lock MERCEDES-BENZ SLC 2019 Owners Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2019, Model line: SLC, Model: MERCEDES-BENZ SLC 2019Pages: 306, PDF Size: 15 MB

Page 278 of 306

vehicle to a halt by braking carefully. Avoidabrupt steering movements.

The tire pressure monitor has a yellow warninglamp in the instrument cluster for indicatingpressure loss or a malfunction. Whether thewarning lamp flashes or lights up indicateswhether a tire pressure is too low or the tirepressure monitor is malfunctioning:

Rif the warning lamp is lit continuously, thetire pressure on one or more tires is signifi-cantly too low. The tire pressure monitor isnot malfunctioning.

Rif the warning lamp flashes for approx-imately a minute and then remains lit con-stantly, the tire pressure monitor is malfunc-tioning.

In addition to the warning lamp, a messageappears in the multifunction display. Observethe information on display messages(Ypage 201).

It may take up to ten minutes for a malfunc-tion of the tire pressure monitor to be indica-ted. A malfunction will be indicated by the tirepressure warning lamp flashing for approx-imately one minute and then remaining lit.When the malfunction has been rectified, thetire pressure warning lamp goes out after afew minutes of driving.

The tire pressure values indicated by the on-board computer may differ from those meas-ured at a gas station with a pressure gage. Thetire pressures shown by the on-board com-puter refer to those measured at sea level. Athigh altitudes, the tire pressure values indica-ted by a pressure gage are higher than thoseshown by the on-board computer. In this case,do not reduce the tire pressures.

The operation of the tire pressure monitor canbe affected by interference from radio trans-mitting equipment (e.g. radio headphones,two-way radios) that may be being operated inor near the vehicle.

Checking the tire pressure electroni-

cally

XMake sure that the SmartKey is in position�H(Ypage 118) in the ignition lock.

XPress the�Yor�ebutton on the steer-ing wheel to select theServ.Serv.menu.

XPress the�cor�dbutton to selectTire PressureTire Pressure.

XPress�v.The current tire pressure of each tire isshown in the multifunction display.

If the vehicle has been parked for over20 minutes, theTire pressure will beTire pressure will bedisplayed after driving a few minutesdisplayed after driving a few minutesmessage appears.

After a teach-in process, the tire pressuremonitor automatically detects new wheels ornew sensors. As long as a clear allocation ofthe tire pressure value to the individual wheelsis not possible, theTire Pressure MonitorTire Pressure MonitorActiveActivedisplay message is shown instead ofthe tire pressure display. The tire pressuresare already being monitored.

If an emergency spare wheel is mounted, thesystem may continue to show the tire pressureof the wheel that has been removed for a fewminutes. Be aware that the value displayed forthe position where the emergency spare wheelis fitted is not the same as the current tirepressure of the emergency spare wheel.

Tire pressure monitor warning mes-

sages

The tire pressure monitor detects a pressureloss in one or more tires:

RIf the tire pressure monitor detects a pres-sure loss in one or more tires, a warningmessage is shown in the multifunction dis-play. The yellow tire pressure warning lampthen lights up.

RIf thePlease Correct Tire PressurePlease Correct Tire Pressuremessage appears in the multifunction dis-play, the tire pressure in at least one tire istoo low. The tire pressure must be correctedwhen the opportunity arises.

RIf theCheck TiresCheck Tiresmessage appears in themultifunction display, the tire pressure in atleast one tire has dropped significantly. Thetires must be checked.

RIf theWarning Tire MalfunctionWarning Tire Malfunctionmes-sage appears in the multifunction display,the tire pressure in at least one tire hasdropped suddenly. The tires must bechecked.

Observe the instructions and safety notes inthe display messages in the "Tires" section(Ypage 201).

276Tire pressure

Wheels and tires

Page 279 of 306

If the wheel positions on the vehicle are rota-ted, the tire pressures may be displayed forthe wrong positions for a short time. This isrectified after a few minutes of driving, and thetire pressures are displayed for the correctpositions.

Restarting the tire pressure monitor

When you restart the tire pressure monitor, allexisting warning messages are deleted and thewarning lamps go out. The monitor uses thecurrently set tire pressures as the referencevalues for monitoring. In most cases, the tirepressure monitor will automatically detect thenew reference values after you have changedthe tire pressure. However, you can also setreference values manually as described here.The tire pressure monitor then monitors thenew tire pressure values.

XSet the tire pressure to the value recom-mended for the corresponding driving situa-tion on the Tire and Loading Informationplacard on the driver's side B-pillar(Ypage 270).

Additional tire pressure values for differentloads can also be found on the tire pressuretable on the inside of the fuel filler flap(Ypage 270).

XMake sure that the tire pressure is correcton all four wheels.

XEnsure that the SmartKey is in position�Hin the ignition lock.

XPress the�Yor�ebutton on the steer-ing wheel to select theServ.Serv.menu.

XPress the�cor�dbutton to selectTire PressureTire Pressure.

