MERCEDES-BENZ S-CLASS SEDAN & MAYBACH 2019 Owner's Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2019, Model line: S-CLASS SEDAN & MAYBACH, Model: MERCEDES-BENZ S-CLASS SEDAN & MAYBACH 2019Pages: 578, PDF Size: 54.01 MB

Page 461 of 578

#

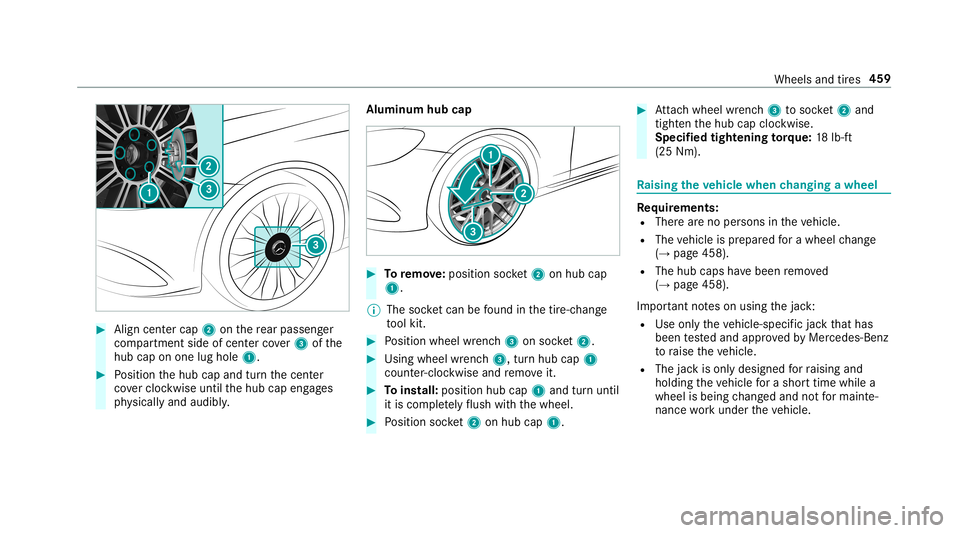

Align cent ercap 2onthere ar passe nger

com partment side ofcen terco ver3 ofthe

hub caponone lughole 1. #

Position thehub capand turnth ecent er

co vercloc kwise untilthehub capengages

ph ysicall yand audibly . Alum

inum hubcap #

Toremo ve:po sitio nsoc ket2 onhubcap

1.

% The socketcan befound inthetir e-c hang e

to ol kit. #

Position wheel wrenc h3 onsoc ket2. #

Usingwheelwr enc h3, turnhu bcap 1

cou nter-clo ckwise andremo veit. #

Toins tall: posit ionhub cap1and turnunt il

it is com pletely flush withth ewheel. #

Position socket2 onhubcap 1. #

Attach wheel wrenc h3 tosoc ket2 and

tig hten thehub capclockwise.

Specif iedtight ening torq ue: 18lb-f t

(25 Nm). Ra

ising theve hicl ewhe nch angi ngawhe el Re

quirement s:

R Ther ear eno per sons intheve hicle.

R The vehicle isprepar edfora whee lch ang e

(→ pag e45 8).

R The hub caps have been remo ved

( → pag e458).

Im por tant noteson using thejac k:

R Use onlyth eve hicle-specif icjac kth at has

been tested and appr oved byMer cedes-Ben z

to raise theve hicle.

