MERCEDES-BENZ ML55AMG 2001 W163 Owner's Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2001, Model line: ML55AMG, Model: MERCEDES-BENZ ML55AMG 2001 W163Pages: 317, PDF Size: 10.4 MB

Page 241 of 317

238 Spare wheel, vehicle jack

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

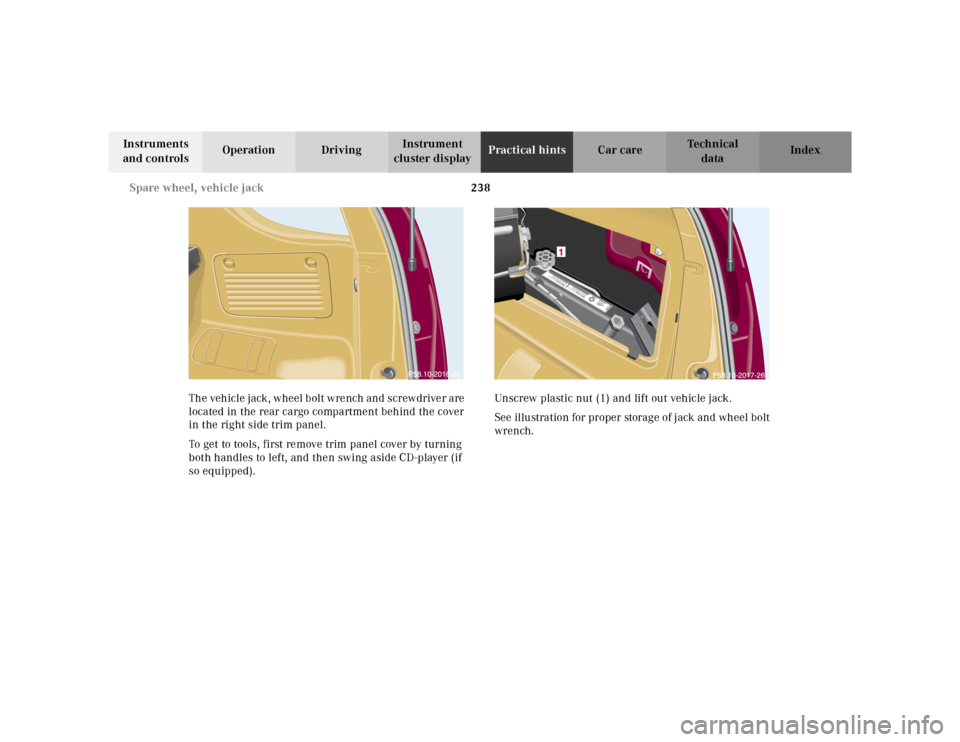

The vehicle jack, wheel bolt wrench and screwdriver are

located in the rear cargo compartment behind the cover

in the right side trim panel.

To get to tools, first remove trim panel cover by turning

both handles to left, and then swing aside CD-player (if

so equipped).Unscrew plastic nut (1) and lift out vehicle jack.

See illustration for proper storage of jack and wheel bolt

wrench.

Warnung!Sich nicht unter

das nur mit dem W

agenheber

aufgebockte Fahrzeug begeben!Warnung!Sich nicht unter

das nur mit dem W

agenheber

aufgebockte Fahrzeug begeben!

