run flat MERCEDES-BENZ SLK ROADSTER 2008 Owners Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2008, Model line: SLK ROADSTER, Model: MERCEDES-BENZ SLK ROADSTER 2008Pages: 273, PDF Size: 4.42 MB

Page 9 of 273

6

Emergency running mod

e

Automatic transmission . . . . . . . . .203

Emergency unlocking

Boot . . . . . . . . . . . . . . . . . . . . . . . .211

Vehicle . . . . . . . . . . . . . . . . . . . . . .210

Engine

Display message . . . . . . . . . . . . . .187

Running irregularl y.. . . . . . . . . . . .201

Starting problems . . . . . . . . . . . . .201

Starting with the key . . . . . . . . . . . .81

Technical data . . . . . . . . . . . . . . . .244

Engine diagnostic warning lamp . ..1 95

Engine electronics . . . . . . . . . . . . . ..241

Malfunction . . . . . . . . . . . . . . . . . .201

Engine number . . . . . . . . . . . . . . . . . .243

Engine oil . . . . . . . . . . . . . . . . . . . . . .258

Checking the oil level (dipstick) . . .153

Checking the oil level (on-board

computer) . . . . . . . . . . . . . . . . . . .152

Consumption . . . . . . . . . . . . . . . . .151

Display message . . . . . . . . . . . . . . . . . . .152, 186, 187

Filler neck . . . . . . . . . . . . . . . . . . .153

Temperature display (on-board

computer) . . . . . . . . . . . . . . . . . . . .96

Topping up . . . . . . . . . . . . . . . . . . .153

ESP ®

(Electronic Stability Program) .51

Activating/deactivating . . . . . . . . . .51

Display message . . . . . . . . . .176, 177

Warning lamp . . . . . . . . . . . . . .51, 194 Exterior lighting

Delayed switch-off (on-board

computer) . . . . . . . . . . . . . . . . . . .105

Exterior mirror parking position

Storing . . . . . . . . . . . . . . . . . . . .67, 69

Exterior mirrors

Adjusting . . . . . . . . . . . . . . . . . . . . .66

Anti-dazzle mode (automatic) . . . . .67

Folding in/out (automatically ).. . . .66

Folding in/out (electrically) . . . . . . .66

Folding in when locking (on-board

computer) . . . . . . . . . . . . . . . . . . .106

Malfunction . . . . . . . . . . . . . . . . . .206

Parking position . . . . . . . . . . . . .67, 69

Resetting . . . . . . . . . . . . . . . . . . . . .66

Storing settings . . . . . . . . . . . . . . . .68

Exterior view

Overview . . . . . . . . . . . . . . . . . . . . .18 F

Fire extinguishe r. . . . . . . . . . . . . . . .174

First-aid kit . . . . . . . . . . . . . . . . . . . . .174

Flat tyre Preparing the vehicle . . . . . . . . . . .218

TIREFIT kit . . . . . . . . . . . . . . . . . . .219

Floormat . . . . . . . . . . . . . . . . . . . . . . .146

Foglamps Display message . . . . . . . . . . . . . .185

Fording . . . . . . . . . . . . . . . . . . . . . . . .164 Frequencies

Garage door opene r.. . . . . . . . . . .262

Telephone . . . . . . . . . . . . . . . . . . .242

Front airbag . . . . . . . . . . . . . . . . . . . . .42

Front-passenger airbag . . . . . . . . . . ..42

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . .255

Loss . . . . . . . . . . . . . . . . . . . . . . . .200

Petrol . . . . . . . . . . . . . . . . . . . . . . .149

Fuel consumptio n. . . . . . . . . . .256, 257

Fuel filler flap Opening/closing . . . . . . . . . . . . . .148

Fuel lin e

Malfunction . . . . . . . . . . . . . . . . . .200

Fuel tank

Malfunction . . . . . . . . . . . . . . . . . .200

Fuse allocation chart . . . . . . . . . . ..237

Fuse box Boot . . . . . . . . . . . . . . . . . . . . . . . .238

Dashboard . . . . . . . . . . . . . . . . . . .238

Engine compartment . . . . . . . . . . .238

Fuse s. . . . . . . . . . . . . . . . . . . . . . . . . .237 G

Garage door Opening/closing (with the remote

control) . . . . . . . . . . . . . . . . . . . . .145

Garage door opener . . . . . . . . . . . . ..144

