oil type MERCEDES-BENZ SLC 2019 Owners Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2019, Model line: SLC, Model: MERCEDES-BENZ SLC 2019Pages: 306, PDF Size: 15 MB

Page 20 of 306

Technical data

Capacities ...................................... 298

Emergency spare wheel ................. 294

Information .................................... 296

Tires/wheels ................................. 292

Vehicle data ................................... 303

TELEAID

Call priority .................................... 233

Emergency call .............................. 231

General notes ................................ 230

MB info call button ........................233

Roadside Assistance button .......... 232

Self-test ......................................... 230

System .......................................... 230

Vehicle Health Check .................... 233

Telephone

Accepting a call (multifunction

steering wheel) .............................. 174

Authorizing a mobile phone (con-

necting) ......................................... 221

Authorizing a mobile phone via

the device manager (connecting) ... 222

Connecting a mobile phone

(device manager) ........................... 222

Connecting a mobile phone (gen-

eral information) ............................ 221

Display message ............................ 205

Menu (on-board computer) ............ 173

Number from the phone book ........174

Redialing ........................................ 174

Rejecting/ending a call ................. 174

see also Digital Operator's Man-

ual ..................................................217

Temperature

Coolant .......................................... 168

Coolant (on-board computer,

Mercedes-AMG SLC 43) ................ 179

Engine oil (on-board computer,

Mercedes-AMG SLC 43) ................ 179

Outside temperature ......................167

Setting (climate control) ................ 111

Transmission oil (on-board com-

puter, Mercedes-AMG SLC 43) ...... 179

Timing (RACETIMER)......................... 180

Tire pressure

Calling up (on-board computer) ..... 274

Checking manually ........................ 273

Display message ............................ 201

Maximum ....................................... 273

Not reached (TIREFIT) .................... 256

Notes ............................................. 272

Reached (TIREFIT) .......................... 256

Recommended ............................... 270

Tire pressure loss warning sys-

tem

General notes ................................ 273

Important safety notes .................. 274

Restarting ...................................... 274

Tire pressure monitor

Checking the tire pressure elec-

tronically ........................................ 276

Function/notes .............................274

General notes ................................ 274

Important safety notes .................. 275

Radio type approval for the tire

pressure monitor ........................... 278

Restarting ...................................... 277

Warning lamp ................................. 216

Warning message .......................... 276

Tire-change tool kit........................... 252

TIREFIT kit.......................................... 254

Important safety notes .................. 254

Storage location ............................ 252

Tire pressure not reached .............. 256

Tire pressure reached .................... 256

Tires

Aspect ratio (definition) ................. 287

Average weight of the vehicle

occupants (definition) .................... 286

Bar (definition) ............................... 286

Changing a wheel .......................... 288

Characteristics .............................. 286

Checking ........................................ 267

Curb weight (definition) ................. 287

Definition of terms ......................... 286

Direction of rotation...................... 289

Display message ............................ 201

Distribution of the vehicle occu-

pants (definition) ............................ 288

DOT (Department of Transporta-

tion) (definition) ............................. 286

DOT, Tire Identification Number

(TIN) ............................................... 285

GAWR (Gross Axle Weight Rat-

ing) (definition) .............................. 287

18Index

Page 249 of 306

XThoroughly hose down the vehicle with agentle jet of water.

XDo not point the water jet directly towardsthe air inlet or the edges of decorative foils.

XUse plenty of water and rinse out thesponge frequently.

XRinse the vehicle with clean water and drythoroughly with a chamois.

XDo not let the cleaning agent dry on thepaintwork or the decorative foils.

Carefully remove all deposits of road salt assoon as possible when driving in winter.

Power washers

GWARNING

The water jet from a circular jet nozzle (dirt

blasters) can cause invisible exterior dam-

age to the tires or chassis components.

Components damaged in this way may fail

unexpectedly. There is a risk of an accident.

Do not use power washers with circular jet

nozzles to clean the vehicle. Have damaged

tires or chassis components replaced imme-

diately.

!Vehicles with decorative film: parts of yourvehicle are covered with decorative film.Maintain a distance of at least 27.5 in(70 cm) between the film-covered parts ofthe vehicle and the nozzle of the powerwasher.

Information about the correct distance isavailable from the equipment manufacturer.

Move the power washer nozzle around whencleaning your vehicle.

The water temperature of the power washermust not exceed 140 ‡ (60 †).

!Always maintain a distance of at least12 in (30 cm) between the vehicle and thepower washer nozzle. Information about thecorrect distance is available from the equip-ment manufacturer.

Move the power washer nozzle around whencleaning your vehicle.

Do not aim directly at any of the following:

RTires

RDoor gaps, roof gaps, joints, etc.

RElectrical components

RBattery

RPlug-type couplings

RLight bulbs

RSeals

RTrim elements

RVentilation slots

Damaged seals or electrical componentscan lead to leaks or failures.

!If you clean the tank filler recess when it isopen, do not use a power washer. This cancause damage to the seals or other compo-nents.

Cleaning the paintwork

!Do not affix:

Rstickers

Rfilms

Rmagnetic plates or similar items

to painted surfaces. You could otherwisedamage the paintwork.

Scratches, corrosive deposits, areas affectedby corrosion and damage caused by inade-quate care cannot always be completelyrepaired. In such cases, visit a qualified spe-cialist workshop.

XRemove dirt immediately, where possible,while avoiding rubbing too hard.

XSoak insect remains with insect removerand rinse off the treated areas afterwards.

