flat tire MERCEDES-BENZ SLK-Class 2016 R172 Owner's Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2016, Model line: SLK-Class, Model: MERCEDES-BENZ SLK-Class 2016 R172Pages: 358, PDF Size: 7.24 MB

Page 334 of 358

Securing the vehicle on slight downhill gradients

XOn light downhill gradients:place

chocks or other suitable items in front of

the wheels of the front and rear axle.

Raising the vehicle

GWARNING

If you do not position the jack correctly at the

appropriate jacking point of the vehicle, the

jack could tip over with the vehicle raised.

There is a risk of injury.

Only position the jack at the appropriate jack-

ing point of the vehicle. The base of the jack

must be positioned vertically, directly under

the jacking point of the vehicle.

!The jack is designed exclusively for jack-

ing up the vehicle at the jacking points.

Otherwise, your vehicle could be damaged.

Observe the following when raising the vehi-

cle:

RTo raise the vehicle, only use the vehicle-

specific jack that has been tested and

approved by Mercedes-Benz. If used incor-

rectly, the jack could tip over with the vehi- cle raised.

RThe jack is designed only to raise and hold

the vehicle for a short time while a wheel

is being changed. It is not suited for per-

forming maintenance work under the vehi-

cle.

RAvoid changing the wheel on uphill and

downhill slopes.

RBefore raising the vehicle, secure it from

rolling away by applying the parking brake

and inserting wheel chocks. Never disen-

gage the parking brake while the vehicle is

raised.

RThe jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a

large, flat, load-bearing underlay must be

used. On a slippery surface, a non-slip

und erla

y must be used, e.g. rubber mats.

RDo not use wooden blocks or similar

objects as a jack underlay. Otherwise, the

jack will not be able to achieve its load-

bearing capacity due to the restricted

height.

RMake sure that the distance between the

underside of the tires and the ground does

not exceed 1.2 in (3 cm).

RNever place your hands and feet under the

raised vehicle.

RDo not lie under the vehicle.

RDo not start the engine when the vehicle is

raised.

RDo not open or close a door or the trunk lid

when the vehicle is raised.

RMake sure that no persons are present in

the vehicle when the vehicle is raised.

