lock MERCEDES-BENZ SLK CLASS 2002 Owners Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2002, Model line: SLK CLASS, Model: MERCEDES-BENZ SLK CLASS 2002Pages: 290, PDF Size: 18.21 MB

Page 220 of 290

217 Tires, wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

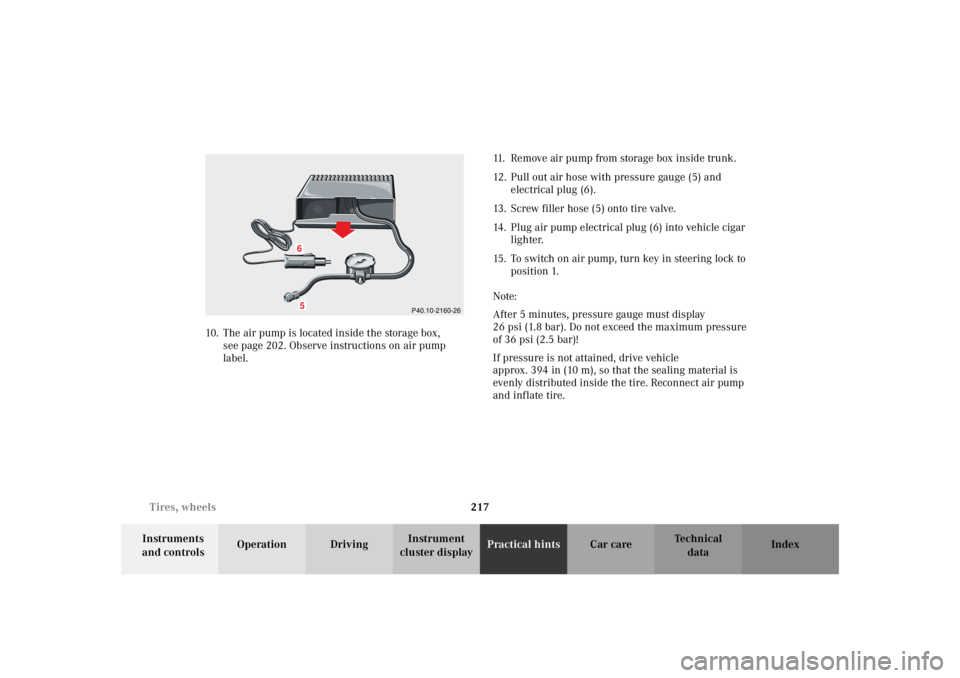

cluster displayPractical hintsCar care Index 10. The air pump is located inside the storage box,

see page 202. Observe instructions on air pump

label.11. Remove air pump from storage box inside trunk.

12. Pull out air hose with pressure gauge (5) and

electrical plug (6).

13. Screw filler hose (5) onto tire valve.

14. Plug air pump electrical plug (6) into vehicle cigar

lighter.

15. To switch on air pump, turn key in steering lock to

position 1.

Note:

After 5 minutes, pressure gauge must display

26 psi (1.8 bar). Do not exceed the maximum pressure

of 36 psi (2.5 bar)!

If pressure is not attained, drive vehicle

approx. 394 in (10 m), so that the sealing material is

evenly distributed inside the tire. Reconnect air pump

and inflate tire.

P40.10-2160-26

65

Page 221 of 290

218 Tires, wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

Note:

Do not operate electric air pump longer that 6 minutes

without interruption. Air pump could overheat! After air

pump has cooled off, operate air pump again.

16. To switch off air pump, turn key in steering lock to

position 0.

17. Reinstall valve tire cap.

18. Drive vehicle to distribute the sealant evenly inside

the tire.Notes:

If TIREFIT is liquid, clean water and a damp cloth will

remove the material from the vehicle or tire and wheel

components. Once TIREFIT sealing material had dried,

it can easily be peeled off and properly discarded.

Replace TIREFIT every 4 years.

Wa r n i n g !

If a tire pressure of 26 psi (1.8 bar) is not attained,

tire is too severely damaged for TIREFIT to provide

a reliable tire repair.In this case TIREFIT can not properly seal the tire.Do not drive the vehicle.Contact the nearest Mercedes-Benz Center or call

Roadside Assistance.

Wa r n i n g !

Do not exceed vehicle speed of 50 mph (80 km / h).