R The jackis onl ydesigned forra ising and

holdin gth eve hicle fora shor ttime whilea

whee lis being chang edand notfo rmaint e‐

nance workund ertheve hicle. Wheels

andtires 459

Page 462 of 578

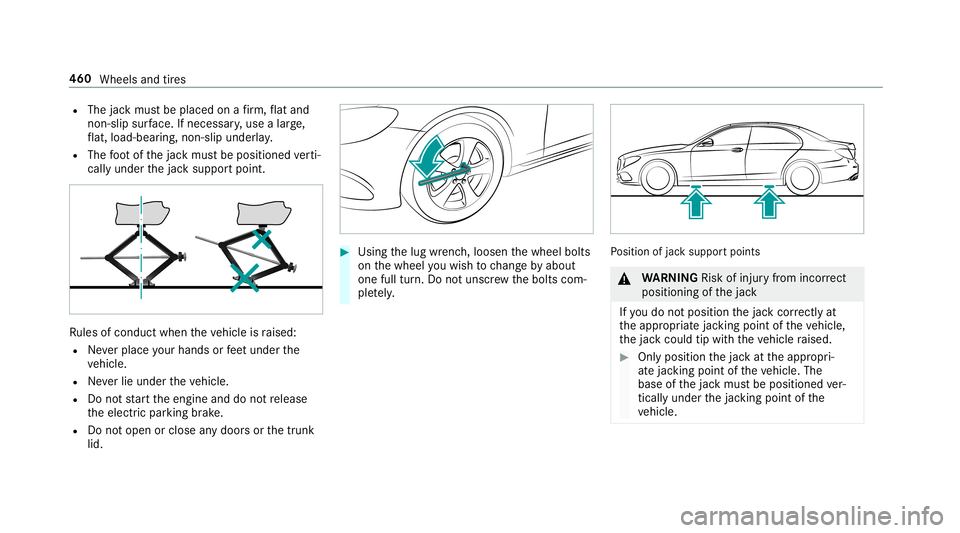

R

The jackmus tbe placed onafirm ,fl at and

no n-slip surface. Ifneces sary,use alar ge,

fl at, load- bearing,no n-slip unde rlay .

R The foot ofthejac kmus tbe position edverti‐

call yunder thejac ksuppor tpoint . Ru

les ofcon duct when theve hicle israised:

R Neverpla ceyour han dsorfeet und erthe

ve hicle.

R Neverlie under theve hicle.

R Donotst ar tth eengine anddonotre lease

th eelectr icpar king brak e.

