clock MERCEDES-BENZ SL ROADSTER 2016 User Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2016, Model line: SL ROADSTER, Model: MERCEDES-BENZ SL ROADSTER 2016Pages: 333, PDF Size: 11.85 MB

Page 318 of 333

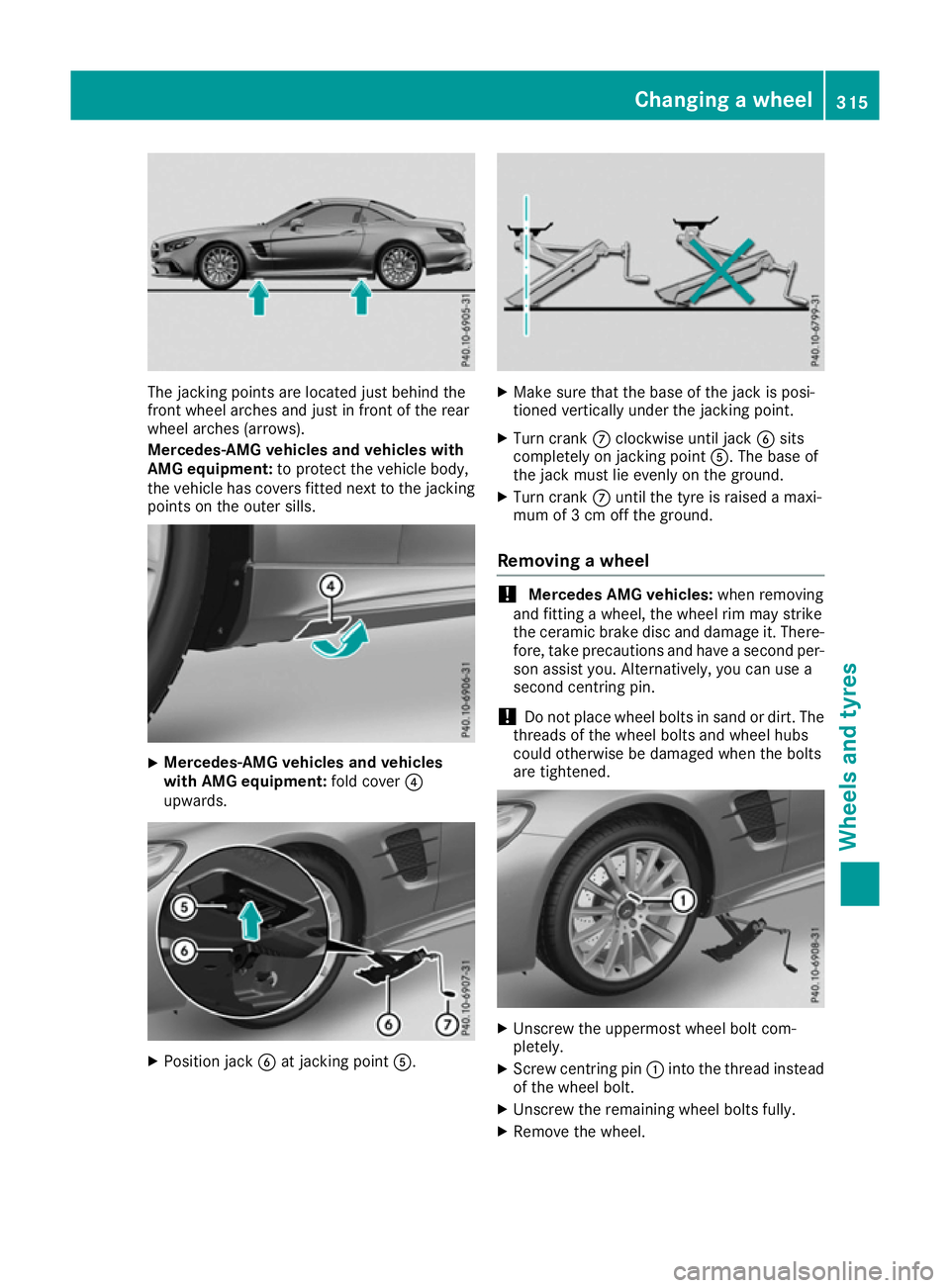

The jacking points are located just behind the

front wheel arches and just in front of the rear

wheel arches (arrows).