XPress�v.The multifunction display shows the currenttire pressure for the individual tires or theTire pressure will be displayedTire pressure will be displayedafter driving a few minutesafter driving a few minutesmessage.

XPress the�dbutton.TheUse Current Pressures as NewUse Current Pressures as NewReference ValuesReference Valuesmessage appears in themultifunction display.

If you wish to confirm the restart:

XPress�v.TheTire Press. Monitor RestartedTire Press. Monitor Restartedmessage appears in the multifunction dis-play.

After driving for a few minutes, the systemchecks whether the current tire pressuresare within the specified range. The new tirepressures are then accepted as referencevalues and monitored.

If you wish to cancel the restart:

XPress�8.The tire pressure values stored at the lastrestart will continue to be monitored.

Tire pressure277

Wheels and tires

Z

Page 291 of 306

Clean the contact surfaces of the wheel andthe brake disc thoroughly every time a wheelis rotated. Check the tire pressure and, if nec-essary, restart the tire pressure loss warningsystem or the tire pressure monitor.

Direction of rotation

Tires with a specified direction of rotation haveadditional benefits, e.g. if there is a risk ofhydroplaning. These advantages can only begained if the tires are installed correspondingto the direction of rotation.

An arrow on the sidewall of the tire indicatesits correct direction of rotation.

Storing wheels

Store wheels that are not being used in a cool,dry and preferably dark place. Protect the tiresfrom oil, grease, gasoline and diesel.

Mounting a wheel

Preparing the vehicle

XStop the vehicle on solid, non-slippery andlevel ground.

XApply the electric parking brake manually.

XBring the front wheels into the straight-ahead position.

XShift the transmission to position�].

XSwitch off the engine.

XVehicles without KEYLESS-GO:removethe SmartKey from the ignition lock.

XVehicles with KEYLESS-GO:open the driv-er's door.The vehicle electronics now have status0.This is the same as the SmartKey havingbeen removed.

XVehicles with KEYLESS-GO:remove theStart/Stop button from the ignition lock(Ypage 118).

XIf included in the vehicle equipment, removethe tire-change tool kit from the vehicle.

XSafeguard the vehicle against rolling away.

iDue to differences in vehicle equipment,not all vehicles are equipped with a tire-change tool kit. For information on which

tools are required to perform a wheelchange on your vehicle, consult an author-ized Mercedes-Benz Center.

Necessary tire-changing tools can include,for example:

