light MERCEDES-BENZ SL CLASS 2011 Workshop Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2011, Model line: SL CLASS, Model: MERCEDES-BENZ SL CLASS 2011Pages: 316, PDF Size: 6.55 MB

Page 275 of 316

GObserve Safety notes, see page 271.

ROnly use 12-volt bulbs of the same type and

with the specified watt rating.

RSwitch the lights off before changing a bulb

to prevent short circuits.

RAlways use a clean lint-free cloth when

handling bulbs.

RYour hands should be dry and free of oil and

grease.

RIf the newly installed bulb does not come

on, contact an authorized Mercedes-Benz

Center.

iMercedes-Benz recommends using

Longlife (LL) bulbs.

Replacing bulbs for front lamps

GWarning!

Do not remove the cover for the Bi-Xenon

headlamp. Because of high voltage in Xenon

lamps, it is dangerous to replace the bulb or

repair the lamp and its components. It is

recommended to have such work done by a

qualified technician.

Before you start to replace a bulb for a front

lamp, do the following:

XSwitch off the ignition.XTurn the exterior lamp switch to position

\000'.

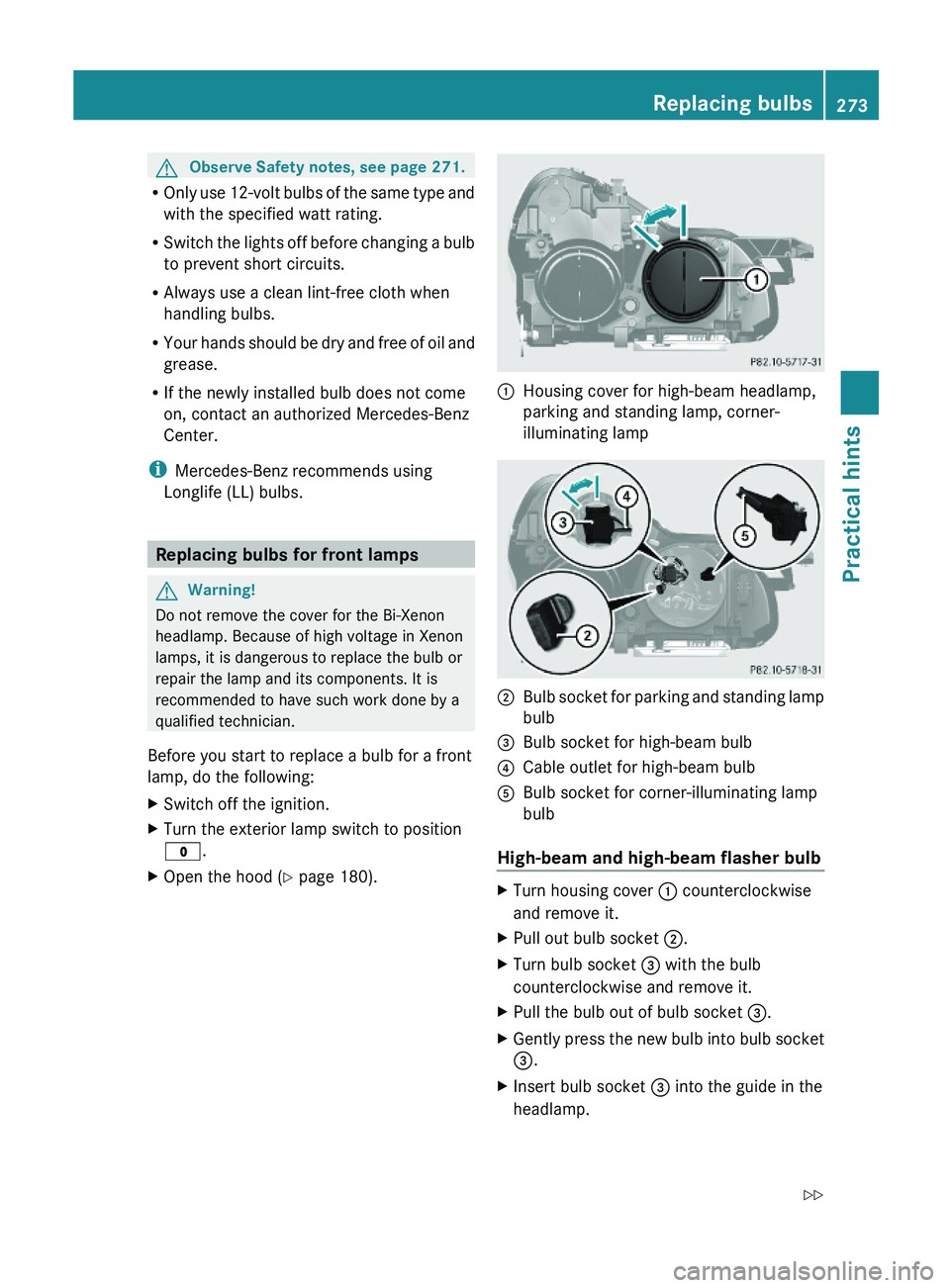

XOpen the hood (Y page 180).\000FHousing cover for high-beam headlamp,

parking and standing lamp, corner-

illuminating lamp

\000GBulb socket for parking and standing lamp

bulb

\000

Page 280 of 316

XPress on both clips \000G simultaneously to

release buckle \000F.