R Donotopen orclose anydoor sor thetrunk

lid. #

Using thelug wrenc h,loosen thewheel bolts

on thewheel youwish tochang eby about

on efull turn.Do notuns crew thebolts com‐

ple tely. Po

sition ofjac ksuppor tpoints &

WARNIN GRisk ofinju ryfrom incor rect

pos itioning ofthejac k

If yo udo notposi tionth ejac kcor rectly at

th eappr opriatejac king point oftheve hicle,

th ejac kcould tipwithth eve hicle raised. #

Onlyposit ionthejac kat theappr opri‐

at ejac king point oftheve hicle. The

base ofthejac kmus tbe position edver‐

tically underthejac king point ofthe

ve hicle. 460

Wheels andtires

Page 463 of 578

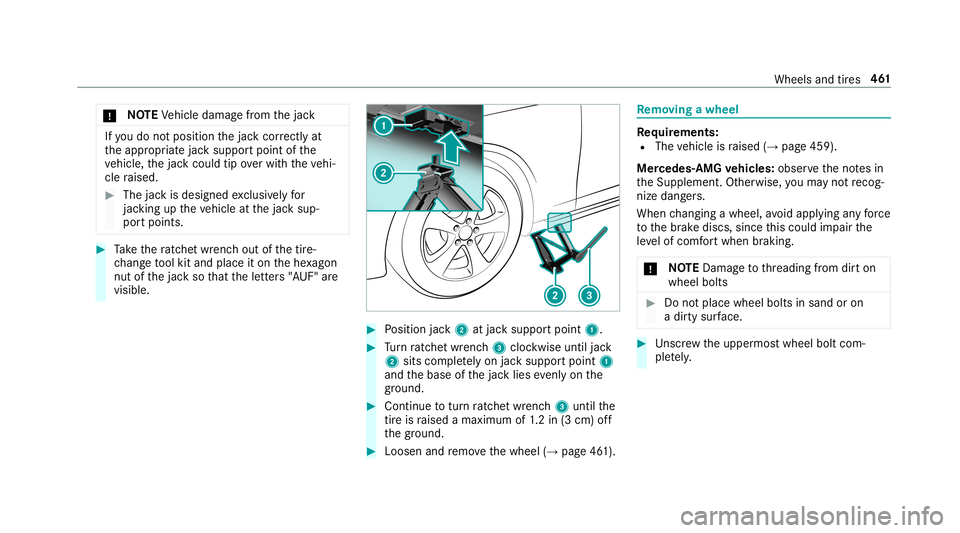

*

NO

TEVehicle damag efrom thejac k If

yo udo notposi tionth ejac kcor rectl yat

th eappr opriatejac ksuppor tpoint ofthe

ve hicle, thejac kcould tipove rwit hth eve hi‐

cle raised. #

The jackis design edexclu sively for

jac king uptheve hicle atthejac ksup‐

por tpoint s. #

Take thera tche twrenc hou tof thetir e-

ch ang eto ol kit and place iton thehe xagon

nut ofthejac kso that theletter s"A UF" are

visible. #

Position jack2 atjac ksuppor tpoint 1. #

Turn ratche twr enc h3 clockwise untiljac k

2 sitscom pletely on jacksuppor tpoint 1

and thebase ofthejac klies evenlyon the

gr ou nd . #

Con tinue totur nra tche twr enc h3 unti lth e

tir eis raised amaxim umof1.2 in (3 cm) off

th egr ound. #

Loosen andremo vethewheel (→pag e46 1). Re

mo ving awh eel Re

quirement s:

R The vehicle israised (→pag e459).

Mer cedes- AMGvehicl es:obse rveth eno tesin

th eSupplement .Ot her wise, youma yno tre cog‐

nize dangers.

Whe nch ang ingawheel, avoidappl ying anyfo rc e

to thebr ak ediscs, sincethis could impair the

le ve lof com fort when brakin g.

* NO

TEDama getothre adin gfrom dirton

wheel bolts #

Donotplace wheel boltsin san dor on

a dir tysur face. #

Unscr ew theupper mostwheel boltcom‐

ple tely. Wh

eelsand tires 46

1

Page 464 of 578

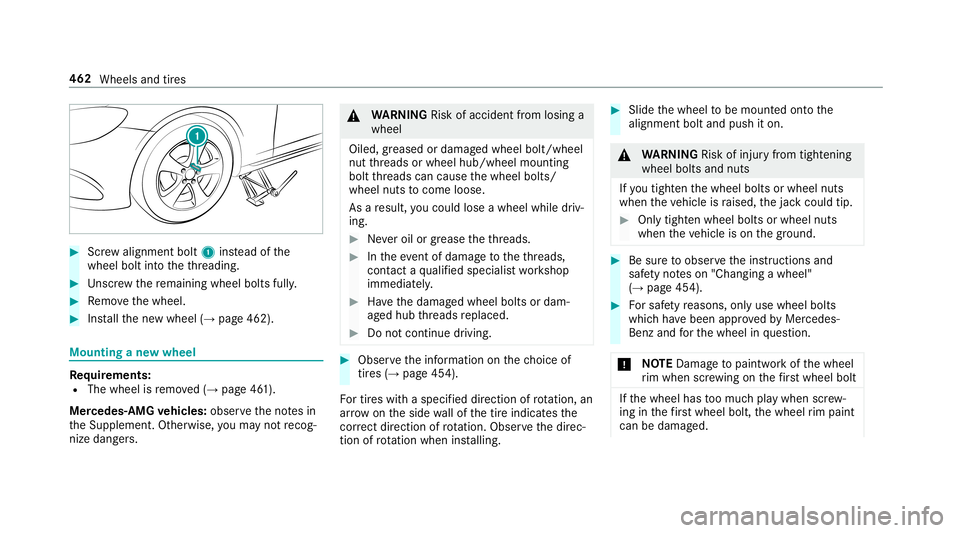

#

Screw align mentbolt 1instead ofthe

wheel boltintoth eth re adin g. #

Unscr ew there maini ngwhee lbolts fully. #

Remo vethewheel. #

Installth ene wwheel (→pag e462). Mounting

ane wwheel Re

quirement s:

R The wheel isremo ved(→ pag e46 1).

