engine MERCEDES-BENZ SLK CLASS 2002 Manual PDF

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2002, Model line: SLK CLASS, Model: MERCEDES-BENZ SLK CLASS 2002Pages: 290, PDF Size: 18.21 MB

Page 201 of 290

198 Coolant level

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

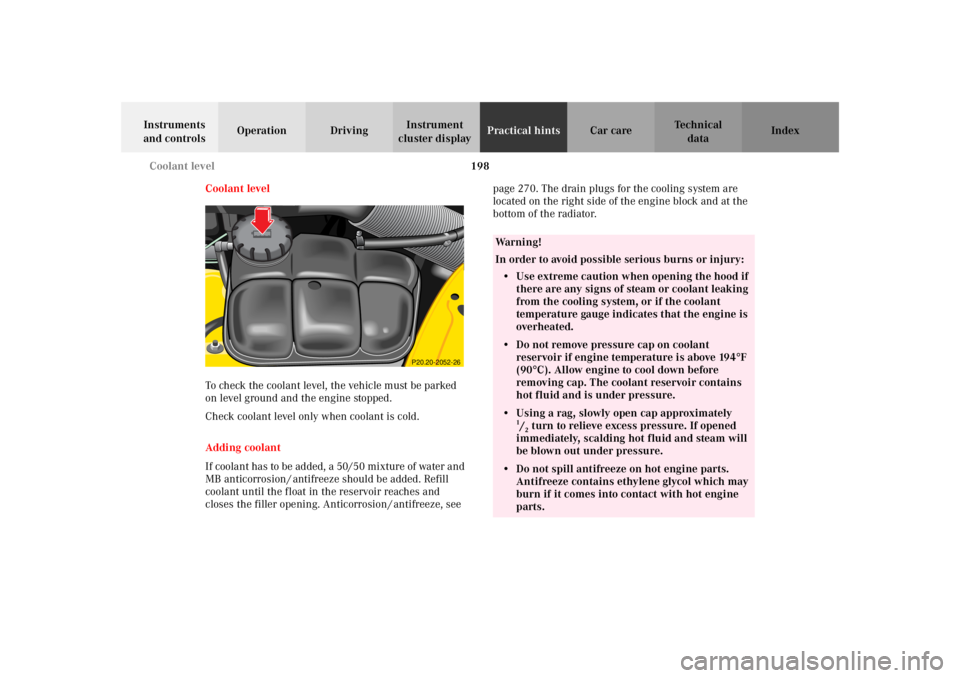

Coolant level

To check the coolant level, the vehicle must be parked

on level ground and the engine stopped.

Check coolant level only when coolant is cold.

Adding coolant

If coolant has to be added, a 50/50 mixture of water and

MB anticorrosion / antifreeze should be added. Refill

coolant until the float in the reservoir reaches and

closes the filler opening. Anticorrosion / antifreeze, see page 270. The drain plugs for the cooling system are

located on the right side of the engine block and at the

bottom of the radiator.

P20.20-2052-26

Wa r n i n g !

In order to avoid possible serious burns or injury:

• Use extreme caution when opening the hood if

there are any signs of steam or coolant leaking

from the cooling system, or if the coolant

temperature gauge indicates that the engine is

overheated.• Do not remove pressure cap on coolant

reservoir if engine temperature is above 194°F

(90°C). Allow engine to cool down before

removing cap. The coolant reservoir contains

hot fluid and is under pressure.• Using a rag, slowly open cap approximately

1/2 turn to relieve excess pressure. If opened

immediately, scalding hot fluid and steam will

be blown out under pressure.

• Do not spill antifreeze on hot engine parts.

Antifreeze contains ethylene glycol which may

burn if it comes into contact with hot engine

parts.

Page 210 of 290

207 Tires, wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index Changing wheelsMove vehicle to a level area which is a safe distance

from the roadway.

1. Set parking brake and turn on hazard warning

flasher.

2. Move selector lever to position “P” and turn off

engine (manual transmission to 1st or reverse gear).

