MERCEDES-BENZ SLK500 2011 R170 Owner's Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2011, Model line: SLK500, Model: MERCEDES-BENZ SLK500 2011 R170Pages: 312, PDF Size: 5.64 MB

Page 271 of 312

Bulbs

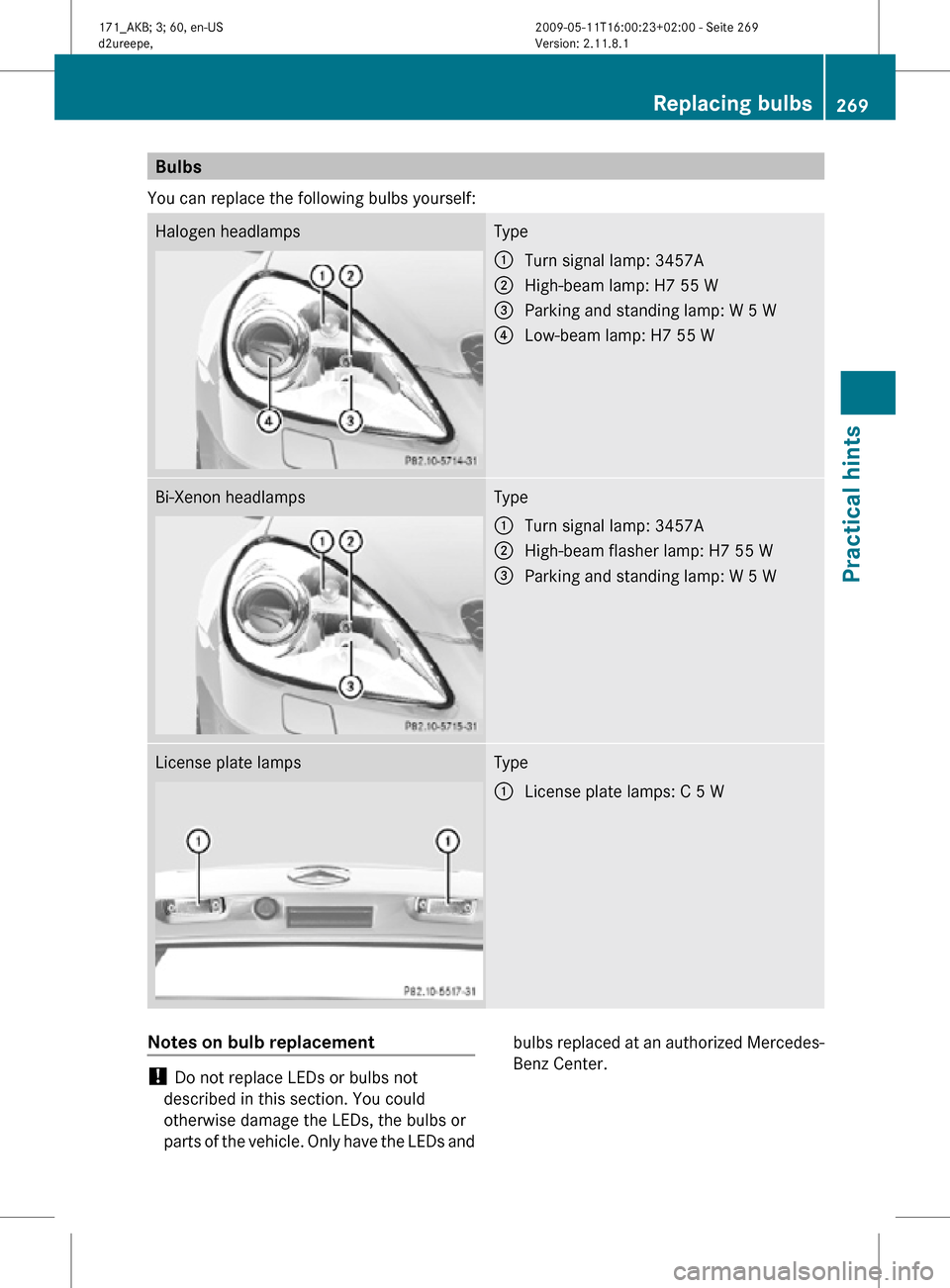

You can replace the following bulbs yourself: Halogen headlamps Type

:

Turn signal lamp: 3457A

; High-beam lamp: H7 55 W

= Parking and standing lamp: W 5 W

? Low-beam lamp: H7 55 W Bi-Xenon headlamps Type

:

Turn signal lamp: 3457A

; High-beam flasher lamp: H7 55 W

= Parking and standing lamp: W 5 W License plate lamps Type

:

License plate lamps: C 5 W Notes on bulb replacement

!

Do not replace LEDs or bulbs not

described in this section. You could

otherwise damage the LEDs, the bulbs or

parts of the vehicle. Only have the LEDs and bulbs replaced at an authorized Mercedes-

Benz Center. Replacing bulbs

269Practical hints

171_AKB; 3; 60, en-US

d2ureepe, Version: 2.11.8.1 2009-05-11T16:00:23+02:00 - Seite 269 Z

Page 272 of 312

G

Observe Safety notes, see page 267.

R Only use 12-volt bulbs of the same type and

with the specified watt rating.

R Switch the lights off before changing a bulb

to prevent short circuits.

R Always use a clean lint-free cloth when

handling bulbs.

R Your hands should be dry and free of oil and

grease.

