202 of 4133

The parking lock gear and drive flange are connected to the output shaft by gearing.

Freewheels F1 and F2 optimize shifting. The front freewheel (F1) rests against the stator shaft extension on the

transmission side and connects the sun gear of the front planetary gear set tot the transmission housing in the

locking direction.

The torque converter housing and transmission housing are made of a metal alloy. They are bolted together and

centered via the outer multiple-disc carrier of the multiple-disc brake B1. A coated intermediate panel seals the

two components.

The oil pump and outer multiple-disc carrier of the front multiple-disc brake are bolted to the converter housing.

The mechanical part consists of the propeller shaft, output shaft, a sun gear shaft and three planetary gearsets

which are coupled together.

In transmissions for powerful engines, the planetary gearsets have 4 planetary gears, while for less powerful

engines the front and rear planetary gear system has three planetary gear wheels. The stator shaft is pressed into

this and is secured against turning by a spline.

The rear freewheel (F2) connects the sun gear of the center planetary gear set to the sun gear of the rear

planetary gearset in the locking direction.

The electrohydraulic control unit consists of the shift plate made of light alloy for hydraulic control and an

electronic control unit.

The electrical control unit consists of a supporting body made of plastic in which the electrical components are

combined. The shell is screwed tot he shift plate. Conductor tracks which are integrated into the shell, connect

the electric components to a plug connector. This 13-pin plug connector forms the connection with the vehicle-

side wiring harness and with the ETC 5 (Electronic Transmission Control) control module (N15/5) via a

bayonet lock.

Automatic Transmission, Location Of Mechanical Parts

See AUTOMATIC TRANSMISSION, LOCATION OF MECHANICAL PARTS

.

Automatic Transmission, Location Of Electric/Electronic Components

See AUTOMATIC TRANSMISSION, LOCATION OF ELECTRIC/ELECTRONIC

COMPONENTS.

Automatic Transmission, Location Of Hydraulic Components

See AUTOMATIC TRANSMISSION, POSITION OF HYDRAULIC COMPONENTS

.

Automatic Transmission, Location Of Components, Floor Shift

See AUTOMATIC TRANSMISSION, LOCATION OF COMPONENTS, FLOOR SHIFT

.

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMISSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:26 PMPage 33 © 2006 Mitchell Repair Information Company, LLC.

Page 1232 of 4133

vehicle is stationary and the engine is idling, boosts the engine torque and provides infinitely variable

engine speed and torque matching when moving off.

Torque Converter, Design

The impeller (P) is connected to the engine, the turbine wheel (T) is connected to the transmission input

shaft.

The stator (L) is connected to the transmission housing via a freewheel and the stator shaft (8).

Torque Converter, Function

See TORQUE CONVERTER, FUNCTION

.

Torque Converter, Function

Due to the effect of centrifugal force, the blades of the impeller (P) pump the oil outwards to the turbine wheel

(T), causing it to rotate. See Fig. 31

. The turbine wheel blades direct the oil onto the blades of the stator, which

in turn push the oil back to the impeller (P) (arrow). This diversion at the stator (L), which is supported against

the transmission housing via the freewheel, produces and increase in torque. At the maximum speed difference

between the impeller and the turbine wheel (T), the torque conversion achieves its maximum value at a factor of

1.8 to 2.0, dropping to a torque ratio of 1:1 as the speeds converge. From this operating state onwards, also

referred to as the coupling point, the stator (l) rotates with the impeller (P) and the turbine wheel (T).

Efficiencies of up to approximately 98% are achieved in the coupling range.

The oil in the torque converter is constantly being replaced so that the heat produced in the operating phase can

be dissipated via the transmission oil cooler.

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMISSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:26 PMPage 63 © 2006 Mitchell Repair Information Company, LLC.

