clock MERCEDES-BENZ S-CLASS COUPE 2018 User Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2018, Model line: S-CLASS COUPE, Model: MERCEDES-BENZ S-CLASS COUPE 2018Pages: 502, PDF Size: 6.29 MB

Page 359 of 502

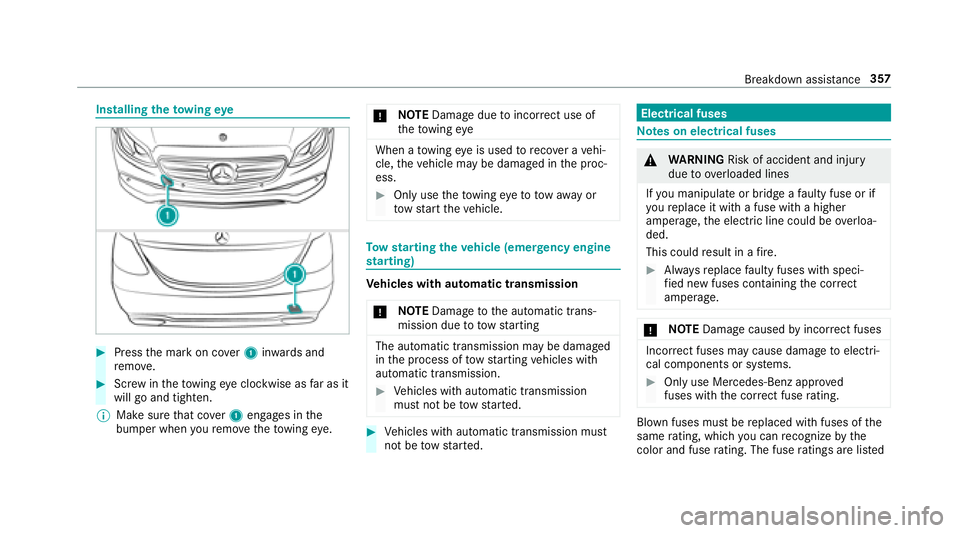

Installingtheto wing eye

#Press the mark on co ver1 inwa rds and

re mo ve.

#Scr ew intheto wing eyeclockwise as far as it

will go and tighten.

% Make sure that co ver1 engages in the

bumper when youre mo vetheto wing eye. *

NO

TEDama gedue toincor rect use of

th eto wing eye

When a towing eye is used toreco ver a vehi‐

cle, theve hicle may be damaged in the proc‐

ess.

#Only use theto wing eyeto to waw ay or

to w start theve hicle.

To w starting theve hicle (eme rgency engine

st arting)

Ve hicles with automatic transmission

* NO

TEDama getothe automatic trans‐

mission due to towstarting

The automatic transmission may be damaged

in the process of tow starting vehicles with

automatic transmission.

#Ve hicles with automatic transmission

must not be tow star ted.

#Ve hicles with automatic transmission must

not be tow star ted.

Electrical fuses

Note s on electrical fuses

&

WARNING Risk of accident and injury

due to ov erloaded lines

If yo u manipulate or bridge a faulty fuse or if

yo ure place it with a fuse with a higher

amperage, the electric line could be overloa‐

ded.

This could result in a fire .

#Alw aysre place faulty fuses with speci‐

fi ed new fuses conta iningthe cor rect

amperage.

* NO

TEDama gecaused byincor rect fuses

Incor rect fuses may cause damage toelectri‐

cal components or sy stems.

#Only use Mercedes-Benz appr oved

fuses with the cor rect fuse rating.

Blown fuses must bereplaced with fuses of the

same rating, which you can recognize bythe

color and fuse rating. The fuse ratings are li sted

Breakdown assis tance 357

Page 387 of 502

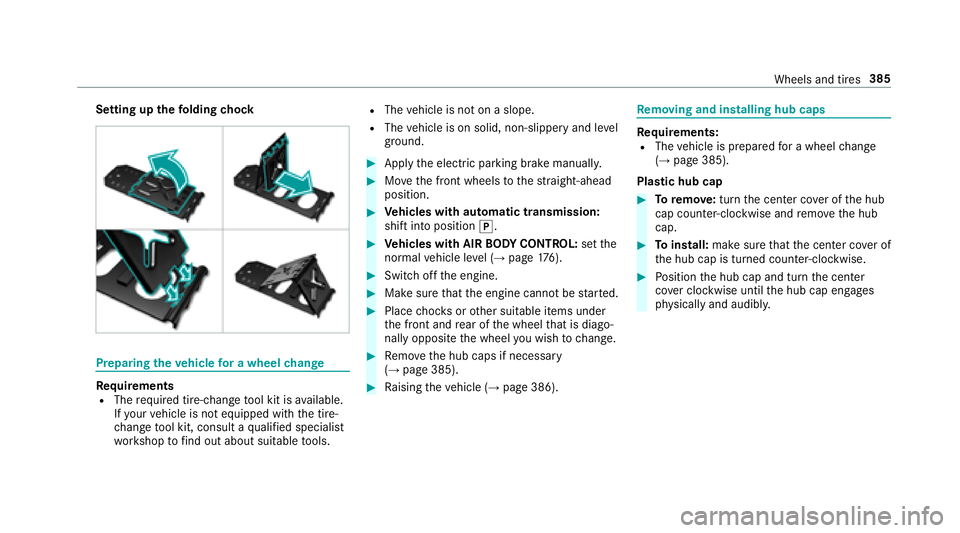

Setting upthefo lding chock

Prepa ring theve hicle for a wheel change

Re quirementsRThe requ ired tire-change tool kit is available.