XStore the tensioning straps in a safe place.

You will need them to store the spare wheel

in the trunk after use (Y page 225).

Lifting the vehicle

GWarning!

When jacking up the vehicle, only use the jack

which has been specifically approved by

Mercedes-Benz for your vehicle.

The jack is designed exclusively for jacking up

the vehicle at the jack tubes built into both

sides of the vehicle. Make sure the jack arm

is fully inserted in the jack tube. The jack must

always be vertical when in use, especially on

inclines or declines.

The jack is intended only for lifting the vehicle

briefly for wheel changes. It is not suited for

performing maintenance work under the

vehicle. To help avoid personal injury, use the

jack only to lift the vehicle during a wheel

change.

Never get beneath the vehicle while it is

supported by the jack. Keep hands and feet

away from the area under the lifted vehicle.

Always lower the vehicle onto sufficient

capacity jackstands before working under the

vehicle.

Always engage the parking brake firmly and

block the wheels with wheel chocks or other

sizeable objects before raising the vehicle

with the jack. Do not disengage the parking

brake while the vehicle is raised.

Make sure that the ground on which the

vehicle is standing and where you place the

jack is solid, level and not slippery. If

necessary, use a large underlay. On slippery

surfaces, such as tiled floors, you should use

a non-slip underlay, for example a rubber mat.

Do not use wooden blocks or similar objects

to support the jack. Otherwise the jack may

not be able to achieve its load-bearing

capacity if it is not at its full height.

Never start the engine when the vehicle is

raised.

Also observe the notes on the jack.

XPrevent the vehicle from rolling away by

blocking wheels with wheel chocks (not

included) or other sizeable objects.

When changing a wheel on a level surface:

XPlace a wheel chock or other sizeable

object in front of and another wheel chock

or other sizeable object behind the wheel

that is diagonally opposite to the wheel

being changed.

Always try lifting the vehicle using the jack on

a level surface. However, should

circumstances require you to do so on a hill:

XPlace wheel chocks or other sizeable

objects on the downhill side in front of both

wheels on the side opposite to the side on

which the wheel is to be changed.

GWarning!

Only jack up the vehicle on level ground or on

slight inclines/declines. Otherwise, the

vehicle could fall off the jack and injure you or

others.