Page 1264 of 4133

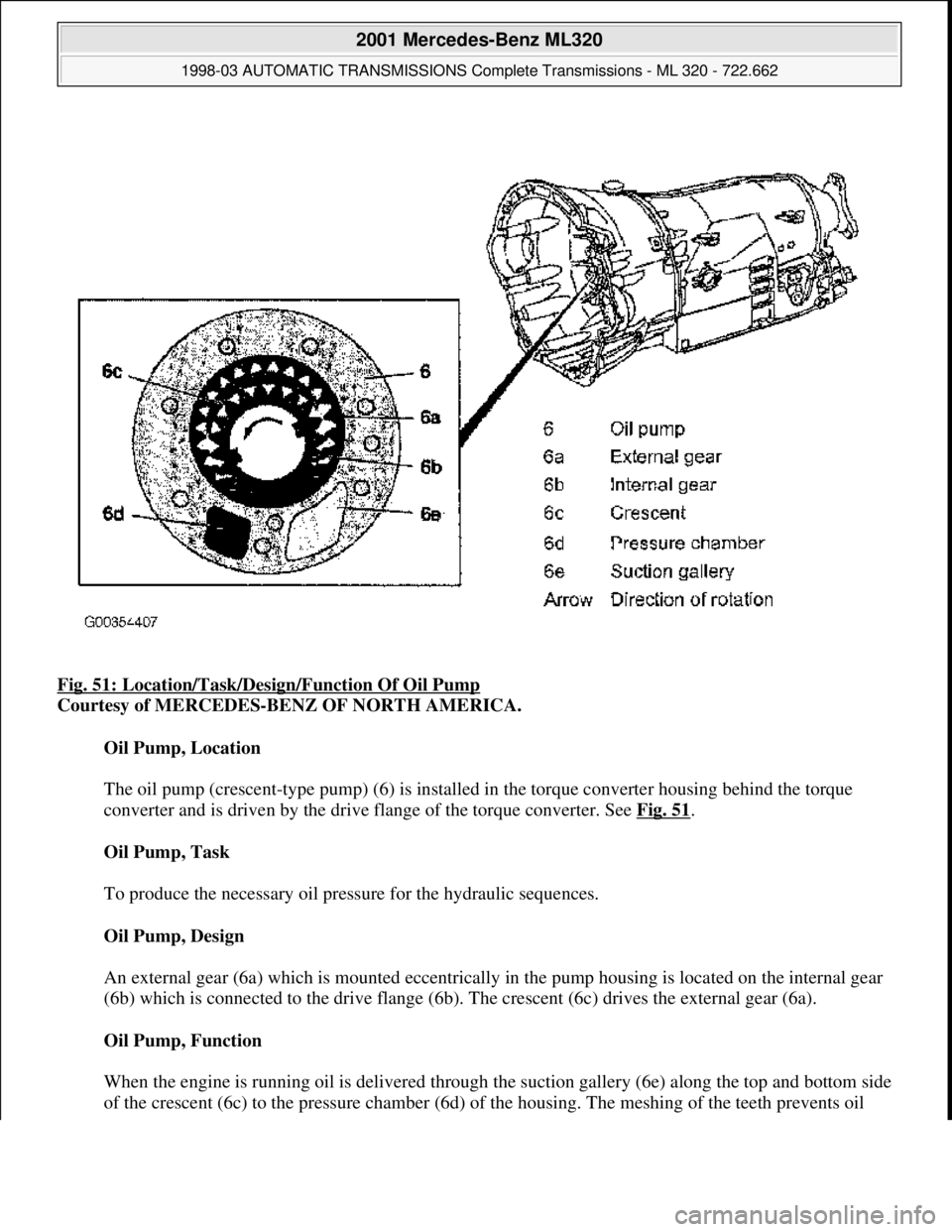

Fig. 51: Location/Task/Desi gn/Function Of Oil Pump

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

Oil Pump, Location

The oil pump (crescent-type pump) (6) is installed in the torque converter housing behind the torque

converter and is driven by the drive flange of the torque converter. See Fig. 51

.

Oil Pump, Task

To produce the necessary oil pressure for the hydraulic sequences.

Oil Pump, Design

An external gear (6a) which is m ounted eccentrically in the pump housi ng is located on the internal gear

(6b) which is connected to the drive flange (6b). The crescent (6c) drives the external gear (6a).

Oil Pump, Function

When the engine is running oil is delivered through th e suction gallery (6e) along the top and bottom side

of the crescent (6c) to the pr essure chamber (6d) of the housin

g. The meshing of the teeth prevents oil

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMI SSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:26 PMPage 95 © 2006 Mitchell Repair Information Company, LLC.

Page 1333 of 4133

Task - The ETC control module (N15/3) determines the instantaneous operating condition of the vehicle and

controls all gearshift sequences taking into account the ease of shifting and the driving situation. This involves

receiving, converting and transmitting various digital and analog signals. See Fig. 96

.

