warning light MERCEDES-BENZ SL CLASS 2011 Owner's Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2011, Model line: SL CLASS, Model: MERCEDES-BENZ SL CLASS 2011Pages: 316, PDF Size: 6.55 MB

Page 223 of 316

GWarning!

Do not bleach or dye seat belts as this may

severely weaken them. In a crash they may

not be able to provide adequate protection.

Upholstery

Using aftermarket seat covers or wearing

clothing that have the tendency to give off

coloring (e.g. when wet, etc.) may cause the

upholstery to become permanently

discolored. By lining the seats with a proper

intermediate cover, contact-discoloration will

be prevented.

Leather upholstery

Please note that leather upholstery is a

natural product and is therefore subject to a

natural aging process. Leather upholstery

may also react to certain ambient influences

such as high humidity or high temperature by

showing wrinkles for example.

XWipe leather upholstery with a damp cloth

and dry thoroughly or clean with Mercedes-

Benz approved Leather Care.

! To avoid damage to leather upholstery:

R Wipe with light pressure only.

R Do not clean with abrasive cleaning

agents such as scouring milk or powder.

R Do not soak the leather upholstery.

As leather is a natural product, it could

otherwise harden or become porous.

R Exercise particular care when cleaning

perforated leather as its underside

should not become wet.

Wood trims

XOnly use water and a damp cloth to clean

wood trims in your vehicle.

! Do not use solvents like tar remover or

wheel cleaner nor polishes or waxes as

these may be abrasive.

Chrome-plated exhaust tip

Regular cleaning and care of chrome-plated

exhaust tips will help to maintain their shine

and the classy appearance.

XUse Mercedes-Benz approved Chrome

Polishing Paste each time the vehicle has

been washed, especially during the winter.

! Do not use alkaline cleaners such as

wheel cleaners as they could cause

corrosion.

Vehicle care221Operation230_AKB; 6; 22, en-USd2ureepe,Version: 2.11.8.12009-07-28T18:49:58+02:00 - Seite 221Z

Page 275 of 316

GObserve Safety notes, see page 271.

ROnly use 12-volt bulbs of the same type and

with the specified watt rating.

RSwitch the lights off before changing a bulb

to prevent short circuits.

RAlways use a clean lint-free cloth when

handling bulbs.

RYour hands should be dry and free of oil and

grease.

RIf the newly installed bulb does not come

on, contact an authorized Mercedes-Benz

Center.

iMercedes-Benz recommends using

Longlife (LL) bulbs.