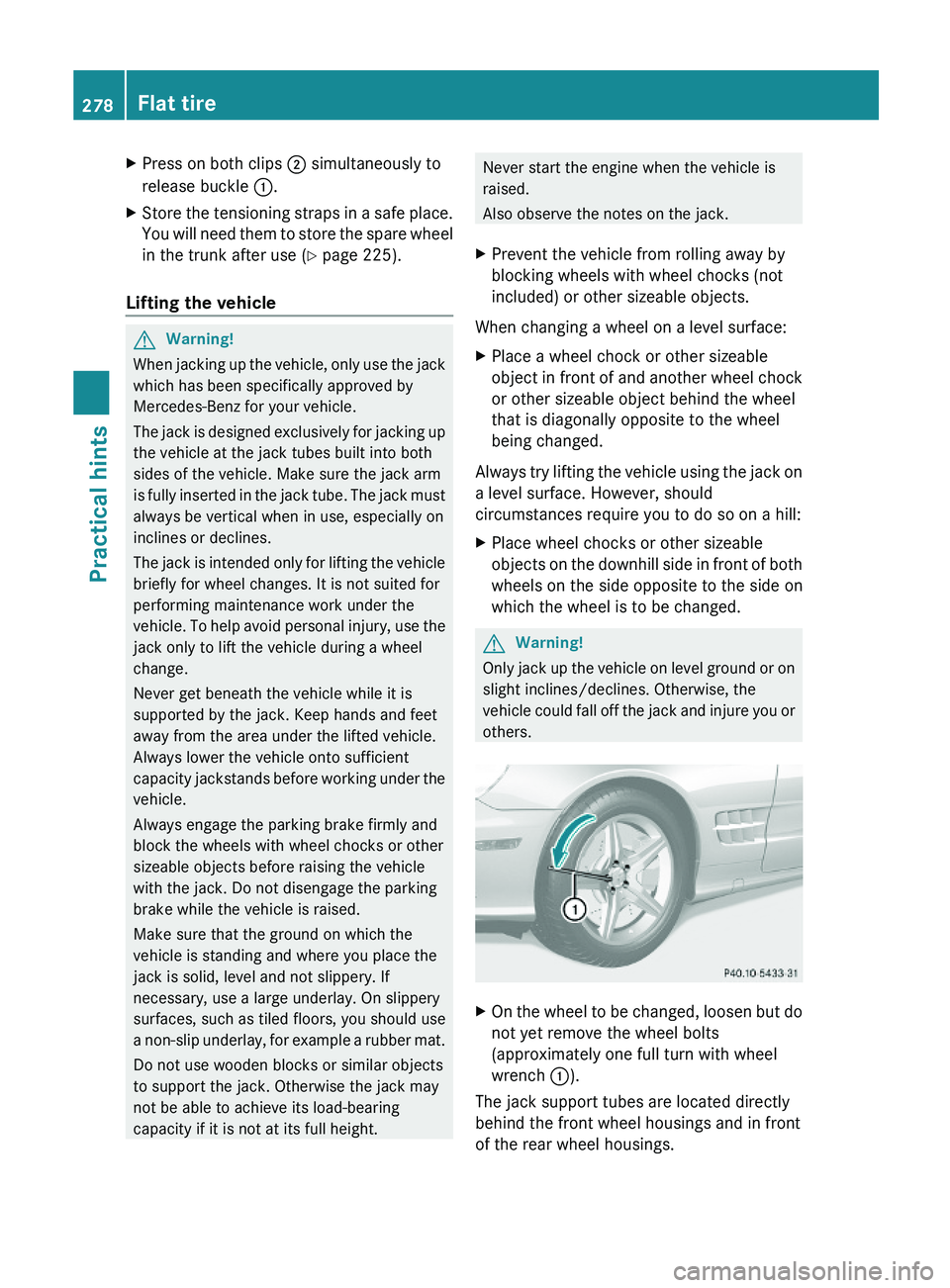

XOn the wheel to be changed, loosen but do

not yet remove the wheel bolts

(approximately one full turn with wheel

wrench \000F).

The jack support tubes are located directly

behind the front wheel housings and in front

of the rear wheel housings.

278Flat tirePractical hints

230_AKB; 6; 22, en-USd2ureepe,Version: 2.11.8.12009-07-28T18:49:58+02:00 - Seite 278

Page 282 of 316

! Do not place wheel bolts in sand or dirt.

This could result in damage to the wheel

bolts and wheel hub threads.

XRemove the wheel.

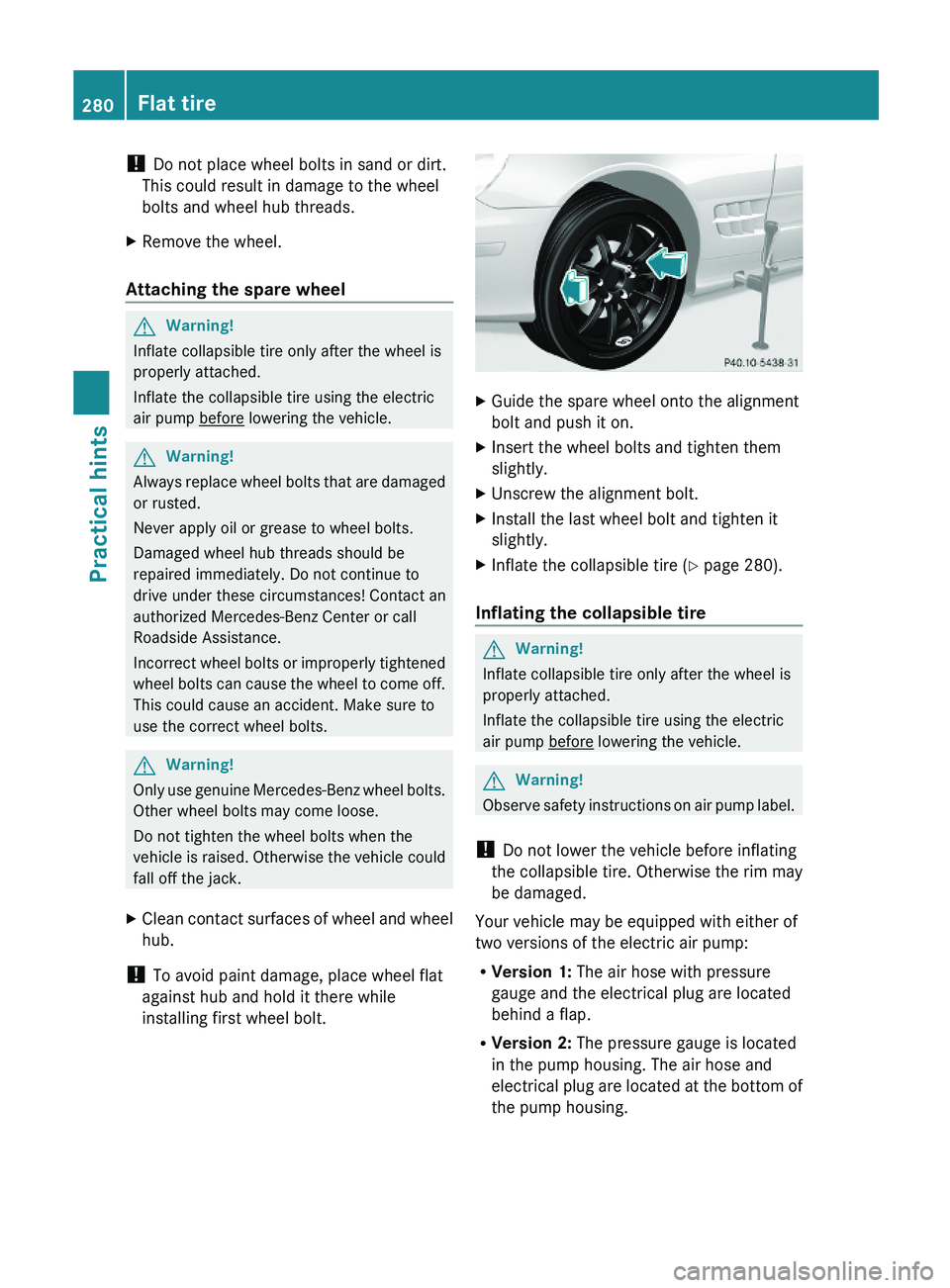

Attaching the spare wheel

GWarning!