Clearing the memory . . . . . . . . . . .146 Index

171_AKB; 3; 4, en-GB

vpfaff7,

2007-11-13T10:50:25+01:00 - Seite

6

Page 42 of 273

Occupant safet

y 39In particular, work relevant to safety or on

safety-related systems must be carried out

at a qualified specialist workshop. If this

work is not carried out correctly, the oper-

ating safety of your vehicle may be affec -

ted. There is a risk of an accident and injury .SRS (Supplemental Restraint System)

The SRS reduces the risk of occupants com-

ing into contact with the vehicle's interior in

the event of an accident. It can also reduce

the forces to which occupants are exposed

during an accident.

The SRS consists of:

R 1 warning lamp

R belt tensioner s

R belt force limiters

R Airbag s

11 warning lam p The SRS functions are checked regularly

when you turn on the ignition and when the

engine is running. Malfunctions can therefore

be detected in good time. The

1 warning lamp in the instrumen t

cluster lights up when the ignition is switched

on. It goes out no later than a few seconds

after the engine is started. G

Risk of injury

If SRS is malfunctioning, individual systems

may be activated unintentionally or not be

triggered in the event of an accident with

heavy braking.

A malfunction has occurred if the 1

warning lamp:

R does not light up when you switch on the

ignition

R does not go out after the engine has been

running for a few seconds

R lights up again once the engine is running

In this case, have SRS checked immedi-

ately at a qualified specialist workshop.

Triggering of belt tensioners, belt force

limiters and airbags In the event of a collision, the sensor in the

airbag control unit evaluates important phys-

ical data such as duration, direction and force

of the vehicle deceleration or acceleration.

Based on the evaluation of this data anddepending on the vehicle's rate of longitudi-

nal deceleration in a collision, in the firs

t

stage the airbag control unit pre-emptively

triggers the belt tensioners.

i The belt tensioners can only be triggered

if the belt tongue is correctly engaged in the

seat belt buckle.

The front airbags are only deployed if there is

an even higher rate of vehicle deceleration in

a longitudinal direction .

Vehicles fitted with adaptive, dual-stage front

airbags: when the first deployment threshold

is reached, the front airbag is filled with

enough gas to reduce the risk of injuries. The

front airbag is only fully inflated if a second

threshold is reached within a few millisec-

onds due to the control unit having detected

further deceleration.

Criteria for triggering belt tensioners and

airbags

In the first stage of a collision, the airbag con-

trol unit evaluates the duration and direction

of vehicle acceleration or deceleration in

order to determine whether it is necessary to

trigger the belt tensioner and/or airbag.

The belt tensioner and airbag triggering

thresholds are variable and are adapted to the

rate of deceleration of the vehicle. This proc- Safety

171_AKB; 3; 4, en-GB

vpfaff7,

2007-11-13T10:50:25+01:00 - Seite 39 Z

Page 158 of 273

Tyres and wheels

15

5

X

Add windscreen washer concentrate to the

washer fluid all year round. G

Risk of fire

Windscreen washer concentrate is highly

flammable. Fire, naked flames and smoking

are prohibited when windscreen washe r

concentrate is being handled.

Use

R a windscreen washer fluid additive

such as MB Summerwash to preven t

smearing (for temperatures above freez-

ing).

R a windscreen washer fluid additive wit h

antifreeze properties such as MB Winter-

wash (if there is a risk of frost).

X Mix the windscreen washer fluid in a con-

tainer beforehand. Adapt the mixing ratio

to the outside temperatures.