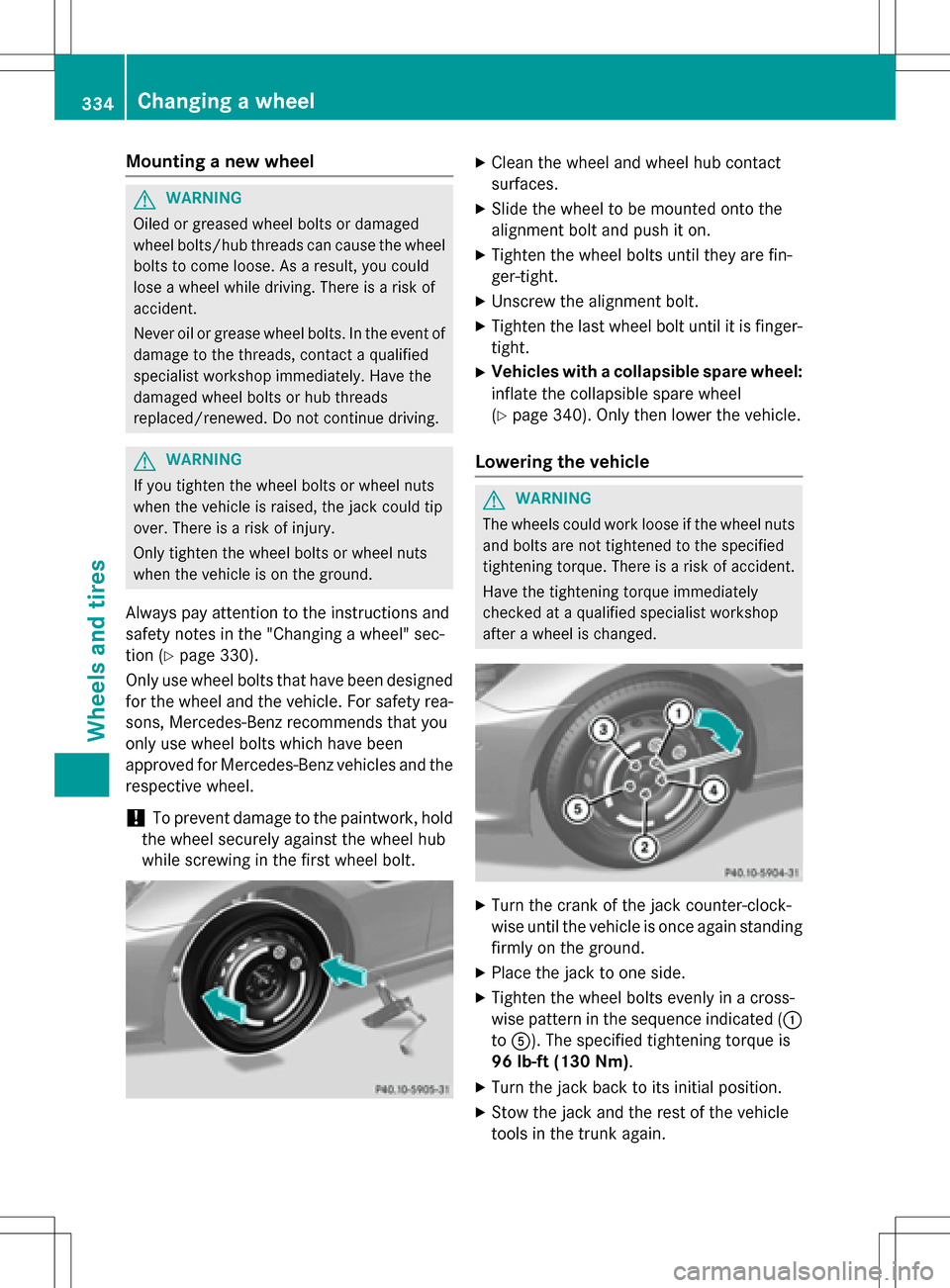

XUsing lug wrench :, loosen the bolts on

the wheel you wish to change by about one

full turn. Do not unscrew the bolts com-

pletely.

332Changing a wheel

Wheels and tires

Page 336 of 358

Mounting a new wheel

GWARNING

Oiled or greased wheel bolts or damaged

wheel bolts/hub threads can cause the wheel bolts to come loose. As a result, you could

lose a wheel while driving. There is a risk of

accident.

Never oil or grease wheel bolts. In the event of

damage to the threads, contact a qualified

specialist workshop immediately. Have the

damaged wheel bolts or hub threads

replaced/renewed. Do not continue driving.

GWARNING

If you tighten the wheel bolts or wheel nuts

when the vehicle is raised, the jack could tip

over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts

when the vehicle is on the ground.

Always pay attention to the instructions and

safety notes in the "Changing a wheel" sec-

tion (

Ypage 330).

Only use wheel bolts that have been designed for the wheel and the vehicle. For safety rea-

sons, Mercedes-Benz recommends that you

only use wheel bolts which have been

approved for Mercedes-Benz vehicles and the

respective wheel.

!To prevent damage to the paintwork, hold

the wheel securely against the wheel hub

while screwing in the first wheel bolt.

XClean the wheel and wheel hub contact

surfaces.

XSlide the wheel to be mounted onto the

alignment bolt and push it on.

XTighten the wheel bolts until they are fin-

ger-tight.

XUnscrew the alignment bolt.

XTighten the last wheel bolt until it is finger-

tight.

XVehicles with a collapsible spare wheel:

inflate the collapsible spare wheel

(

Ypage 340). Only then lower the vehicle.