3. Prevent vehicle from rolling away by blocking

wheels with wheel chocks (not supplied with

vehicle) or sizable wood block or stone. When

changing a wheel on a hill, place chocks on the

downhill side blocking both wheels of the other

axle. On a level road, place one chock in front of and

one behind the wheel that is diagonally opposite to

the wheel being changed.

The jack is designed exclusively for jacking up the

vehicle at the jack tubes built into either side of the

vehicle. To help avoid personal injury, use the jack

only to lift the vehicle during a wheel change.

Never get beneath the vehicle while it is supported

by the jack. Keep hands and feet away from the area

under the lifted vehicle. Always firmly set parking

brake and block wheels before raising vehicle with

jack.Do not disengage parking brake while the vehicle is

raised. Be certain that the jack is always vertical

when in use, especially on hills. Always try to use

the jack on level surface. Be sure that the jack arm

is fully inserted in the jack tube. Always lower the

vehicle onto sufficient capacity jackstands before

working under the vehicle.

Page 212 of 290

209 Tires, wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

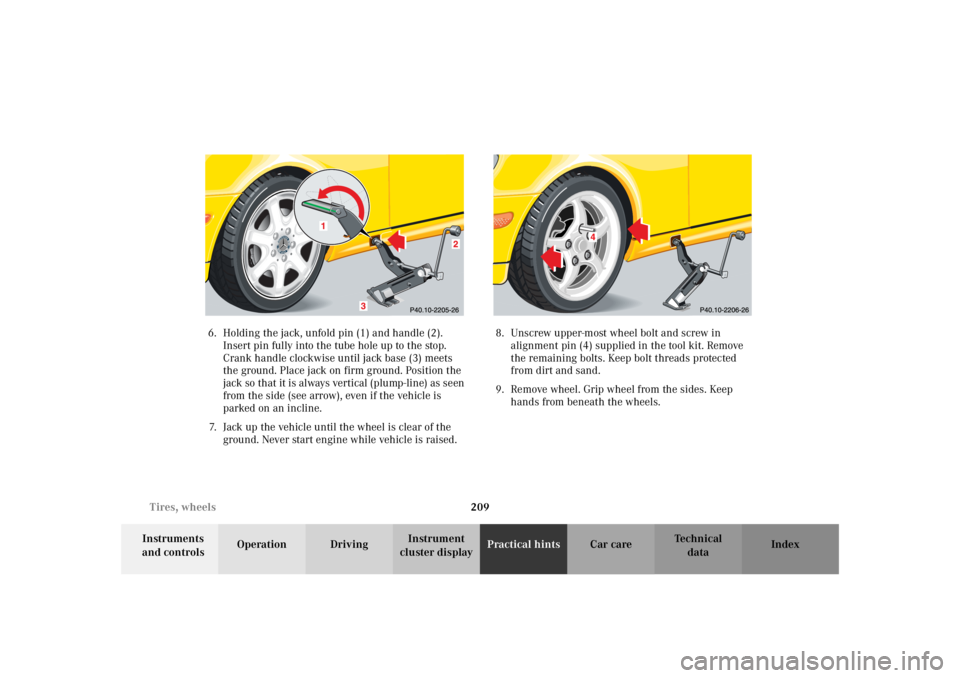

cluster displayPractical hintsCar care Index 6. Holding the jack, unfold pin (1) and handle (2).

Insert pin fully into the tube hole up to the stop.

Crank handle clockwise until jack base (3) meets

the ground. Place jack on firm ground. Position the

jack so that it is always vertical (plump-line) as seen

from the side (see arrow), even if the vehicle is

parked on an incline.

7. Jack up the vehicle until the wheel is clear of the

ground. Never start engine while vehicle is raised.8. Unscrew upper-most wheel bolt and screw in

alignment pin (4) supplied in the tool kit. Remove

the remaining bolts. Keep bolt threads protected

from dirt and sand.

9. Remove wheel. Grip wheel from the sides. Keep

hands from beneath the wheels.