A TIREFIT repair is not designed to operate at

higher speeds.Vehicle handling characteristics may change.After driving vehicle for an initial 10 minutes,

check tire pressure. If tire pressure has fallen

below 20 psi (1.3 bar) do not continue to drive the

vehicle.If tire pressure is at least 20 psi (1.3 bar), inflate

tire to correct pressure (see label on fuel filler

flap), and drive vehicle to nearest tire repair

facility to have tire repaired or replaced.Recommended duration of use: 300 miles (500 km)

at 50 mph (80 km / h) with the recommended tire

pressure.

Page 224 of 290

221 Battery

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index Therefore, we strongly recommend that you have the

battery charge checked frequently, and corrected if

necessary, especially if you use the vehicle less than

approximately 200 miles (300 km) per month,

mostly for short distance trips, or if it is not used for

long periods of time.

Only charge a battery with a battery charger after the

battery has been disconnected from the vehicle’s

electrical circuit.

Always disconnect the battery negative lead first and

connect last.

When removing and connecting the battery, always

make sure that all electrical consumers are off and the

key is in steering lock position 0. The battery must

always be securely installed when the vehicle is in

operation. During removal and installation always

protect the disconnected battery positive (+) terminal

with the cover attached to the battery.

While the engine is running the battery terminal clamps

must not be loosened or detached, otherwise the

generator and other electronic components will be

damaged.Battery recycling

Batteries contain materials that can harm the

environment with improper disposal.

Large 12 Volt storage batteries contain lead.

Recycling of batteries is the preferred method of

disposal.

Many states require sellers of batteries to accept old

batteries for recycling.

Page 230 of 290

227 Towing the vehicle

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index We recommend that the vehicle be transported using

flat bed equipment. This method is preferable to other

types of towing.

Do not tow with sling-type equipment. Front towing

with sling-type equipment over bumpy roads will

damage radiator and supports. Rear towing with sling-

type equipment over bumpy roads will damage the

lower edge of the front bumper cover.

Use wheel lift, dolly, or flat bed equipment, with key in

steering lock turned to position 0.

Towing restrictions for vehicles with automatic

transmission: The vehicle may be towed with all wheels

on the ground and the selector lever in position “N” for

distances up to 30 miles (50 km) and at a speed not to

exceed 30 mph (50 km / h). The key must be in steering

lock position 2.

To be certain to avoid a possibility of damage to the

transmission, however, we recommend the drive shaft

be disconnected at the rear axle drive flange for any

towing beyond a short tow to a nearby garage.Important!

When towing the vehicle, please, note the following:

With the automatic central locking activated and the

key in steering lock position 2, the vehicle doors lock if

the left front wheel as well as the right rear wheel are

turning at vehicle speeds of approximately 9 mph

(15 km / h) or more.

To prevent the vehicle door locks from locking,

deactivate the automatic central locking.

Wa r n i n g !

Prior to towing the vehicle with all wheels on the

ground make certain that the electronic key is in

steering lock position 2.

With the engine not running, there is no power

assistance for the braking and steering systems. In

this case, it is important to keep in mind that a

considerably higher degree of effort in necessary to

brake and steer the vehicle.

Page 231 of 290

228 Towing the vehicle

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

Note:

To signal turns while being towed with hazard warning

flasher in use, turn key in steering lock to position 2 and

activate combination switch for left or right turn signal

in usual manner – only the selected turn signal will

operate. Upon canceling the turn signal, the hazard

warning flasher will operate again.Caution!

If the vehicle is towed with the front axle raised, the

engine must be shut off (key in steering lock position 0

or 1). Otherwise, the ESP will immediately be engaged

and will apply the rear wheel brakes. Switch off the

tow-away alarm as well as the automatic central locking,

see page 37 and page 31.

Page 232 of 290

229 Towing the vehicle

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index Transmission selector lever, manually unlocking

In the case of power failure the transmission selector

lever can be manually unlocked, e.g. when towing the

vehicle.To do so, insert a pin (1), e.g. ball point pen, into the

covered opening below the position “D” of the shift

pattern. While pushing the pin down, move selector

lever from position “P”.

After removal of the pin from the opening, the cover will

not close fully. Only after moving the selector lever to

positions “D+” and “D–” does the cover return to its

closed position.