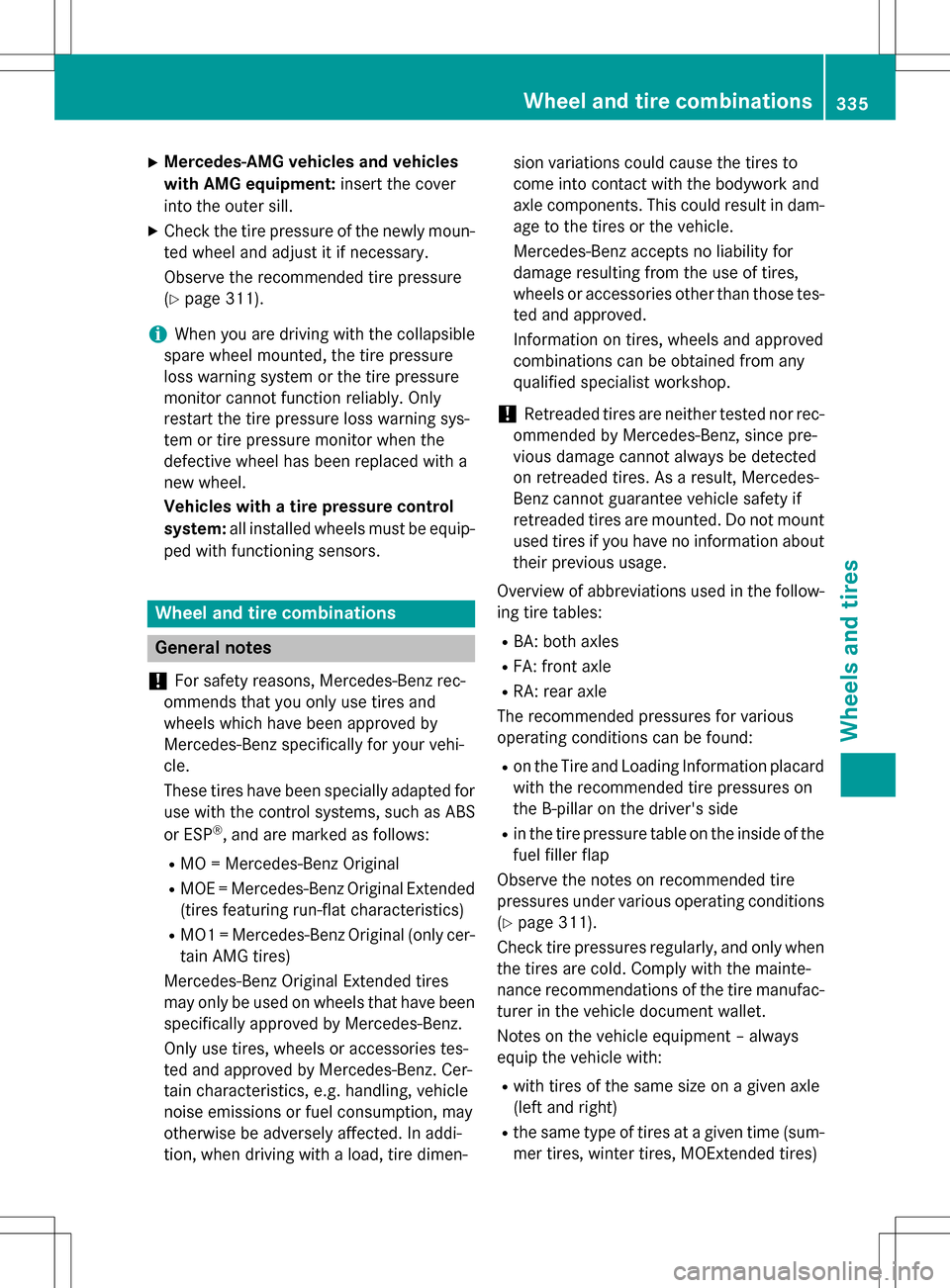

Lowering the vehicle

GWARNING

The wheels could work loose if the wheel nuts and bolts are not tightened to the specified

tightening torque. There is a risk of accident.

Have the tightening torque immediately

checked at a qualified specialist workshop

after a wheel is changed.

XTurn the crank of the jack counter-clock-

wise until the vehicle is once again standing

firmly on the ground.

XPlace the jack to one side.

XTighten the wheel bolts evenly in a cross-

wise pattern in the sequence indicated ( :

to A). The specified tightening torque is

96 lb-ft (130 Nm).

XTurn the jack back to its initial position.

XStow the jack and the rest of the vehicle

tools in the trunk again.