! Only use windscreen washer fluid which

is suitable for plastic lamp lenses. Unsuit-

able windscreen washer fluid could dam-

age the plastic lamp lenses of the head-

lamps. X

To open: pull cap1upwards by the tab .

X To close: press cap 1onto the filler neck

until it clicks into place. Tyres and wheels

Points to remember

! For safety reasons, Mercedes-Benz rec-

ommends that you only use tyres and

wheels which have been approved by

Mercedes-Benz specifically for your vehi-

cle. These tyres have been specially adap-

ted for use with the control systems, such

as ABS or ESP ®

, and are marked as follows:

R MO = Mercedes-Benz Original

R MOE = Mercedes-Benz Original Extended

(with run-flat characteristics)*

Mercedes-Benz Original Extended tyres*

should only be used on wheels that have

been specifically approved by Mercedes-

Benz.

If you use other tyres and wheels,

Mercedes-Benz cannot accept any respon-

sibility for damage that may result from

this. Further information about tyres,

wheels and approved combinations can be

obtained from any Mercedes-Benz Service

Centre.

If you use tyres other than those tested and

recommended for Mercedes-Benz vehi-

cles, characteristics such as handling, vehi-

cle noise emissions and fuel consumption Operation

* optional

171_AKB; 3; 4, en-GB

vpfaff7,

2007-11-13T10:50:25+01:00 - Seite 155 Z

Page 162 of 273

Tyres and wheels

15

9

message will appear in the multi-function dis-

play.

The function of the tyre pressure loss warning

system is limited or delayed if:

R snow chains are fitted to your vehicle's

tyres

R road conditions are wintry

R you are driving on sand or grave l

R you adopt a very sporty driving style (cor -

nering at high speeds or driving with high

rates of acceleration)

R you are driving with a heavy load (in th e

vehicle or on the roof)

Restarting the tyre pressure loss warn-

ing system Restart the tyre pressure loss warning system

if you have :

R changed the tyre pressure

R changed the wheels or tyre s

R fitted new wheels or tyres

X Before restarting, consult the table of tyre

pressures on the inside of the fuel filler fla p

to ensure that the tyre pressure in all fou rtyres is set correctly for the operating con-

ditions concerned

.

X Also observe the notes in the section on

tyre pressures (Y page 157). G

Risk of accident

The tyre pressure loss warning system can

only give reliable warnings if you have set

the correct tyre pressure.

If an incorrect tyre pressure is set, thes e

incorrect values will be monitored.

A tyre with insufficient pressure results in

an instability of the vehicle when driving,

thus increasing the risk of an accident .

X Make sure that the key is in position 2in

the ignition lock .

The standard display appears in the multi-

function display (Y page 95).

X Press korj to select the tyre pres-

sure function:

Run Flat Indicator active

Menu: R-Button æ

X Press the reset button on the left of the

instrument cluster.

The following message appears in the

multi-function display:

Restart Run Flat Indicator ?Yes Cancel

If you wish to confirm the restart:

X Press the æbutton.

The following message appears in the

multi-function display:

Run Flat Indicator restarted

After a teach-in period, the tyre pressure

loss warning system will monitor the set

tyre pressures of all four tyres.

If you wish to cancel the restart:

X Press the çbutton.

or

X Wait until the message

Restart Run Flat Indicator?

Yes Cancel disappears.