P27.60-2101-26

1

Page 234 of 290

231 Exterior lamps

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

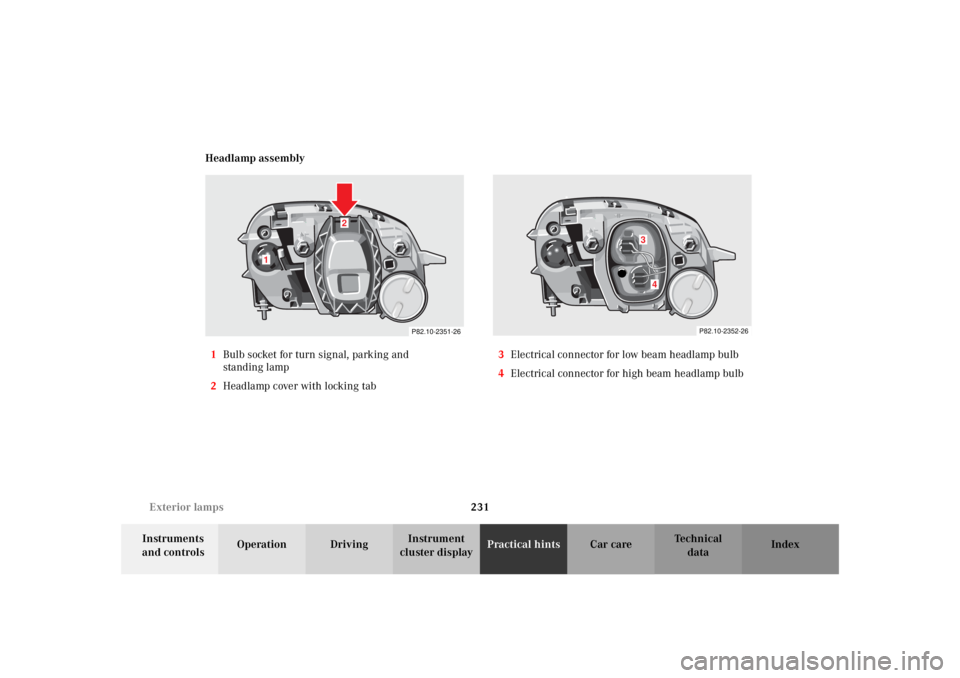

cluster displayPractical hintsCar care Index Headlamp assembly

1Bulb socket for turn signal, parking and

standing lamp

2Headlamp cover with locking tab3Electrical connector for low beam headlamp bulb

4Electrical connector for high beam headlamp bulb

2

P82.10-2351-26

1

P82.10-2352-26

3

4

Page 236 of 290

233 Exterior lamps

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

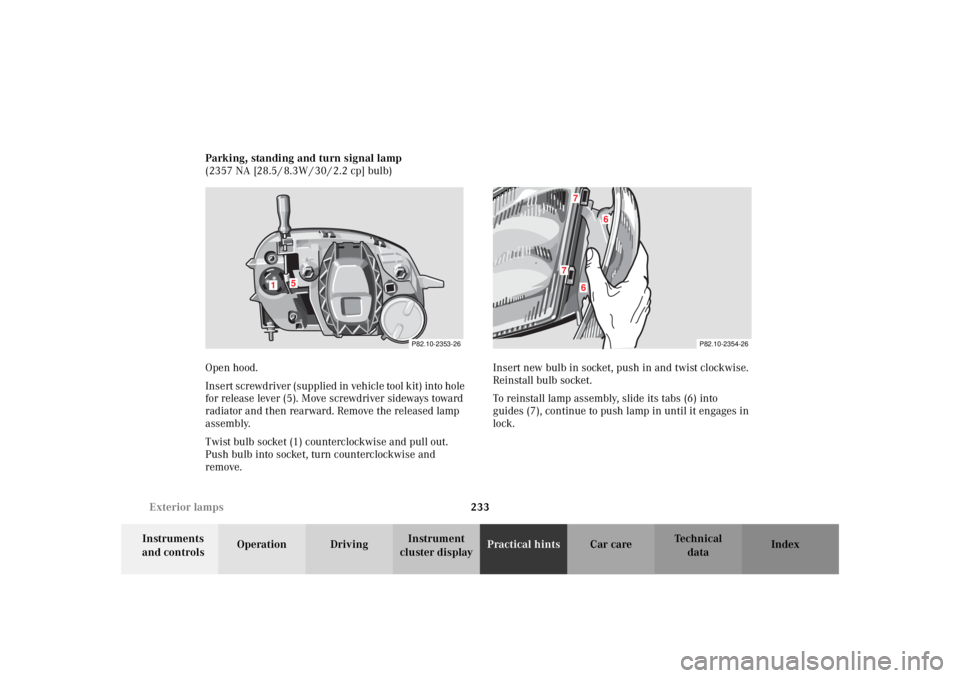

cluster displayPractical hintsCar care Index Parking, standing and turn signal lamp

(2357 NA [28.5 / 8.3W / 30 / 2.2 cp] bulb)

Open hood.