Page 215 of 290

212 Tires, wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

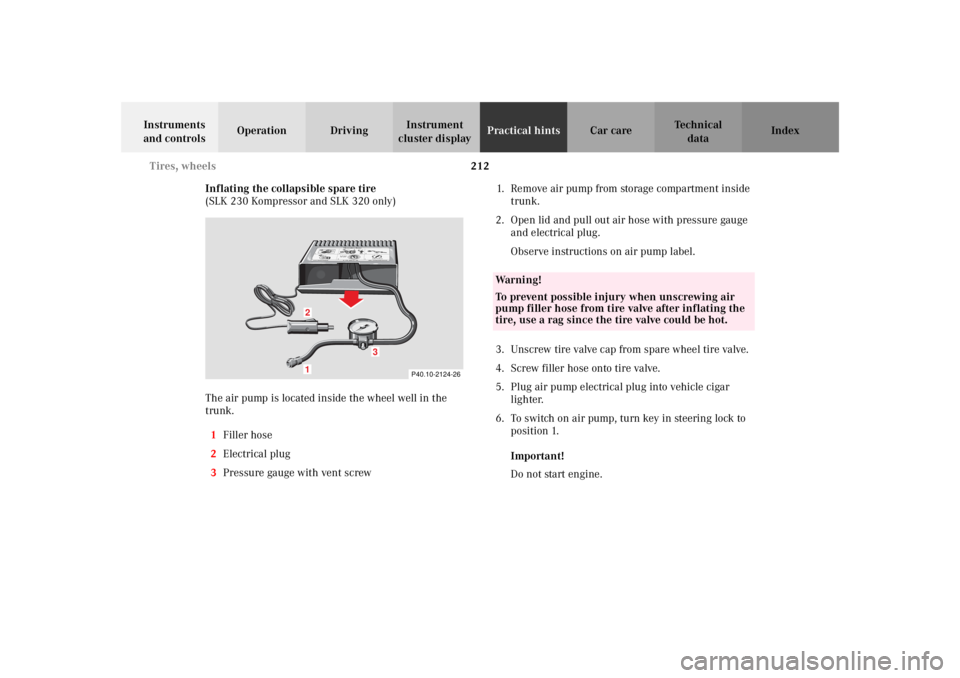

Inflating the collapsible spare tire

(SLK 230 Kompressor and SLK 320 only)

The air pump is located inside the wheel well in the

trunk.

1Filler hose

2Electrical plug

3Pressure gauge with vent screw1. Remove air pump from storage compartment inside

trunk.

2. Open lid and pull out air hose with pressure gauge

and electrical plug.

Observe instructions on air pump label.

3. Unscrew tire valve cap from spare wheel tire valve.

4. Screw filler hose onto tire valve.

5. Plug air pump electrical plug into vehicle cigar

lighter.

6. To switch on air pump, turn key in steering lock to

position 1.

Important!

Do not start engine.

P40.10-2124-26

1

0

45 6max. 6 min

A 170 584 01 38 AIR COMPRESSOR 23

Mercedes-Benz

2

3

2 1

1

2,5 bar

36 psi1

0 23

4

5

620PSI

BAR40

60

80

LUFTPRESSER12

12

3

Wa r n i n g !

To prevent possible injury when unscrewing air

pump filler hose from tire valve after inflating the

tire, use a rag since the tire valve could be hot.

