MERCEDES-BENZ SPRINTER 2006 Service Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 1021 of 2305

INSTALLATION

WARNING: To avoid personal injury or death, during

and following any seat belt service, carefully

inspect all seat belts, buckles, mounting hardware,

retractors, and anchors for proper installation, oper-

ation, or damage. Replace any belt that is cut,

frayed, or torn. Straighten any belt that is twisted.

Tighten any loose fasteners. Replace any belt that

has a damaged or inoperative buckle or retractor.

Replace any belt that has a bent or damaged latch

plate or anchor plate. Never attempt to repair a seat

belt component. Always replace damaged or faulty

seat belt components with the correct, new and

unused replacement parts listed in the

DaimlerChrysler Mopar Parts Catalog.

(1) Position the rear seat belt and retractor unit

onto the bracket of the rear seat cushion frame (Fig.

35). Be certain to engage the guide on the retractor

into the locating notch on the bracket.

(2) Install and tighten the screw that secures the

rear seat belt retractor to the bracket on the rear

seat cushion frame. Tighten the screw to 35 N´m (26

ft. lbs.).

(3) Route the rear seat belt and lower anchor

through the turning loop bracket and the turning

loop trim cover.

(4) Position the rear seat belt lower anchor to the

rear seat cushion frame (Fig. 33) or (Fig. 34).

(5) Install and tighten the screw that secures the

rear seat belt lower anchor to the rear seat cushion

frame. Tighten the screw to 35 N´m (26 ft. lbs.).

(6) For a left outboard seating position only, rein-

stall the plastic cover onto the screw that secures the

rear seat belt lower anchor to the left outboard side

of the seat frame.

(7) Position the two seat belt turning loops to the

turning loop bracket so that one turning loop is

located behind the bracket and one is located in front

of the bracket (Fig. 32).

(8) From the front of the turning loop bracket,

insert the pin through both turning loops and the

bracket, then secure it from behind the bracket with

a new push nut.

(9) Position the turning loop trim cover over the

turning loop bracket.

(10) Lift the seat belt webbing to access and install

the plastic push pin fastener that secures the rear

seat belt turning loop trim cover to the turning loop

bracket at the top of the seat back (Fig. 31).

(11) Reinstall the plastic shield onto the back of

the rear seat. (Refer to 23 - BODY/SEATS/REAR

SEAT BACK SHIELD - INSTALLATION).

(12) Reinstall the rear bench seat into the vehicle.

REAR SEAT BELT BUCKLE

REMOVAL

REMOVAL - INBOARD

WARNING: To avoid personal injury or death, during

and following any seat belt service, carefully

inspect all seat belts, buckles, mounting hardware,

retractors, and anchors for proper installation, oper-

ation, or damage. Replace any belt that is cut,

frayed, or torn. Straighten any belt that is twisted.

Tighten any loose fasteners. Replace any belt that

has a damaged or inoperative buckle or retractor.

Replace any belt that has a bent or damaged latch

plate or anchor plate. Never attempt to repair a seat

belt component. Always replace damaged or faulty

seat belt components with the correct, new and

unused replacement parts listed in the

DaimlerChrysler Mopar Parts Catalog.

(1) Remove the rear bench seat containing the

inboard rear seat belt buckle unit to be serviced from

the vehicle.

(2) Remove the plastic shield from the back of the

rear seat. (Refer to 23 - BODY/SEATS/REAR SEAT

BACK SHIELD - REMOVAL).