It receives operating data in the form of input signals from:

Starter Lock-Out Contact (Y3/6S1)

RPM Sensor 2 (Y3/6N2)

RPM Sensor 3 (Y3/6n3)

Transmission Oil Temperature Sensor (Y3/6B1)

In addition there is a connection via the engine compartment bus to the:

Instrument Cluster (A1)

ME-SFI Control Module (N3/10) or CDI Control Module (N3/9)

The solenoid valves for the modulating and shift pressure and for the gear changes are actuated by the ETC

control module (N15/3).

The pressure required is calculated from all input signals, adjusted to the torque to be transferred. The following

information from other systems is then processed.

ME-SFI Control Module (N3/10) or CDI Control Module (N3/9):

Engine Torque

Engine Speed

Accelerator Pedal Position

Gear Shift

Engine Status

Electronic Selector Lever Module Control Module (N15/5):

Kickdown Switch (S16/6)

Selector Lever Position P/N

Traction System Control Module (N47):

Transmission Ratio

Speeds

Instrument Cluster (A1):

Selector Lever Position/Shift Range

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMISSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:27 PMPage 164 © 2006 Mitchell Repair Information Company, LLC.

Page 1335 of 4133

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

Task - The ETC control module (N15/3) determines the instantaneous operating condition for the vehicle and

controls all gearshift sequences taking into account the ease of shifting and the driving situation. See Fig. 97

.

This involves receiving , converting and transmitting various digital and analog signals.

Input signals:

Starter Lock-Out Contact (Y3/6S1)

RPM Sensor 2 (Y3/6N2)

RPM Sensor 3 (Y3/6N3)

Transmission Oil Temperature Sensor (Y3/6B1)

Kickdown Switch (S16/6)

Gear Recognition Switch (S16/10)

Output signals:

Reverse/parking lock valve

Input and output signals:

Datalink connector (X11/4)

In addition there is a connection via the engine compartment bus to the:

ME-SFI Control Module (N3/10) or CDI Control Module (N3/9)

Traction System Control Module (N47)

Transfer Case Control Module (N78)

The solenoid valves for the modulating and shift pressure and for the gear changes are actuated by the ETC

control module (N15/3). The pressure required is calculated from all input signals, adjusted to the torque to be

transferred.

The following information from other systems is then processed:

ME-SFI Control Module (N3/10) or CDI Control Module (N3/9)

(Y66/1)

Selector lever position P/N to the engine control module (ME-SFI) (N3/10) (only on detection of the

selector lever position "P" or "N" on the transmission range recognition switch (S16/10) and at the starter

interlock contact (Y3/6s1)).

Traction system control module (N47):

Wheel speeds

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMISSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:27 PMPage 166 © 2006 Mitchell Repair Information Company, LLC.