Mer cedes- AMGvehicl es:obse rveth eno tesin

th eSupplement .Ot her wise, youma yno tre cog‐

nize dangers. &

WARNIN GRisk ofacci dent from losing a

whe el

Oil ed, grea sed ordamag edwhe elbol t/whe el

nut thre ads orwheel hub/wheel mounting

bolt thre ads can caus eth ewheel bolts/

wheel nutstocome loose.

As are sult, youco uld lose awheel whiledriv‐

ing . #

Neveroil orgrease theth re ads. #

Intheeve ntofdama getotheth re ads,

con tact aqu alif ied spec ialistwo rkshop

immediat ely. #

Have thedamag edwheel boltsordam‐

ag ed hub thre ads replaced. #

Donotcon tinue driving. #

Obser vetheinf ormation onthech oice of

tir es (→ pag e45 4).

Fo rtir es wit haspecif ieddirection ofrotatio n,an

ar row ontheside wallof thetir eindicat esthe

cor rect dire ction ofrotatio n.Ob serveth edir ec‐

tion ofrotatio nwh en installing. #

Slide thewheel tobe mount edont oth e

align mentbolt andpush iton . &

WARNIN GRisk ofinju ryfrom tight ening

whee lbol tsand nuts

If yo utig hten thewheel boltsorwheel nuts

when theve hicle israised, thejac kcould tip. #

Onlytight enwheel boltsorwheel nuts

when theve hicle ison thegr ound. #

Besureto obser vetheins truction sand

saf etyno teson "Cha nging awheel"

(→ pag e45 4). #

Forsaf etyre ason s,on lyuse wheel bolts

whic hha ve been approvedby Mer cedes-

Benz andforth ewheel inqu estion .