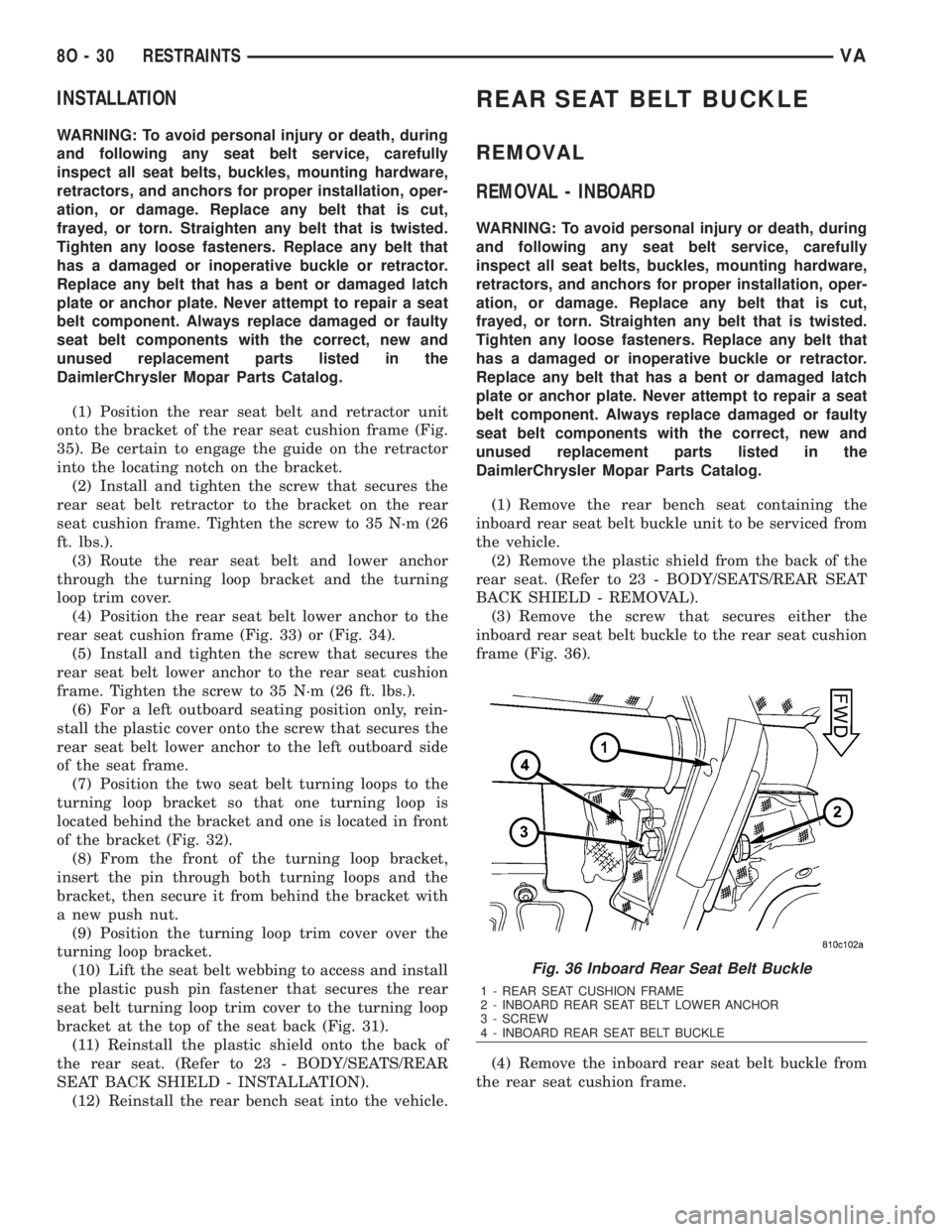

(3) Remove the screw that secures either the

inboard rear seat belt buckle to the rear seat cushion

frame (Fig. 36).

(4) Remove the inboard rear seat belt buckle from

the rear seat cushion frame.

Fig. 36 Inboard Rear Seat Belt Buckle

1 - REAR SEAT CUSHION FRAME

2 - INBOARD REAR SEAT BELT LOWER ANCHOR

3 - SCREW

4 - INBOARD REAR SEAT BELT BUCKLE

8O - 30 RESTRAINTSVA

Page 1022 of 2305

REMOVAL - OUTBOARD

WARNING: To avoid personal injury or death, during

and following any seat belt service, carefully

inspect all seat belts, buckles, mounting hardware,

retractors, and anchors for proper installation, oper-

ation, or damage. Replace any belt that is cut,

frayed, or torn. Straighten any belt that is twisted.

Tighten any loose fasteners. Replace any belt that

has a damaged or inoperative buckle or retractor.

Replace any belt that has a bent or damaged latch

plate or anchor plate. Never attempt to repair a seat

belt component. Always replace damaged or faulty

seat belt components with the correct, new and

unused replacement parts listed in the

DaimlerChrysler Mopar Parts Catalog.