R If the newly installed bulb does not come

on, contact an authorized Mercedes-Benz

Center.

i Mercedes-Benz recommends using

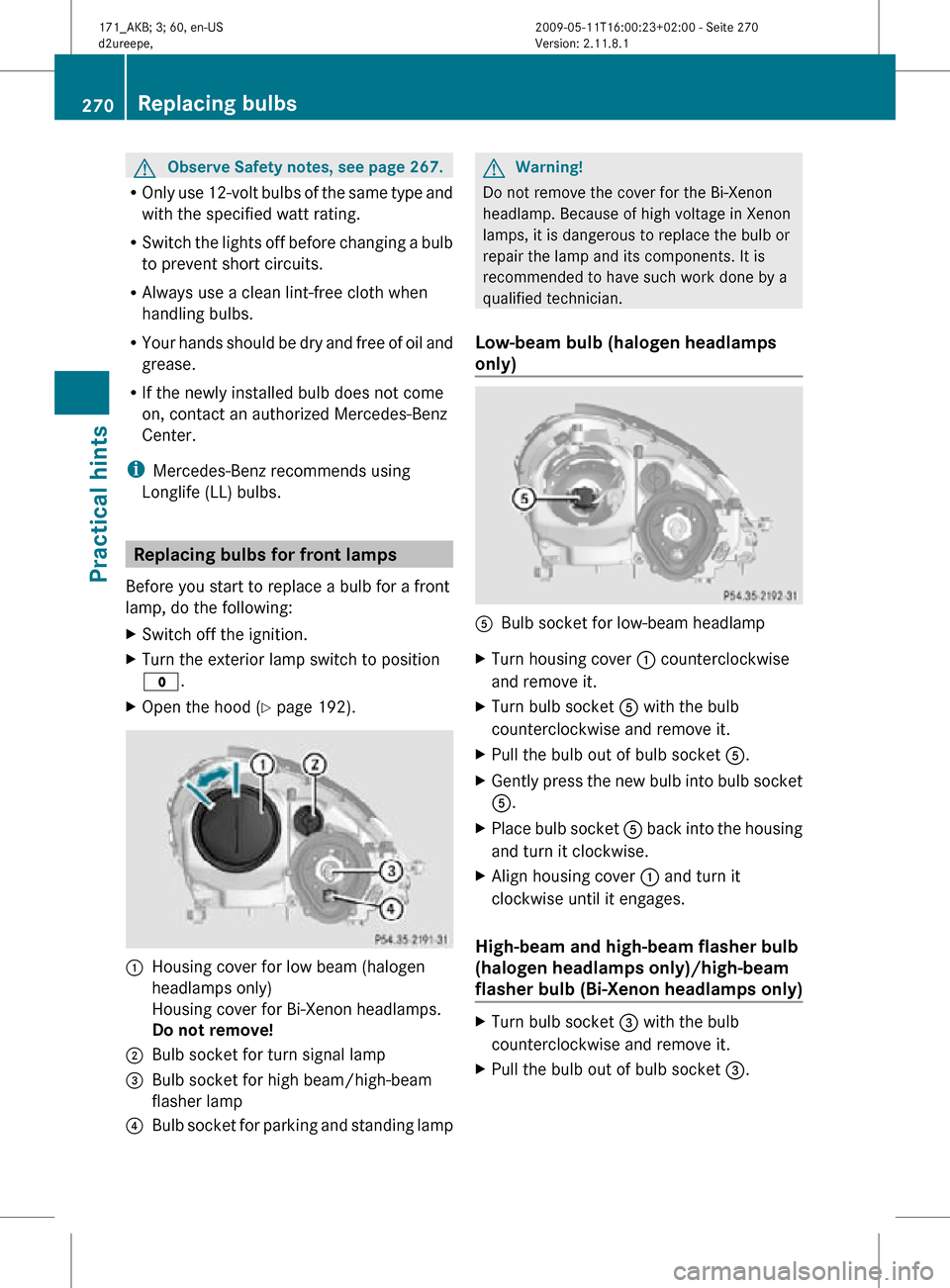

Longlife (LL) bulbs. Replacing bulbs for front lamps

Before you start to replace a bulb for a front

lamp, do the following:

X Switch off the ignition.

X Turn the exterior lamp switch to position

$.

X Open the hood (Y page 192). :

Housing cover for low beam (halogen

headlamps only)

Housing cover for Bi-Xenon headlamps.

Do not remove!

; Bulb socket for turn signal lamp

= Bulb socket for high beam/high-beam

flasher lamp

? Bulb socket for parking and standing lamp G

Warning!

Do not remove the cover for the Bi-Xenon

headlamp. Because of high voltage in Xenon

lamps, it is dangerous to replace the bulb or

repair the lamp and its components. It is

recommended to have such work done by a

qualified technician.

Low-beam bulb (halogen headlamps

only) A

Bulb socket for low-beam headlamp

X Turn housing cover : counterclockwise

and remove it.

X Turn bulb socket A with the bulb

counterclockwise and remove it.

X Pull the bulb out of bulb socket A.

X Gently press the new bulb into bulb socket

A.

X Place bulb socket A back into the housing

and turn it clockwise.

X Align housing cover : and turn it

clockwise until it engages.

High-beam and high-beam flasher bulb

(halogen headlamps only)/high-beam

flasher bulb (Bi-Xenon headlamps only) X

Turn bulb socket = with the bulb

counterclockwise and remove it.

X Pull the bulb out of bulb socket =.270

Replacing bulbsPractical hints

171_AKB; 3; 60, en-US

d2ureepe,

Version: 2.11.8.1 2009-05-11T16:00:23+02:00 - Seite 270

Page 273 of 312

X

Gently press the new bulb into bulb socket

=.

X Place bulb socket = back into the housing

and turn it clockwise until it engages.

Front turn signal lamp bulb X

Turn bulb socket ; with the bulb

counterclockwise and remove it.

X Gently press onto the bulb and turn it

counterclockwise out of bulb socket ;.

X Gently press the new bulb into bulb

socket ; and turn it clockwise until it

engages.

X Place bulb socket ; back into the housing

and turn it clockwise until it engages.

Parking and standing lamp bulb X

Turn bulb socket ? with the bulb

counterclockwise and remove it.

X Pull the bulb out of bulb socket ?.

X Gently press the new bulb into bulb

socket ?.

X Place bulb socket ? back into the housing

and turn it clockwise until it engages. Replacing bulbs for rear lamps

Tail lamp unit Since replacing bulbs in the tail lamp unit is a

technically highly demanding process, we

recommend to have them replaced at an

authorized Mercedes-Benz Center. License plate lamps X

Switch off the ignition.