Page 242 of 317

239 Spare wheel, vehicle jack

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

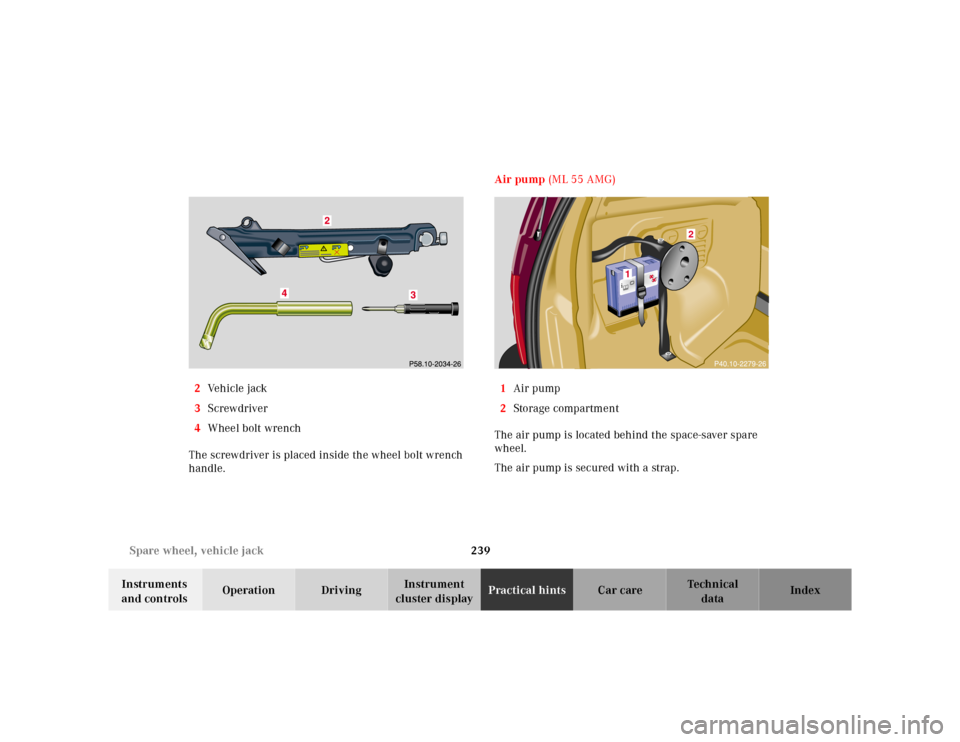

cluster displayPractical hintsCar care Index 2Ve h i c l e j a c k

3Screwdriver

4Wheel bolt wrench

The screwdriver is placed inside the wheel bolt wrench

handle.Air pump (ML 55 AMG)

1Air pump

2Storage compartment

The air pump is located behind the space-saver spare

wheel.

The air pump is secured with a strap.

1

2

Page 243 of 317

240 Tires, Wheels

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

Wheels

Replace rims or tires with the same designation,

manufacturer and type as shown on the original part.

See your authorized Mercedes-Benz Light Truck Center

for further information.

See your authorized Mercedes-Benz Light Truck Center

for information on tested and recommended rims and

tires for summer and winter operation. They can also

offer advice concerning tire service and purchase.Tire replacement

Front and rear tires should be replaced in sets.

Furthermore – in the event of tire replacement – the

optional regular size spare wheel should be used on the

rear axle. Rims and tires must be of the correct size and

type. For dimensions, see technical data on page 288.

We recommend that you break in new tires for

approximately 60 miles (100 km) at moderate speed.

It is imperative that the wheel mounting bolts be

fastened to a tightening torq ue of 110 ft.lb. (150 Nm)

whenever wheels are mounted.

For rim and tire specifications, refer to technical data on

page 288.

Wa r n i n g !

Do not mix different tire construction types (i.e.

radial, bias, bias-belted) on your vehicle because

handling may be adversely affected and may result

in loss of control.

Wa r n i n g !

Worn, old tires can cause accidents. If the tire tread

is badly worn, or if the tires have sustained

damage, replace them.When replacing rims, use only genuine

Mercedes-Benz wheel bolts specified for the

particular rim type. Failure to do so can result in

the bolts loosening and possibly an accident.

Page 244 of 317

241 Tires, Wheels

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index Rotating wheels

The wheels can be rotated according to the degree of

tire wear while retaining the same direction of travel.

Rotating, however, should be carried out as

recommended by the tire manufacturer, before the

characteristic tire wear pattern (shoulder wear on front

wheels and tread center wear on rear wheels) becomes

visible, as otherwise the driving properties deteriorate.

Important!

Unidirectional tires must always be mounted with arrow

on tire sidewall pointing in direction of vehicle forward

movement.Notes:

Thoroughly clean the inner side of the wheels any time

you rotate the wheels or wash the vehicle underside.