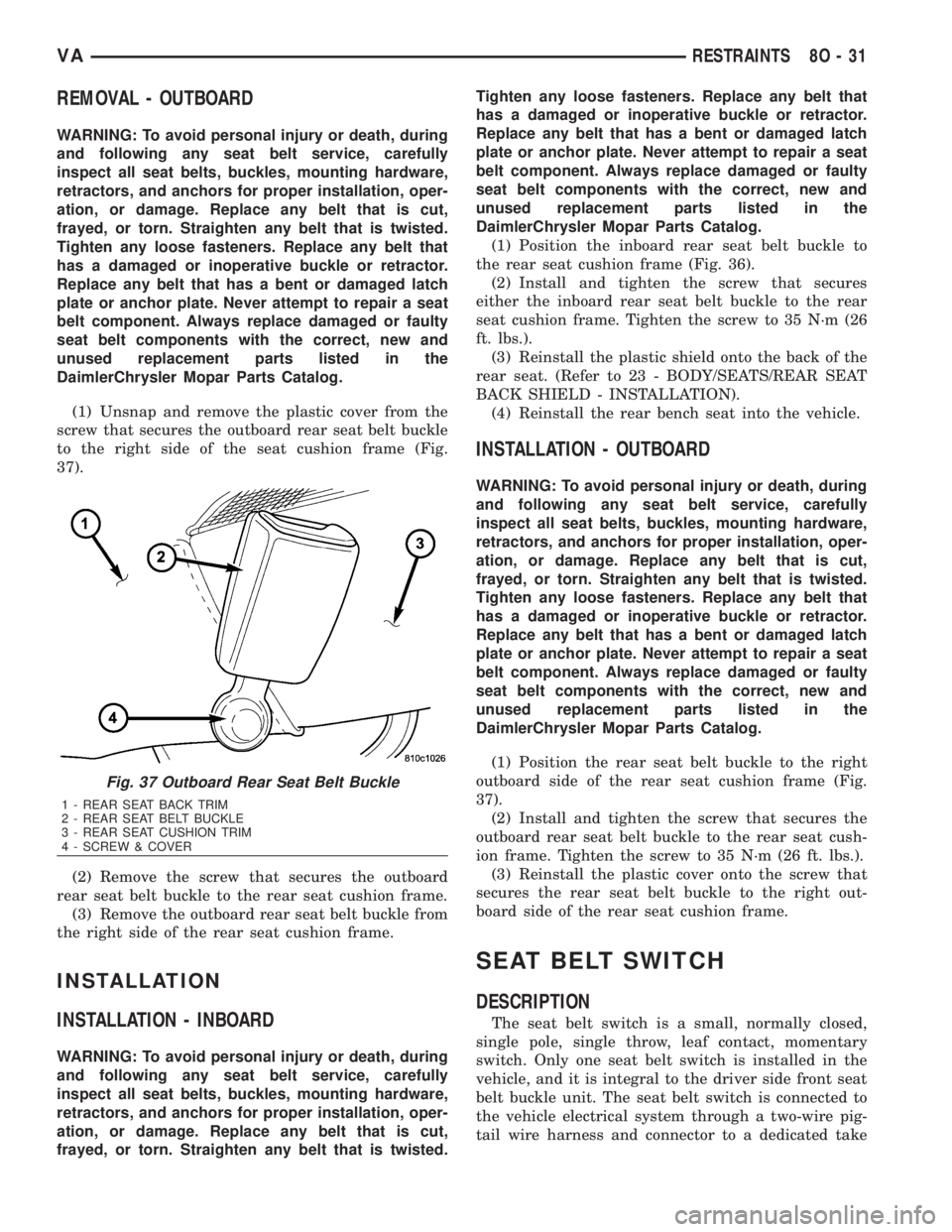

(1) Unsnap and remove the plastic cover from the

screw that secures the outboard rear seat belt buckle

to the right side of the seat cushion frame (Fig.

37).

(2) Remove the screw that secures the outboard

rear seat belt buckle to the rear seat cushion frame.

(3) Remove the outboard rear seat belt buckle from

the right side of the rear seat cushion frame.

INSTALLATION

INSTALLATION - INBOARD

WARNING: To avoid personal injury or death, during

and following any seat belt service, carefully

inspect all seat belts, buckles, mounting hardware,

retractors, and anchors for proper installation, oper-

ation, or damage. Replace any belt that is cut,

frayed, or torn. Straighten any belt that is twisted.Tighten any loose fasteners. Replace any belt that

has a damaged or inoperative buckle or retractor.

Replace any belt that has a bent or damaged latch

plate or anchor plate. Never attempt to repair a seat

belt component. Always replace damaged or faulty

seat belt components with the correct, new and

unused replacement parts listed in the

DaimlerChrysler Mopar Parts Catalog.

(1) Position the inboard rear seat belt buckle to

the rear seat cushion frame (Fig. 36).

(2) Install and tighten the screw that secures

either the inboard rear seat belt buckle to the rear

seat cushion frame. Tighten the screw to 35 N´m (26

ft. lbs.).

(3) Reinstall the plastic shield onto the back of the

rear seat. (Refer to 23 - BODY/SEATS/REAR SEAT

BACK SHIELD - INSTALLATION).

(4) Reinstall the rear bench seat into the vehicle.

INSTALLATION - OUTBOARD

WARNING: To avoid personal injury or death, during

and following any seat belt service, carefully

inspect all seat belts, buckles, mounting hardware,

retractors, and anchors for proper installation, oper-

ation, or damage. Replace any belt that is cut,

frayed, or torn. Straighten any belt that is twisted.