* NO

TEDama getopaintw orkof thewheel

ri m when screwing onthefirs twh eelbo lt If

th ewheel hastoomuc hpla ywhen screw‐

ing inthefirs twh eelbo lt, thewheel rim pai nt

can bedama ged. 462

Wheels andtires

Page 465 of 578

#

Press thewheel firm lyag ains tth e

wheel hubwhen screwing onthefirs t

wheel bolt. #

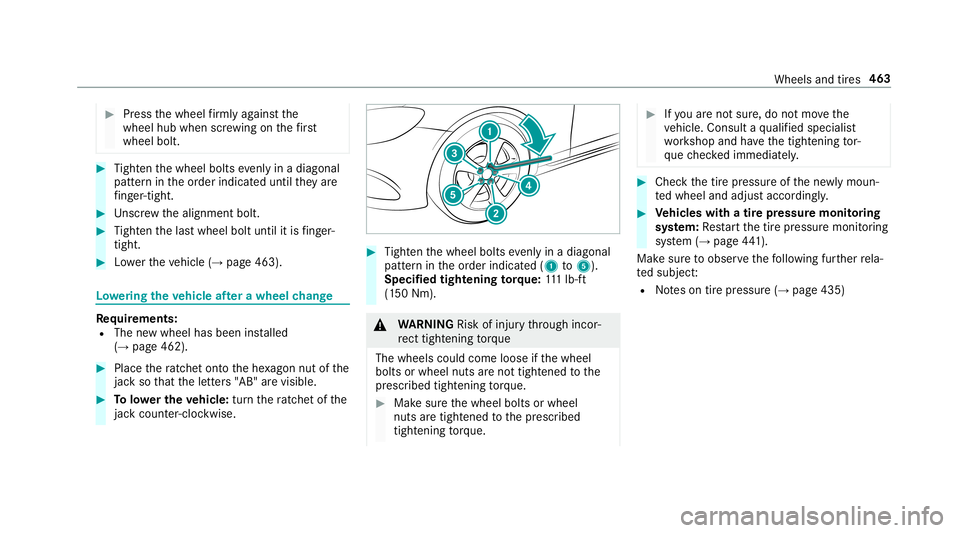

Tight enthewheel boltsevenlyin adi ag ona l

pa tter nin theor der indicat eduntil they are

fi ng er-tig ht. #

Unscr ew thealignment bolt. #

Tight enthelas twheel boltuntil itis fing er-

tig ht. #

Lowe rth eve hicle (→pag e463). Lo

we ring theve hicl eaf te ra wh eelch ang e Re

quirement s:

R The newwheel hasbeen installed

(→ pag e462) . #

Place thera tche tont oth ehe xagon nutofthe

jac kso that theletter s"AB" arevisible. #

Tolowe rthe vehicl e:tur nth era tche tof the

jac kcou nter-clo ckwise. #

Tight enthewheel boltsevenlyin adi ag ona l

pa tter nin theor der indicat ed(1 to5 ).

Specif iedtight ening torq ue: 111 lb-ft

(1 50 Nm). &

WARNIN GRisk ofinju rythro ugh incor‐

re ct tigh tening torq ue

Th ewh eelscou ldcome looseifth ewheel

bolts orwheel nutsareno ttight ened tothe

pr escr ibed tighteningto rq ue. #

Makesur eth ewheel boltsorwheel

nuts aretight ened tothepr escr ibed

tight ening torq ue. #

Ifyo uar eno tsur e,do notmo vethe

ve hicle. Consult aqu alif ied spec ialist

wo rkshop andhave thetight ening tor‐

qu ech eckedimmediat ely. #

Chec kth etir epr essur eof thene wlymoun‐

te dwheel andadjus taccor dingly. #

Vehicl eswith atir epr ess uremonit oring

sy stem: Restar tth etir epr essur emonit oring

sy stem (→pag e44 1).

Ma kesur eto obser vethefo llo wing further rela‐

te dsubjec t:

R Noteson tirepr essur e(→ pag e435) Wheels

andtires 463

Page 466 of 578

No

teson tech nical data

Plug-in hybrid: obser vetheno tesin theSupple‐

ment .Ot her wise, youma yno tre cogni zedan‐

ge rs.

Mer cede s-AMG vehicl es:obse rveth eno tesin

th eSupplement .Ot her wise, youma yno tre cog‐

nize dangers.

The data stat ed onlyapplies tovehicles with

st andar deq uipme nt.Yo ucan obtain further

inf ormation from anaut hor ized Mercedes- Benz

Cent er. Ve

hicl eele ctroni cs Tw

o-w ayradio s No

teson installing two-w ayradio s &

WARNIN GRisk ofacci dent dueto

im proper workon two-w ayradios

The elect romagne ticradiation from two-w ay

ra dios caninterfere wit hth eon- boar delec‐

tr onics ifRF transmit ters areman ipulat edor

re trof itt ed inco rrect ly. This

could jeopar dizetheoper ating safetyof

th eve hicle. #

Yousho uld have all workon electr ical

and electr oniccomponent scar ried out

at aqu alif ied spec ialistwo rkshop. &

WARNIN GRisk ofacci dent from incor ‐

re ct ope ratio nof two-w ayradios

If yo uoper atetw o-wa yra dios incor rectl yin

th eve hicle, theelectr omagne ticradiation

could interfere wit hth eon- boar delectr onics,

e.g. :

