wheel bolts MERCEDES-BENZ S-CLASS SEDAN & MAYBACH 2019 Owner's Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2019, Model line: S-CLASS SEDAN & MAYBACH, Model: MERCEDES-BENZ S-CLASS SEDAN & MAYBACH 2019Pages: 578, PDF Size: 54.01 MB

Page 411 of 578

No

teson car eof vehicl epar ts &

WARNIN GRisk ofentr apment ifth e

winds hieldwiper sar eswit ched on while

th ewindshield isbeing cleaned

If th ewindshield wipersar ese tin mo tion

while youar ecle anin gth ewindshield or

wiper blades, youcan betrapped bythe

wiper arm. #

Alw aysswitc hof fth ewindshield wipers

and theignition beforecleanin gth e

winds hieldorwiper blades. &

WARNIN GRisk ofburning from theta il‐

pipe ortailpipe trim

The tailpipe andtailpipe trim can becom e

ve ry hot.Ifyo uco me intoco ntact withth ese

car parts,youco uld burnyo urself . #

Alw aysbe par ticular lycareful whenin

th evicinit yof theta ilpipe andtailpipe

tr ims and super visechildr envery

clos elywhe nin this area. #

Beforean ycon tact, allo w thecar parts

to cool down. Obs

erve thefo llo wing informa tion: No

teson cleaning andcareA voiding vehicl edamag e

Wheel s/rims

Usewaterand acid-free whee lclea ners. R

Donotuse acidicwhee lclea nersto remo vebrak edus t.

This could damag ewheel boltsandbrak ecom ponen ts.

R Toavoid corrosion ofthebr ak ediscs andbrak epads, drive

th eve hicle fora fe w min utes afte rclea ning beforepar king

it. The brak ediscs andbrak epa dswarm upand dryout .

Wi ndo ws

Cleanthewindo wsontheinside andoutside usingadam p

clo thand cleanin gag ent sre comme ndedbyMer cedes-Ben z.Do

notuse dryclo thsor abr asiv eor sol vent-ba sedcleani ng

ag ents tocle an theinside ofwindo ws.

Wi per blades

Foldout thewiper blades andclean them using adam pclo th.D ono tclean thewiper blades tooof ten. Ma

intena nce and care40

9

Page 462 of 578

R

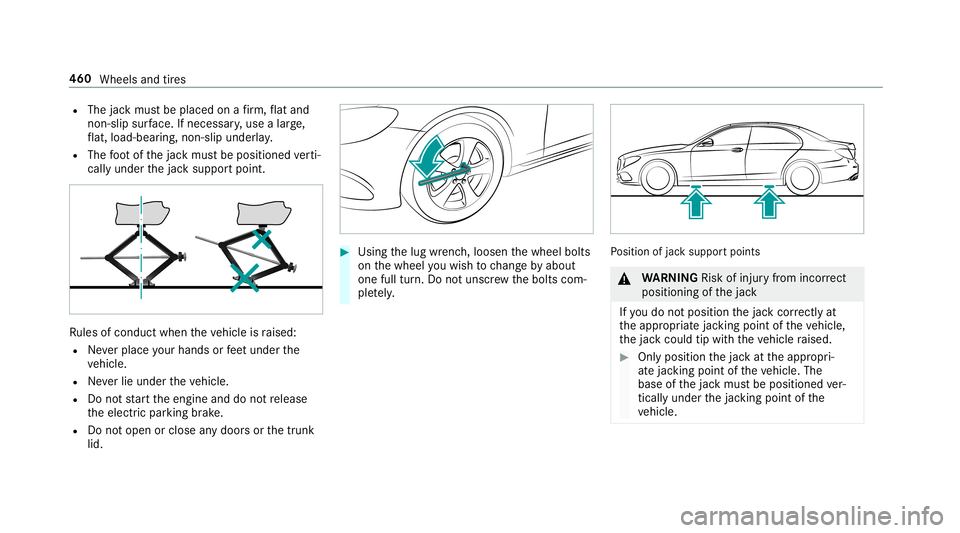

The jackmus tbe placed onafirm ,fl at and

no n-slip surface. Ifneces sary,use alar ge,

fl at, load- bearing,no n-slip unde rlay .