X Turn the exterior lamp switch to position

$.

X Open the trunk.

X Loosen screws : of lamp cover to be

removed.

X Remove lamp cover ;.

X Replace the bulb.

X Reinstall lamp cover ;.

X Retighten screws :. Replacing wiper blades

Safety notes

G

Warning!

For safety reasons, switch off the wipers and

remove the SmartKey from the starter switch

before replacing a wiper blade. Otherwise, the

wiper motor could suddenly turn on and cause

injury. G

Warning!

Wiper blades are components that are subject

to wear and tear. Replace the wiper blades

twice a year, preferably in the spring and fall.

Otherwise the windshield will not be wiped

properly. As a result, you may not be able to

observe surrounding traffic conditions and

could cause an accident. Replacing wiper blades

271Practical hints

171_AKB; 3; 60, en-US

d2ureepe, Version: 2.11.8.1 2009-05-11T16:00:23+02:00 - Seite 271 Z

Page 274 of 312

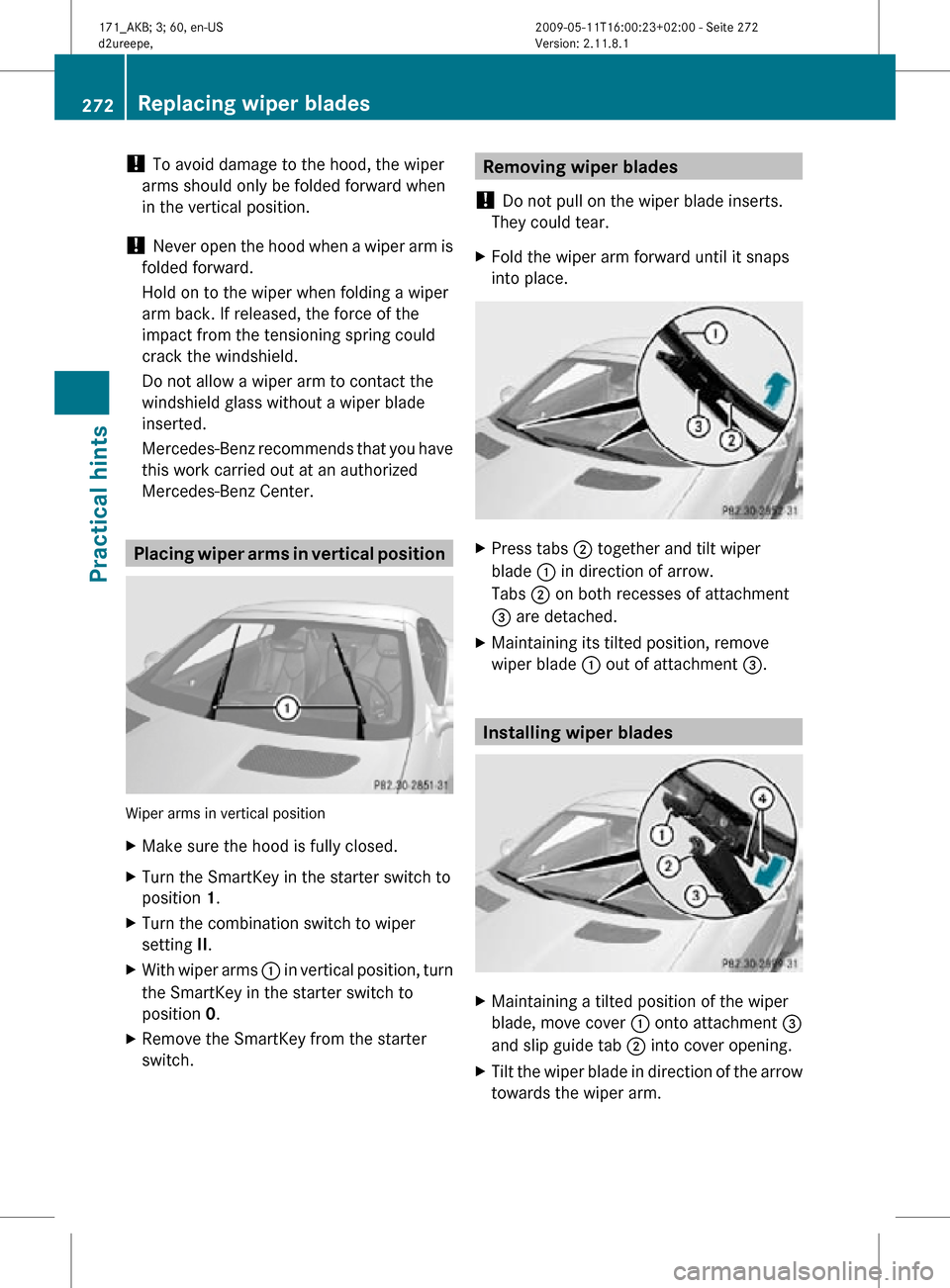

!

To avoid damage to the hood, the wiper

arms should only be folded forward when

in the vertical position.

! Never open the hood when a wiper arm is

folded forward.

Hold on to the wiper when folding a wiper

arm back. If released, the force of the

impact from the tensioning spring could

crack the windshield.

Do not allow a wiper arm to contact the

windshield glass without a wiper blade

inserted.

Mercedes-Benz recommends that you have

this work carried out at an authorized

Mercedes-Benz Center. Placing wiper arms in vertical position

Wiper arms in vertical position

X

Make sure the hood is fully closed.

X Turn the SmartKey in the starter switch to

position 1.

X Turn the combination switch to wiper

setting II.

X With wiper arms : in vertical position, turn

the SmartKey in the starter switch to

position 0.

X Remove the SmartKey from the starter

switch. Removing wiper blades

! Do not pull on the wiper blade inserts.

They could tear.

X Fold the wiper arm forward until it snaps

into place. X

Press tabs ; together and tilt wiper

blade : in direction of arrow.