RJack

RWheel chock

RLug wrench

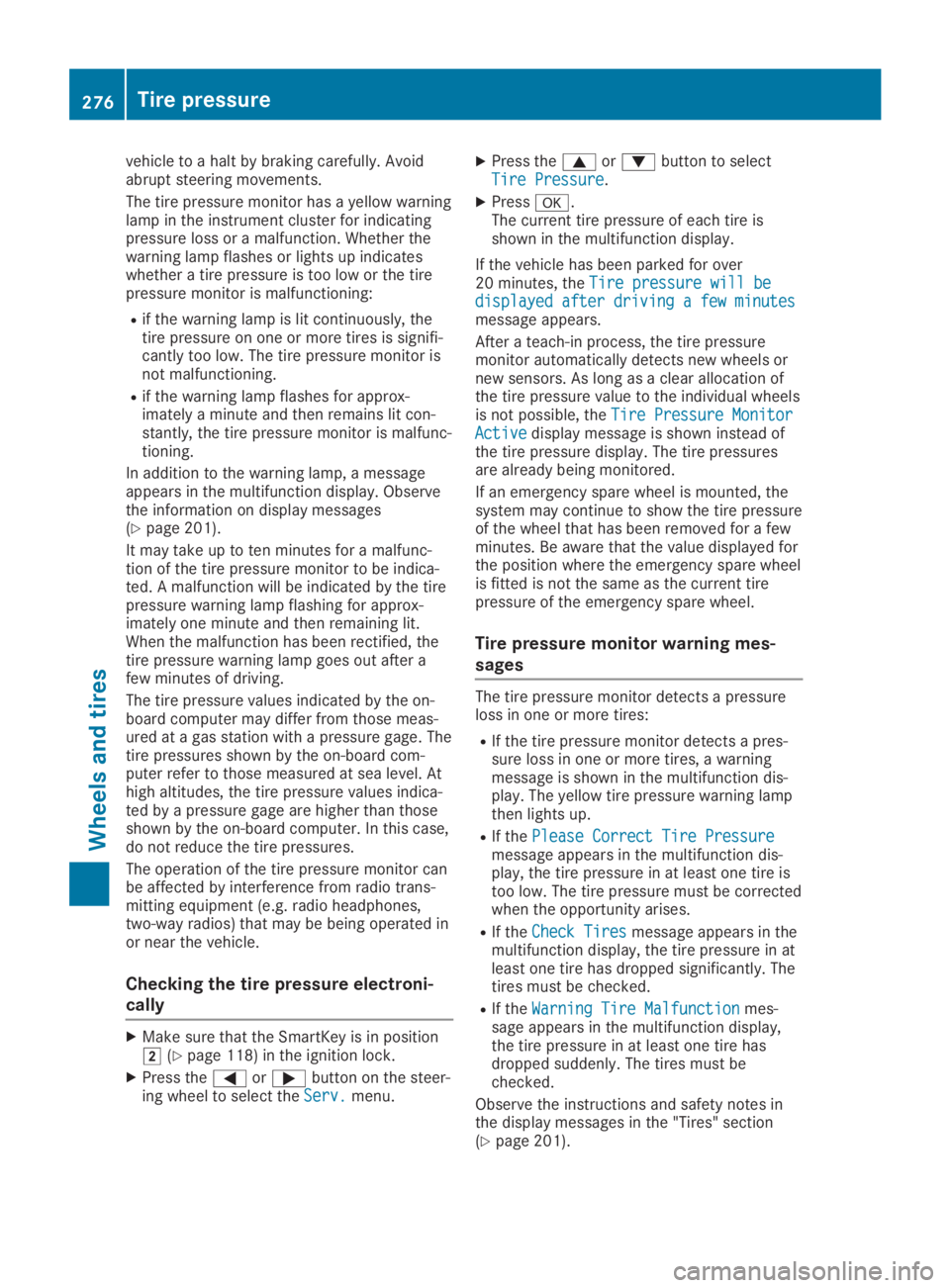

Securing the vehicle to prevent it from

rolling away

If your vehicle is equipped with a wheel chock,it can be found in the tire-change tool kit(Ypage 252).

The folding wheel chock is an additional safetymeasure to prevent the vehicle from rollingaway, for example when changing a wheel.

XFold both plates upwards�C.

XFold out lower plate�D.