Tighten any loose fasteners. Replace any belt that

has a damaged or inoperative buckle or retractor.

Replace any belt that has a bent or damaged latch

plate or anchor plate. Never attempt to repair a seat

belt component. Always replace damaged or faulty

seat belt components with the correct, new and

unused replacement parts listed in the

DaimlerChrysler Mopar Parts Catalog.

(1) Position the rear seat belt buckle to the right

outboard side of the rear seat cushion frame (Fig.

37).

(2) Install and tighten the screw that secures the

outboard rear seat belt buckle to the rear seat cush-

ion frame. Tighten the screw to 35 N´m (26 ft. lbs.).

(3) Reinstall the plastic cover onto the screw that

secures the rear seat belt buckle to the right out-

board side of the rear seat cushion frame.

SEAT BELT SWITCH

DESCRIPTION

The seat belt switch is a small, normally closed,

single pole, single throw, leaf contact, momentary

switch. Only one seat belt switch is installed in the

vehicle, and it is integral to the driver side front seat

belt buckle unit. The seat belt switch is connected to

the vehicle electrical system through a two-wire pig-

tail wire harness and connector to a dedicated take

Fig. 37 Outboard Rear Seat Belt Buckle

1 - REAR SEAT BACK TRIM

2 - REAR SEAT BELT BUCKLE

3 - REAR SEAT CUSHION TRIM

4 - SCREW & COVER

VARESTRAINTS 8O - 31

Page 1023 of 2305

out and connector of the vehicle wire harness located

within the driver side front seat riser.

The seat belt switch cannot be adjusted or repaired

and, if faulty or damaged, the entire driver side seat

belt buckle unit must be replaced.

OPERATION

The seat belt switch is designed to control a path

to ground for the seat belt switch sense input of the

Electro-Mechanical Instrument Cluster (EMIC). The

seat belt switch contact is actuated by the seat belt

latch plate being inserted in to the buckle. When the

seat belt latch plate is inserted into the buckle far

enough to be engaged by the seat belt buckle latch,

the switch leaf contact opens the seat belt switch

sense circuit ground path; and, when the seat belt

latch plate is released and extracted from the seat

belt buckle latch the switch leaf contact is released,

closing the circuit to ground.

The seat belt switch is connected is series between

ground and the seat belt switch sense input of the

instrument cluster. The seat belt switch receives

ground at all times through its pigtail wire connec-

tion to the vehicle wire harness from another take

out of the vehicle wire harness. An eyelet terminal

connector on the vehicle wire harness ground take

out is secured under a nut to a ground stud located

on the floor panel within the driver side front seat

riser. The seat belt switch may de diagnosed using

conventional diagnostic tools and methods.