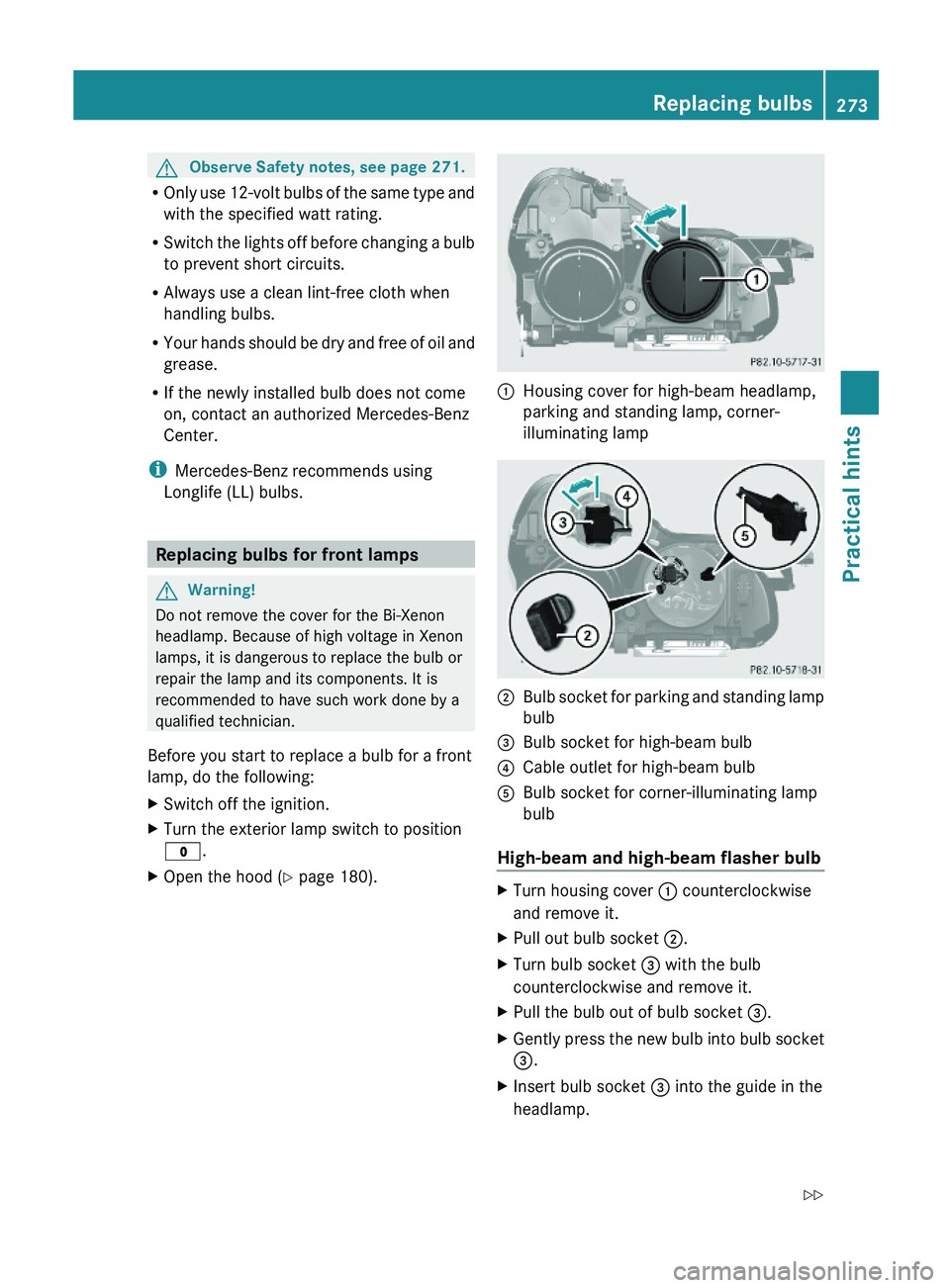

Replacing bulbs for front lamps

GWarning!

Do not remove the cover for the Bi-Xenon

headlamp. Because of high voltage in Xenon

lamps, it is dangerous to replace the bulb or

repair the lamp and its components. It is

recommended to have such work done by a

qualified technician.

Before you start to replace a bulb for a front

lamp, do the following:

XSwitch off the ignition.XTurn the exterior lamp switch to position

\000'.

XOpen the hood (Y page 180).\000FHousing cover for high-beam headlamp,

parking and standing lamp, corner-

illuminating lamp

\000GBulb socket for parking and standing lamp

bulb

\000

Page 280 of 316

XPress on both clips \000G simultaneously to

release buckle \000F.

XStore the tensioning straps in a safe place.

You will need them to store the spare wheel

in the trunk after use (Y page 225).

Lifting the vehicle

GWarning!

When jacking up the vehicle, only use the jack

which has been specifically approved by

Mercedes-Benz for your vehicle.

The jack is designed exclusively for jacking up

the vehicle at the jack tubes built into both

sides of the vehicle. Make sure the jack arm

is fully inserted in the jack tube. The jack must

always be vertical when in use, especially on

inclines or declines.

The jack is intended only for lifting the vehicle

briefly for wheel changes. It is not suited for

performing maintenance work under the

vehicle. To help avoid personal injury, use the

jack only to lift the vehicle during a wheel

change.

Never get beneath the vehicle while it is

supported by the jack. Keep hands and feet

away from the area under the lifted vehicle.

Always lower the vehicle onto sufficient

capacity jackstands before working under the

vehicle.

Always engage the parking brake firmly and

block the wheels with wheel chocks or other

sizeable objects before raising the vehicle

with the jack. Do not disengage the parking

brake while the vehicle is raised.

Make sure that the ground on which the

vehicle is standing and where you place the

jack is solid, level and not slippery. If

necessary, use a large underlay. On slippery

surfaces, such as tiled floors, you should use

a non-slip underlay, for example a rubber mat.