XGuide the lugs on the lower plate fully intothe openings in base plate�

Page 292 of 306

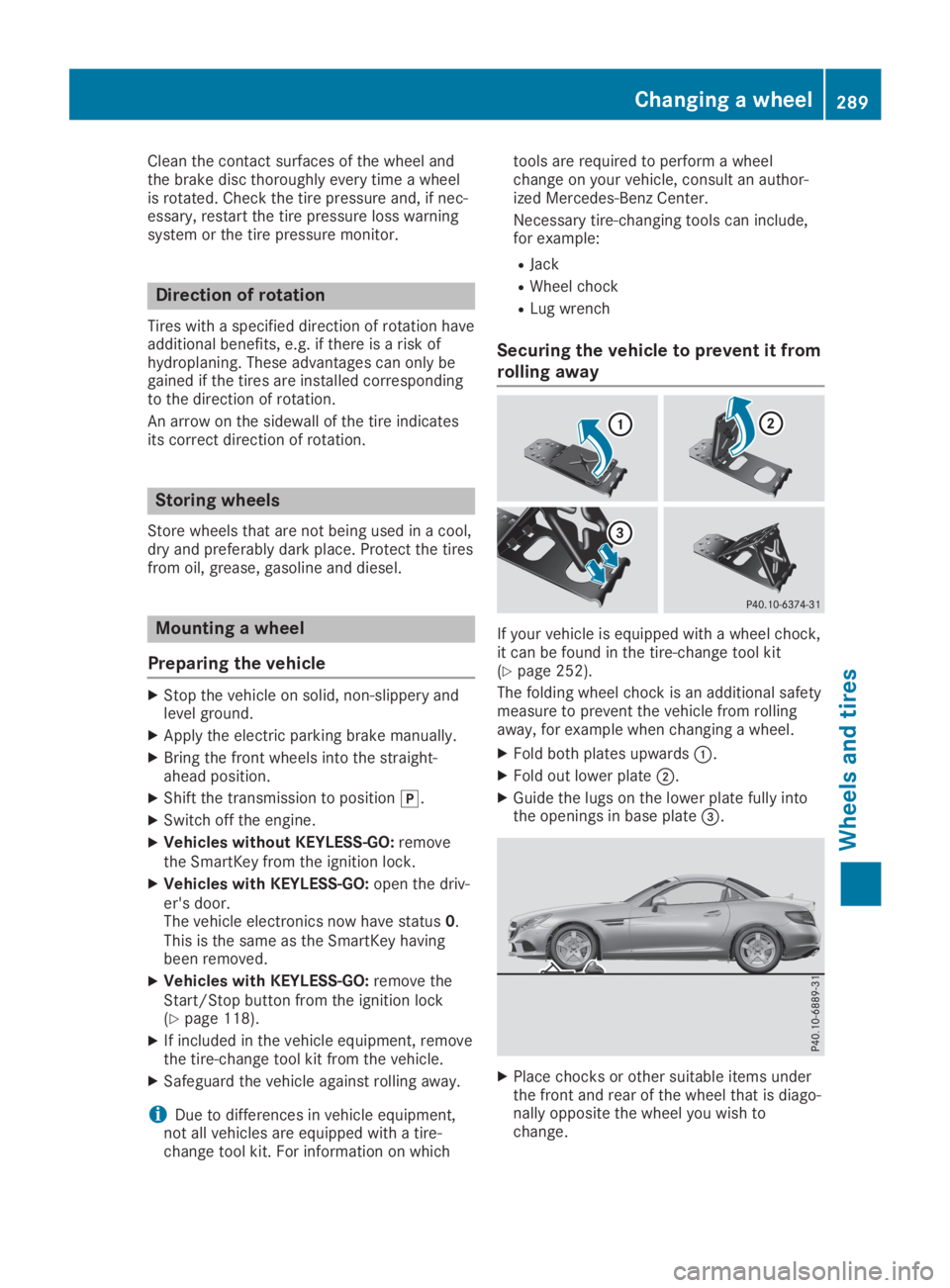

Raising the vehicle

GWARNING

If you do not position the jack correctly at

the appropriate jacking point of the vehicle,

the jack could tip over with the vehicle

raised. There is a risk of injury.

Only position the jack at the appropriate

jacking point of the vehicle. The base of the

jack must be positioned vertically, directly

under the jacking point of the vehicle.

!Only position the jack at the appropriatejacking point of the vehicle. Otherwise, youcould damage the vehicle.

Observe the following when raising the vehi-cle:

RTo raise the vehicle, only use the vehicle-specific jack that has been tested andapproved by Mercedes-Benz. If used incor-rectly, the jack could tip over with the vehi-cle raised.

RThe jack is designed only to raise and holdthe vehicle for a short time while a wheelis being changed. It must not be used forperforming maintenance work under thevehicle.

RAvoid changing the wheel on uphill anddownhill slopes.

RBefore raising the vehicle, secure it fromrolling away by applying the parking brakeand inserting wheel chocks. Do not disen-gage the parking brake while the vehicle israised.

RThe jack must be placed on a firm, flat andnon-slip surface. On a loose surface, a large,flat, load-bearing underlay must be used. Ona slippery surface, a non-slip underlay mustbe used, e.g. rubber mats.

RDo not use wooden blocks or similar objectsas a jack underlay. Otherwise, the jack willnot be able to achieve its load-bearing capa-city due to the restricted height.

RMake sure that the distance between theunderside of the tires and the ground doesnot exceed 1.2 in (3 cm).

RNever place your hands and feet under theraised vehicle.

RDo not lie under the vehicle.

RDo not start the engine when the vehicle israised.

RDo not open or close a door or the trunk lidwhen the vehicle is raised.

RMake sure that no persons are present inthe vehicle when the vehicle is raised.