R The foot ofthejac kmus tbe position edverti‐

call yunder thejac ksuppor tpoint . Ru

les ofcon duct when theve hicle israised:

R Neverpla ceyour han dsorfeet und erthe

ve hicle.

R Neverlie under theve hicle.

R Donotst ar tth eengine anddonotre lease

th eelectr icpar king brak e.

R Donotopen orclose anydoor sor thetrunk

lid. #

Using thelug wrenc h,loosen thewheel bolts

on thewheel youwish tochang eby about

on efull turn.Do notuns crew thebolts com‐

ple tely. Po

sition ofjac ksuppor tpoints &

WARNIN GRisk ofinju ryfrom incor rect

pos itioning ofthejac k

If yo udo notposi tionth ejac kcor rectly at

th eappr opriatejac king point oftheve hicle,

th ejac kcould tipwithth eve hicle raised. #

Onlyposit ionthejac kat theappr opri‐

at ejac king point oftheve hicle. The

base ofthejac kmus tbe position edver‐

tically underthejac king point ofthe

ve hicle. 460

Wheels andtires

Page 463 of 578

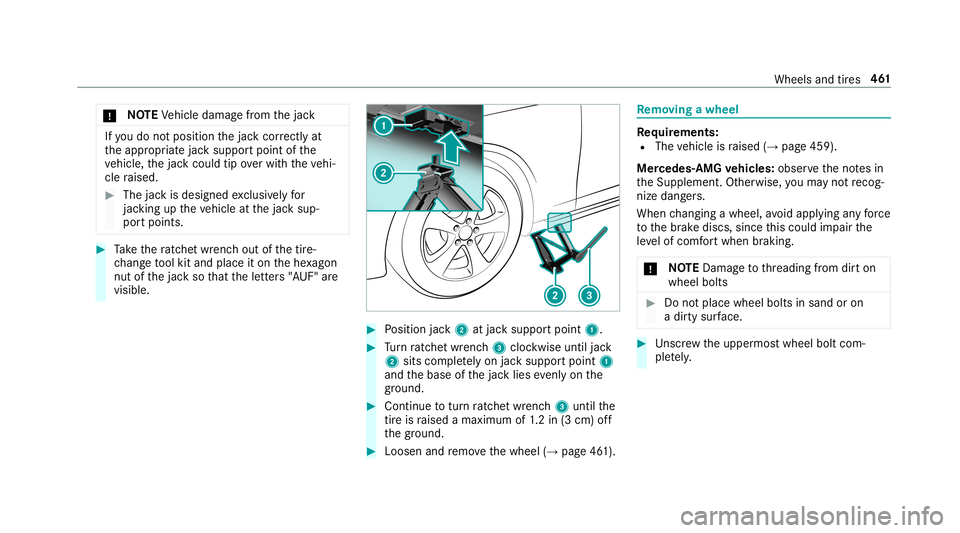

*

NO

TEVehicle damag efrom thejac k If

yo udo notposi tionth ejac kcor rectl yat

th eappr opriatejac ksuppor tpoint ofthe

ve hicle, thejac kcould tipove rwit hth eve hi‐

cle raised. #

The jackis design edexclu sively for

jac king uptheve hicle atthejac ksup‐

por tpoint s. #

Take thera tche twrenc hou tof thetir e-

ch ang eto ol kit and place iton thehe xagon

nut ofthejac kso that theletter s"A UF" are

visible. #

Position jack2 atjac ksuppor tpoint 1. #

Turn ratche twr enc h3 clockwise untiljac k

2 sitscom pletely on jacksuppor tpoint 1

and thebase ofthejac klies evenlyon the

gr ou nd . #

Con tinue totur nra tche twr enc h3 unti lth e

tir eis raised amaxim umof1.2 in (3 cm) off

th egr ound. #

Loosen andremo vethewheel (→pag e46 1). Re

mo ving awh eel Re

quirement s:

R The vehicle israised (→pag e459).

Mer cedes- AMGvehicl es:obse rveth eno tesin

th eSupplement .Ot her wise, youma yno tre cog‐

nize dangers.