The tyre pressure values stored at the last

restart will continue to be monitored. Operation

171_AKB; 3; 4, en-GB

vpfaff7

, 2007-11-13T10:50:25+01:00 - Seite 159

Page 181 of 273

Display

messages 17

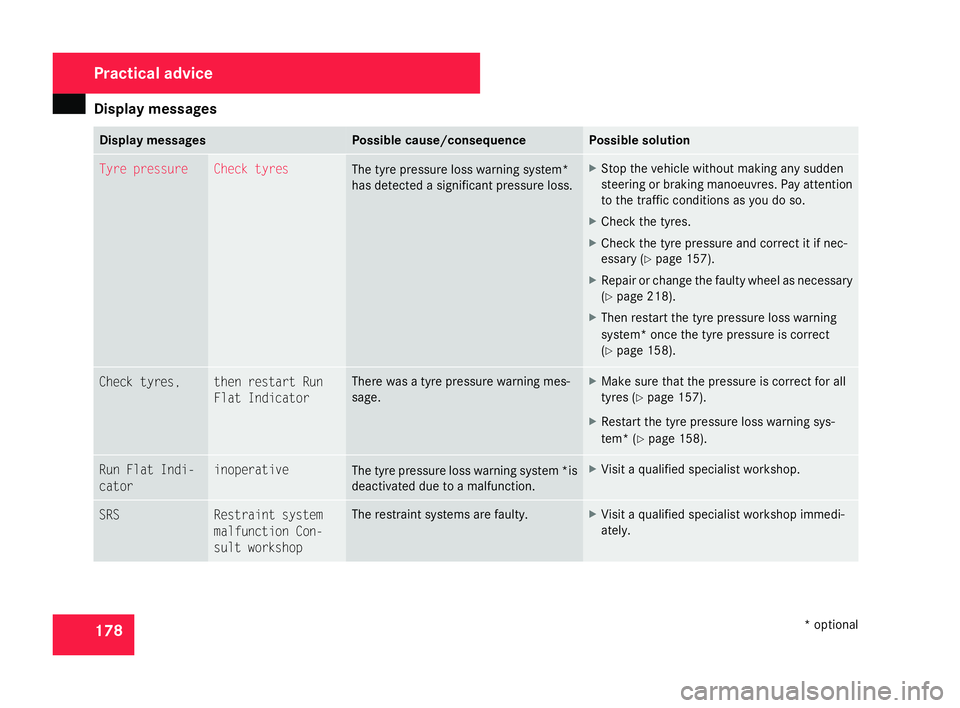

8 Display messages Possible cause/consequence Possible solution

Tyre pressure Check tyres

The tyre pressure loss warning system*

has detected a significant pressure loss. X

Stop the vehicle without making any sudden

steering or braking manoeuvres. Pay attention

to the traffic conditions as you do so.

X Check the tyres.

X Check the tyre pressure and correct it if nec-

essary (Y page 157).

X Repair or change the faulty wheel as necessar y

( Y page 218).

X Then restart the tyre pressure loss warning

system* once the tyre pressure is correc t

( Y page 158). Check tyres, then restart Run

Flat Indicator There was a tyre pressure warning mes-

sage. X

Make sure that the pressure is correct for all

tyres (Y page 157).