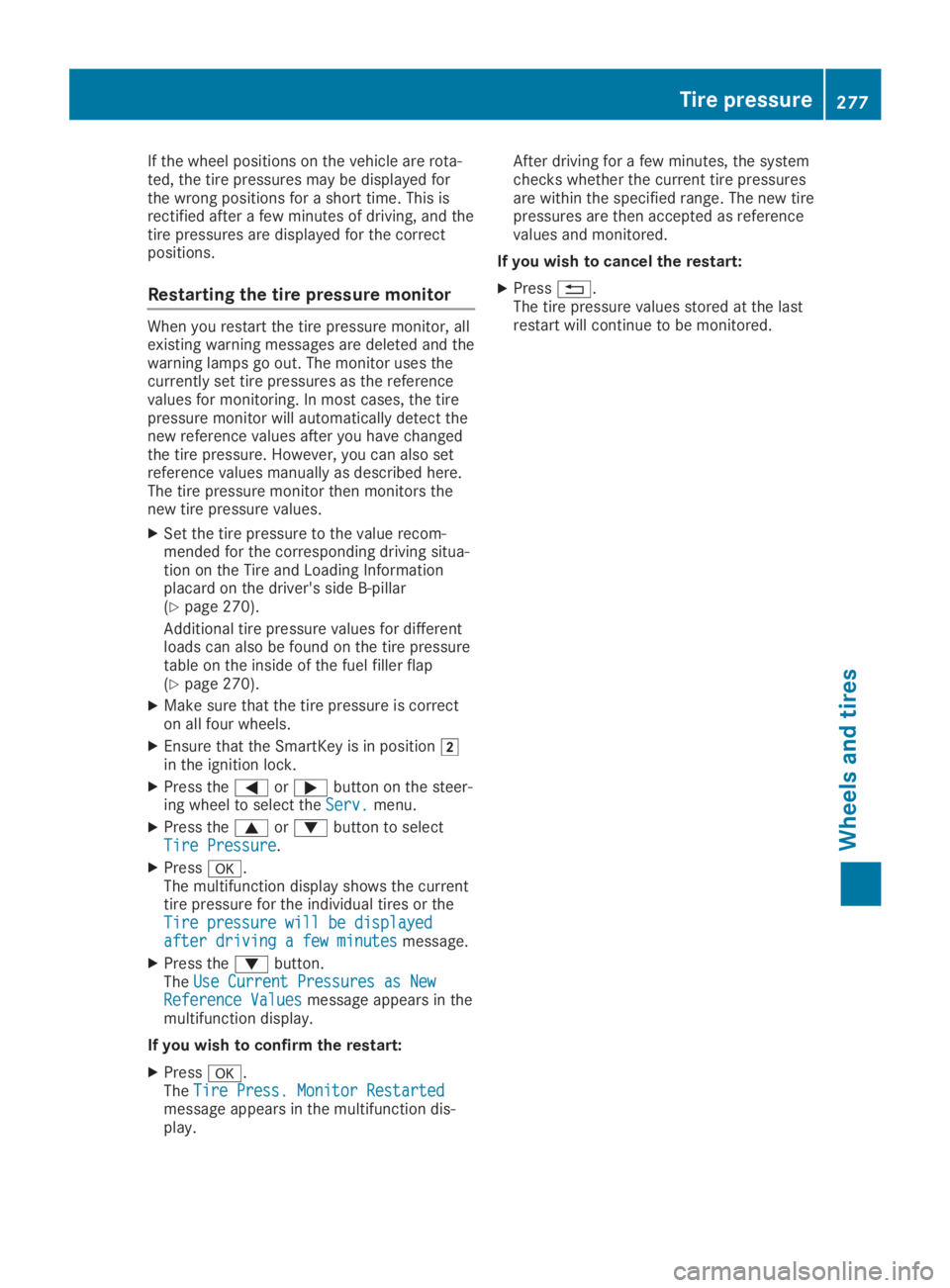

XUsing lug wrench�C, loosen the bolts onthe wheel you wish to change by about onefull turn. Do not unscrew the bolts com-pletely.

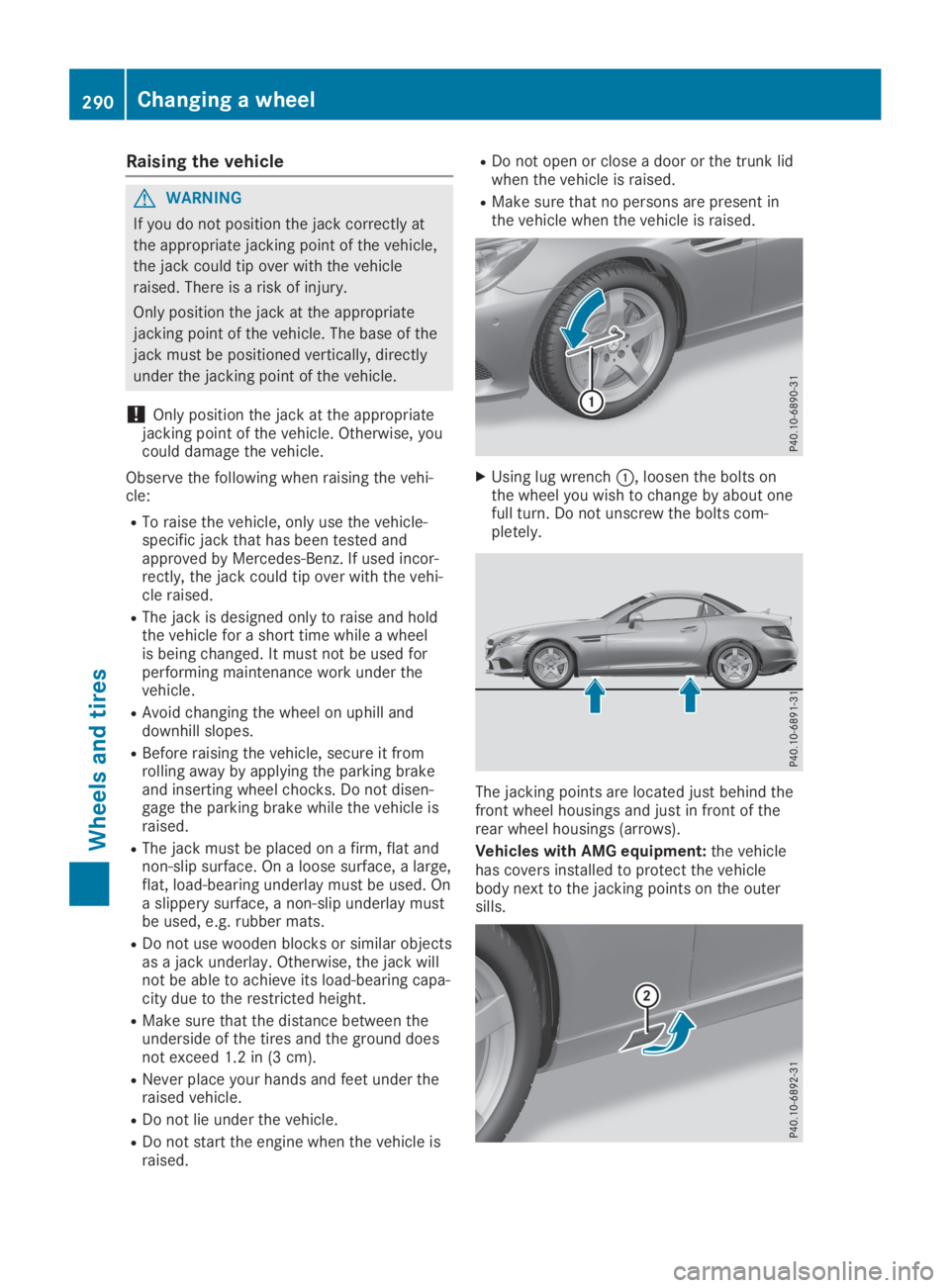

The jacking points are located just behind thefront wheel housings and just in front of therear wheel housings (arrows).