Whe nch ang ingawheel, avoidappl ying anyfo rc e

to thebr ak ediscs, sincethis could impair the

le ve lof com fort when brakin g.

* NO

TEDama getothre adin gfrom dirton

wheel bolts #

Donotplace wheel boltsin san dor on

a dir tysur face. #

Unscr ew theupper mostwheel boltcom‐

ple tely. Wh

eelsand tires 46

1

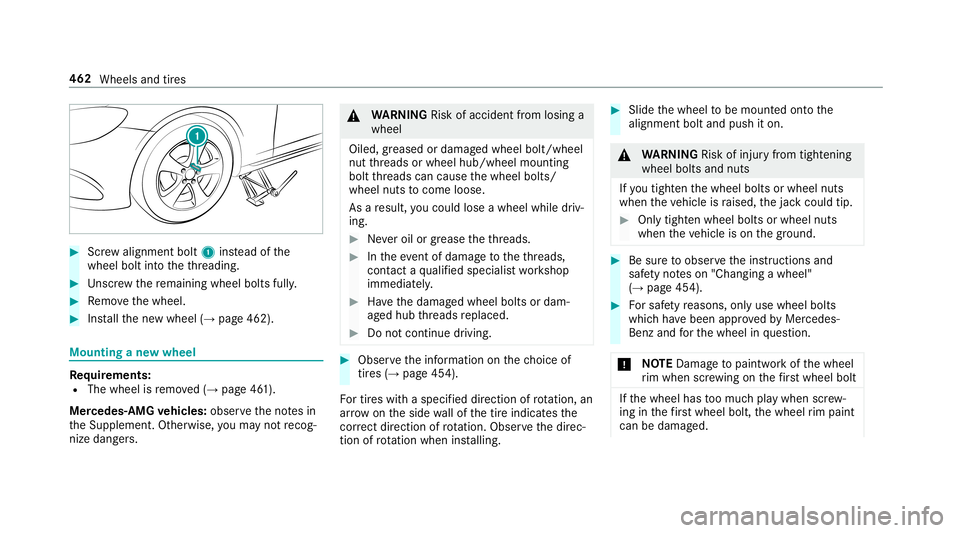

Page 464 of 578

#

Screw align mentbolt 1instead ofthe

wheel boltintoth eth re adin g. #

Unscr ew there maini ngwhee lbolts fully. #

Remo vethewheel. #

Installth ene wwheel (→pag e462). Mounting

ane wwheel Re

quirement s:

R The wheel isremo ved(→ pag e46 1).

Mer cedes- AMGvehicl es:obse rveth eno tesin

th eSupplement .Ot her wise, youma yno tre cog‐

nize dangers. &

WARNIN GRisk ofacci dent from losing a

whe el

Oil ed, grea sed ordamag edwhe elbol t/whe el

nut thre ads orwheel hub/wheel mounting

bolt thre ads can caus eth ewheel bolts/

wheel nutstocome loose.

As are sult, youco uld lose awheel whiledriv‐

ing . #

Neveroil orgrease theth re ads. #

Intheeve ntofdama getotheth re ads,

con tact aqu alif ied spec ialistwo rkshop

immediat ely. #

Have thedamag edwheel boltsordam‐

ag ed hub thre ads replaced. #

Donotcon tinue driving. #

Obser vetheinf ormation onthech oice of

tir es (→ pag e45 4).

Fo rtir es wit haspecif ieddirection ofrotatio n,an

ar row ontheside wallof thetir eindicat esthe

cor rect dire ction ofrotatio n.Ob serveth edir ec‐

tion ofrotatio nwh en installing. #

Slide thewheel tobe mount edont oth e

align mentbolt andpush iton . &

WARNIN GRisk ofinju ryfrom tight ening

whee lbol tsand nuts

If yo utig hten thewheel boltsorwheel nuts

when theve hicle israised, thejac kcould tip. #

Onlytight enwheel boltsorwheel nuts

when theve hicle ison thegr ound. #

Besureto obser vetheins truction sand

saf etyno teson "Cha nging awheel"

(→ pag e45 4). #

Forsaf etyre ason s,on lyuse wheel bolts

whic hha ve been approvedby Mer cedes-

Benz andforth ewheel inqu estion .