Inflate collapsible tire only after the wheel is

properly attached.

Inflate the collapsible tire using the electric

air pump before lowering the vehicle.

GWarning!

Always replace wheel bolts that are damaged

or rusted.

Never apply oil or grease to wheel bolts.

Damaged wheel hub threads should be

repaired immediately. Do not continue to

drive under these circumstances! Contact an

authorized Mercedes-Benz Center or call

Roadside Assistance.

Incorrect wheel bolts or improperly tightened

wheel bolts can cause the wheel to come off.

This could cause an accident. Make sure to

use the correct wheel bolts.

GWarning!

Only use genuine Mercedes-Benz wheel bolts.

Other wheel bolts may come loose.

Do not tighten the wheel bolts when the

vehicle is raised. Otherwise the vehicle could

fall off the jack.

XClean contact surfaces of wheel and wheel

hub.

! To avoid paint damage, place wheel flat

against hub and hold it there while

installing first wheel bolt.

XGuide the spare wheel onto the alignment

bolt and push it on.

XInsert the wheel bolts and tighten them

slightly.

XUnscrew the alignment bolt.XInstall the last wheel bolt and tighten it

slightly.

XInflate the collapsible tire (Y page 280).

Inflating the collapsible tire

GWarning!

Inflate collapsible tire only after the wheel is

properly attached.

Inflate the collapsible tire using the electric

air pump before lowering the vehicle.

GWarning!

Observe safety instructions on air pump label.

! Do not lower the vehicle before inflating

the collapsible tire. Otherwise the rim may

be damaged.

Your vehicle may be equipped with either of

two versions of the electric air pump:

RVersion 1: The air hose with pressure

gauge and the electrical plug are located

behind a flap.

RVersion 2: The pressure gauge is located

in the pump housing. The air hose and

electrical plug are located at the bottom of

the pump housing.

280Flat tirePractical hints

230_AKB; 6; 22, en-USd2ureepe,Version: 2.11.8.12009-07-28T18:49:58+02:00 - Seite 280