334Changing a wheel

Wheels and tires

Page 337 of 358

XMercedes-AMG vehicles and vehicles

with AMG equipment:insert the cover

into the outer sill.

XCheck the tire pressure of the newly moun-

ted wheel and adjust it if necessary.

Observe the recommended tire pressure

(

Ypage 311).

iWhen you are driving with the collapsible

spare wheel mounted, the tire pressure

loss warning system or the tire pressure

monitor cannot function reliably. Only

restart the tire pressure loss warning sys-

tem or tire pressure monitor when the

defective wheel has been replaced with a

new wheel.

Vehicles with a tire pressure control

system: all installed wheels must be equip-

ped with functioning sensors.

Wheel and tire combinations

General notes

!

For safety reasons, Mercedes-Benz rec-

ommends that you only use tires and

wheels which have been approved by

Mercedes-Benz specifically for your vehi-

cle.

These tires have been specially adapted for

use with the control systems, such as ABS

or ESP

®, and are marked as follows:

RMO = Mercedes-Benz Original

RMOE = Mercedes-Benz Original Extended

(tires featuring run-flat characteristics)

RMO1 = Mercedes-Benz Original (only cer-

tain AMG tires)

Mercedes-Benz Original Extended tires

may only be used on wheels that have been

specifically approved by Mercedes-Benz.

Only use tires, wheels or accessories tes-

ted and approved by Mercedes-Benz. Cer-

tain characteristics, e.g. handling, vehicle

noise emissions or fuel consumption, may

otherwise be adversely affected. In addi-

tion, when driving with a load, tire dimen- sion variations could cause the tires to

come into contact with the bodywork and

axle components. This could result in dam-

age to the tires or the vehicle.

Mercedes-Benz accepts no liability for

damage resulting from the use of tires,

wheels or accessories other than those tes-

ted and approved.

Information on tires, wheels and approved

combinations can be obtained from any

qualified specialist workshop.

!Retreaded tires are neither tested nor rec-

ommended by Mercedes-Benz, since pre-

vious damage cannot always be detected

on retreaded tires. As a result, Mercedes-

Benz cannot guarantee vehicle safety if

retreaded tires are mounted. Do not mount

used tires if you have no information about

their previous usage.

Overview of abbreviations used in the follow-

ing tire tables:

RBA: both axles

RFA: front axle

RRA: rear axle

The recommended pressures for various

operating conditions can be found:

Ron the Tire and Loading Information placard

with the recommended tire pressures on

the B-pillar on the dri

ver's side

Rin the tire pressure table on the inside of the

fuel filler flap

Observe the notes on recommended tire

pressures under various operating conditions

(

Ypage 311).

Check tire pressures regularly, and only when

the tires are cold. Comply with the mainte-

nance recommendations of the tire manufac-

turer in the vehicle document wallet.

Notes on the vehicle equipment – always

equip the vehicle with:

Rwith tires of the same size on a given axle

(left and right)

Rthe same type of tires at a given time (sum-

mer tires, winter tires, MOExtended tires)

Wheel and tire combinations335

Wheels and tires

Z

Page 338 of 358

Exception: it is permissible to install a dif-

ferent type or make in the event of a flat

tire. Observe the "MOExtended tires (tires

with run-flat characteristics" section

(

Ypage 291).

Vehicles equipped with MOExtended tires are not equipped with a TIREFIT kit at the factory.

It is therefore recommended that you addi-

tionally equip your vehicle with a TIREFIT kit if

you mount tires that do not feature run-flat

properties, e.g. winter tires. A TIREFIT kit may

be obtained from a qualified specialist work-

shop.

iNot all wheel and tire combinations are

available at the factory for all countries.

iThe following pages contain information

on approved wheel rims and tire sizes for

equipping your vehicle with winter tires.

Winter tires are not available at the factory

as standard equipment or optional extras.

If you want to equip your vehicle with

approved winter tires, it may be necessary

to obtain wheel rims in the corresponding

size. The size of the approved winter tires

may differ from the standard tires. This is

dependent on the model and the equip-

ment installed at the factory.

The tire

s and wheel rims, as well as further

information, can be obtained at a qualified

specialist workshop.