* NO

TEDama getopaintw orkof thewheel

ri m when screwing onthefirs twh eelbo lt If

th ewheel hastoomuc hpla ywhen screw‐

ing inthefirs twh eelbo lt, thewheel rim pai nt

can bedama ged. 462

Wheels andtires

Page 465 of 578

#

Press thewheel firm lyag ains tth e

wheel hubwhen screwing onthefirs t

wheel bolt. #

Tight enthewheel boltsevenlyin adi ag ona l

pa tter nin theor der indicat eduntil they are

fi ng er-tig ht. #

Unscr ew thealignment bolt. #

Tight enthelas twheel boltuntil itis fing er-

tig ht. #

Lowe rth eve hicle (→pag e463). Lo

we ring theve hicl eaf te ra wh eelch ang e Re

quirement s:

R The newwheel hasbeen installed

(→ pag e462) . #

Place thera tche tont oth ehe xagon nutofthe

jac kso that theletter s"AB" arevisible. #

Tolowe rthe vehicl e:tur nth era tche tof the

jac kcou nter-clo ckwise. #

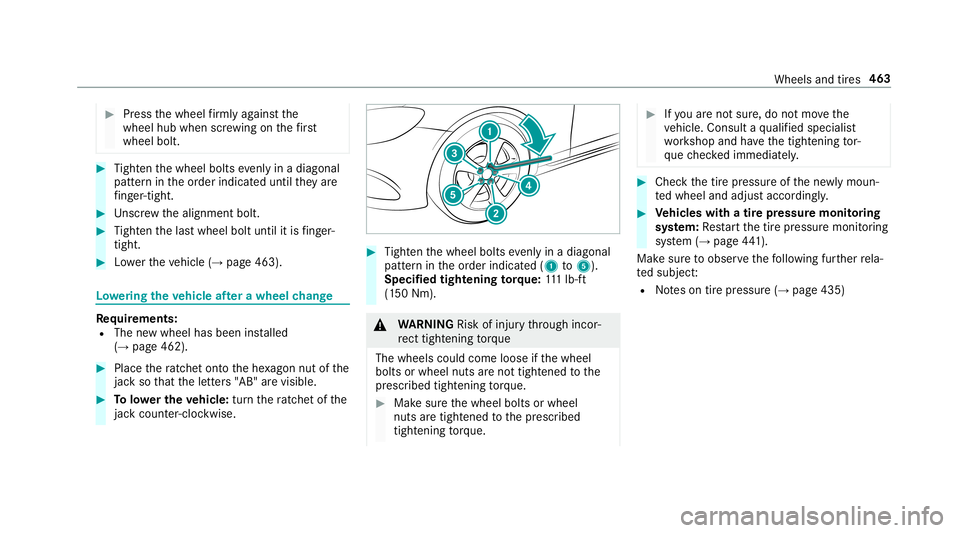

Tight enthewheel boltsevenlyin adi ag ona l

pa tter nin theor der indicat ed(1 to5 ).

Specif iedtight ening torq ue: 111 lb-ft

(1 50 Nm). &

WARNIN GRisk ofinju rythro ugh incor‐

re ct tigh tening torq ue

Th ewh eelscou ldcome looseifth ewheel

bolts orwheel nutsareno ttight ened tothe

pr escr ibed tighteningto rq ue. #

Makesur eth ewheel boltsorwheel

nuts aretight ened tothepr escr ibed

tight ening torq ue. #

Ifyo uar eno tsur e,do notmo vethe

ve hicle. Consult aqu alif ied spec ialist

wo rkshop andhave thetight ening tor‐

qu ech eckedimmediat ely. #

Chec kth etir epr essur eof thene wlymoun‐

te dwheel andadjus taccor dingly. #

Vehicl eswith atir epr ess uremonit oring

sy stem: Restar tth etir epr essur emonit oring

sy stem (→pag e44 1).

Ma kesur eto obser vethefo llo wing further rela‐

te dsubjec t:

R Noteson tirepr essur e(→ pag e435) Wheels

andtires 463