Page 1352 of 4133

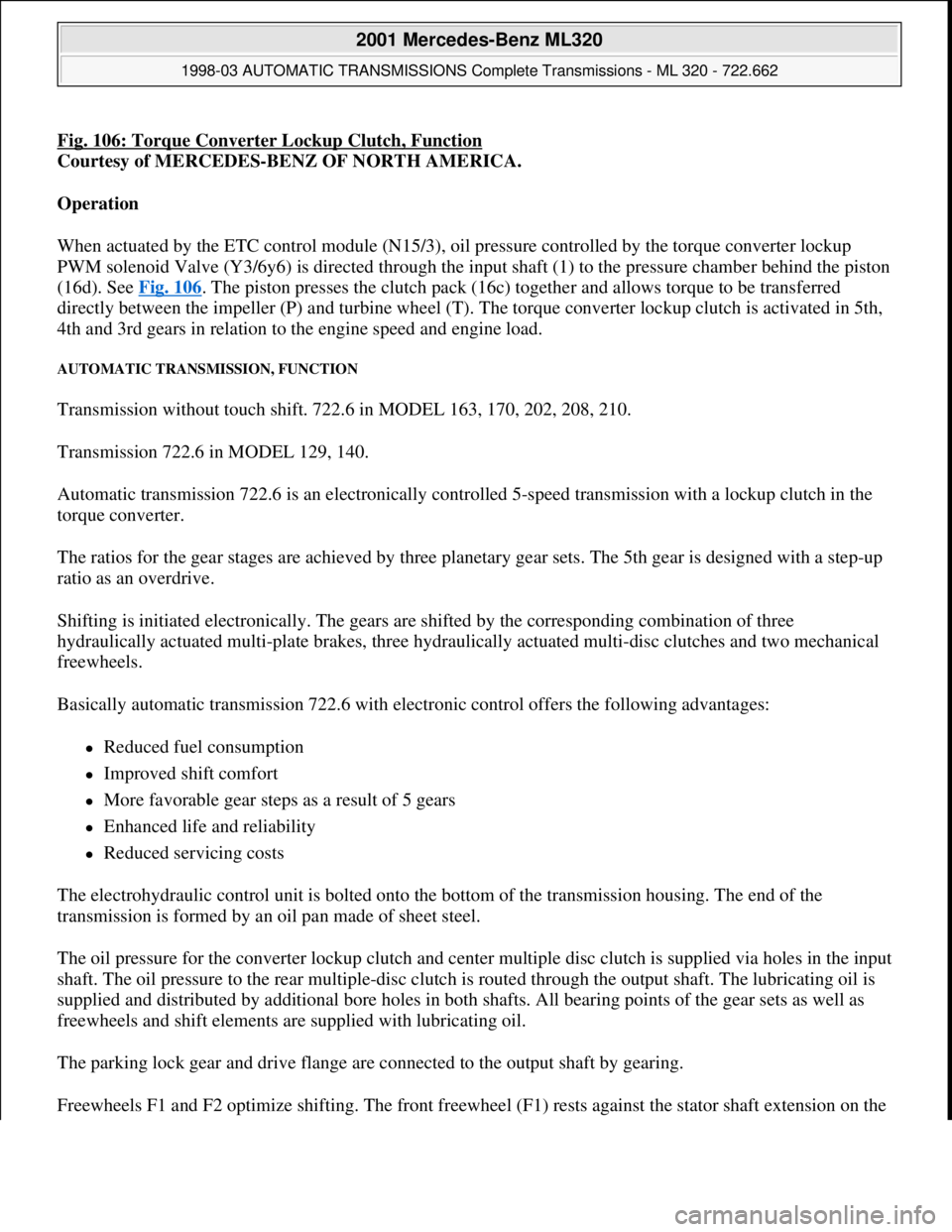

Fig. 106: Torque Converter Lockup Clutch, Function

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

Operation

When actuated by the ETC control module (N15/3), oil pressure controlled by the torque converter lockup

PWM solenoid Valve (Y3/6y6) is directed through the input shaft (1) to the pressure chamber behind the piston

(16d). See Fig. 106

. The piston presses the clutch pack (16c) together and allows torque to be transferred

directly between the impeller (P) and turbine wheel (T). The torque converter lockup clutch is activated in 5th,

4th and 3rd gears in relation to the engine speed and engine load.

AUTOMATIC TRANSMISSION, FUNCTION

Transmission without touch shift. 722.6 in MODEL 163, 170, 202, 208, 210.

Transmission 722.6 in MODEL 129, 140.

Automatic transmission 722.6 is an electronically controlled 5-speed transmission with a lockup clutch in the

torque converter.

The ratios for the gear stages are achieved by three planetary gear sets. The 5th gear is designed with a step-up

ratio as an overdrive.

Shifting is initiated electronically. The gears are shifted by the corresponding combination of three

hydraulically actuated multi-plate brakes, three hydraulically actuated multi-disc clutches and two mechanical

freewheels.

Basically automatic transmission 722.6 with electronic control offers the following advantages:

Reduced fuel consumption

Improved shift comfort

More favorable gear steps as a result of 5 gears

Enhanced life and reliability

Reduced servicing costs

The electrohydraulic control unit is bolted onto the bottom of the transmission housing. The end of the

transmission is formed by an oil pan made of sheet steel.

The oil pressure for the converter lockup clutch and center multiple disc clutch is supplied via holes in the input

shaft. The oil pressure to the rear multiple-disc clutch is routed through the output shaft. The lubricating oil is

supplied and distributed by additional bore holes in both shafts. All bearing points of the gear sets as well as

freewheels and shift elements are supplied with lubricating oil.

The parking lock gear and drive flange are connected to the output shaft by gearing.

Freewheels F1 and F2 optimize shiftin

g. The front freewheel (F1) rests against the stator shaft extension on the

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMISSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:28 PMPage 183 © 2006 Mitchell Repair Information Company, LLC.