Tabs ; on both recesses of attachment

= are detached.

X Maintaining its tilted position, remove

wiper blade : out of attachment =. Installing wiper blades

X

Maintaining a tilted position of the wiper

blade, move cover : onto attachment =

and slip guide tab ; into cover opening.

X Tilt the wiper blade in direction of the arrow

towards the wiper arm. 272

Replacing wiper bladesPractical hints

171_AKB; 3; 60, en-US

d2ureepe,

Version: 2.11.8.1 2009-05-11T16:00:23+02:00 - Seite 272

Page 275 of 312

X

Simultaneously press tabs ? together and

let the wiper blade engage into both

recesses of attachment =.

X Check if the wiper blade is securely

fastened.

X Fold the wiper arm backward to rest on the

windshield.

Make sure you hold on to the wiper arm

when folding it back.

! Make sure the wiper blades are installed

properly.

Improperly installed wiper blades

may cause windshield damage. Flat tire

Safety notes

Your vehicle may be equipped with a TIREFIT

kit or a spare wheel with collapsible tire.

Vehicles

with a TIREFIT kit do not have a spare

wheel.

For information on your vehicle’s equipment,

see “Rims and tires” ( Y page 297).G

Warning!

The dimensions of the spare wheel are

different from those of the road wheels. As a

result, the vehicle handling characteristics

change when driving with a spare wheel

mounted. Adapt your driving style

accordingly.

The spare wheel is for temporary use only.

When driving with a spare wheel mounted,

ensure proper tire inflation pressure and do

not exceed a vehicle speed of 50 mph

(80 km/h).

Contact the nearest authorized Mercedes-

Benz Center as soon as possible to have the

spare wheel replaced with a regular road

wheel.

Never

operate the vehicle with more than one

spare wheel mounted.

Do not switch off the ESP ®

when a spare

wheel is mounted. Preparing the vehicle

X Whenever possible, park the vehicle in a

safe

distance from moving traffic on a hard,

flat surface.

X Turn on the hazard warning flasher.

X Turn the steering wheel so that the front

wheels are in a straight-ahead position.

X Engage the parking brake.

X Shift the automatic transmission into park

position P (manual transmission to 1st or

reverse gear R).

X Turn off the engine.

X Remove the SmartKey from the starter

switch.

X Have any passenger exit the vehicle at a

safe distance from the roadway. Open

doors only when conditions are safe to do

so. Sealing tires with TIREFIT

This section applies to SLK 55 AMG with

Performance Package only.

Small

tire punctures, particularly those in the

tread, can be sealed with TIREFIT.

TIREFIT can be used in ambient temperatures

down to -4‡ (-20†). G

Warning!

TIREFIT is a limited repair device. TIREFIT

cannot be used for cuts or punctures larger

than approximately 0.16 in (4 mm) and tire

damage

caused by driving with extremely low

tire inflation pressure, or on a flat tire, or a

damaged wheel.

Do not drive the vehicle under such

circumstances.

Contact the nearest authorized Mercedes-

Benz Center for assistance or call Roadside

Assistance. Flat tire

273

Practical hints

171_AKB; 3; 60, en-US

d2ureepe, Version: 2.11.8.1 2009-05-11T16:00:23+02:00 - Seite 273 Z

Page 276 of 312

X

Foreign objects (e.g. screws or nails)

should not be removed from the tire.