Mercedes-AMG vehicles and vehicles with

AMG equipment: to protect the vehicle body,

the vehicle has covers fitted next to the jacking

points on the outer sills. X

Mercedes-AMG vehicles and vehicles

with AMG equipment:

fold cover?

upwards. X

Position jack Bat jacking point A. X

Make sure that the base of the jack is posi-

tioned vertically under the jacking point.

X Turn crank Cclockwise until jack Bsits

completely on jacking point A. The base of

the jack must lie evenly on the ground.

X Turn crank Cuntil the tyre is raised a maxi-

mum of 3 cm off the ground.

Removing a wheel !

Mercedes AMG vehicles:

when removing

and fitting a wheel, the wheel rim may strike

the ceramic brake disc and damage it. There-

fore, take precautions and have a second per- son assist you. Alternatively, you can use a

second centring pin.

! Do not place wheel bolts in sand or dirt. The

threads of the wheel bolts and wheel hubs

could otherwise be damaged when the bolts

are tightened. X

Unscrew the uppermost wheel bolt com-

pletely.

X Screw centring pin :into the thread instead

of the wheel bolt.

X Unscrew the remaining wheel bolts fully.

X Remove the wheel. Changing a wheel

315Wheels and tyres Z

Page 319 of 333

Fitting a new wheel

G

WARNING

Oiled or greased wheel bolts or damaged

wheel bolts/hub threads can cause the wheel bolts to come loose. As a result, you could

lose a wheel while driving. There is a risk of

accident.

Never oil or grease wheel bolts. In the event ofdamage to the threads, contact a qualified

specialist workshop immediately. Have the

damaged wheel bolts or hub threads

replaced/renewed. Do not continue driving. G

WARNING

If you tighten the wheel bolts or wheel nuts

when the vehicle is raised, the jack could tip

over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts

when the vehicle is on the ground.

It is imperative to observe the instructions and

safety notes on "Changing a wheel"

(Y page 312).

Only use wheel bolts that have been designed

for the wheel and the vehicle. For safety rea-

sons, Mercedes-Benz recommends that you

only use wheel bolts which have been approved for Mercedes-Benz vehicles and the respective

wheel.

! Mercedes AMG vehicles:

when removing

and fitting a wheel, the wheel rim may strike

the ceramic brake disc and damage it. There-

fore, take precautions and have a second per- son assist you. Alternatively, you can use a

second centring pin. X

Clean the wheel and wheel hub contact sur-

faces.

X Slide the wheel to be mounted onto the cen-

tring pin and push it on.

X Tighten the wheel bolts until they are finger-

tight.

X Unscrew the centring pin.

X Tighten the last wheel bolt until it is finger-

tight.

X Vehicles with a collapsible emergency

spare wheel:

inflate the collapsible emer-

gency spare wheel (Y page 319).

Only then lower the vehicle.