If yo ur vehicle is not equipped with the tire-

ch ange tool kit, consult a qualified specialist

wo rkshop tofind out about suitable tools.

RThe vehicle is not on a slope.

RThe vehicle is on solid, non-slippery and le vel

ground .

#Applythe electric parking brake manually.

#Mo vethe front wheels tothest ra ight-ahead

position.

#Ve hicles with automatic transmission:

shift into position j.

#Vehicles with AIR BODY CONT ROL:set the

normal vehicle le vel (→page 176).

#Switch off the engine.

#Make sure that the engine cannot bestar ted.

#Place choc ks orother suitable items under

th e front and rear of the wheel that is diago‐

nally opposite the wheel youwish tochange.

#Re mo vethe hub caps if necessary

(→page 385).

#Ra ising theve hicle (→page 386).

Re moving and in stalling hub caps

Re quirements:RThe vehicle is prepared for a wheel change

(→page 385).

Plast ic hub cap

#Toremo ve:turn the center co ver of the hub

cap counter-clockwise and remo vethe hub

cap.

#To install: make sure that the center co ver of

th e hub cap is turned counter-clockwise.

#Po sition the hub cap and turn the center

co ver clockwise until the hub cap engages

ph ysically and audibly.

Wheels and tires 385

Page 388 of 502

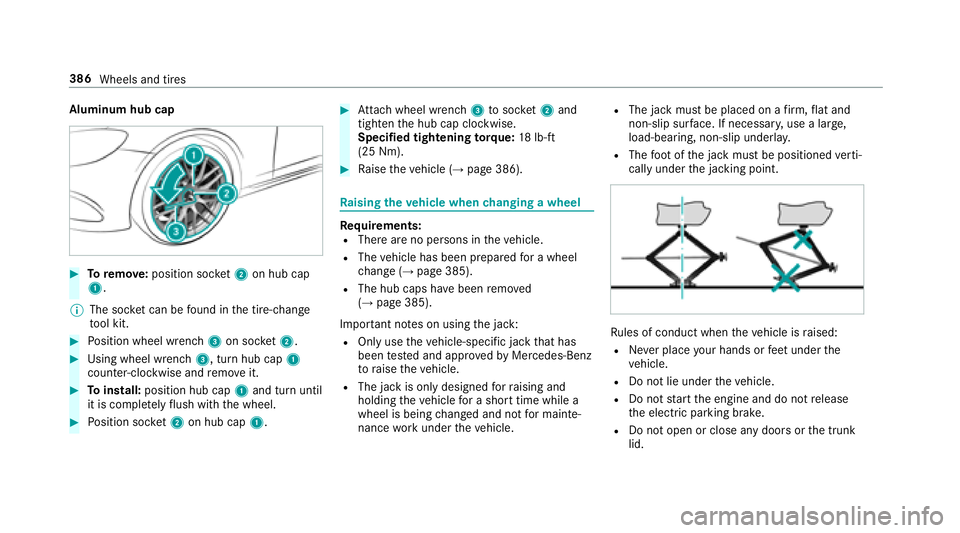

Aluminum hub cap

#Toremo ve:position soc ket2 on hub cap

1.

% The soc ket can be found inthe tire-change

to ol kit.

#Po sition wheel wrench 3on soc ket2.

#Using wheel wrench 3, turn hub cap1

counter-clo ckwise and remo veit.

#To install: position hub cap 1and turn until

it is comple tely flush withth e wheel.

#Po sition soc ket2 on hub cap 1.

#Attach wheel wrench 3tosoc ket2 and

tighten the hub cap clockwise.

Specified tightening torq ue: 18lb-ft

(25 Nm).

#Ra ise theve hicle (→page 386).

Ra ising theve hicle when changing a wheel

Re quirements:RThere are no persons in theve hicle.

RThe vehicle has been prepared for a wheel

ch ange (→page 385).

RThe hub caps ha vebeen remo ved

(→page 385).

Impor tant no tes on using the jack:

ROnly use theve hicle-specific jack that has

been tested and appr ovedby Mercedes-Benz

to raise theve hicle.

RThe jack is only designed forra ising and

holding theve hicle for a short time while a

wheel is being changed and not for mainte‐

nance workunder theve hicle.

RThe jack must be placed on a firm ,fl at and

non-slip sur face. If necessar y,use a lar ge,

load-bearing, non-slip underla y.

RThefoot ofthe jack must be positioned verti‐

cally under the jacking point.

Ru les of conduct when theve hicle is raised:

RNe ver place your hands or feet under the

ve hicle.

RDo not lie under theve hicle.

RDo not start the engine and do not release

th e electric parking brake.

