clock MERCEDES-BENZ S CLASS 2019 User Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2019, Model line: S CLASS, Model: MERCEDES-BENZ S CLASS 2019Pages: 578, PDF Size: 23.31 MB

Page 431 of 578

#Press and hold button1for at leastfiveseconds.Thevehicle is adjustedtothe height ofthelast active drive program. Indicator lamp2goes out.

#Drivethevehicle offthe transporter.

4MATICvehicles

#Make surethatthe front andrear axles cometorestonthe same transportationvehicle.

*NOTEDamagetothe drivetrain duetoincorrect positioning

#Do not positionthevehicle abovetheconnection point ofthe transportvehi‐cle.

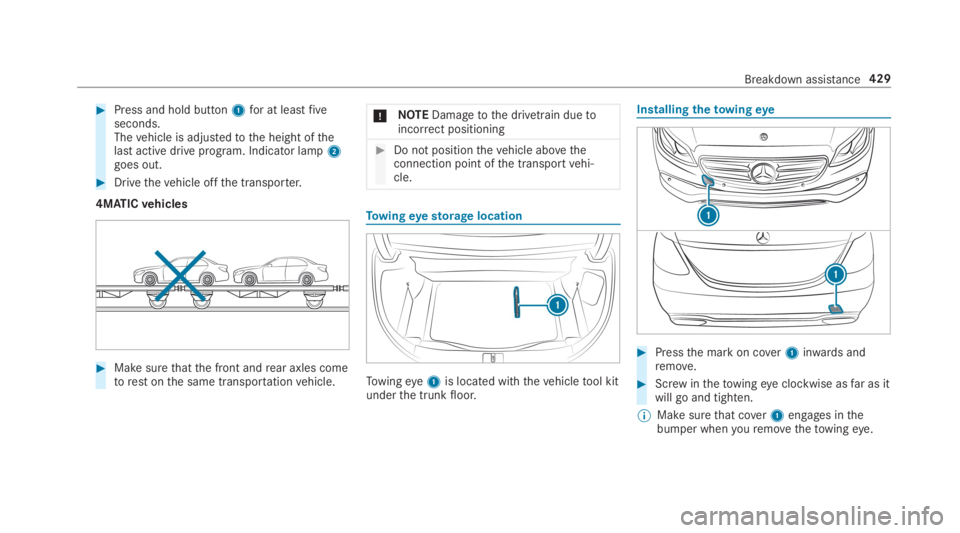

Towingeyestoragelocation

Towingeye1is located withthevehicletool kitunderthe trunkfloor.

Installingthetowingeye

#Pressthe mark on cover1inwards andremove.

#Screwinthetowingeyeclockwise asfar as itwill go and tighten.

%Make surethat cover1engages inthebumper whenyouremovethetowingeye.

Breakdown assistance429

Page 460 of 578

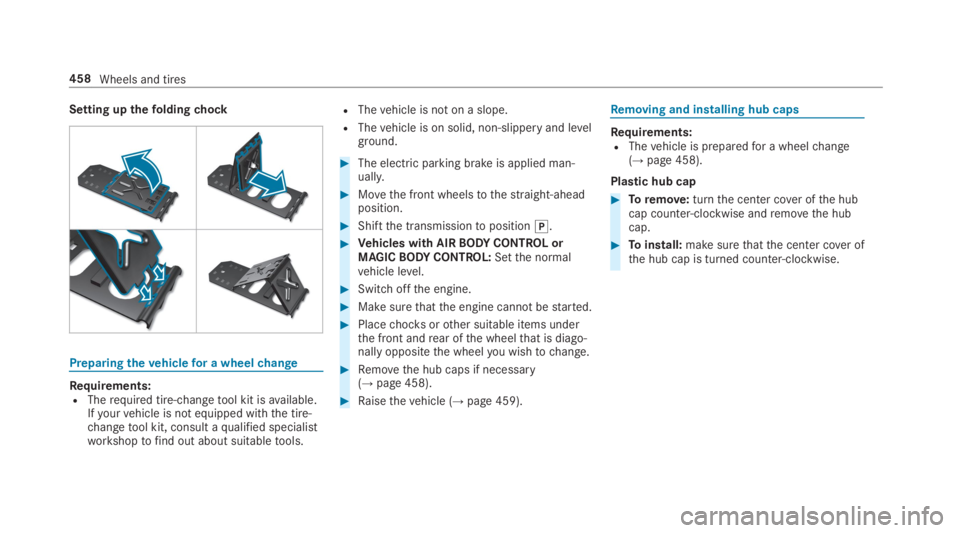

Setting upthefoldingchock

Preparingthevehiclefor a wheelchange

Requirements:RTherequired tire-changetool kit isavailable.Ifyourvehicle is not equipped withthe tire-changetool kit, consult aqualified specialistworkshoptofind out about suitabletools.