R ifth etw o-w ayradio isno tcon nectedto

an exterior ant enna

R ifth eex terior ant enna isno tcor rectly

mou nted orisno tof low reflect ion

This could jeopar diestheoper ating safetyof

th eve hicle. #

Have thelow- reflect ion exterior

ant enna installed ataqu alif ied spec ial‐

is two rkshop. #

When operating two-w ayradios inthe

ve hicle, alwaysconn ectthem tothe

lo w- reflect ion exterior ant enna. *

NO

TEInva lidation oftheoper ating per‐

mit due tofailur eto com plywith the

ins truct ions forins tallation anduse The

oper atingper mit maybe inva lidat edif

th eins truction sfo rins tallation anduseof

tw o-w ayradios areno tobser ved. #

Onlyuse appr oved freq uency bands. #

Obser vethemaximum permissible out‐

put powe rin these freq uency bands. #

Onlyuse appr oved ant enn aposition s. 46

4

Tech nica lda ta

Page 467 of 578

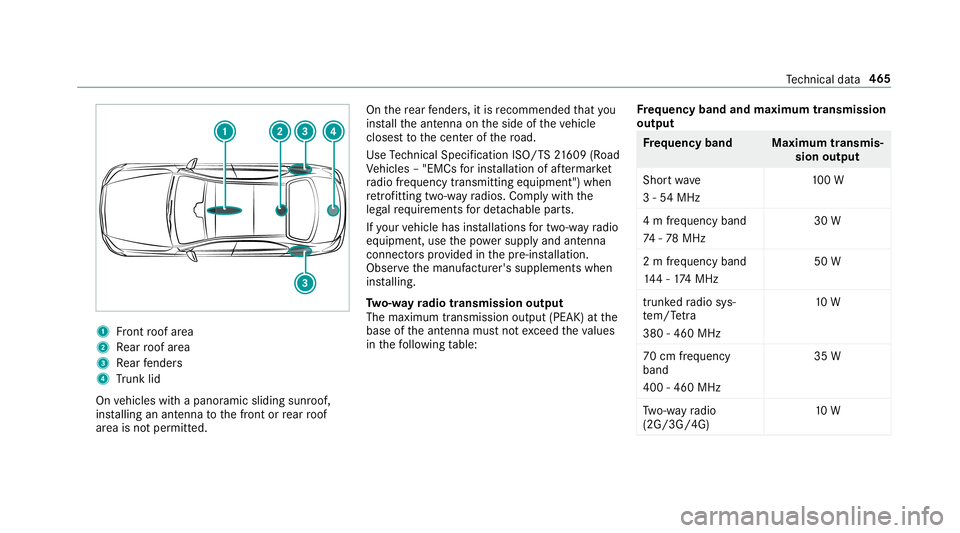

1

Front roof area

2 Rear roof area

3 Rear fende rs

4 Trunk lid

On vehicles withapanor amicsliding sunroof,

ins talling anant enn ato thefront orrear roof

ar ea isno tper mitt ed. On

there ar fende rs,it is recomme ndedthat you

ins tallth eant enn aon theside oftheve hicle

closes tto thecent erofthero ad.

Use Tech nica lSpe cifica tionISO/T S21 609 (Road

Ve hicles –"EMCs forins tallation ofafte rm arke t

ra dio freq uency transmit tingeq uipment ")when

re trof itti ng two-w ayradios. Complywithth e

leg alrequ iremen tsforde tach able parts.

If yo ur vehicle hasinstallation sfo rtw o-w ayradio

eq uipment ,use thepo we rsupp lyand antenn a

con nectors prov ided inthepr e-ins tallation .

Obser vethemanuf acturer'ssupplement swhen

ins talling.

Tw o-w ayradio transmi ssion output

The maxi mum transm ission outpu t(PEAK) atthe

base oftheant enn amus tno texc eed theva lues

in thefo llo wing table: Fr

eq uency bandandmaxim um transm ission

out put Fr

eq uency band Maximumtransm is‐

sion output

Sho rtwa ve

3 -54 MHz 10

0W

4 m freq uency band

74 -78 MHz 30

W

2 m freq uency band

14 4-17 4MHz 50

W

tr unk edradio sys‐

te m/T etra

380 -460 MHz 10

W

70 cm freq uency

band

400 -460 MHz 35

W

Tw o-w ayradio

(2G/3G/ 4G) 10

W Te

ch nica lda ta 465

Page 468 of 578

The

follo wing canbeused intheve hicle without

re strictions :

R RFtransm itterswi th amax imum trans mis‐

sion output ofup to100mW

R RFtransmi tter swit htransmi tter freq uenci es

in the380 -41 0MHz freq uency bandanda

maximu mtransmi ssionoutpu tof up to2W

(tr unk edradio system/T etra )

R mobil ephones (2G/3G/4G)

Ther ear eno restrictions whenpos itioning the

ant enn aon theoutside oftheve hicle forsome

wav ebands.