SEAT BELT TENSIONER

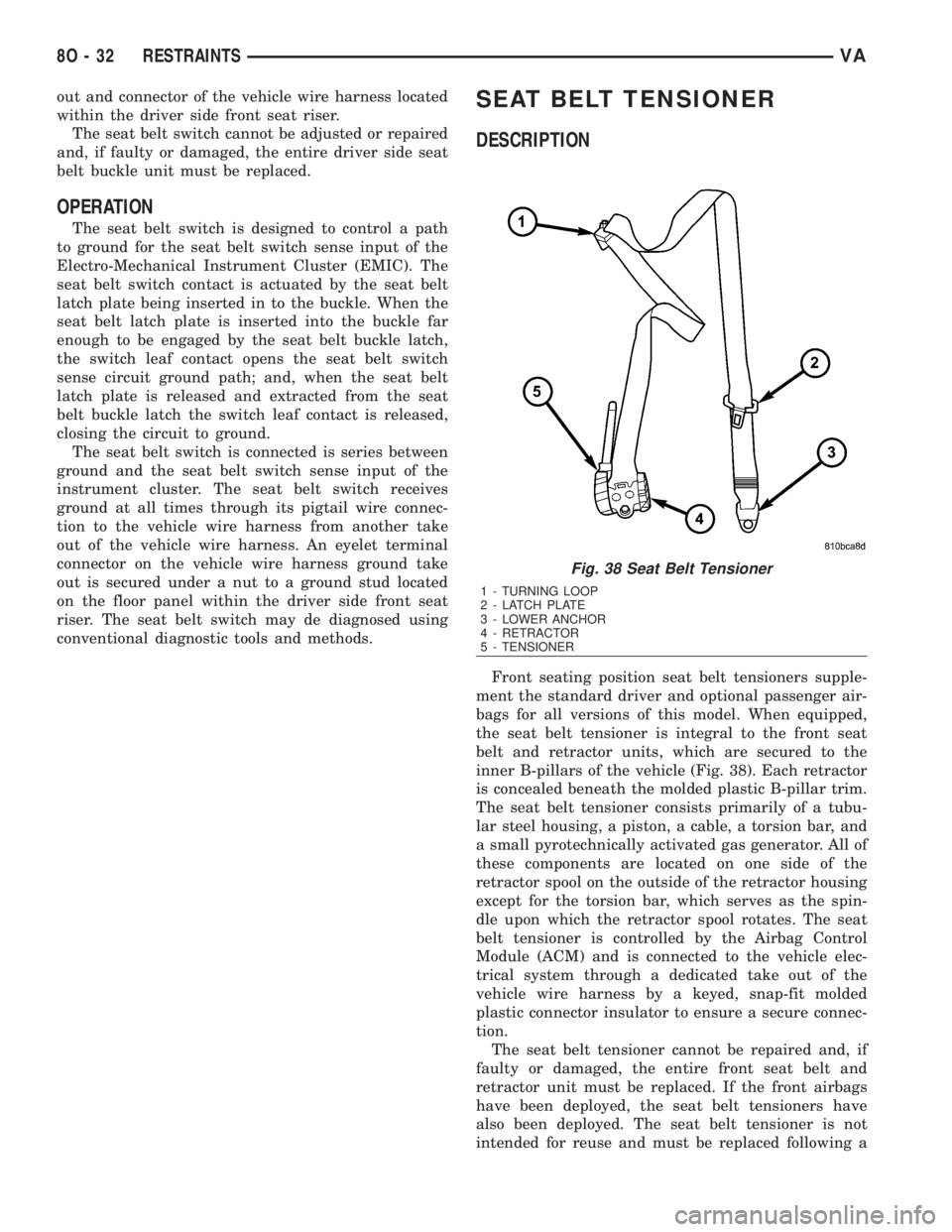

DESCRIPTION

Front seating position seat belt tensioners supple-

ment the standard driver and optional passenger air-

bags for all versions of this model. When equipped,

the seat belt tensioner is integral to the front seat

belt and retractor units, which are secured to the

inner B-pillars of the vehicle (Fig. 38). Each retractor

is concealed beneath the molded plastic B-pillar trim.

The seat belt tensioner consists primarily of a tubu-

lar steel housing, a piston, a cable, a torsion bar, and

a small pyrotechnically activated gas generator. All of

these components are located on one side of the

retractor spool on the outside of the retractor housing

except for the torsion bar, which serves as the spin-

dle upon which the retractor spool rotates. The seat

belt tensioner is controlled by the Airbag Control

Module (ACM) and is connected to the vehicle elec-

trical system through a dedicated take out of the

vehicle wire harness by a keyed, snap-fit molded

plastic connector insulator to ensure a secure connec-

tion.

The seat belt tensioner cannot be repaired and, if

faulty or damaged, the entire front seat belt and

retractor unit must be replaced. If the front airbags

have been deployed, the seat belt tensioners have

also been deployed. The seat belt tensioner is not

intended for reuse and must be replaced following a

Fig. 38 Seat Belt Tensioner

1 - TURNING LOOP

2 - LATCH PLATE

3 - LOWER ANCHOR

4 - RETRACTOR

5 - TENSIONER

8O - 32 RESTRAINTSVA

Page 1024 of 2305

deployment. A growling or grinding sound while

attempting to operate the seat belt retractor is a sure

indication that the seat belt tensioner has been

deployed and requires replacement. (Refer to 8 -

ELECTRICAL/RESTRAINTS/FRONT SEAT BELT &

RETRACTOR - REMOVAL).