X Restart the tyre pressure loss warning sys-

tem* (Y page 158). Run Flat Indi-

cator inoperative

The tyre pressure loss warning system

*is

deactivated due to a malfunction . X

Visit a qualified specialist workshop. SRS Restraint system

malfunction Con-

sult workshop The restraint systems are faulty. X

Visit a qualified specialist workshop immedi-

ately. Practical advice

* optional

171_AKB; 3; 4, en-GB

vpfaff7,

2007-11-13T10:50:25+01:00 - Seite 178

Page 221 of 273

Flat tyre

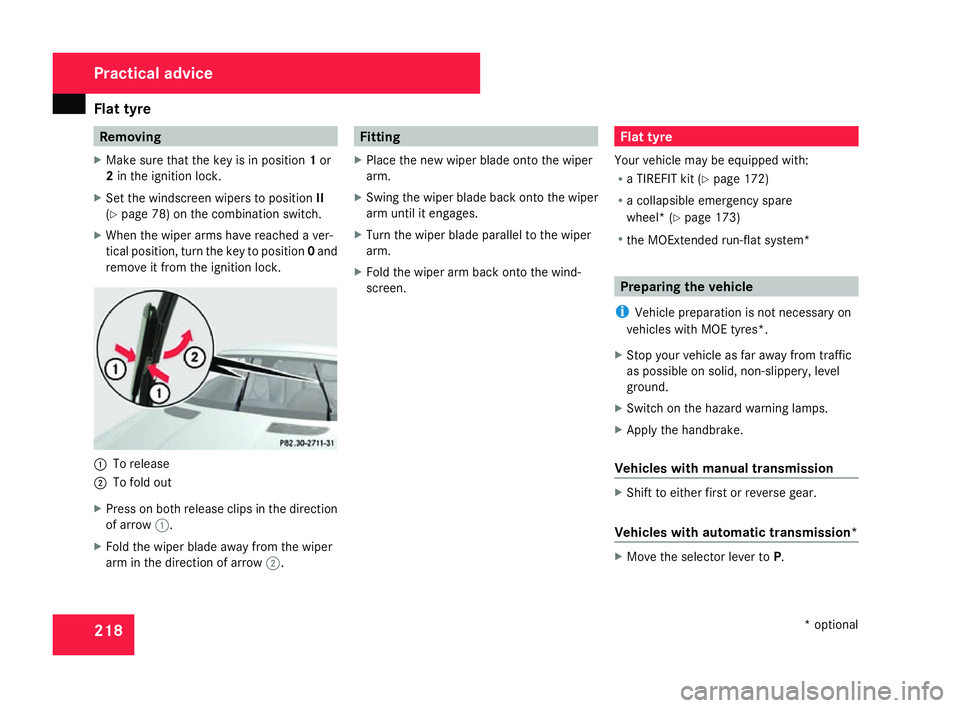

218 Removin

g

X Make sure that the key is in position 1or

2 in the ignition lock .

X Set the windscreen wipers to position II

( Y page 78) on the combination switch.

X When the wiper arms have reached a ver-

tical position, turn the key to position 0and

remove it from the ignition lock. 1

To release

2 To fold out

X Press on both release clips in the direction

of arrow 1.

X Fold the wiper blade away from the wipe r

arm in the direction of arrow 2. Fitting

X Place the new wiper blade onto the wiper

arm.

X Swing the wiper blade back onto the wipe r

arm until it engages.

X Turn the wiper blade parallel to the wiper

arm.

X Fold the wiper arm back onto the wind-

screen. Flat tyre

Your vehicle may be equipped with:

R a TIREFIT kit (Y page 172)

R a collapsible emergency spare

wheel* (Y page 173)

R the MOExtended run-flat system* Preparing the vehicle

i Vehicle preparation is not necessary on

vehicles with MOE tyres*.

X Stop your vehicle as far away from traffi c

as possible on solid, non-slippery, level

ground.

X Switch on the hazard warning lamps.

X Apply the handbrake.

Vehicles with manual transmissio n X

Shift to either first or reverse gear .