Insert screwdriver (supplied in vehicle tool kit) into hole

for release lever (5). Move screwdriver sideways toward

radiator and then rearward. Remove the released lamp

assembly.

Twist bulb socket (1) counterclockwise and pull out.

Push bulb into socket, turn counterclockwise and

remove.Insert new bulb in socket, push in and twist clockwise.

Reinstall bulb socket.

To reinstall lamp assembly, slide its tabs (6) into

guides (7), continue to push lamp in until it engages in

lock.

5

1

P82.10-2353-26

P82.10-2354-26

7

6

7

6

Page 237 of 290

234 Exterior lamps

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

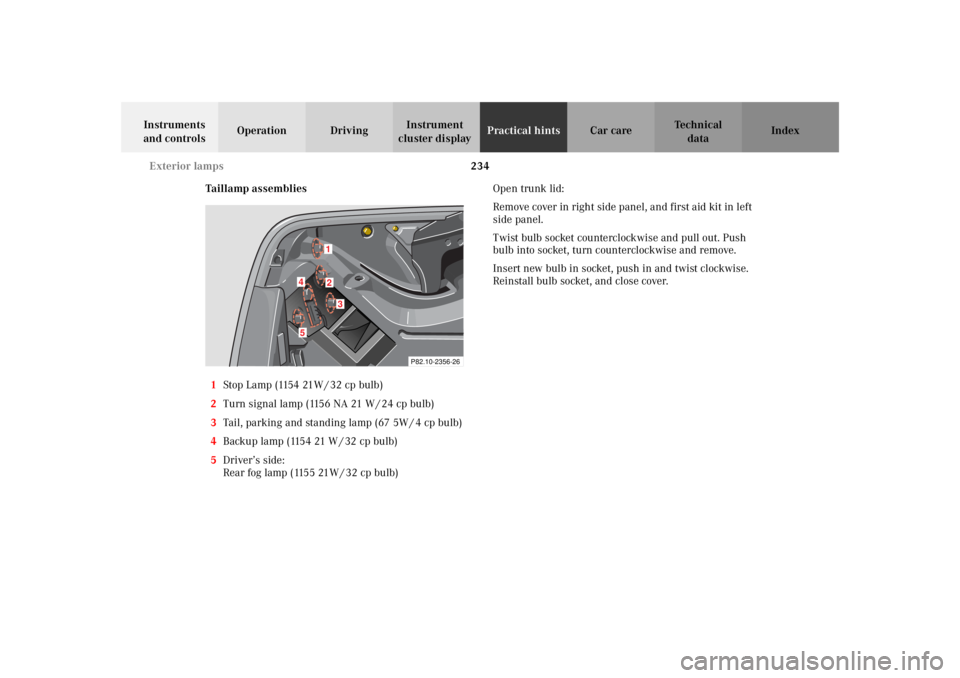

Taillamp assemblies

1Stop Lamp (1154 21W / 32 cp bulb)

2Turn signal lamp (1156 NA 21 W / 24 cp bulb)

3Tail, parking and standing lamp (67 5W / 4 cp bulb)

4Backup lamp (1154 21 W / 32 cp bulb)

5Driver’s side:

Rear fog lamp (1155 21W / 32 cp bulb)Open trunk lid:

Remove cover in right side panel, and first aid kit in left

side panel.

Twist bulb socket counterclockwise and pull out. Push

bulb into socket, turn counterclockwise and remove.

Insert new bulb in socket, push in and twist clockwise.

Reinstall bulb socket, and close cover.

P82.10-2356-26

4

12

5

3

Page 238 of 290

235 Exterior lamps

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index Side marker lamp, front

(5 W / 4 cp bulb)

Carefully slide lamp towards front (arrow), and remove

back end first from bumper.

Turn bulb socket with bulb counterclockwise and pull

out. Push bulb into socket, turn counterclockwise and

remove.Insert new bulb in socket, push in and twist clockwise.

Insert bulb socket with bulb in lamp and twist

clockwise.

To reinstall lamp, set back end of lamp into bumper and

let front end snap into place.

High mounted stop lamp,

Additional turn signals on the exterior mirror

The high mounted stop lamp (3rd brake lamp) and the

additional turn signals on the exterior mirrors are

equipped with LEDs.

Have the system checked at an authorized

Mercedes-Benz Center if a malfunction occurs.

P82.10-2477-26