RDo not open or close any doors or the trunk

lid.

386 Wheels and tires

Page 390 of 502

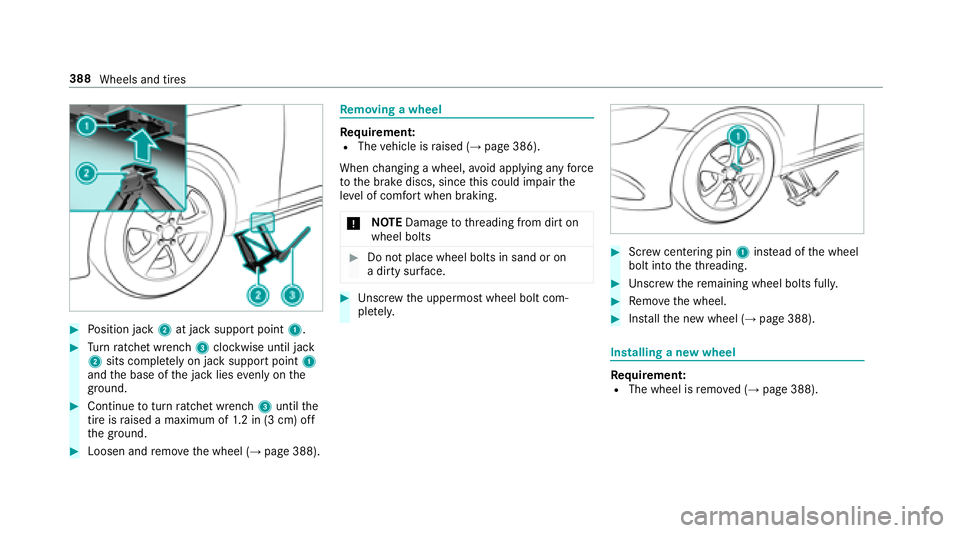

#Position jack 2at jack support point 1.

#Turn ratchet wrench 3clockwise until jack

2 sits comple tely on jack support point 1

and the base of the jack lies evenly on the

ground .

#Continue toturn ratchet wrench 3until the

tire is raised a maximum of 1.2 in (3 cm) off

th e ground.

#Loosen and remo vethe wheel (→page 388).

Re moving a wheel

Requirement:RThe vehicle is raised (→page 386).

When changing a wheel, avoid applying any forc e

to the brake discs, since this could impair the

le ve l of com fort when braking.

* NO

TEDama getothre ading from dirt on

wheel bolts

#Do not place wheel bolts in sand or on

a dirty sur face.

#Un scr ew the uppermost wheel bolt com‐

ple tely.

#Scr ew centering pin 1instead of the wheel

bolt into theth re ading.

#Un scr ew there maining wheel bolts fully.

#Re mo vethe wheel.

#Ins tallth e new wheel (→page 388).

Installing a new wheel

Re quirement:RThe wheel is remo ved (→page 388).

388

Wheels and tires

Page 391 of 502

&WARNING Risk of accident from losing a

wheel

Oiled, greased or damaged wheel bolt/wheel

nut thre ads or wheel hub/wheel mounting

bolt thre ads can cause the wheel bolts/

wheel nuts tocome loose.

As a result, you could lose a wheel while driv‐

ing.

#Ne ver oil or grease theth re ads.

#In theeve nt of damage totheth re ads,

con tact a qualified specialist workshop

immediatel y.

#Have the damaged wheel bolts or dam‐

aged hub thre ads replaced.

#Do not continue driving.

#Obser vethe information on thech oice of

tires (→page 381).

Fo r tires with a specified direction of rotation, an

ar row onthe side wall of the tire indicates the

cor rect dire ction of rotation. Observ eth e direc‐

tion of rotation when ins talling.

#Slide the wheel tobe mounted onto the cen‐

te ring pin and push it on.

&

WARNING Risk of injury from tightening

wheel bolts and nuts

If yo u tighten the wheel bolts or wheel nuts

when theve hicle is raised, the jack could tip.

#Only tighten wheel bolts or wheel nuts

when theve hicle is on the ground.

#Fo r saf etyre asons, only use wheel bolts

which ha vebeen appr ovedby Mercedes-

Benz and forth e wheel in question.

* NO

TEDama getopaintwork of the wheel

ri m when scr ewing on thefirs t wheel bolt

If th e wheel has too much play when scr ew‐

ing in thefirs t wheel bolt, the wheel rim paint

can be dama ged.

#Press the wheel firm lyagainst the

wheel hub when scr ewing on thefirs t

wheel bolt.

#Ti ghten the wheel bolts until they are finger-

tight.

#Un scr ew the centering pin.

#Tighten the last wheel bolt until it is finger-

tight.

#Lo we rth eve hicle (→page 389).

Lo weri ngtheve hicle af ter a wheel change

Re quirements:RThe new wheel has been ins talled

(→page 388).

#Place thera tchet wrench onto the he xagon

nut of the jack so that the lettering "AB" is

visible.

#To lowe r the vehicle: turnthera tchet

wrench of the jack counter-clockwise.

Wheels and tires 389