Vehicles with automatic transmission* X

Move the selector lever to P. Practical advice

* optional

171_AKB; 3; 4, en-GB

vpfaff7,

2007-11-13T10:50:25+01:00 - Seite 218

Page 224 of 273

Flat tyre

221

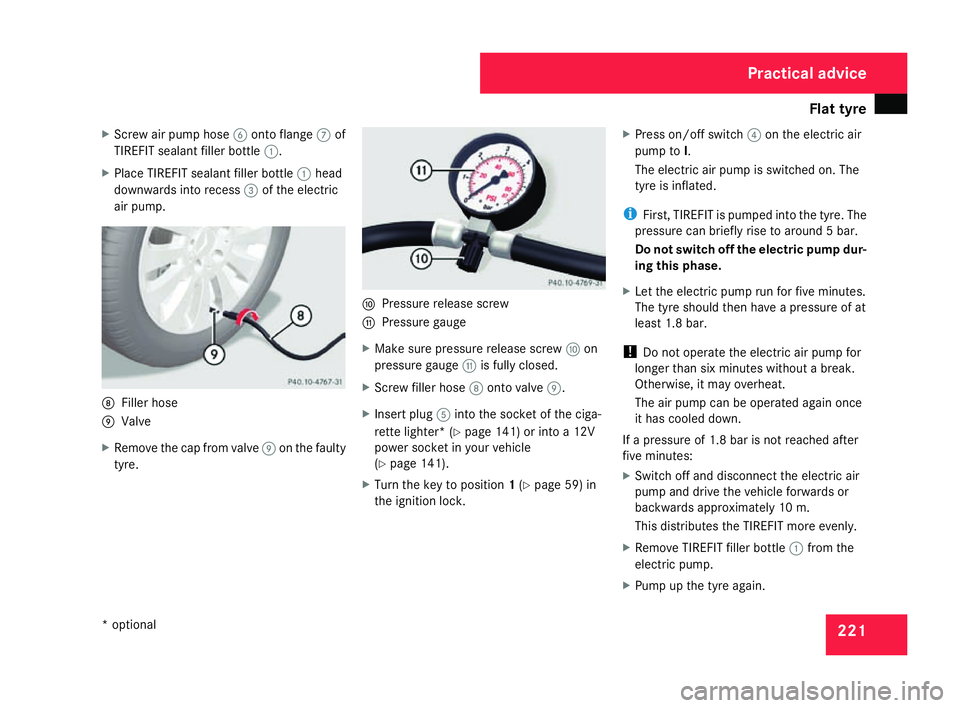

X

Screw air pump hose 6onto flange 7of

TIREFIT sealant filler bottle 1.

X Place TIREFIT sealant filler bottle 1head

downwards into recess 3of the electric

air pump. 8

Filler hos e

9 Valve

X Remove the cap from valve 9on the faulty

tyre. a

Pressure release screw

b Pressure gauge

X Make sure pressure release screw aon

pressure gauge bis fully closed.

X Screw filler hose 8onto valve 9.

X Insert plug 5into the socket of the ciga-

rette lighter* (Y page 141) or into a 12V

power socket in your vehicle

( Y page 141).

X Turn the key to position 1(Y page 59) in

the ignition lock. X

Press on/off switch 4on the electric air

pump to I.

The electric air pump is switched on. The

tyre is inflated.

i First, TIREFIT is pumped into the tyre. The

pressure can briefly rise to around 5 bar.

Do not switch off the electric pump dur-

ing this phase.

X Let the electric pump run for five minutes.

The tyre should then have a pressure of at

least 1.8 bar.

! Do not operate the electric air pump for

longer than six minutes without a break.

Otherwise, it may overheat.

The air pump can be operated again once

it has cooled down.

If a pressure of 1.8 bar is not reached after

five minutes:

X Switch off and disconnect the electric ai r

pump and drive the vehicle forwards or

backwards approximately 10 m.

This distributes the TIREFIT more evenly.

X Remove TIREFIT filler bottle 1from the

electric pump.