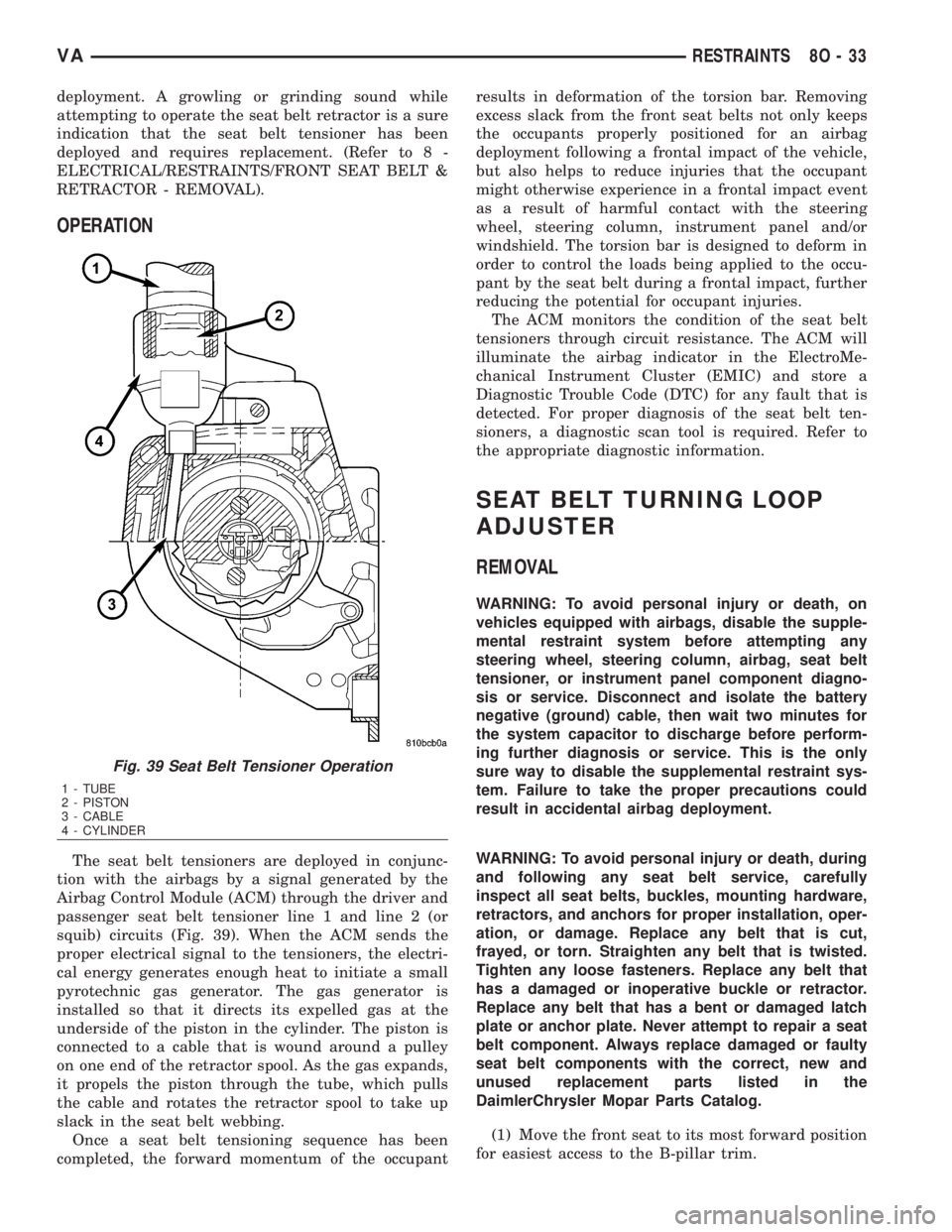

OPERATION

The seat belt tensioners are deployed in conjunc-

tion with the airbags by a signal generated by the

Airbag Control Module (ACM) through the driver and

passenger seat belt tensioner line 1 and line 2 (or

squib) circuits (Fig. 39). When the ACM sends the

proper electrical signal to the tensioners, the electri-

cal energy generates enough heat to initiate a small

pyrotechnic gas generator. The gas generator is

installed so that it directs its expelled gas at the

underside of the piston in the cylinder. The piston is

connected to a cable that is wound around a pulley

on one end of the retractor spool. As the gas expands,

it propels the piston through the tube, which pulls

the cable and rotates the retractor spool to take up

slack in the seat belt webbing.

Once a seat belt tensioning sequence has been

completed, the forward momentum of the occupantresults in deformation of the torsion bar. Removing

excess slack from the front seat belts not only keeps

the occupants properly positioned for an airbag

deployment following a frontal impact of the vehicle,

but also helps to reduce injuries that the occupant

might otherwise experience in a frontal impact event

as a result of harmful contact with the steering

wheel, steering column, instrument panel and/or

windshield. The torsion bar is designed to deform in

order to control the loads being applied to the occu-

pant by the seat belt during a frontal impact, further

reducing the potential for occupant injuries.

The ACM monitors the condition of the seat belt

tensioners through circuit resistance. The ACM will

illuminate the airbag indicator in the ElectroMe-

chanical Instrument Cluster (EMIC) and store a

Diagnostic Trouble Code (DTC) for any fault that is

detected. For proper diagnosis of the seat belt ten-

sioners, a diagnostic scan tool is required. Refer to

the appropriate diagnostic information.