The use of retread tires is not recommended. Retread

tires may adversely affect the handling characteristics

and safety of the vehicle.

Dented or bent rims can cause tire pressure loss and

dam age to t he tire bead s. For this reason, ch eck rims for

damage at regular intervals. The rim flanges must be

checked for wear before a tire is mounted. Remove

burrs, if any.

Check and ensure proper tire inflation pressure after

rotating the wheels. For tire inflation pressure see

page 250.

Page 245 of 317

242 Tires, Wheels

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

Spare wheel

In the case of a flat tire or break-down, you may

temporarily use the space-saver spare wheel, while

observing the following restrictions:

•Do not exceed vehicle speed of 50 mph (80 km / h).

•Drive to the nearest repair facility to have the f lat

tire repaired or replaced as appropriate.

•Do not operate vehicle with more than one spare

wheel mounted.

For rim and tire specifications, refer to “Technical data”

on page 288.

Caution!

Exercise care when removing or installing spare wheel

to prevent personal injury.Space-saver tire (ML 55 AMG only)

Removing spare wheel (space-saver tire):

1. Open buckle of clamp, then remove cover (1).

2. Unscrew the three wheel bolts using wrench

supplied with vehicle tools, and take out space-saver

spare wheel, and remove the air pump from its

compartment.

Page 246 of 317

243 Tires, Wheels

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index Important!

To realize the total crumple zone in case of a rear end

collision, the space-saver spare wheel must be stored in

its holder with the tire deflated. Properly inflate the tire

prior to mounting it on the axle. See page 249 for

detailed instructions.

When storing the space-saver spare wheel in its holder,

tighten the three wheel bolts with a tightening torque of

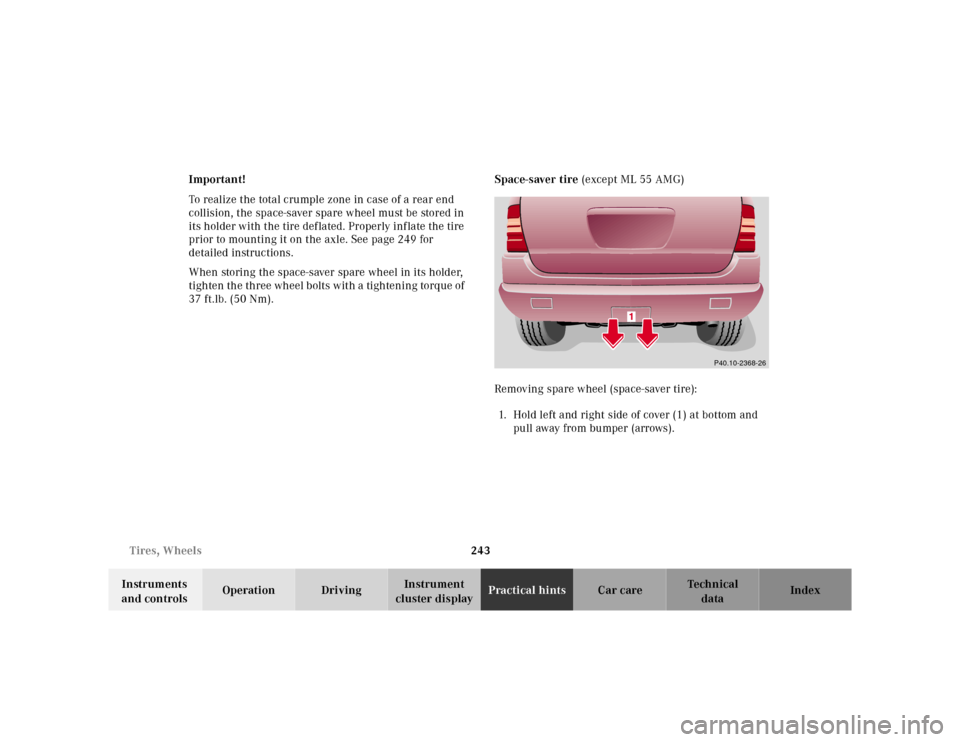

37 ft.lb. (50 Nm).Space-saver tire (except ML 55 AMG)

Removing spare wheel (space-saver tire):

1. Hold left and right side of cover (1) at bottom and

pu ll aw ay fr o m b u mpe r ( arr ows ) .