XSoak bird droppings with water and rinse offthe treated areas afterwards.

XRemove tree resin, oils, fuels and greases byrubbing gently with a cloth soaked in petro-leum ether or lighter fluid

XRemove coolant and brake fluid with a moistcloth and clear water.

XUse tar remover to remove tar stains.

XUse silicone remover to remove wax.

If water no longer forms "beads" on the paintsurface, use the paint care products recom-mended and approved by Mercedes-Benz. Thisis the case approximately every three to fivemonths, depending on the climate conditionsand the care product used.

If dirt has penetrated the paint surface or ifthe paint has become dull, the paint cleanerrecommended and approved by Mercedes-Benz should be used.

Care247

Maintenance and care

Z

Page 305 of 306

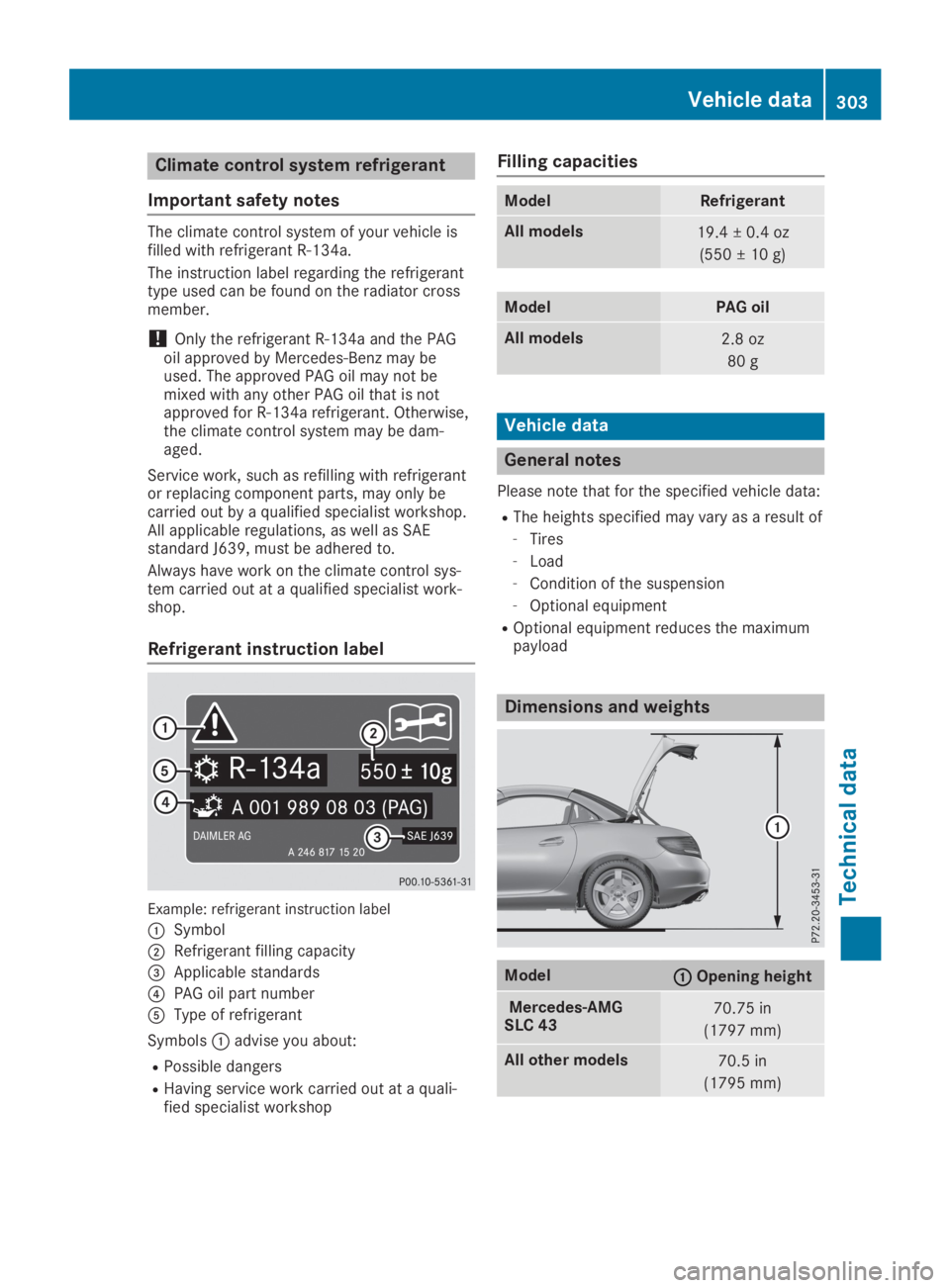

Climate control system refrigerant

Important safety notes

The climate control system of your vehicle isfilled with refrigerant R‑134a.

The instruction label regarding the refrigeranttype used can be found on the radiator crossmember.

!Only the refrigerant R‑134a and the PAGoil approved by Mercedes-Benz may beused. The approved PAG oil may not bemixed with any other PAG oil that is notapproved for R-134a refrigerant. Otherwise,the climate control system may be dam-aged.

Service work, such as refilling with refrigerantor replacing component parts, may only becarried out by a qualified specialist workshop.All applicable regulations, as well as SAEstandard J639, must be adhered to.

Always have work on the climate control sys-tem carried out at a qualified specialist work-shop.

Refrigerant instruction label

Example: refrigerant instruction label

�CSymbol

�DRefrigerant filling capacity