X Take the TIREFIT kit, the sticker, and the

electric air pump out of the

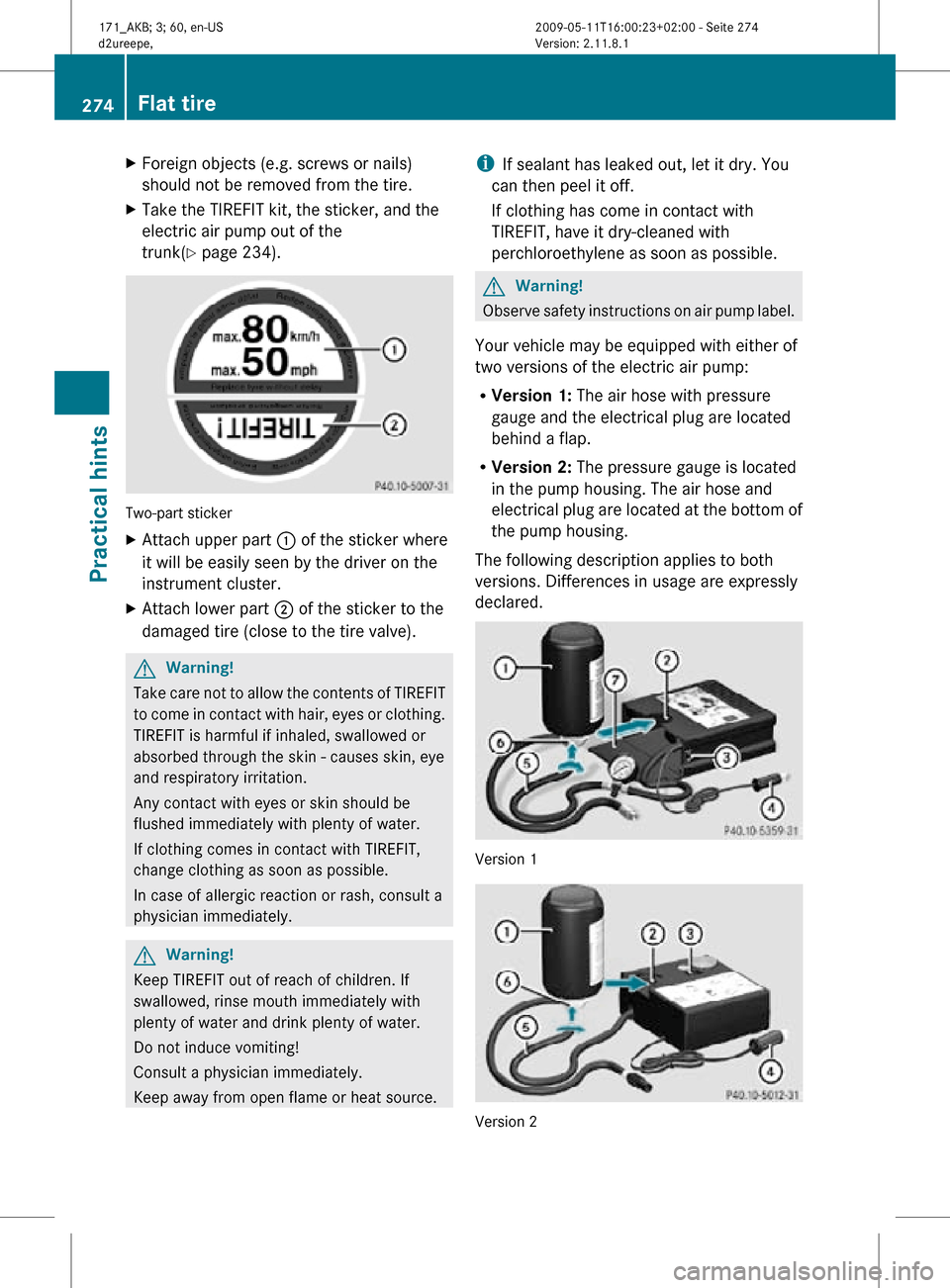

trunk(Y page 234). Two-part sticker

X

Attach upper part : of the sticker where

it will be easily seen by the driver on the

instrument cluster.

X Attach lower part ; of the sticker to the

damaged tire (close to the tire valve). G

Warning!

Take care not to allow the contents of TIREFIT

to come in contact with hair, eyes or clothing.

TIREFIT is harmful if inhaled, swallowed or

absorbed through the skin - causes skin, eye

and respiratory irritation.

Any contact with eyes or skin should be

flushed immediately with plenty of water.

If clothing comes in contact with TIREFIT,

change clothing as soon as possible.

In case of allergic reaction or rash, consult a

physician immediately. G

Warning!

Keep TIREFIT out of reach of children. If

swallowed, rinse mouth immediately with

plenty of water and drink plenty of water.

Do not induce vomiting!

Consult a physician immediately.

Keep away from open flame or heat source. i

If sealant has leaked out, let it dry. You

can then peel it off.

If clothing has come in contact with

TIREFIT, have it dry-cleaned with

perchloroethylene as soon as possible. G

Warning!

Observe safety instructions on air pump label.

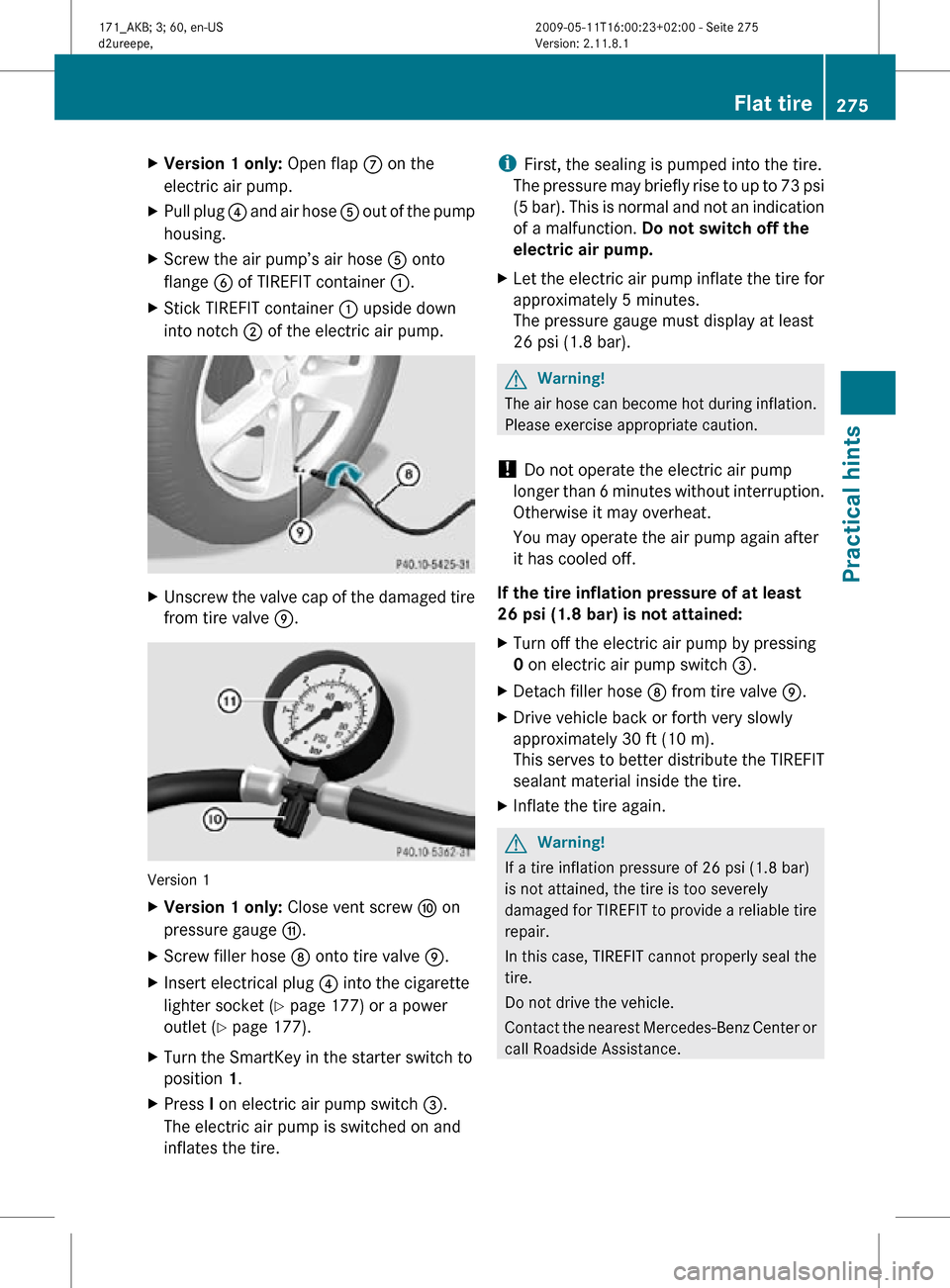

Your vehicle may be equipped with either of

two versions of the electric air pump:

R Version 1: The air hose with pressure

gauge and the electrical plug are located

behind a flap.