RThevehicle is not on a slope.

RThevehicle is on solid, non-slippery and levelground.

#The electric parking brake is applied man‐ually.

#Movethe front wheelstothestraight-aheadposition.

#Shiftthe transmissiontoposition�].

#Vehicles with AIRBODYCONTROL orMAGICBODYCONTROL:Setthe normalvehicle level.

#Switchoffthe engine.

#Make surethatthe engine cannotbestarted.

#Placechocksorother suitable items underthe front andrear ofthe wheelthat is diago‐nally oppositethe wheelyou wishtochange.

#Removethe hub caps if necessary(→page 458).

#Raisethevehicle (→page 459).

Removing and installing hub caps

Requirements:RThevehicle is preparedfor a wheelchange(→page 458).

Plastic hub cap

#Toremove:turnthe center cover ofthe hubcap counter-clockwise andremovethe hubcap.

#Toinstall:make surethatthe center cover ofthe hub cap is turned counter-clockwise.

458Wheels and tires

Page 461 of 578

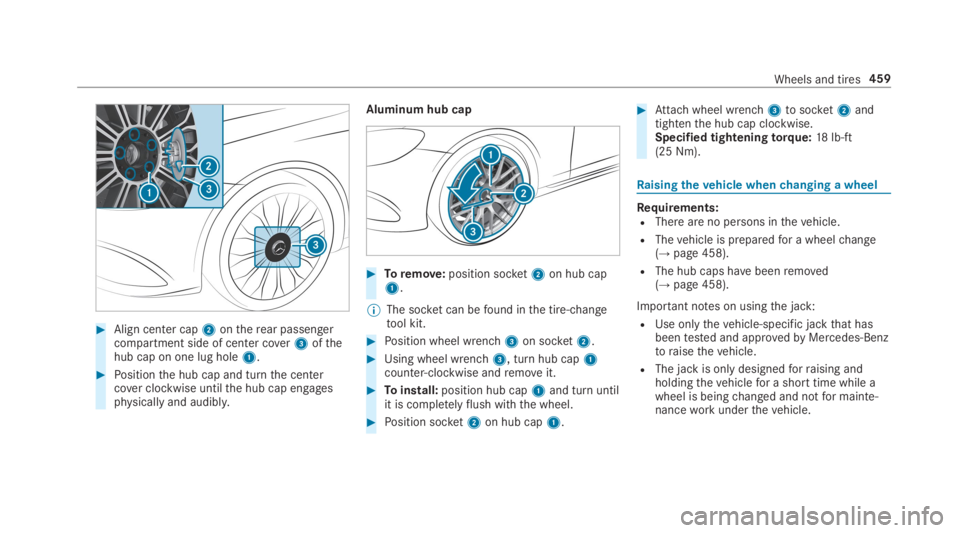

#Align center cap2ontherear passengercompartment side of center cover3ofthehub cap on one lug hole1.

#Positionthe hub cap and turnthe centercover clockwise untilthe hub cap engagesphysically and audibly.

Aluminum hub cap

#Toremove:position socket2on hub cap1.

%The socket can befound inthe tire-changetool kit.

#Position wheel wrench3on socket2.

#Using wheel wrench3, turn hub cap1counter-clockwise andremoveit.

#Toinstall:position hub cap1and turn untilit is completelyflush withthe wheel.

#Position socket2on hub cap1.

#Attachwheel wrench3tosocket2andtightenthe hub cap clockwise.Specified tighteningtorque:18lb-ft(25 Nm).

Raisingthevehicle whenchanging a wheel

Requirements:RThere are no persons inthevehicle.

RThevehicle is preparedfor a wheelchange(→page 458).

RThe hub caps havebeenremoved(→page 458).

Important notes on usingthe jack:

RUse onlythevehicle-specific jackthat hasbeentested and approvedbyMercedes-Benztoraisethevehicle.

RThe jack is only designedforraising andholdingthevehiclefor a short time while awheel is beingchanged and notfor mainte‐nanceworkunderthevehicle.