Vehicles with AMG equipment:the vehiclehas covers installed to protect the vehiclebody next to the jacking points on the outersills.

290Changing a wheel

Wheels and tires

Page 294 of 306

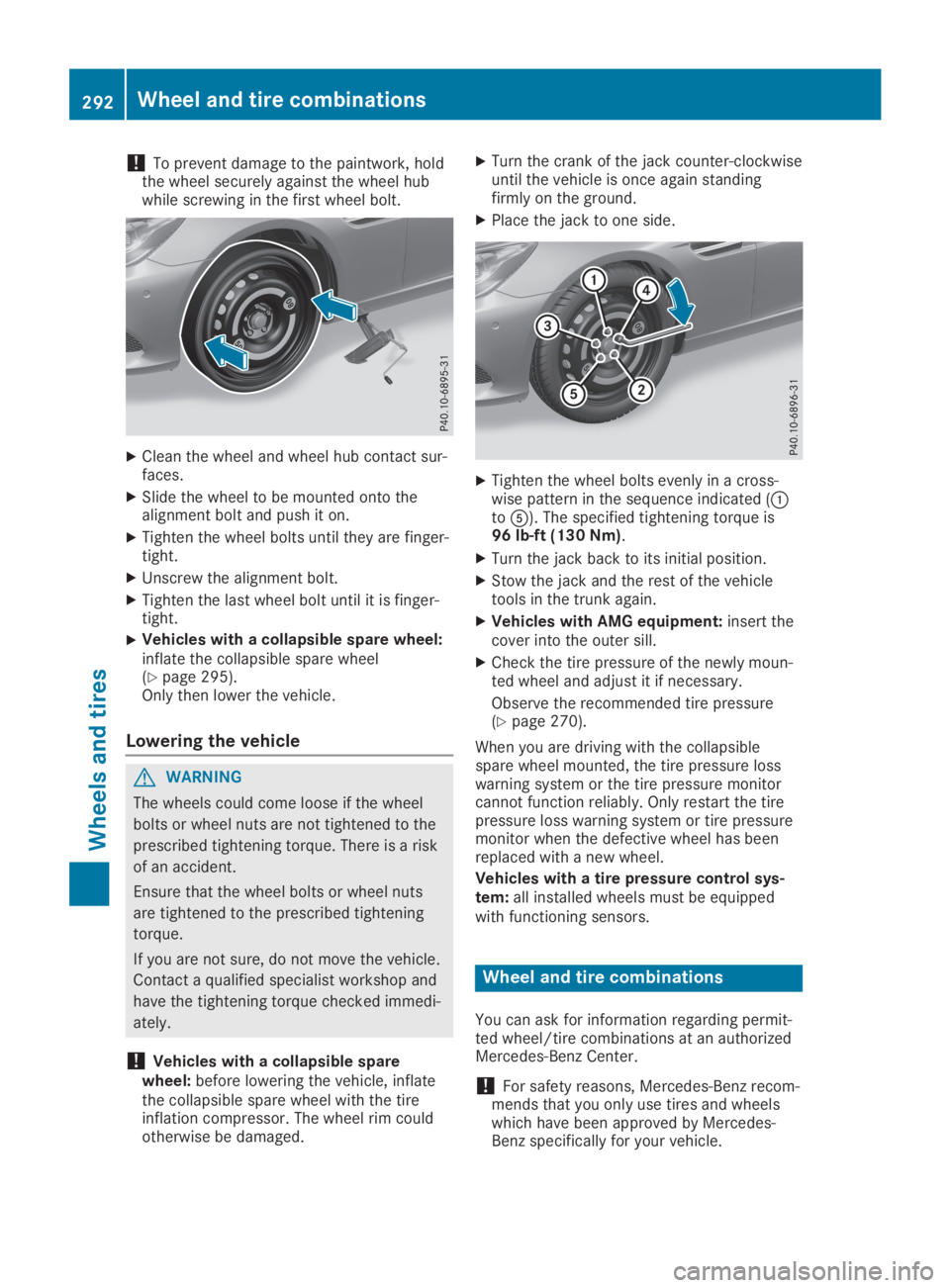

!To prevent damage to the paintwork, holdthe wheel securely against the wheel hubwhile screwing in the first wheel bolt.

XClean the wheel and wheel hub contact sur-faces.

XSlide the wheel to be mounted onto thealignment bolt and push it on.

XTighten the wheel bolts until they are finger-tight.

XUnscrew the alignment bolt.

XTighten the last wheel bolt until it is finger-tight.

XVehicles with a collapsible spare wheel:inflate the collapsible spare wheel(Ypage 295).Only then lower the vehicle.