R Version 2: The pressure gauge is located

in the pump housing. The air hose and

electrical plug are located at the bottom of

the pump housing.

The following description applies to both

versions. Differences in usage are expressly

declared. Version 1

Version 2274

Flat tirePractical hints

171_AKB; 3; 60, en-US

d2ureepe,

Version: 2.11.8.1 2009-05-11T16:00:23+02:00 - Seite 274

Page 277 of 312

X

Version 1 only: Open flap C on the

electric air pump.

X Pull plug ? and air hose A out of the pump

housing.

X Screw the air pump’s air hose A onto

flange B of TIREFIT container :.

X Stick TIREFIT container : upside down

into notch ; of the electric air pump. X

Unscrew the valve cap of the damaged tire

from tire valve E. Version 1

X

Version 1 only: Close vent screw F on

pressure gauge G.

X Screw filler hose D onto tire valve E.

X Insert electrical plug ? into the cigarette

lighter socket ( Y page 177) or a power

outlet (Y page 177).

X Turn the SmartKey in the starter switch to

position 1.

X Press I on electric air pump switch =.

The electric air pump is switched on and

inflates the tire. i

First, the sealing is pumped into the tire.

The pressure may briefly rise to up to 73 psi

(5 bar). This is normal and not an indication

of a malfunction. Do not switch off the

electric air pump.

X Let the electric air pump inflate the tire for

approximately 5 minutes.

The pressure gauge must display at least

26 psi (1.8 bar). G

Warning!

The air hose can become hot during inflation.

Please exercise appropriate caution.

! Do not operate the electric air pump

longer than 6 minutes without interruption.

Otherwise it may overheat.

You may operate the air pump again after

it has cooled off.

If the tire inflation pressure of at least

26 psi (1.8 bar) is not attained:

X Turn off the electric air pump by pressing

0 on electric air pump switch =.

X Detach filler hose D from tire valve E.

X Drive vehicle back or forth very slowly

approximately 30 ft (10 m).

This serves to better distribute the TIREFIT

sealant material inside the tire.

X Inflate the tire again. G

Warning!

If a tire inflation pressure of 26 psi (1.8 bar)

is not attained, the tire is too severely

damaged for TIREFIT to provide a reliable tire

repair.

In this case, TIREFIT cannot properly seal the

tire.

Do not drive the vehicle.

Contact the nearest Mercedes-Benz Center or

call Roadside Assistance. Flat tire

275Practical hints

171_AKB; 3; 60, en-US

d2ureepe, Version: 2.11.8.1 2009-05-11T16:00:23+02:00 - Seite 275 Z

Page 278 of 312

After attaining a tire inflation pressure of

at least 26 psi (1.8 bar):

X

Press 0 on electric air pump switch =.

The electric air pump is switched off.

X Detach the TIREFIT kit from the tire valve. G

Warning!

The air hose may still be hot. Exercise proper

caution to avoid burning yourself when

detaching the electric air pump.

! Remaining TIREFIT sealant could escape

from the filler hose after it has been

detached from the tire valve. TIREFIT

sealant may cause stains.

Therefore, cover the filler hose, e.g. by

inserting it into the plastic bag the TIREFIT

kit was packed in.

X Drive off immediately. G

Warning!

Do not exceed a vehicle speed of 50 mph

(80 km/h). A TIREFIT repair is not designed to

operate at higher speeds.

The sticker must be attached on the

instrument cluster where it will be easily seen

by the driver.

Vehicle handling characteristics of a TIREFIT

repaired tire may change. Adapt your driving

accordingly.

X After driving the vehicle for an initial

10 minutes, check the tire inflation

pressure using pressure gauge. G

Warning!

If tire inflation pressure has fallen below

20 psi (1.3 bar) do not continue to drive the

vehicle.

Park your vehicle safely away from the

roadway and contact the nearest authorized

Mercedes-Benz Center or Roadside

Assistance.