P40.10-2368-26

Page 247 of 317

244 Tires, Wheels

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

2. Loosen screw (2) using wrench supplied with

vehicle tools, see page 237. The screw (2) remains

in the holder.

3. Lift spare wheel carrier slightly and push lever (3)

to the right using screwdriver supplied with vehicle

tools, swing spare wheel carrier down and pull it out

from under the bumper.

4. Remove space-saver spare wheel.

Page 248 of 317

245 Tires, Wheels

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index Changing wheels

Position vehicle jack only at the jack take-up bracket

when raising the vehicle.

Wa r n i n g !

The jack is designed exclusively for jacking up the

veh icle at the jack take-u p brackets bu ilt i nto eit her

side of the vehicle. To help avoid personal injury,

use the jack only to lift the vehicle during a wheel

change. Never get beneath the vehicle while it is

supported by the jack. Keep hands and feet away

from the area under the lifted vehicle. Always

firmly set parking brake and block wheels before

raising vehicle with jack.Do not disengage parking brake while the vehicle is

raised. Be certain that the jack is always vertical

when in use, especially on hills. Always try to use

the jack on level surface. Be sure that the jack arm

end is fully seated in the jack take-up bracket.

Always lower the vehicle onto sufficient capacity

jackstands before working under the vehicle.

Page 249 of 317

246 Tires, Wheels

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

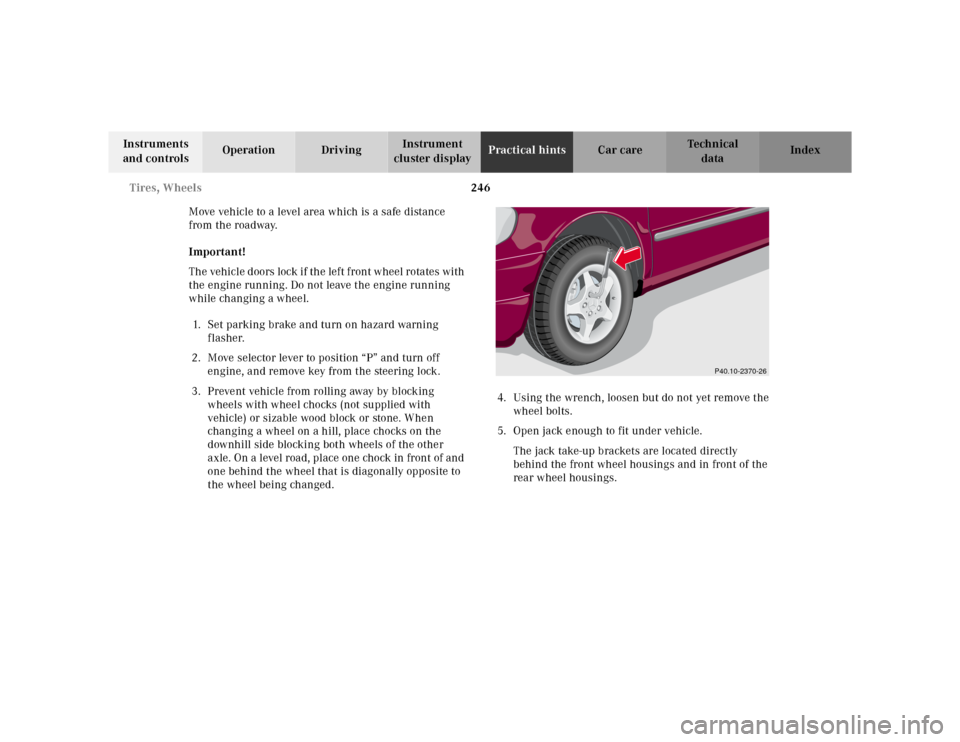

Move vehicle to a level area which is a safe distance

from the roadway.

Important!

The vehicle doors lock if the left front wheel rotates with

the engine running. Do not leave the engine running

while changing a wheel.