Do not use wooden blocks or similar objects

to support the jack. Otherwise the jack may

not be able to achieve its load-bearing

capacity if it is not at its full height.

Never start the engine when the vehicle is

raised.

Also observe the notes on the jack.

XPrevent the vehicle from rolling away by

blocking wheels with wheel chocks (not

included) or other sizeable objects.

When changing a wheel on a level surface:

XPlace a wheel chock or other sizeable

object in front of and another wheel chock

or other sizeable object behind the wheel

that is diagonally opposite to the wheel

being changed.

Always try lifting the vehicle using the jack on

a level surface. However, should

circumstances require you to do so on a hill:

XPlace wheel chocks or other sizeable

objects on the downhill side in front of both

wheels on the side opposite to the side on

which the wheel is to be changed.

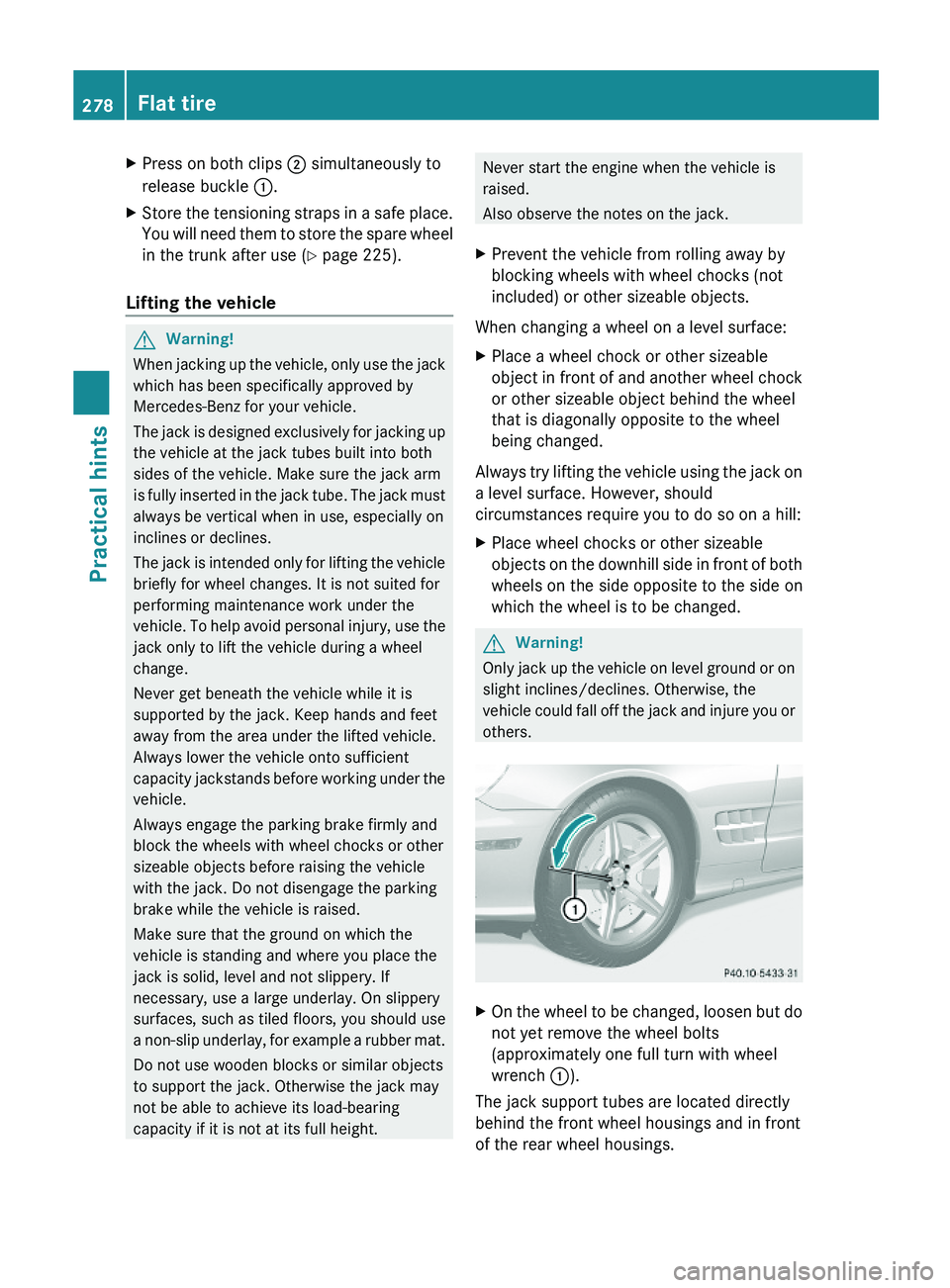

GWarning!