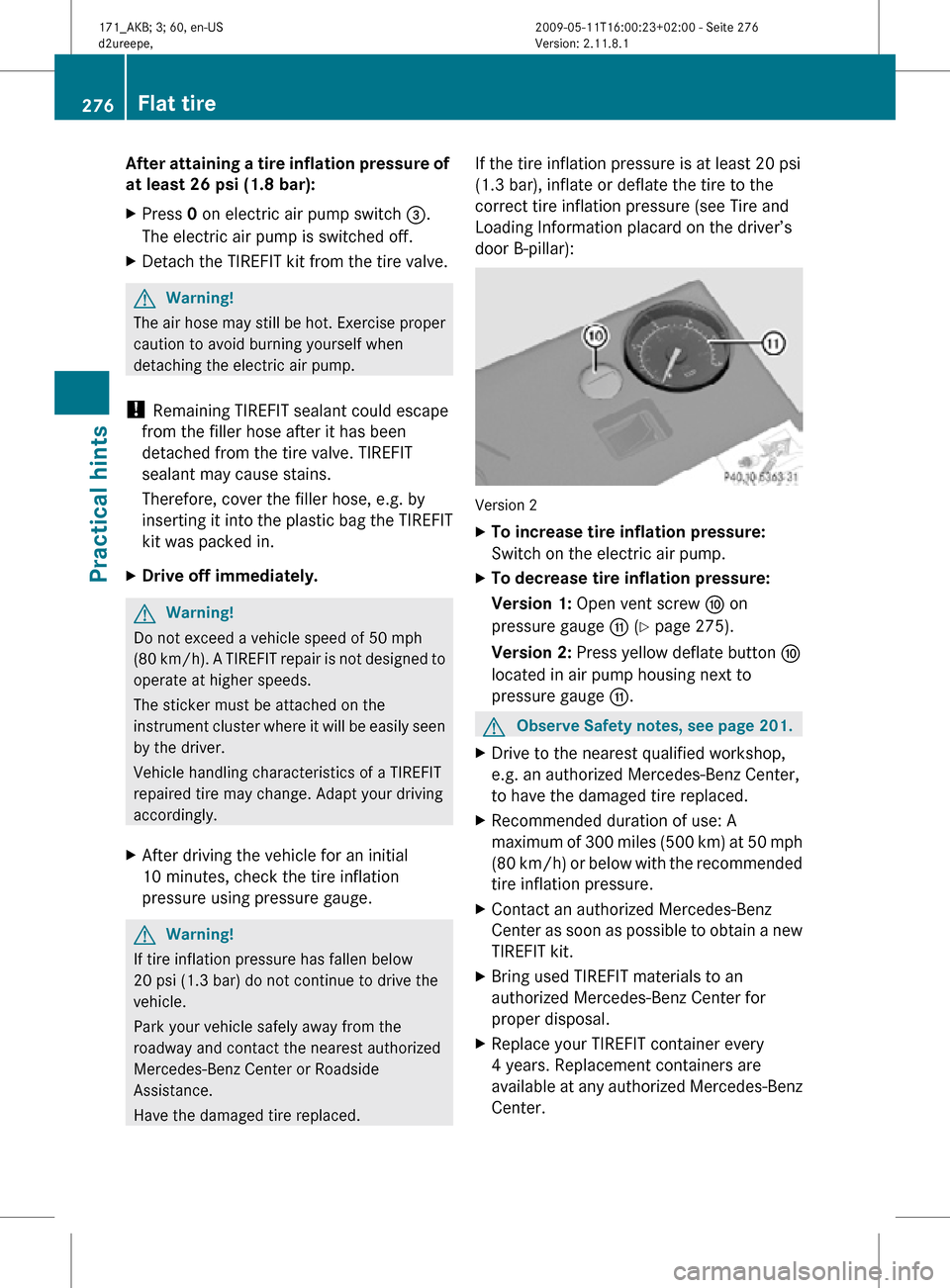

Have the damaged tire replaced. If the tire inflation pressure is at least 20 psi

(1.3 bar), inflate or deflate the tire to the

correct tire inflation pressure (see Tire and

Loading Information placard on the driver’s

door B-pillar):

Version 2

X

To increase tire inflation pressure:

Switch on the electric air pump.

X To decrease tire inflation pressure:

Version 1: Open vent screw F on

pressure gauge G (Y page 275).

Version 2: Press yellow deflate button a

located in air pump housing next to

pressure gauge G. G

Observe Safety notes, see page 201.

X Drive to the nearest qualified workshop,

e.g. an authorized Mercedes-Benz Center,

to have the damaged tire replaced.

X Recommended duration of use: A

maximum of 300 miles (500 km) at 50 mph

(80 km/h) or below with the recommended

tire inflation pressure.

X Contact an authorized Mercedes-Benz

Center as soon as possible to obtain a new

TIREFIT kit.

X Bring used TIREFIT materials to an

authorized Mercedes-Benz Center for

proper disposal.

X Replace your TIREFIT container every

4 years. Replacement containers are

available at any authorized Mercedes-Benz

Center. 276

Flat tirePractical hints

171_AKB; 3; 60, en-US

d2ureepe,

Version: 2.11.8.1 2009-05-11T16:00:23+02:00 - Seite 276

Page 279 of 312

Mounting the spare wheel

Introduction X

Prepare the vehicle as described

(Y page 273).

X Take the following out of the vehicle:

R

spare wheel

R jack

R wheel wrench

R collapsible wheel chock

R wheel bolts for spare wheel

R alignment bolt

R electric air pump

For information on where to find the

respective items, see “Where will I find ...?”

(Y page 234) and ( Y page 235).

i Vehicles without spare wheel are not

factory-equipped

with the tools required for

a wheel change such as a jack or a wheel

wrench. Some tools required for a wheel

change are specific to your vehicle.

Contact an authorized Mercedes-Benz

Center to obtain the tools approved for

your vehicle. This section describes the

wheel change using the tools approved and

recommended for your vehicle.

Lifting the vehicle G

Warning!

When jacking up the vehicle, only use the jack

which has been specifically approved by

Mercedes-Benz for your vehicle.

The

jack is designed exclusively for jacking up

the vehicle at the jack take-up brackets built

into both sides of the vehicle. Make sure the

jack arm is fully seated in the jack take-up

bracket. The jack must always be vertical

when in use, especially on inclines or

declines.

The jack is intended only for lifting the vehicle

briefly for wheel changes. It is not suited for

performing maintenance work under the vehicle. To help avoid personal injury, use the

jack only to lift the vehicle during a wheel

change.

Never get beneath the vehicle while it is

supported by the jack. Keep hands and feet

away from the area under the lifted vehicle.

Always lower the vehicle onto sufficient

capacity

jackstands before working under the

vehicle.

Always engage the parking brake firmly and

block the wheels with wheel chocks or other

sizeable objects before raising the vehicle

with the jack. Do not disengage the parking

brake while the vehicle is raised.

Make sure that the ground on which the

vehicle is standing and where you place the

jack is solid, level and not slippery. If

necessary, use a large underlay. On slippery

surfaces, such as tiled floors, you should use

a non-slip underlay, for example a rubber mat.

Do not use wooden blocks or similar objects

to support the jack. Otherwise the jack may

not be able to achieve its load-bearing

capacity if it is not at its full height.

Never start the engine when the vehicle is

raised.

Also observe the notes on the jack.

X Prevent the vehicle from rolling away by

blocking

wheels with wheel chocks or other

sizeable objects.