1. Set parking brake and turn on hazard warning

flasher.

2. Move selector lever to position “P” and turn off

engine, and remove key from the steering lock.

3. Prevent vehicle from rolling away by blocking

wheels with wheel chocks (not supplied with

vehicle) or sizable wood block or stone. When

changing a wheel on a hill, place chocks on the

downhill side blocking both wheels of the other

axle. On a level road, place one chock in front of and

one behind the wheel that is diagonally opposite to

the wheel being changed.4. Using the wrench, loosen but do not yet remove the

wheel bolts.

5. Open jack enough to fit under vehicle.

The jack take-up brackets are located directly

behind the front wheel housings and in front of the

rear wheel housings.

P40.10-2370-26

Page 250 of 317

247 Tires, Wheels

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

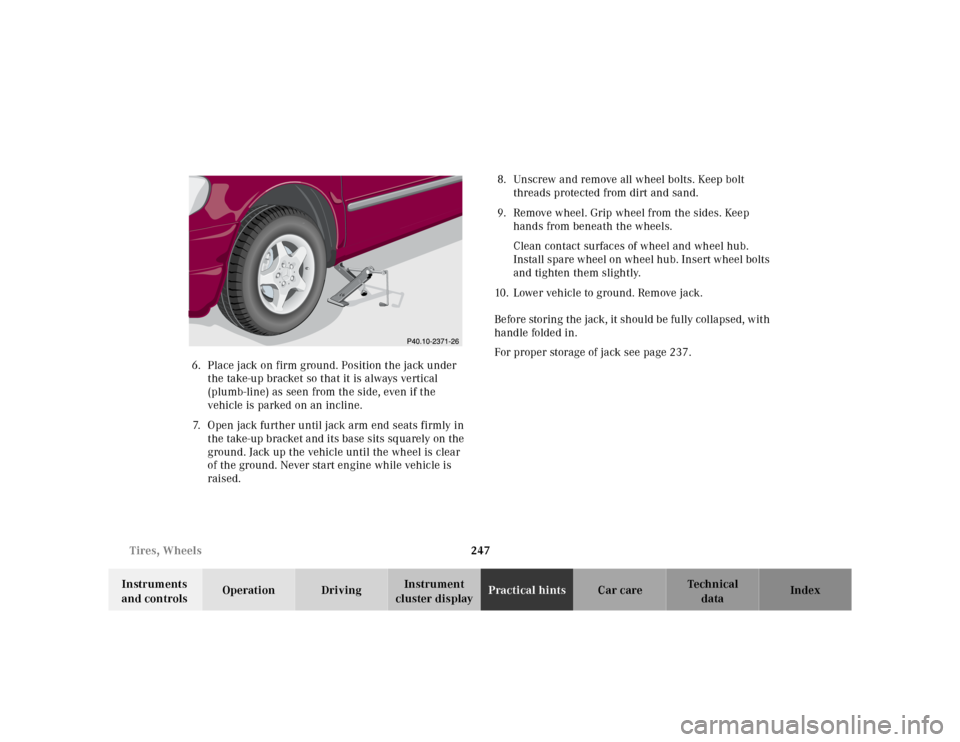

cluster displayPractical hintsCar care Index 6. Place jack on firm ground. Position the jack under

t he take-up bracket so t hat it is always ve rtical

(plumb-line) as seen from the side, even if the

vehicle is parked on an incline.

7. Open jack further until jack arm end seats firmly in

the take-up bracket and its base sits sq uarely on the

ground. Jack up the vehicle until the wheel is clear

of the ground. Never start engine while vehicle is

raised.8. Unscrew and remove all wheel bolts. Keep bolt

threads protected from dirt and sand.

9. Remove wheel. Grip wheel from the sides. Keep

hands from beneath the wheels.

Clean contact surfaces of wheel and wheel hub.

Install spare wheel on wheel hub. Insert wheel bolts

and tighten them slightly.

10. Lower vehicle to ground. Remove jack.

Before storing the jack, it should be fully collapsed, with

handle folded in.

For proper storage of jack see page 237.