Only jack up the vehicle on level ground or on

slight inclines/declines. Otherwise, the

vehicle could fall off the jack and injure you or

others.

XOn the wheel to be changed, loosen but do

not yet remove the wheel bolts

(approximately one full turn with wheel

wrench \000F).

The jack support tubes are located directly

behind the front wheel housings and in front

of the rear wheel housings.

278Flat tirePractical hints

230_AKB; 6; 22, en-USd2ureepe,Version: 2.11.8.12009-07-28T18:49:58+02:00 - Seite 278

Page 282 of 316

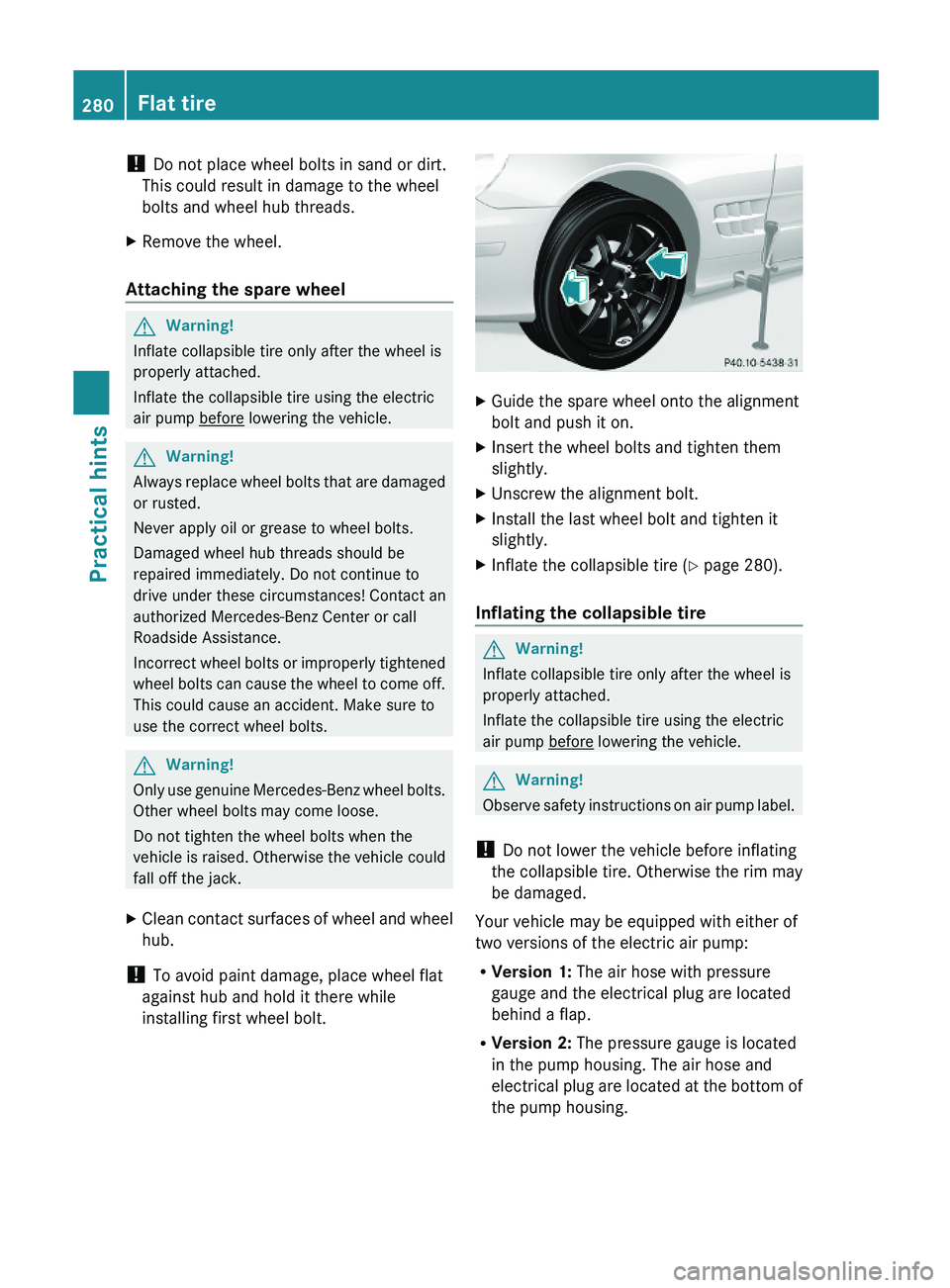

! Do not place wheel bolts in sand or dirt.

This could result in damage to the wheel

bolts and wheel hub threads.

XRemove the wheel.

Attaching the spare wheel

GWarning!

Inflate collapsible tire only after the wheel is

properly attached.

Inflate the collapsible tire using the electric

air pump before lowering the vehicle.

GWarning!

Always replace wheel bolts that are damaged

or rusted.

Never apply oil or grease to wheel bolts.

Damaged wheel hub threads should be

repaired immediately. Do not continue to

drive under these circumstances! Contact an

authorized Mercedes-Benz Center or call

Roadside Assistance.

Incorrect wheel bolts or improperly tightened

wheel bolts can cause the wheel to come off.

This could cause an accident. Make sure to

use the correct wheel bolts.

GWarning!