Lowering the vehicle

GWARNING

The wheels could come loose if the wheel

bolts or wheel nuts are not tightened to the

prescribed tightening torque. There is a risk

of an accident.

Ensure that the wheel bolts or wheel nuts

are tightened to the prescribed tightening

torque.

If you are not sure, do not move the vehicle.

Contact a qualified specialist workshop and

have the tightening torque checked immedi-

ately.

!Vehicles with a collapsible sparewheel:before lowering the vehicle, inflatethe collapsible spare wheel with the tireinflation compressor. The wheel rim couldotherwise be damaged.

XTurn the crank of the jack counter-clockwiseuntil the vehicle is once again standingfirmly on the ground.

XPlace the jack to one side.

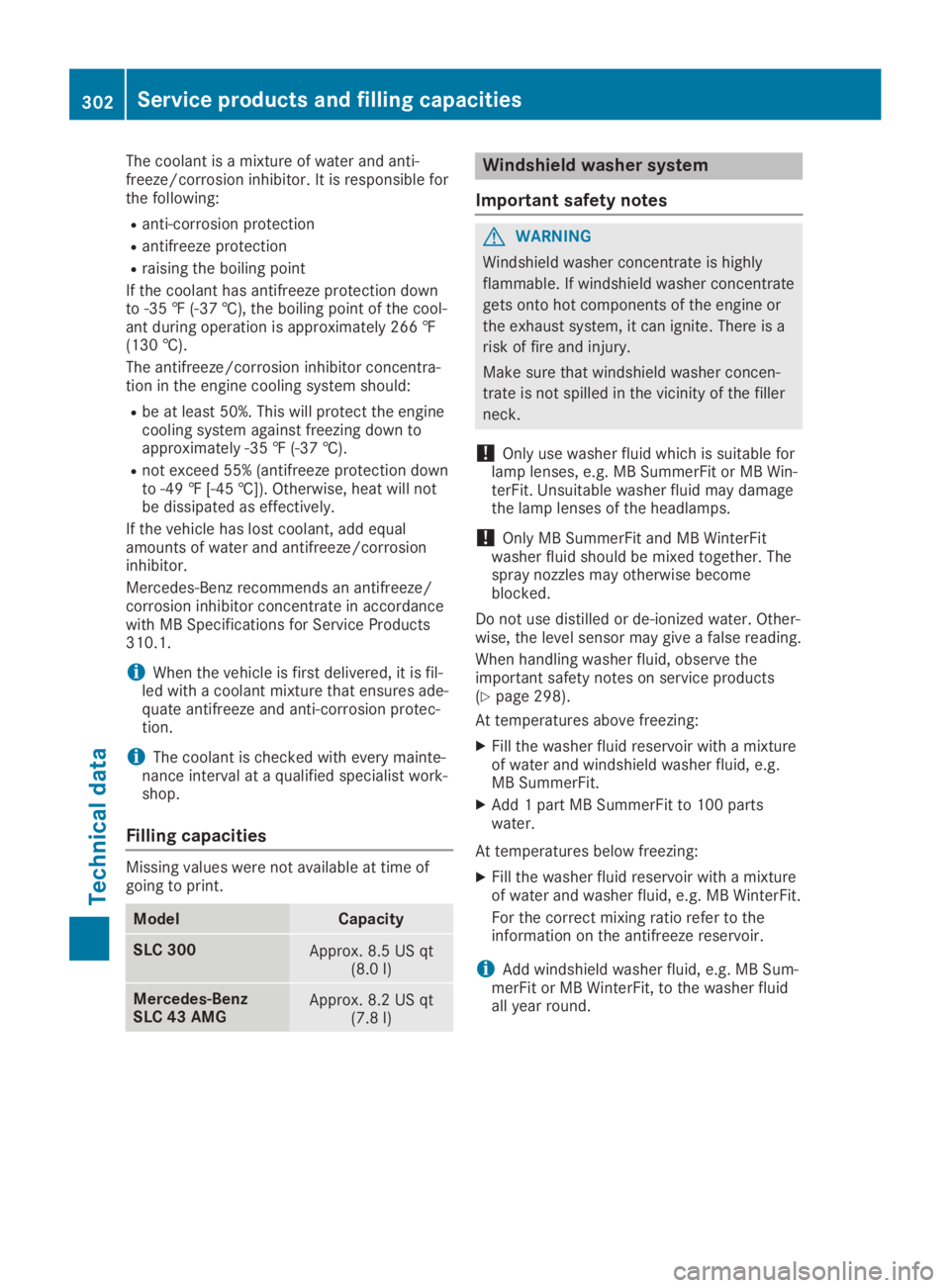

XTighten the wheel bolts evenly in a cross-wise pattern in the sequence indicated (�Cto�

Page 296 of 306

When using an emergency spare wheel orspare wheel of a different size, you must notexceed the maximum speed of 50 mph(80 km/h).

Snow chains must not be mounted on emer-gency spare wheels.