336Wheel and tire combinations

Wheels and tires

Page 342 of 358

found on the wheel or under "Technical data"

(

Ypage 342).

An emergency spare wheel may also be

mounted against the direction of rotation.

Observe the time restriction on use as well as

the speed limitation specified on the emer-

gency spare wheel.

Replace the tires after six years at the latest,

regardless of wear. This also applies to the

emergency spare wheel.

iWhen you are driving with the collapsible

spare wheel mounted, the tire pressure

loss warning system or the tire pressure

monitor cannot function reliably. Only

restart the tire pressure loss warning sys-

tem or tire pressure monitor when the

defective wheel has been replaced with a

new wheel.

Vehicles with tire pressure monitor:

after mounting an emergency spare wheel,

the system may still display the tire pres-

sure of the removed wheel for a few

minutes. The value displayed for the moun-

ted emergency spare wheel is not the same

as the current tire pressure of the emer-

gency spare wheel.

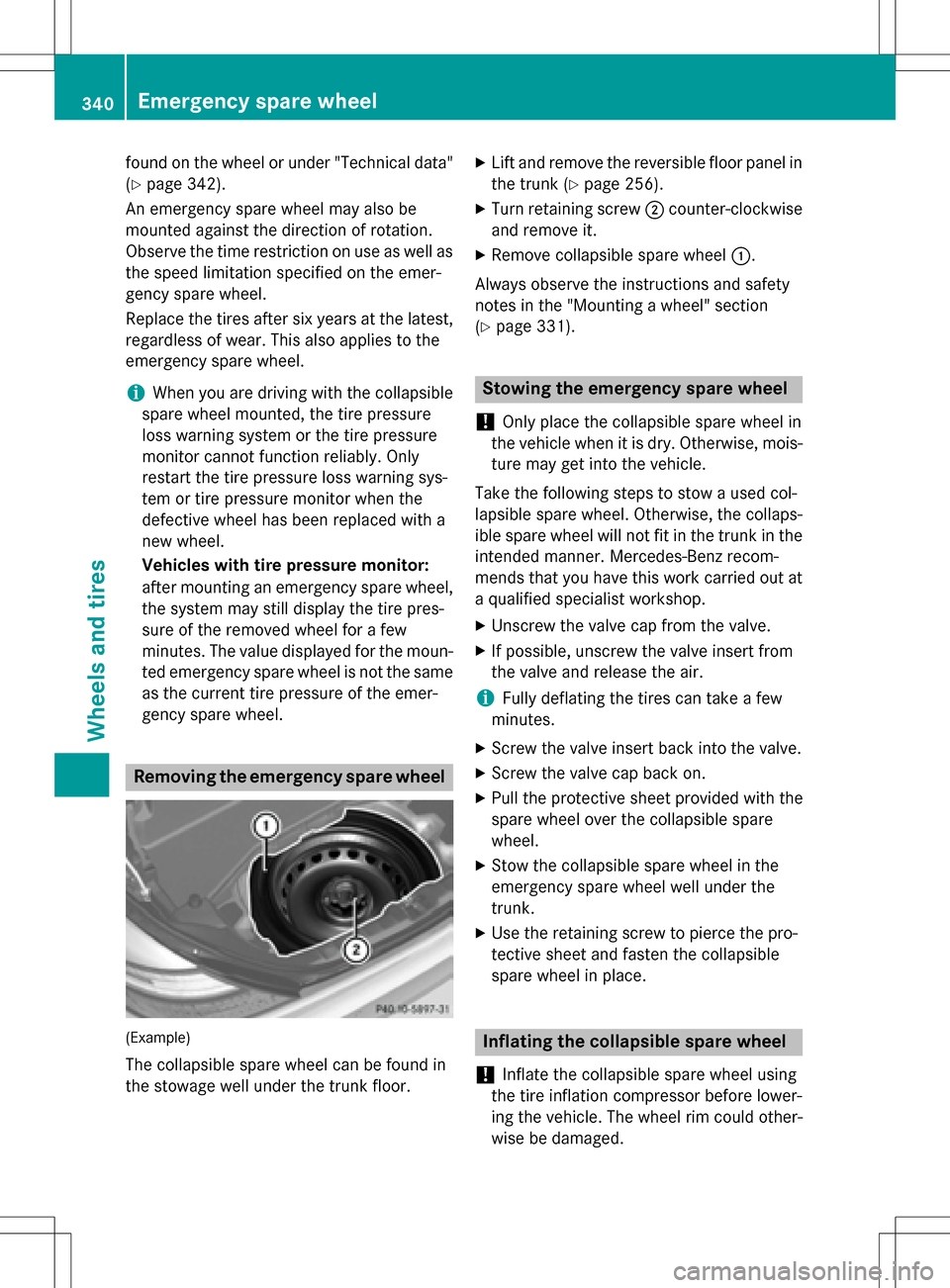

Removing the emergency spare wheel

(Example)

The collapsible spare wheel can be found in

the stowage well under the trunk floor.

XLift and remove the reversible floor panel in

the trunk (

Ypage 256).

XTurn retaining screw ;counter-clockwise

and remove it.

XRemove collapsible spare wheel :.

Always observe the instructions and safety

notes in the "Mounting a wheel" section

(

Ypage 331).

Stowing the emergency spare wheel

!

Only place the collapsible spare wheel in

the vehicle when it is dry. Otherwise, mois-

ture may get into the vehicle.

Take the following steps to stow a used col-

lapsible spare wheel. Otherwise, the collaps-

ible spare wheel will not fit in the trunk in the

intended manner. Mercedes-Benz recom-

mends that you have this work carried out at

a qualified specialist workshop.

XUnscrew the valve cap from the valve.

XIf possible, unscrew the valve insert from

the valve and release the air.

iFully deflating the tires can take a few

minutes.

XScrew the valve insert back into the valve.

XScrew the valve cap back on.

XPull the protective sheet provided with the

spare wheel over the collapsible spare

wheel.

XStow the collapsible spare wheel in the

emergency spare wheel well under the

trunk.

XUse the retaining screw to pierce the pro-

tective sheet and fasten the collapsible

spare wheel in place.