Only use genuine Mercedes-Benz wheel bolts.

Other wheel bolts may come loose.

Do not tighten the wheel bolts when the

vehicle is raised. Otherwise the vehicle could

fall off the jack.

XClean contact surfaces of wheel and wheel

hub.

! To avoid paint damage, place wheel flat

against hub and hold it there while

installing first wheel bolt.

XGuide the spare wheel onto the alignment

bolt and push it on.

XInsert the wheel bolts and tighten them

slightly.

XUnscrew the alignment bolt.XInstall the last wheel bolt and tighten it

slightly.

XInflate the collapsible tire (Y page 280).

Inflating the collapsible tire

GWarning!

Inflate collapsible tire only after the wheel is

properly attached.

Inflate the collapsible tire using the electric

air pump before lowering the vehicle.

GWarning!

Observe safety instructions on air pump label.

! Do not lower the vehicle before inflating

the collapsible tire. Otherwise the rim may

be damaged.

Your vehicle may be equipped with either of

two versions of the electric air pump:

RVersion 1: The air hose with pressure

gauge and the electrical plug are located

behind a flap.

RVersion 2: The pressure gauge is located

in the pump housing. The air hose and

electrical plug are located at the bottom of

the pump housing.

280Flat tirePractical hints

230_AKB; 6; 22, en-USd2ureepe,Version: 2.11.8.12009-07-28T18:49:58+02:00 - Seite 280