This applies tothefo llo wing wavebands:

R trunk edradio system/T etra

R 70cm freq uency band

R 2G/3G /4G Ve

hicl eiden tificati onplat e,VIN and engine

number overview

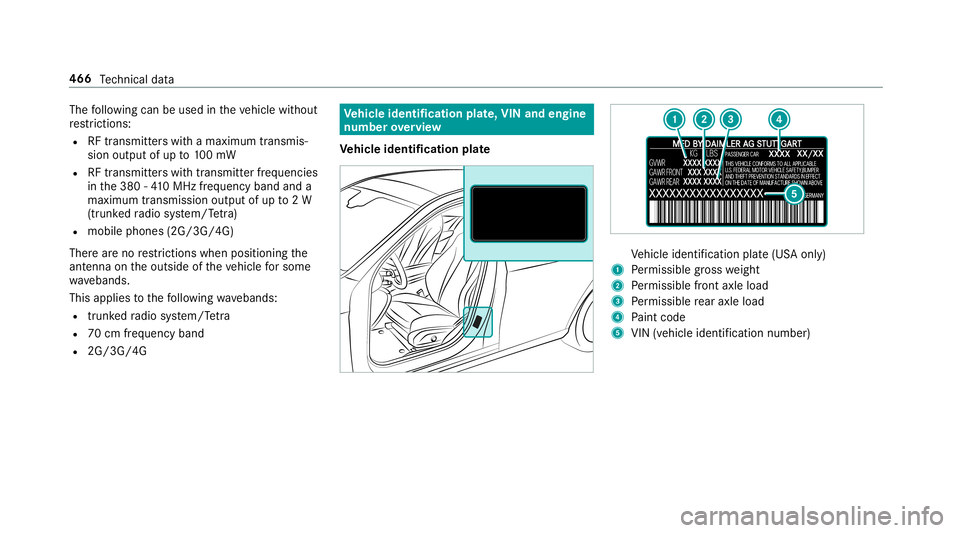

Ve hicl eiden tificati onplat e Ve

hicle identif ication plate(US Aonl y)