X Pump up the tyre again. Practical advice

* optional

171_AKB; 3; 4, en-GB

vpfaff7,

2007-11-13T10:50:25+01:00 - Seite 221

Page 226 of 273

Flat tyre

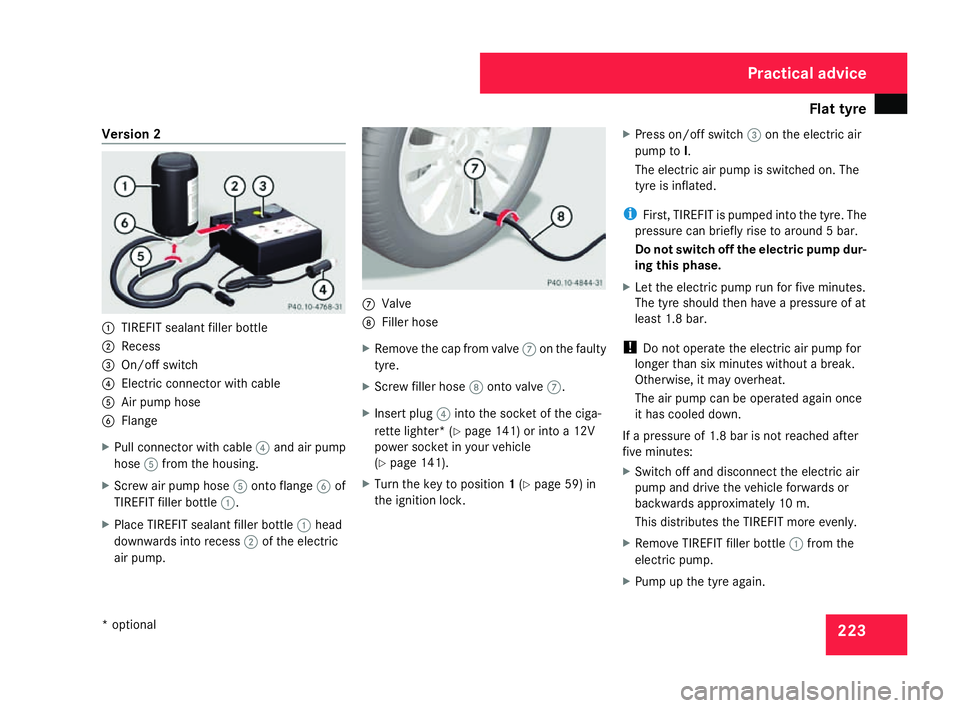

223

Version

2 1

TIREFIT sealant filler bottle

2 Recess

3 On/off switch

4 Electric connector with cable

5 Air pump hos e

6 Flange

X Pull connector with cable 4and air pump

hose 5from the housing.

X Screw air pump hose 5onto flange 6of

TIREFIT filler bottle 1.

X Place TIREFIT sealant filler bottle 1head

downwards into recess 2of the electric

air pump. 7

Valve

8 Filler hos e

X Remove the cap from valve 7on the faulty

tyre.

X Screw filler hose 8onto valve 7.

X Insert plug 4into the socket of the ciga-

rette lighter* (Y page 141) or into a 12V

power socket in your vehicle

( Y page 141).

X Turn the key to position 1(Y page 59) in

the ignition lock . X

Press on/off switch 3on the electric air

pump to I.

The electric air pump is switched on. The

tyre is inflated.

i First, TIREFIT is pumped into the tyre. The

pressure can briefly rise to around 5 bar.

Do not switch off the electric pump dur-

ing this phase .

X Let the electric pump run for five minutes.

The tyre should then have a pressure of at

least 1.8 bar.

! Do not operate the electric air pump for

longer than six minutes without a break.

Otherwise, it may overheat.

The air pump can be operated again once

it has cooled down.

If a pressure of 1.8 bar is not reached after

five minutes:

X Switch off and disconnect the electric ai r

pump and drive the vehicle forwards or

backwards approximately 10 m.

This distributes the TIREFIT more evenly.

X Remove TIREFIT filler bottle 1from the

electric pump .

X Pump up the tyre again. Practical advice

* optional

171_AKB; 3; 4, en-GB

vpfaff7

, 2007-11-13T10:50:25+01:00 - Seite 223

Page 249 of 273

Tyres and wheels

24

6 Tyres and wheels

! For safety reasons, Mercedes-Benz rec-

ommends that you only use tyres which

have been approved by Mercedes-Benz

specifically for your vehicle. These tyres ar e

specially adapted for use with the control

systems, such as ABS or ESP ®

, and are

marked as follows:

R MO = Mercedes-Benz Original

R MOE = Mercedes-Benz Original Exten-

ded* (with run-flat characteristics)

If you use other tyres, Mercedes-Benz can-

not accept any responsibility for damage

which may occur. Information about tyres

can be obtained from any Mercedes-Ben z

Service Centre.

! If you fit tyres other than those tested and

recommended by Mercedes-Benz, charac-

teristics such as handling, noise levels and

fuel consumption, etc. may be adversel y

affected. In addition, when driving with a

load, dimensional variations and differen t

tyre deformation characteristics could

cause the tyres to make contact with the

bodywork and axle components. This could

result in damage to the tyres or the vehicle. i

Further information about tyres and

wheels can be obtained from any

Mercedes-Benz Service Centre.