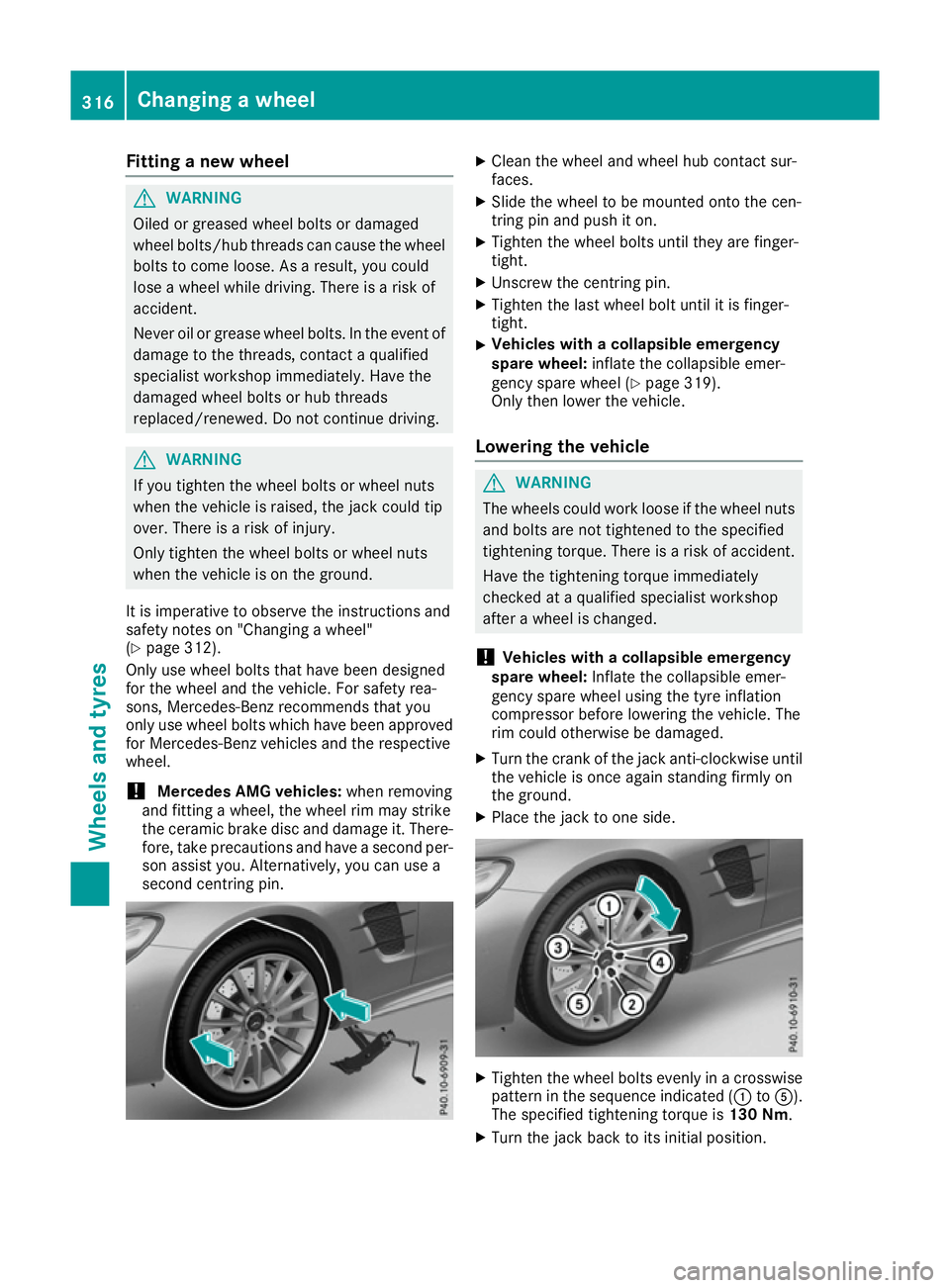

Lowering the vehicle G

WARNING

The wheels could work loose if the wheel nuts and bolts are not tightened to the specified

tightening torque. There is a risk of accident.

Have the tightening torque immediately

checked at a qualified specialist workshop

after a wheel is changed.

! Vehicles with a collapsible emergency

spare wheel: Inflate the collapsible emer-

gency spare wheel using the tyre inflation

compressor before lowering the vehicle. The

rim could otherwise be damaged.

X Turn the crank of the jack anti-clockwise until

the vehicle is once again standing firmly on

the ground.

X Place the jack to one side. X

Tighten the wheel bolts evenly in a crosswise

pattern in the sequence indicated (: toA).

The specified tightening torque is 130 Nm.

X Turn the jack back to its initial position. 316

Changing a wheelWheels and ty

res