1 Perm issible gros swe ight

2 Perm issible front axle load

3 Perm issible rear axle load

4 Paint code

5 VIN (vehicle identificat ion numb er) 466

Tech nica lda ta

Page 469 of 578

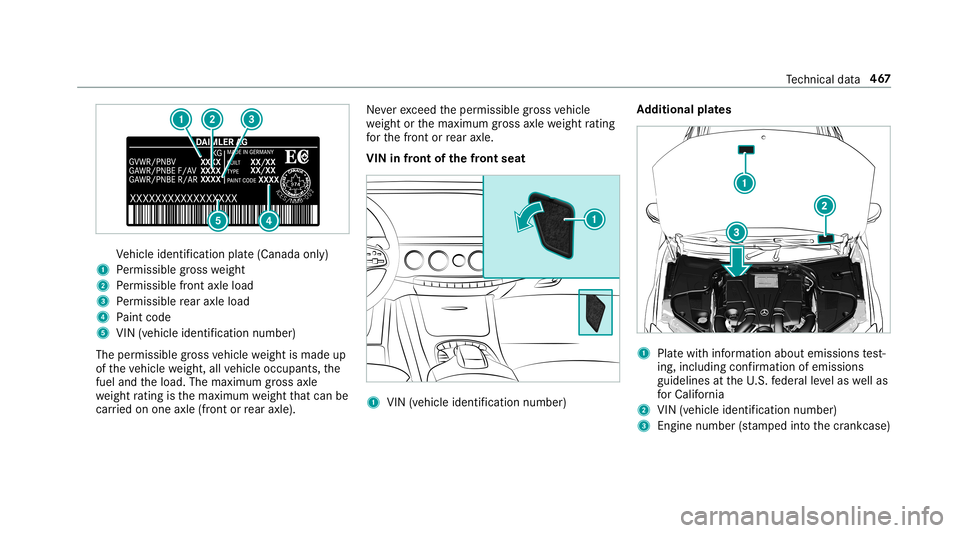

Ve

hicle identif ication plate(Canada only)

1 Perm issible gros swe ight

2 Perm issible front axle load

3 Perm issible rear axle load

4 Paint code

5 VIN (vehicle identificat ion numb er)

The permissib legross vehicle weight ismade up

of theve hicle weight ,all vehicle occupants, the

fuel andtheload. Themaximum gross axle

we ight rating isthemaximum weight that can be

car ried on one axle (front orrear axle ). Ne

verexc eed theper missible gross vehicle

we ight orthemaximum gross axle weight rating

fo rth efront orrear axle .

VIN infront ofthefront seat 1

VIN (vehic leiden tificat ion num ber) Ad

diti onalplat es 1

Platewit hinf ormat ionabout emissionstest‐

ing, including confirm atio nof emis sions

guideli nesattheU. S. feder alleve las wellas

fo rCa lifor nia

2 VIN (vehicl eidentif icationnumber)

3 Engine number (sta mp edintoth ecr ankc ase) Te

ch nica lda ta 46

7

Page 470 of 578

Oper

ating fluids No

teson oper ating fluids Mer

cedes- AMG vehicl es:obse rveth eno tesin

th eSupplement .Ot her wise, youma yfa ilto rec‐

ogni zedangers. &

WARNIN GRisk ofinju ryfrom oper ating

fl uids harmfulto your healt h

Oper atingfluids maybe pois onous and harm‐

ful toyour healt h. #

Obs erve thete xt on theor iginal con‐

ta iner swhen using, stor ing ordisposing

of oper ating fluids. #

Alw aysst or eoper ating fluids seale din

th eir original container s. #

Alw ayske ep childr enaway from oper at‐

ing fluids. &

WARNIN GRisk offire or explosion from

fuel

Fu els arehighly flammab le. #

Fire,open flames ,smo kingand creat ion

of spar ksmus tbe avo ided. #

Swit choffth eignition and,ifav ailable,

th est atio naryheat er,bef oreand while

re fuel ingtheve hicle. &

WARNIN GRisk ofinju ryfrom fuels

Fu els arepoisonous andhazar dous toyour

healt h. #

Donotsw allo wfuel orletit co me into

co ntact withsk in, eyes orclo thing. #

Donotinhale fuelvapor . #

Keep childr enaway from fuel. #

Keep door sand windo wsclos edduring

th ere fuel ingprocess.

If yo uor other people comeintocont actwith

fuel, obser vethefo llo wing: #

Imm ediat elyrinse fuelof fyo ur skin wit h

soap andwater. #

Iffuel comes intocont actwithyo ur

ey es, immediat elyrinse them thor‐ oughl

ywit hclean water.Seek medical

att entio nimm ediately . #

Ifyo usw allo wfuel, seek medicalatten‐

tio nimm ediat ely. Do notind uce vomit‐

ing. #

Cha ngeimmedi ately out ofclo thing that

has com eint ocon tact with fuel . +

ENVIR

ONMENT ALNOTEEnvironme ntal

po lluti on cau sed byenvironmen tallyirre ‐

sponsible disposal #

Dispose ofoper ating fluids inan envi‐

ro nment ally responsible manner. Oper

ating fluids include thefo llo wing:

R Fuels

R Lubricant s

R Coolant

R Brak efluid

R Windsh ield wa sher fluid

R Climat eco ntro lsy stem refrig er ant 468

Tech nica lda ta