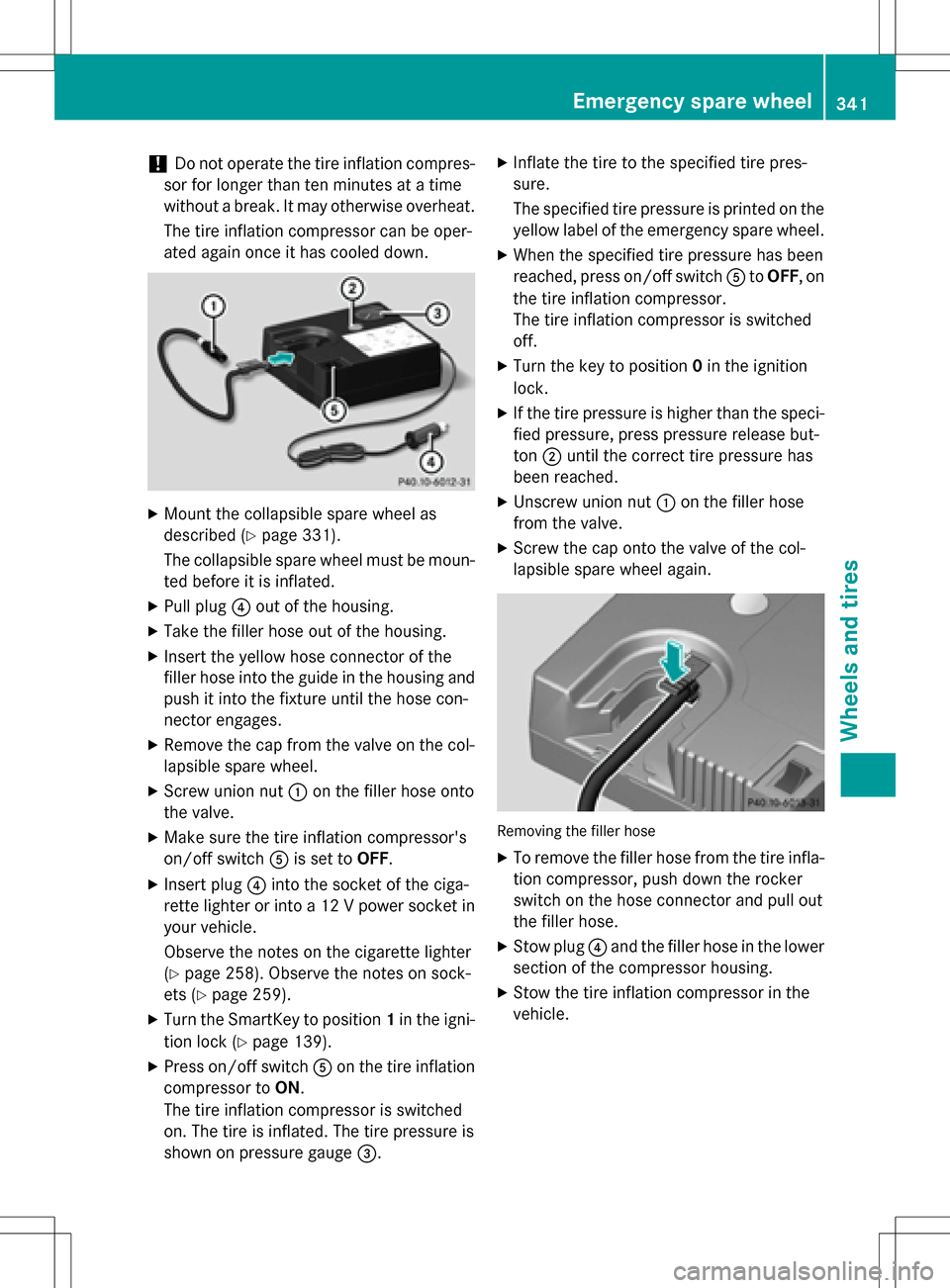

Inflating the collapsible spare wheel

!

Inflate the collapsible spare wheel using

the tire inflation compressor before lower-

ing the vehicle. The wheel rim could other-

wise be damaged.

340Emergency spare wheel

Wheels and tires

Page 343 of 358

!Do not operate the tire inflation compres-

sor for longer than ten minutes at a time

without a break. It may otherwise overheat.

The tire inflation compressor can be oper-

ated again once it has cooled down.

XMount the collapsible spare wheel as

described (

Ypage 331).

The collapsible spare wheel must be moun-

ted before it is inflated.

XPull plug ?out of the housing.

XTake the filler hose out of the housing.

XInsert the yellow hose connector of the

filler hose into the guide in the housing and

push it into the fixture until the hose con-

nector engages.

XRemove the cap from the valve on the col-

lapsible spare wheel.

XScrew union nut :on the filler hose onto

the valve.

XMake sure the tire inflation compressor's

on/off switch Ais set to OFF.

XInsert plug ?into the socket of the ciga-

rette lighter or into a 12 V power socket in

your vehicle.

Observe the notes on the cigarette lighter

(

Ypage 258). Observe the notes on sock-

ets (

Ypage 259).

XTurn the SmartKey to position 1in the igni-

tion lock (

Ypage 139).

XPress on/off switch Aon the tire inflation

compressor to ON.

The tire inflation compressor is switched

on. The tire is inflated. The tire pressure is

shown on pressure gauge =.

XInflate the tire to the specified tire pres-

sure.

The specified tire pressure is printed on the

yellow label of the emergency spare wheel.

XWhen the specified tire pressure has been

reached, press on/off switch AtoOFF , on

the tire inflation compressor.

The tire inflation compressor is switched

off.

XTurn the key to position 0in the ignition

lock.

XIf the tire pressure is higher than the speci- fied pressure, press pressure release but-

ton ;until the correct tire pressure has

been reached.

XUnscrew union nut :on the filler hose

from the valve.

XScrew the cap onto the valve of the col-

lapsible spare wheel again.

Removing the filler hose

XTo remove the filler hose from the tire infla-

tion compressor, push down the rocker

switch on the hose connector and pull out

the filler hose.

XStow plug ?and the filler hose in the lower

section of the compressor housing.

XStow the tire inflation compressor in the

vehicle.

Emergency spare wheel341

Wheels and tires

Z