You will find a table of tyre pressures on the

inside of your vehicle's fuel filler flap . You

will find further information about tyre pres-

sures in the "Operation" section

( Y page 157). Technical data

* optional

171_AKB; 3; 4, en-GB

vpfaff7,

2007-11-13T10:50:25+01:00 - Seite 246

Page 250 of 273

Tyres and wheels

24

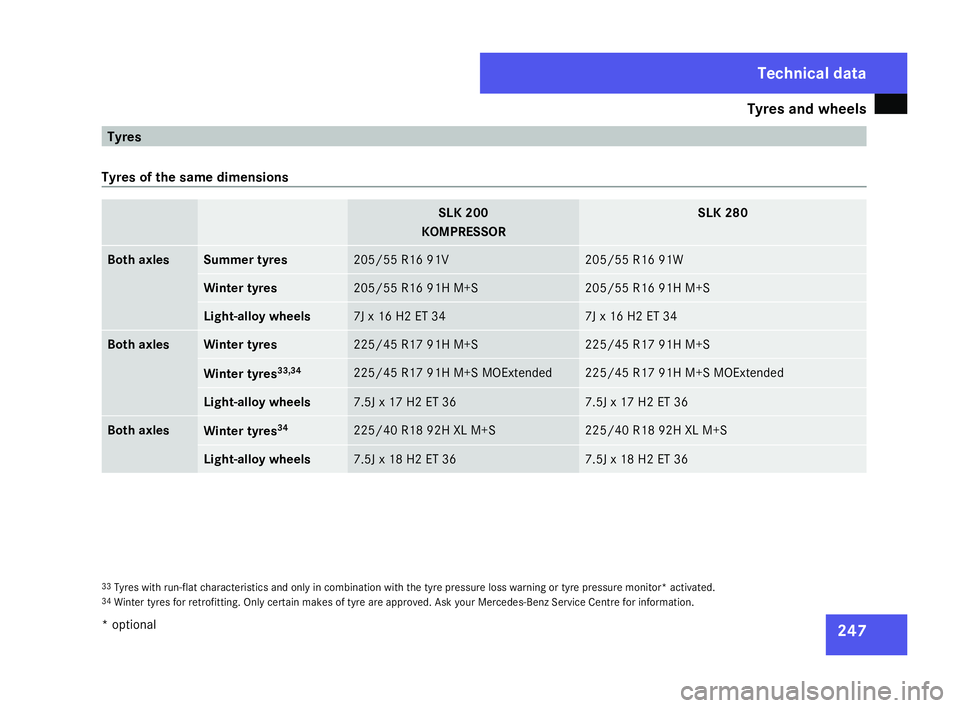

7 Tyre

s

Tyres of the same dimensions SLK 20

0

KOMPRESSOR SLK 280

Both axles Summer tyres 205/55 R16 91

V 205/55 R16 91W

Winter tyres 205/55 R16 91H M+S 205/55 R16 91H M+S

Light-alloy wheels 7J x 16 H2 ET 34 7J x 16 H2 ET 34

Both axle

s Winter tyres 225/45 R17 91H M+S 225/45 R17 91H M+S

Winter tyres

33,34 225/45 R17 91H M+S MOExtended 225/45 R17 91H M+S MOExtended

Light-alloy wheels 7.5J x 17 H2 ET 36 7.5J x 17 H2 ET 36

Both axle

s Winter tyres

34 225/40 R18 92H XL M+S 225/40 R18 92H XL M+S

Light-alloy wheels 7.5J x 18 H2 ET 36 7.5J x 18 H2 ET 36

33

Tyres with run-flat characteristics and only in combination with the tyre pressure loss warning or tyre pressure monitor* activated.

34 Winter tyres for retrofitting. Only certain makes of tyre are approved. Ask your Mercedes-Benz Service Centre for information. Technical data

* optiona l

171_AKB; 3; 4, en-GB

vpfaff7,

2007-11-13T10:50:25+01:00 - Seite 247