Page 291 of 316

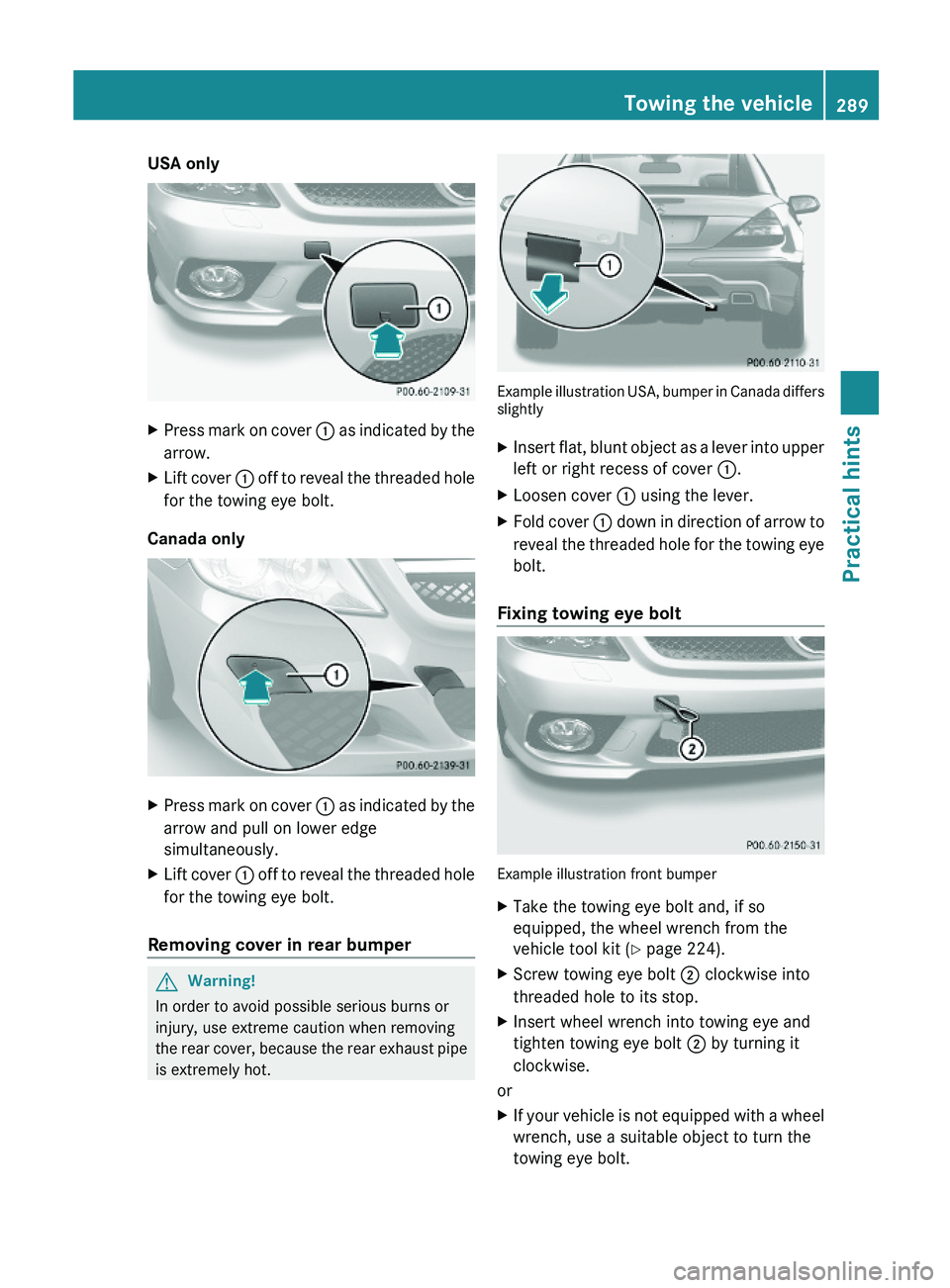

USA onlyXPress mark on cover \000F as indicated by the

arrow.

XLift cover \000F off to reveal the threaded hole

for the towing eye bolt.

Canada only

XPress mark on cover \000F as indicated by the

arrow and pull on lower edge

simultaneously.

XLift cover \000F off to reveal the threaded hole

for the towing eye bolt.

Removing cover in rear bumper

GWarning!

In order to avoid possible serious burns or

injury, use extreme caution when removing

the rear cover, because the rear exhaust pipe

is extremely hot.

Example illustration USA, bumper in Canada differsslightly

XInsert flat, blunt object as a lever into upper

left or right recess of cover \000F.

XLoosen cover \000F using the lever.XFold cover \000F down in direction of arrow to

reveal the threaded hole for the towing eye

bolt.

Fixing towing eye bolt

Example illustration front bumper

XTake the towing eye bolt and, if so

equipped, the wheel wrench from the

vehicle tool kit (Y page 224).

XScrew towing eye bolt \000G clockwise into

threaded hole to its stop.

XInsert wheel wrench into towing eye and

tighten towing eye bolt \000G by turning it

clockwise.

or

XIf your vehicle is not equipped with a wheel

wrench, use a suitable object to turn the

towing eye bolt.

Towing the vehicle289Practical hints230_AKB; 6; 22, en-USd2ureepe,Version: 2.11.8.12009-07-28T18:49:58+02:00 - Seite 289Z