SEAT BELT TURNING LOOP

ADJUSTER

REMOVAL

WARNING: To avoid personal injury or death, on

vehicles equipped with airbags, disable the supple-

mental restraint system before attempting any

steering wheel, steering column, airbag, seat belt

tensioner, or instrument panel component diagno-

sis or service. Disconnect and isolate the battery

negative (ground) cable, then wait two minutes for

the system capacitor to discharge before perform-

ing further diagnosis or service. This is the only

sure way to disable the supplemental restraint sys-

tem. Failure to take the proper precautions could

result in accidental airbag deployment.

WARNING: To avoid personal injury or death, during

and following any seat belt service, carefully

inspect all seat belts, buckles, mounting hardware,

retractors, and anchors for proper installation, oper-

ation, or damage. Replace any belt that is cut,

frayed, or torn. Straighten any belt that is twisted.

Tighten any loose fasteners. Replace any belt that

has a damaged or inoperative buckle or retractor.

Replace any belt that has a bent or damaged latch

plate or anchor plate. Never attempt to repair a seat

belt component. Always replace damaged or faulty

seat belt components with the correct, new and

unused replacement parts listed in the

DaimlerChrysler Mopar Parts Catalog.

(1) Move the front seat to its most forward position

for easiest access to the B-pillar trim.

Fig. 39 Seat Belt Tensioner Operation

1 - TUBE

2 - PISTON

3 - CABLE

4 - CYLINDER

VARESTRAINTS 8O - 33

Page 1025 of 2305

(2) Disconnect and isolate the battery negative

cable. Wait two minutes for the system capacitor to

discharge before further service.

(3) Remove the trim panel from the inside of the

B-pillar. (Refer to 23 - BODY/INTERIOR/B-PILLAR

TRIM - REMOVAL).