Page 218 of 290

215 Tires, wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

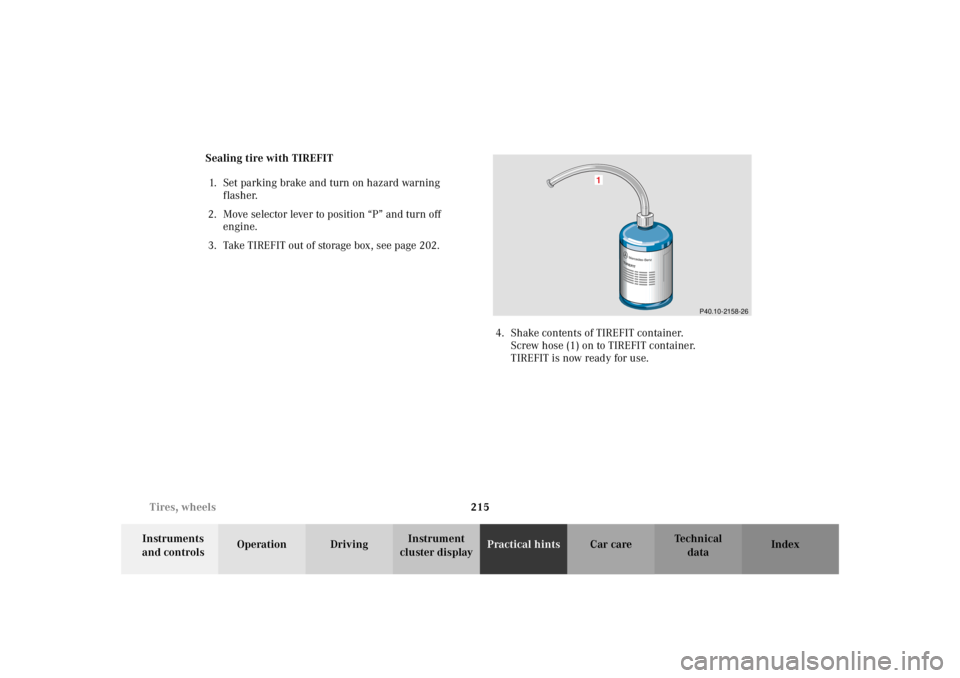

cluster displayPractical hintsCar care Index Sealing tire with TIREFIT

1. Set parking brake and turn on hazard warning

flasher.

2. Move selector lever to position “P” and turn off

engine.

3. Take TIREFIT out of storage box, see page 202.

4. Shake contents of TIREFIT container.

Screw hose (1) on to TIREFIT container.

TIREFIT is now ready for use.

1

P40.10-2158-26

Page 223 of 290

220 Battery

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

If a tire constantly loses air, it should be inspected for

damage.

The spare tire should be checked periodically for

condition. Spare tire will age and become worn over

time even if never used, and thus should be inspected

and replaced when necessary.Battery

Important!

Battery replacement information:

The maintenance-free battery is located in the engine

compartment.

The service life of the battery is dependent on its

condition of charge. The battery should always be kept

sufficiently charged, in order to last an optimum length

of time.

Wa r n i n g !

Do not overinflate tires. Overinflating tires can

result in sudden deflation (blowout) because they

are more likely to become punctured or damaged

by road debris, potholes etc.. Follow recommended

inflation pressures.Do not overload the tires by exceeding the specified

vehicle capacity weight (as indicated by the label

on the driver’s door latch post). Overloading the

tires can overheat them, possibly causing a

blowout.

Wa r n i n g !

Failure to follow these instructions can result in

severe injury or death.Never lean over batteries while connecting, you

might get injured.Battery fluid contains sulfuric acid. Do not allow

this fluid to come in contact with eyes, skin or

clothing. In case it does, immediately flush affected

area with water and seek medical help.A battery will also produce hydrogen gas, which is

flammable and explosive. Keep flames or sparks

away from battery, avoid improper connection of

jumper cables, smoking etc..

Page 224 of 290

221 Battery

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index Therefore, we strongly recommend that you have the

battery charge checked frequently, and corrected if

necessary, especially if you use the vehicle less than

approximately 200 miles (300 km) per month,

mostly for short distance trips, or if it is not used for

long periods of time.

Only charge a battery with a battery charger after the

battery has been disconnected from the vehicle’s

electrical circuit.

Always disconnect the battery negative lead first and

connect last.

When removing and connecting the battery, always

make sure that all electrical consumers are off and the

key is in steering lock position 0. The battery must

always be securely installed when the vehicle is in

operation. During removal and installation always

protect the disconnected battery positive (+) terminal

with the cover attached to the battery.

While the engine is running the battery terminal clamps

must not be loosened or detached, otherwise the

generator and other electronic components will be

damaged.Battery recycling

Batteries contain materials that can harm the

environment with improper disposal.

Large 12 Volt storage batteries contain lead.

Recycling of batteries is the preferred method of

disposal.

Many states require sellers of batteries to accept old

batteries for recycling.

Page 225 of 290

222 Battery

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

Jump startingImportant!

A discharged battery can freeze at approximately +14°F

(–10°C). In that case, it must be thawed out before

jumper cables are used. Attempting to jump start a

frozen battery can result in exploding, causing personal

injury.