Page 303 of 316

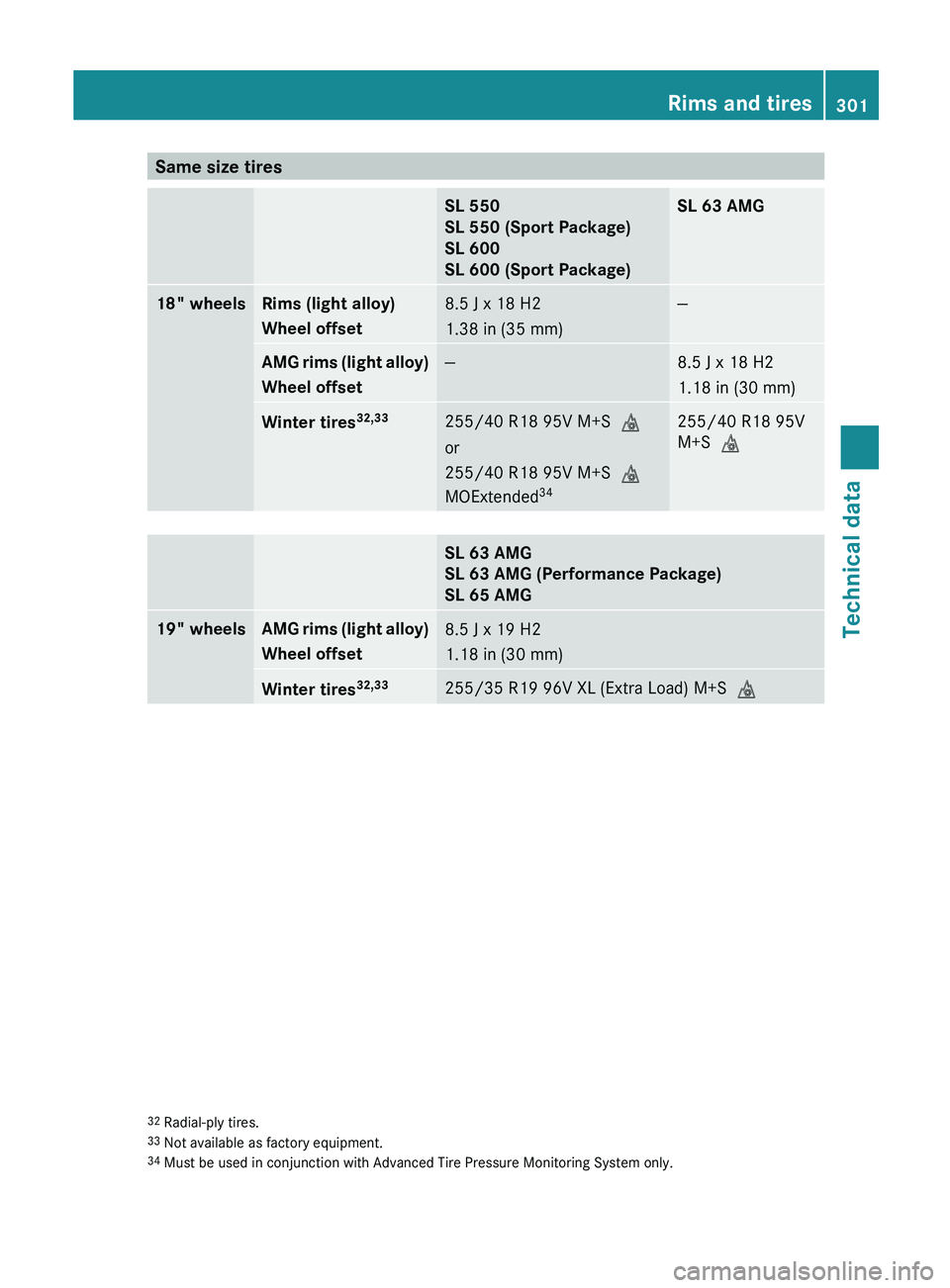

Same size tiresSL 550

SL 550 (Sport Package)

SL 600

SL 600 (Sport Package)SL 63 AMG18" wheelsRims (light alloy)

Wheel offset8.5 J x 18 H2

1.38 in (35 mm)—AMG rims (light alloy)

Wheel offset—8.5 J x 18 H2

1.18 in (30 mm)Winter tires 32,33255/40 R18 95V M+S

004D

or

255/40 R18 95V M+S 004D

MOExtended 34255/40 R18 95V

M+S 004DSL 63 AMG

SL 63 AMG (Performance Package)

SL 65 AMG19" wheelsAMG rims (light alloy)

Wheel offset8.5 J x 19 H2

1.18 in (30 mm)Winter tires 32,33255/35 R19 96V XL (Extra Load) M+S

004D32

Radial-ply tires.

33 Not available as factory equipment.

34 Must be used in conjunction with Advanced Tire Pressure Monitoring System only.Rims and tires301Technical data230_AKB; 6; 22, en-USd2ureepe,Version: 2.11.8.12009-07-28T18:49:58+02:00 - Seite 301Z