General notes

You can ask for information regarding permit-ted emergency spare wheels at an authorizedMercedes-Benz Center.

You should regularly check the pressure of theemergency spare wheel, particularly prior tolong trips, and correct the pressure as neces-sary (Ypage 270). The value on the wheel isvalid.

An emergency spare wheel may also be moun-ted against the direction of rotation. Observethe time restriction on use as well as thespeed limitation specified on the emergencyspare wheel.

Replace the tires after six years at the latest,regardless of wear. This also applies to theemergency spare wheel.

When you are driving with the collapsiblespare wheel mounted, the tire pressure losswarning system or the tire pressure monitorcannot function reliably. Only restart the tirepressure loss warning system or tire pressuremonitor when the defective wheel has beenreplaced with a new wheel.

Vehicles with tire pressure monitor:aftermounting an emergency spare wheel, the sys-tem may still display the tire pressure of theremoved wheel for a few minutes. The valuedisplayed for the mounted emergency sparewheel is not the same as the current tire pres-sure of the emergency spare wheel.

Removing the emergency spare

wheel

Vehicles with a collapsible spare

wheel

The collapsible spare wheel can be found inthe stowage well under the trunk floor(Ypage 227).

XTurn retaining screw�Dcounter-clockwiseand remove it.

XRemove collapsible spare wheel�C.

Always observe the instructions and safetynotes in the "Mounting a wheel" section(Ypage 289).

Stowing the emergency spare wheel

!Only place the collapsible spare wheel inthe vehicle when it is dry. Otherwise, mois-ture may get into the vehicle.

Take the following steps to stow a used col-lapsible spare wheel. Otherwise, the collapsi-ble spare wheel will not fit in the trunk in theintended manner. Mercedes-Benz recom-mends that you have this work carried out at aqualified specialist workshop.

XUnscrew the valve cap from the valve.

XIf possible, unscrew the valve insert fromthe valve and release the air.Fully deflating the tires can take a fewminutes.

XScrew the valve insert back into the valve.

XScrew the valve cap back on.

XPull the protective sheet provided with thespare wheel over the collapsible sparewheel.

XStow the collapsible spare wheel in theemergency spare wheel well under thetrunk.

XUse the retaining screw to pierce the pro-tective sheet and fasten the collapsiblespare wheel in place.

294Emergency spare wheel

Wheels and tires

Page 304 of 306

The coolant is a mixture of water and anti-freeze/corrosion inhibitor. It is responsible forthe following:

Ranti-corrosion protection

Rantifreeze protection

Rraising the boiling point

If the coolant has antifreeze protection downto -35 ‡ (-37 †), the boiling point of the cool-ant during operation is approximately 266 ‡(130 †).

The antifreeze/corrosion inhibitor concentra-tion in the engine cooling system should:

Rbe at least 50%. This will protect the enginecooling system against freezing down toapproximately -35 ‡ (-37 †).

Rnot exceed 55% (antifreeze protection downto -49 ‡ [-45 †]). Otherwise, heat will notbe dissipated as effectively.

If the vehicle has lost coolant, add equalamounts of water and antifreeze/corrosioninhibitor.

Mercedes-Benz recommends an antifreeze/corrosion inhibitor concentrate in accordancewith MB Specifications for Service Products310.1.

iWhen the vehicle is first delivered, it is fil-led with a coolant mixture that ensures ade-quate antifreeze and anti-corrosion protec-tion.

iThe coolant is checked with every mainte-nance interval at a qualified specialist work-shop.

Filling capacities

Missing values were not available at time ofgoing to print.

ModelCapacity

SLC 300Approx. 8.5 US qt(8.0 l)

Mercedes‑BenzSLC 43 AMGApprox. 8.2 US qt(7.8 l)

Windshield washer system

Important safety notes

GWARNING

Windshield washer concentrate is highly

flammable. If windshield washer concentrate

gets onto hot components of the engine or

the exhaust system, it can ignite. There is a

risk of fire and injury.

Make sure that windshield washer concen-

trate is not spilled in the vicinity of the filler

neck.

!Only use washer fluid which is suitable forlamp lenses, e.g. MB SummerFit or MB Win-terFit. Unsuitable washer fluid may damagethe lamp lenses of the headlamps.

!Only MB SummerFit and MB WinterFitwasher fluid should be mixed together. Thespray nozzles may otherwise becomeblocked.

Do not use distilled or de-ionized water. Other-wise, the level sensor may give a false reading.

When handling washer fluid, observe theimportant safety notes on service products(Ypage 298).

At temperatures above freezing:

XFill the washer fluid reservoir with a mixtureof water and windshield washer fluid, e.g.MB SummerFit.

XAdd 1 part MB SummerFit to 100 partswater.

At temperatures below freezing:

XFill the washer fluid reservoir with a mixtureof water and washer fluid, e.g. MB WinterFit.

For the correct mixing ratio refer to theinformation on the antifreeze reservoir.

iAdd windshield washer fluid, e.g. MB Sum-merFit or MB WinterFit, to the washer fluidall year round.

302Service products and filling capacities

Technical data