When your vehicle is equipped with a wheel

chock, it is included with the vehicle tool kit

(Y page 234). For information on setting up

the collapsible wheel chock, see

(Y page 234).

When changing a wheel on a level surface:

X Place a wheel chock or other sizeable

object

in front of and another wheel chock

or other sizeable object behind the wheel

that is diagonally opposite to the wheel

being changed. Flat tire

277

Practical hints

171_AKB; 3; 60, en-US

d2ureepe, Version: 2.11.8.1 2009-05-11T16:00:23+02:00 - Seite 277 Z

Page 280 of 312

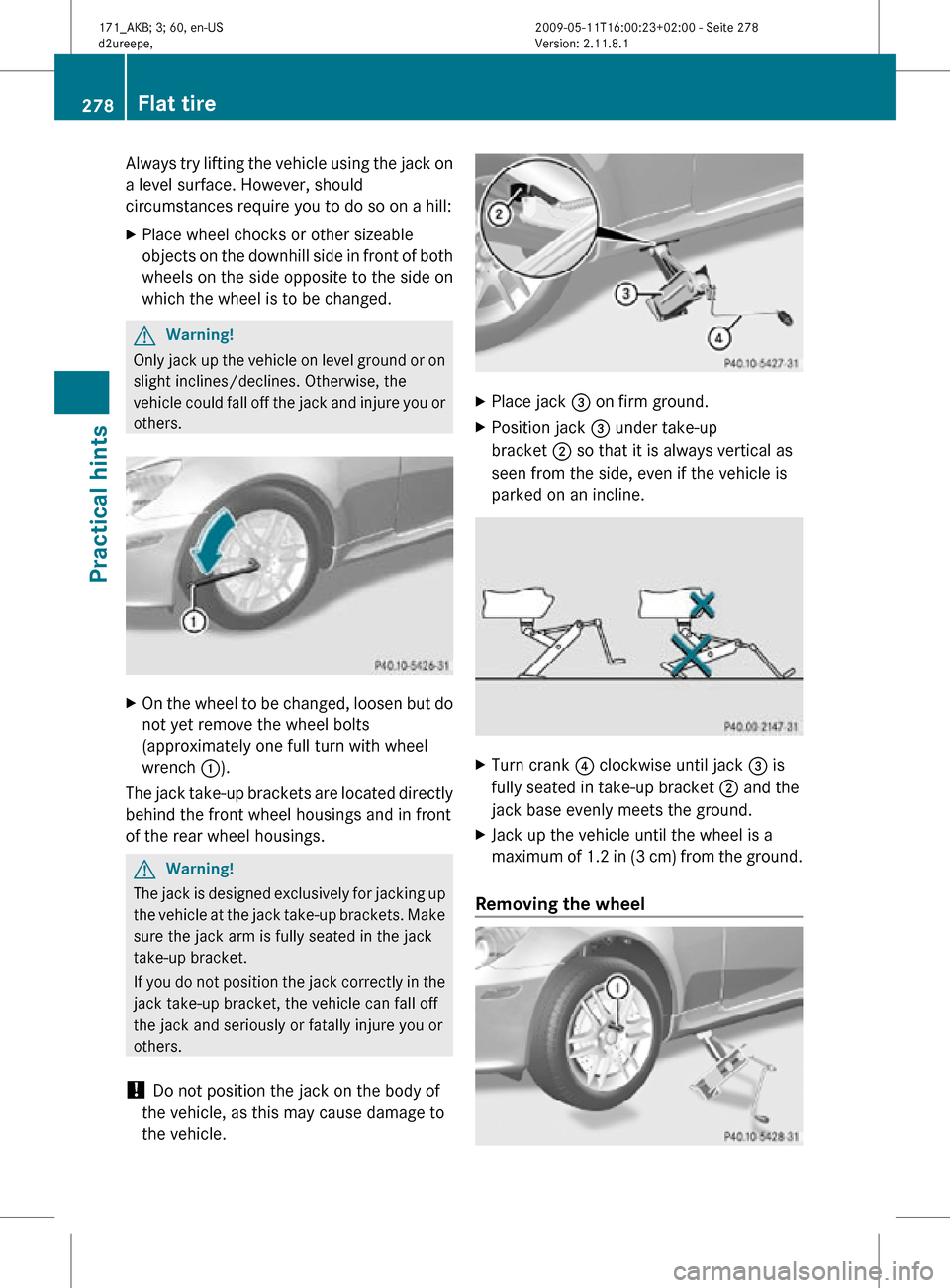

Always try lifting the vehicle using the jack on

a level surface. However, should

circumstances require you to do so on a hill:

X

Place wheel chocks or other sizeable

objects on the downhill side in front of both

wheels on the side opposite to the side on

which the wheel is to be changed. G

Warning!

Only jack up the vehicle on level ground or on

slight inclines/declines. Otherwise, the

vehicle could fall off the jack and injure you or

others. X

On the wheel to be changed, loosen but do

not yet remove the wheel bolts

(approximately one full turn with wheel

wrench :).

The jack take-up brackets are located directly

behind the front wheel housings and in front

of the rear wheel housings. G

Warning!

The jack is designed exclusively for jacking up

the vehicle at the jack take-up brackets. Make

sure the jack arm is fully seated in the jack

take-up bracket.

If you do not position the jack correctly in the

jack take-up bracket, the vehicle can fall off

the jack and seriously or fatally injure you or

others.

! Do not position the jack on the body of

the vehicle, as this may cause damage to

the vehicle. X

Place jack = on firm ground.

X Position jack = under take-up

bracket ; so that it is always vertical as

seen from the side, even if the vehicle is

parked on an incline. X

Turn crank ? clockwise until jack = is

fully seated in take-up bracket ; and the

jack base evenly meets the ground.

X Jack up the vehicle until the wheel is a

maximum of 1.2 in (3 cm) from the ground.

Removing the wheel 278

Flat tirePractical hints

171_AKB; 3; 60, en-US

d2ureepe,

Version: 2.11.8.1 2009-05-11T16:00:23+02:00 - Seite 278