Page 304 of 316

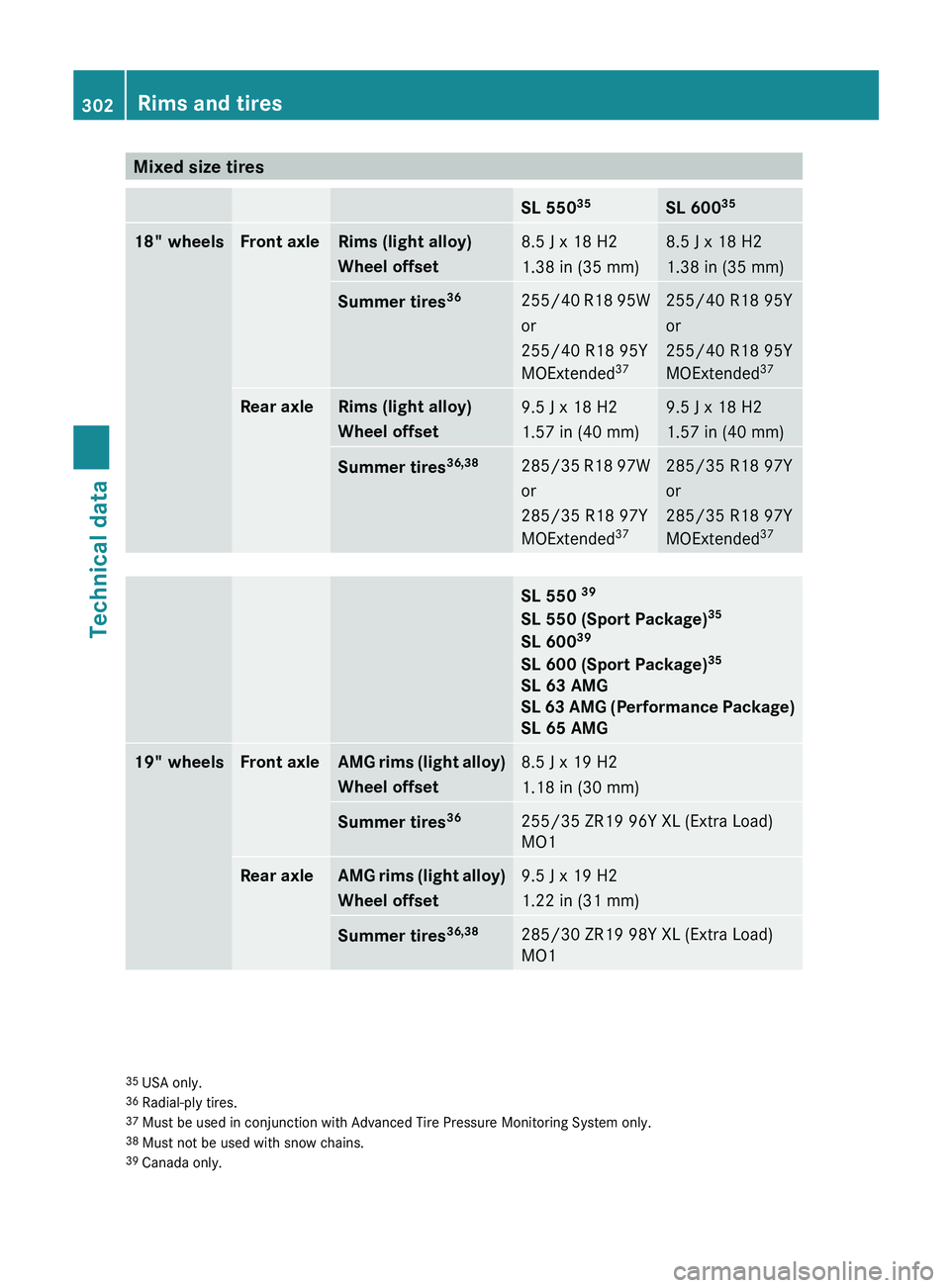

Mixed size tiresSL 55035SL 6003518" wheelsFront axleRims (light alloy)

Wheel offset8.5 J x 18 H2

1.38 in (35 mm)8.5 J x 18 H2

1.38 in (35 mm)Summer tires 36255/40 R18 95W

or

255/40 R18 95Y

MOExtended 37255/40 R18 95Y

or

255/40 R18 95Y

MOExtended 37Rear axleRims (light alloy)

Wheel offset9.5 J x 18 H2

1.57 in (40 mm)9.5 J x 18 H2

1.57 in (40 mm)Summer tires 36,38285/35 R18 97W

or

285/35 R18 97Y

MOExtended 37285/35 R18 97Y

or

285/35 R18 97Y

MOExtended 37SL 550 39

SL 550 (Sport Package) 35

SL 600 39

SL 600 (Sport Package) 35

SL 63 AMG

SL 63 AMG (Performance Package)

SL 65 AMG19" wheelsFront axleAMG rims (light alloy)

Wheel offset8.5 J x 19 H2

1.18 in (30 mm)Summer tires 36255/35 ZR19 96Y XL (Extra Load)

MO1Rear axleAMG rims (light alloy)

Wheel offset9.5 J x 19 H2

1.22 in (31 mm)Summer tires 36,38285/30 ZR19 98Y XL (Extra Load)

MO135 USA only.

36 Radial-ply tires.

37 Must be used in conjunction with Advanced Tire Pressure Monitoring System only.

38 Must not be used with snow chains.

39 Canada only.302Rims and tiresTechnical data

230_AKB; 6; 22, en-USd2ureepe,Version: 2.11.8.12009-07-28T18:49:58+02:00 - Seite 302

Page 309 of 316

with premium unleaded gasoline as soon

as possible.

R Avoid full throttle driving and abrupt

acceleration.

R Do not exceed an engine speed of

3 000 rpm if the vehicle is loaded with a

light load such as two persons and no

luggage.

R Do not exceed 2

/ 3 of maximum

accelerator pedal position if the vehicle

is fully loaded or operating in

mountainous terrain.