Page 291 of 316

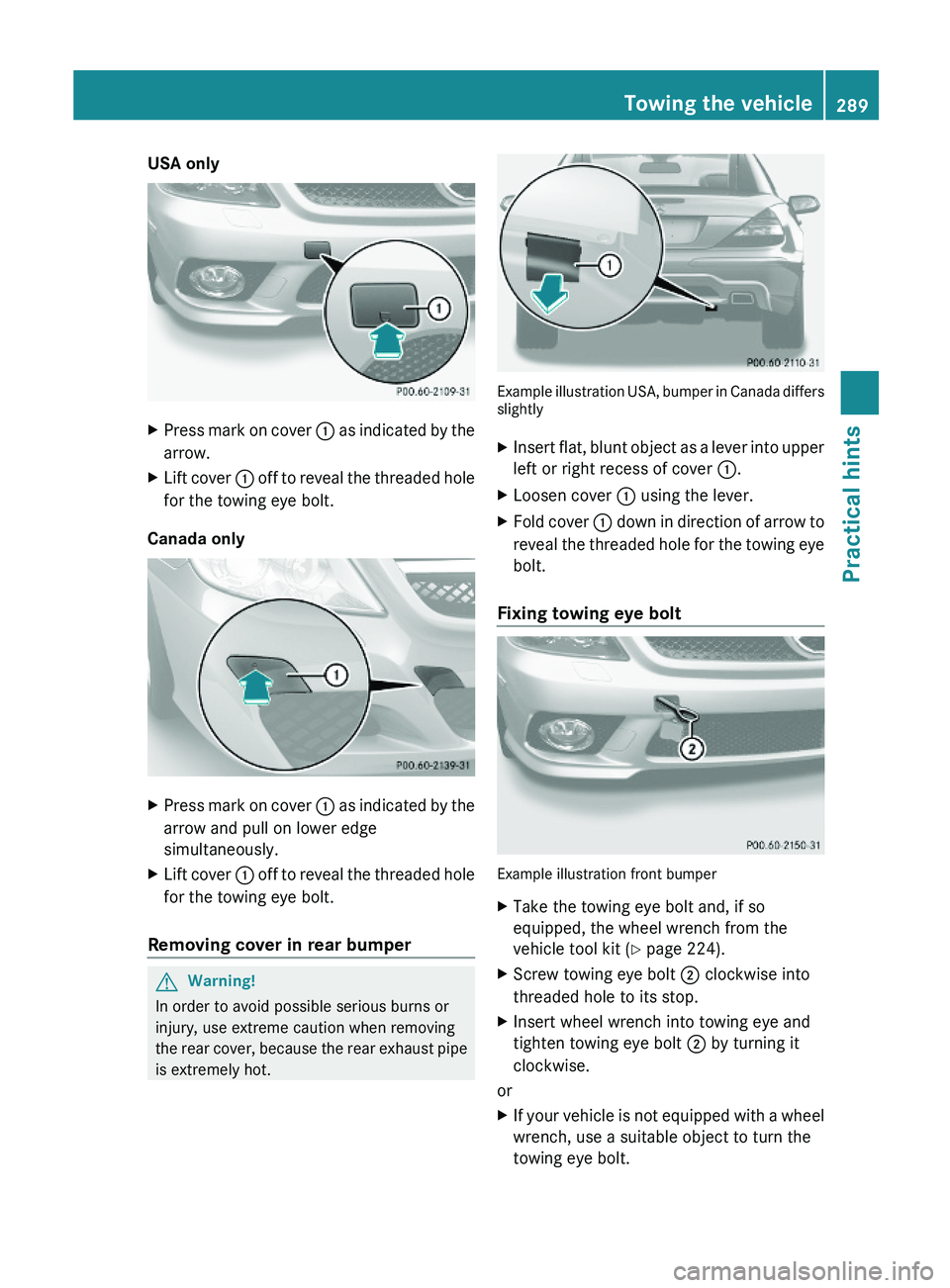

USA onlyXPress mark on cover \000F as indicated by the

arrow.

XLift cover \000F off to reveal the threaded hole

for the towing eye bolt.

Canada only

XPress mark on cover \000F as indicated by the

arrow and pull on lower edge

simultaneously.

XLift cover \000F off to reveal the threaded hole

for the towing eye bolt.

Removing cover in rear bumper

GWarning!

In order to avoid possible serious burns or

injury, use extreme caution when removing

the rear cover, because the rear exhaust pipe

is extremely hot.

Example illustration USA, bumper in Canada differsslightly

XInsert flat, blunt object as a lever into upper

left or right recess of cover \000F.

XLoosen cover \000F using the lever.XFold cover \000F down in direction of arrow to

reveal the threaded hole for the towing eye

bolt.

Fixing towing eye bolt

Example illustration front bumper

XTake the towing eye bolt and, if so

equipped, the wheel wrench from the

vehicle tool kit (Y page 224).

XScrew towing eye bolt \000G clockwise into

threaded hole to its stop.

XInsert wheel wrench into towing eye and

tighten towing eye bolt \000G by turning it

clockwise.

or

XIf your vehicle is not equipped with a wheel

wrench, use a suitable object to turn the

towing eye bolt.

Towing the vehicle289Practical hints230_AKB; 6; 22, en-USd2ureepe,Version: 2.11.8.12009-07-28T18:49:58+02:00 - Seite 289Z