Wheels and tires459

Page 463 of 578

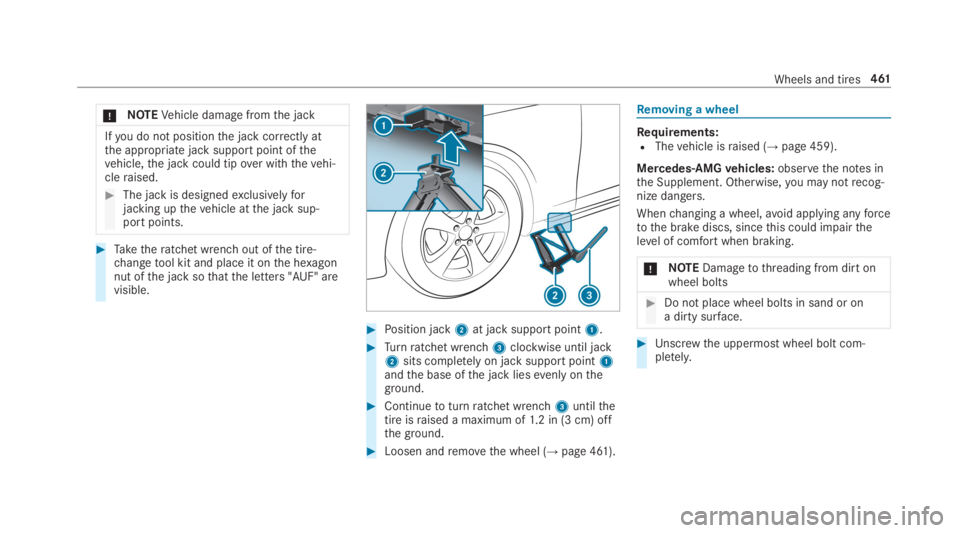

*NOTEVehicle damage fromthe jack

Ifyou do not positionthe jack correctly atthe appropriate jack support point ofthevehicle,the jack could tipover withthevehi‐cleraised.

#The jack is designedexclusivelyforjacking upthevehicle atthe jack sup‐port points.

#Taketheratchet wrench out ofthe tire-changetool kit and place it onthe hexagonnut ofthe jack sothatthe letters "AUF" arevisible.

#Position jack2at jack support point1.

#Turnratchet wrench3clockwise until jack2sits completelyon jack support point1andthe base ofthe jack liesevenly ontheground.

#Continuetoturnratchet wrench3untilthetire israised a maximum of1.2 in (3 cm) offthe ground.

#Loosen andremovethe wheel (→page 461).

Removing a wheel

Requirements:RThevehicle israised (→page 459).

Mercedes-AMGvehicles:observethe notes inthe Supplement. Otherwise,you may notrecog‐nize dangers.

Whenchanging a wheel,avoid applying anyforcetothe brake discs, sincethis could impairthelevel of comfortwhen braking.

*NOTEDamagetothreading from dirt onwheel bolts

#Do not place wheel bolts in sand or ona dirty surface.

#Unscrewthe uppermost wheel bolt com‐pletely.

Wheelsand tires461

Page 465 of 578

#Pressthe wheelfirmlyagainstthewheel hub when screwing onthefirstwheel bolt.

#Tightenthe wheel boltsevenly in a diagonalpattern inthe order indicated untiltheyarefinger-tight.

#Unscrewthe alignment bolt.

#Tightenthe last wheel bolt until it isfinger-tight.

#Lowerthevehicle (→page 463).

Loweringthevehicle after a wheelchange

Requirements:RThe new wheel has been installed(→page 462).

#Placetheratchet ontothe hexagon nut ofthejack sothatthe letters "AB" are visible.

#Tolower thevehicle:turntheratchet ofthejack counter-clockwise.

#Tightenthe wheel boltsevenly in a diagonalpattern inthe order indicated (1to5).Specified tighteningtorque:111lb-ft(150 Nm).

&WARNINGRisk of injurythrough incor‐rect tighteningtorque

The wheelscould come loose ifthe wheelbolts or wheel nuts are not tightenedtotheprescribed tighteningtorque.

#Makesurethe wheel bolts or wheelnuts are tightenedtothe prescribedtighteningtorque.

#Ifyou are not sure, do not movethevehicle. Consult aqualified specialistworkshop and havethe tighteningtor‐quechecked immediately.

#Checkthe tire pressure ofthe newly moun‐ted wheel and adjust accordingly.

#Vehicles with a tire pressure monitoringsystem:Restartthe tire pressure monitoringsystem (→page441).

Makesuretoobservethefollowing furtherrela‐ted subject:

RNotes on tire pressure (→page 435)

Wheels and tires463