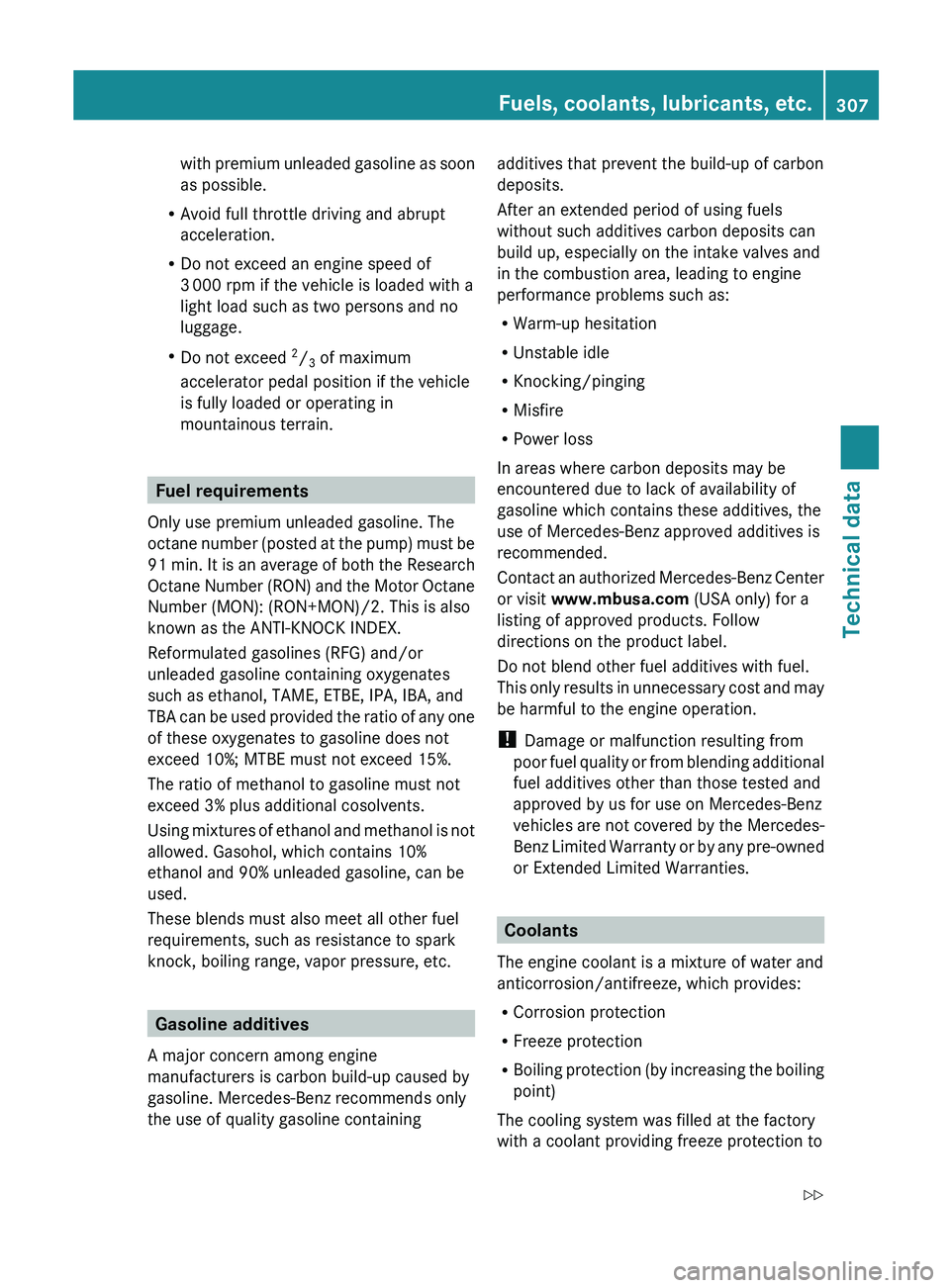

Fuel requirements

Only use premium unleaded gasoline. The

octane number (posted at the pump) must be

91 min. It is an average of both the Research

Octane Number (RON) and the Motor Octane

Number (MON): (RON+MON)/2. This is also

known as the ANTI-KNOCK INDEX.

Reformulated gasolines (RFG) and/or

unleaded gasoline containing oxygenates

such as ethanol, TAME, ETBE, IPA, IBA, and

TBA can be used provided the ratio of any one

of these oxygenates to gasoline does not

exceed 10%; MTBE must not exceed 15%.

The ratio of methanol to gasoline must not

exceed 3% plus additional cosolvents.

Using mixtures of ethanol and methanol is not

allowed. Gasohol, which contains 10%

ethanol and 90% unleaded gasoline, can be

used.

These blends must also meet all other fuel

requirements, such as resistance to spark

knock, boiling range, vapor pressure, etc.

Gasoline additives

A major concern among engine

manufacturers is carbon build-up caused by

gasoline. Mercedes-Benz recommends only

the use of quality gasoline containing

additives that prevent the build-up of carbon

deposits.

After an extended period of using fuels

without such additives carbon deposits can

build up, especially on the intake valves and

in the combustion area, leading to engine

performance problems such as:

R Warm-up hesitation

R Unstable idle

R Knocking/pinging

R Misfire

R Power loss

In areas where carbon deposits may be

encountered due to lack of availability of

gasoline which contains these additives, the

use of Mercedes-Benz approved additives is

recommended.

Contact an authorized Mercedes-Benz Center

or visit www.mbusa.com (USA only) for a

listing of approved products. Follow

directions on the product label.

Do not blend other fuel additives with fuel.

This only results in unnecessary cost and may

be harmful to the engine operation.

! Damage or malfunction resulting from

poor fuel quality or from blending additional

fuel additives other than those tested and

approved by us for use on Mercedes-Benz

vehicles are not covered by the Mercedes-

Benz Limited Warranty or by any pre-owned

or Extended Limited Warranties.

Coolants

The engine coolant is a mixture of water and

anticorrosion/antifreeze, which provides:

R Corrosion protection

R Freeze protection

R Boiling protection (by increasing the boiling

point)

The cooling system was filled at the factory

with a coolant providing freeze protection to

Fuels, coolants, lubricants, etc.307Technical data230_AKB; 6; 22, en-USd2ureepe,Version: 2.11.8.12009-07-28T18:49:58+02:00 - Seite 307Z