Jumper cable specifications:

•Minimum cable cross-section of 25 mm

2 or

approximately 2 AWG

•Maximum length of 11.5 ft. (3.5 m).

If the battery is discharged, the engine should be started

with jumper cables and the (12 V) battery of another

vehicle.

Only use 12 V battery to jump start your vehicle. Jump

starting with more powerful battery could damage the

vehicle’s electrical systems, which will not be covered

by the Mercedes-benz Limited Warranty.

The battery is located in the engine compartment.

Wa r n i n g !

Failure to follow these directions will cause

damage to the electronic components, and can lead

to a battery explosion and severe injury or death.Never lean over batteries while connecting or jump

starting, you might get injured.Battery fluid contains sulfuric acid. Do not allow

this fluid to come in contact with eyes, skin or

clothing. In case it does, immediately flush affected

area with water, and seek medical help if

necessary.A battery will also produce hydrogen gas, which is

flammable and very explosive. Keep flames or

sparks away from battery, avoid improper

connection of jumper cables, smoking etc..Read all instructions before proceeding.

Page 226 of 290

223 Jump starting

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index Proceed as follows:

1. Position the vehicle with the charged battery so that

the jumper cables will reach, but never let the

vehicles touch. Make sure the jumper cables do not

have loose or missing insulation.

2. On both vehicles:

•Turn off engine and all lights and accessories,

except hazard warning flashers or work lights.

•Apply parking brake and shift selector lever to

position “P” (manual transmission to Neutral).

Important!

3. Clamp one end of the first jumper cable to the

positive (+) terminal of the discharged battery and

the other end to the positive (+) terminal of the

charged battery. Make sure the cable clamps do not

touch any other metal parts.

4. Clamp one end of the second jumper cable to the

grounded negative (–) terminal of the charged

battery and the final connection to a grounded

heavy metal bracket in the engine compartment or

on the engine of the disabled vehicle.Important!

5. Start engine of the vehicle with the charged battery

and run at high idle. Make sure the cables are not

on or near pulleys, fans, or other parts that will

move when the engine is started. Allow the

discharged battery to charge for a few minutes. Start

engine of the disabled vehicle in the usual manner.

6. After the engine has started, remove jumper cables

by exactly reversing the above installation

sequence, starting with the last connection made

first. When removing each clamp, make sure that it

does not touch any other metal while the other end

is still attached.

Note:

If engine does not run after several unsuccessful

starting attempts, have it checked at the nearest

authorized Mercedes-Benz Center.

Excessive unburned fuel may damage the catalytic

converter.

Page 230 of 290

227 Towing the vehicle

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index We recommend that the vehicle be transported using

flat bed equipment. This method is preferable to other

types of towing.

Do not tow with sling-type equipment. Front towing

with sling-type equipment over bumpy roads will

damage radiator and supports. Rear towing with sling-

type equipment over bumpy roads will damage the

lower edge of the front bumper cover.

Use wheel lift, dolly, or flat bed equipment, with key in

steering lock turned to position 0.

Towing restrictions for vehicles with automatic

transmission: The vehicle may be towed with all wheels

on the ground and the selector lever in position “N” for

distances up to 30 miles (50 km) and at a speed not to

exceed 30 mph (50 km / h). The key must be in steering

lock position 2.

To be certain to avoid a possibility of damage to the

transmission, however, we recommend the drive shaft

be disconnected at the rear axle drive flange for any

towing beyond a short tow to a nearby garage.Important!

When towing the vehicle, please, note the following:

With the automatic central locking activated and the

key in steering lock position 2, the vehicle doors lock if

the left front wheel as well as the right rear wheel are

turning at vehicle speeds of approximately 9 mph

(15 km / h) or more.

To prevent the vehicle door locks from locking,

deactivate the automatic central locking.

Wa r n i n g !

Prior to towing the vehicle with all wheels on the

ground make certain that the electronic key is in

steering lock position 2.

With the engine not running, there is no power

assistance for the braking and steering systems. In

this case, it is important to keep in mind that a

considerably higher degree of effort in necessary to

brake and steer the vehicle.