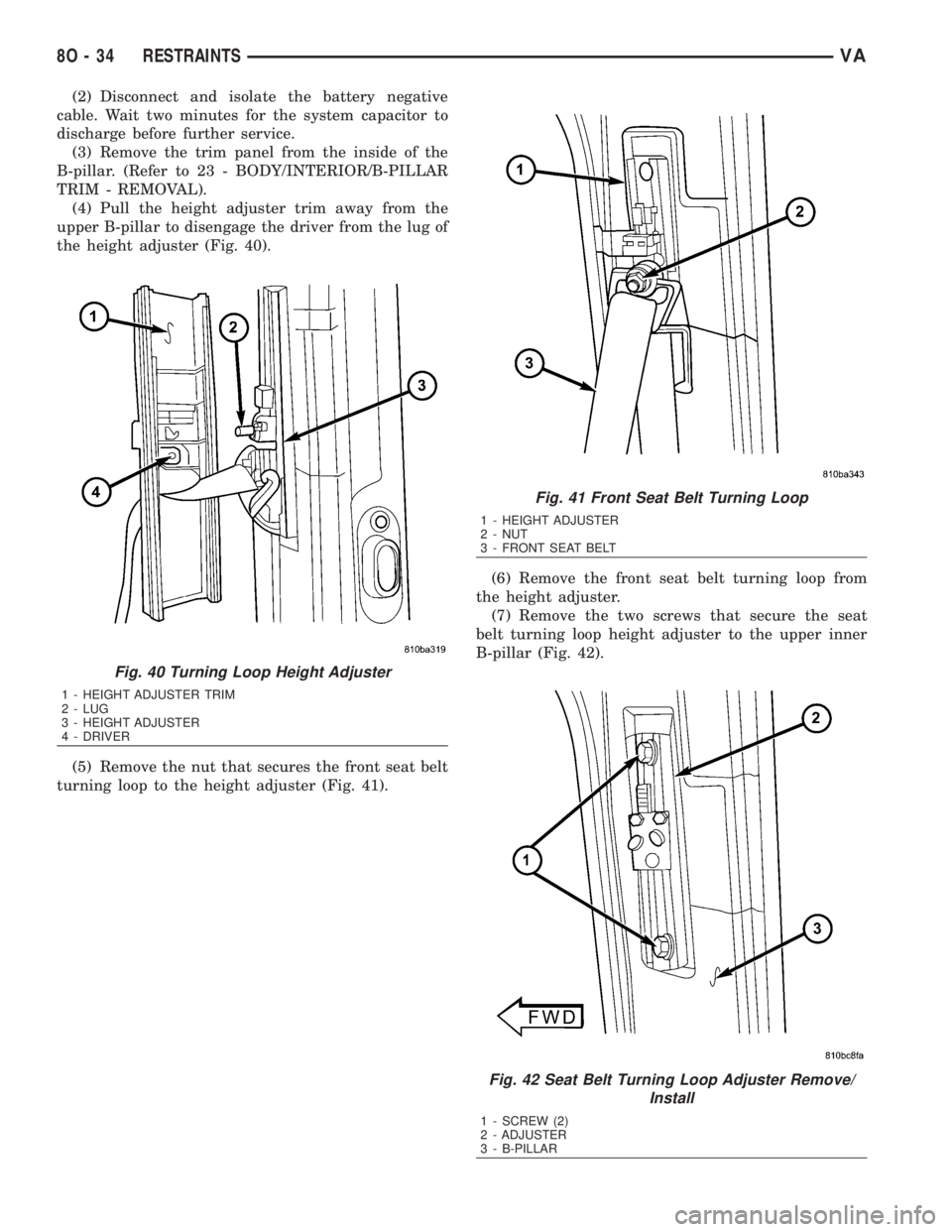

(4) Pull the height adjuster trim away from the

upper B-pillar to disengage the driver from the lug of

the height adjuster (Fig. 40).

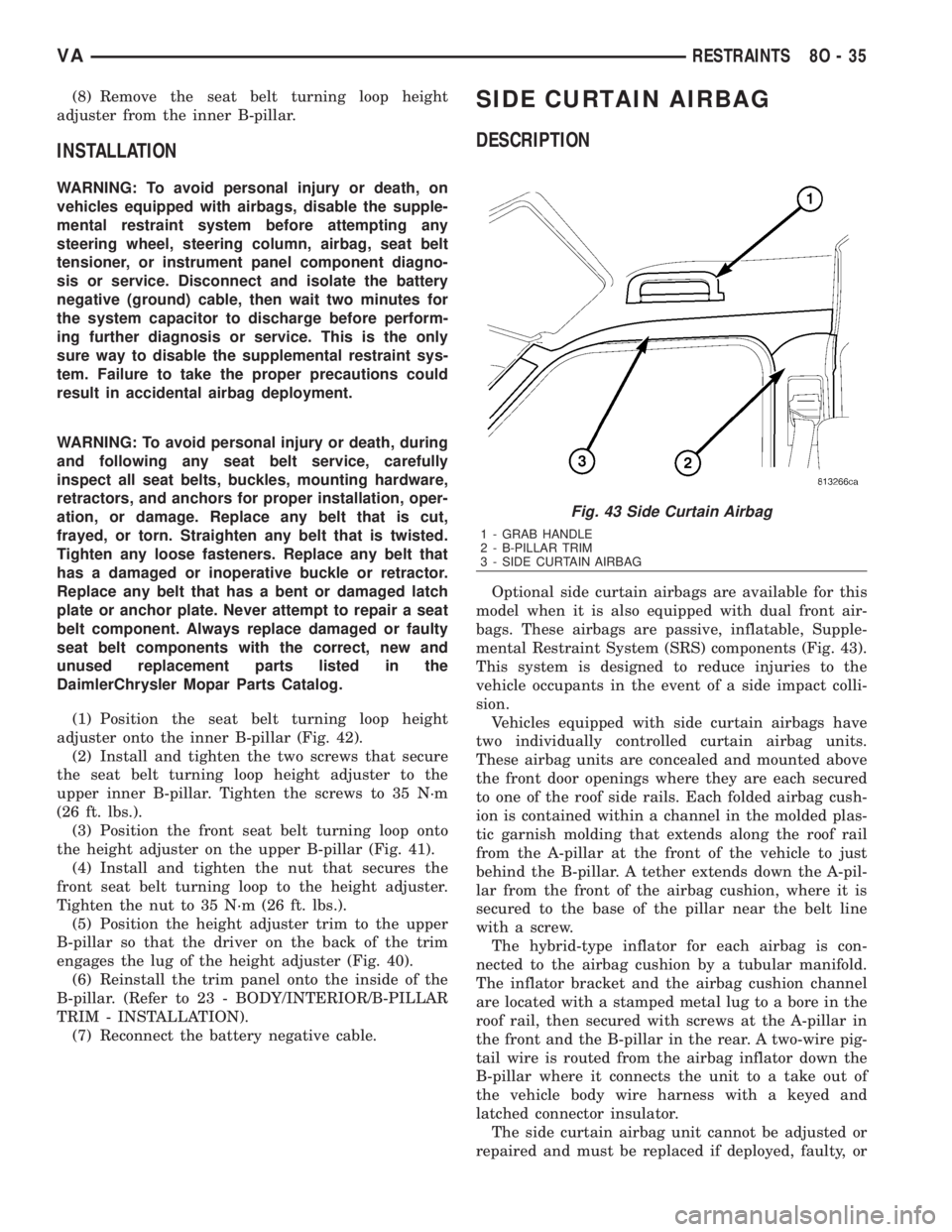

(5) Remove the nut that secures the front seat belt

turning loop to the height adjuster (Fig. 41).(6) Remove the front seat belt turning loop from

the height adjuster.

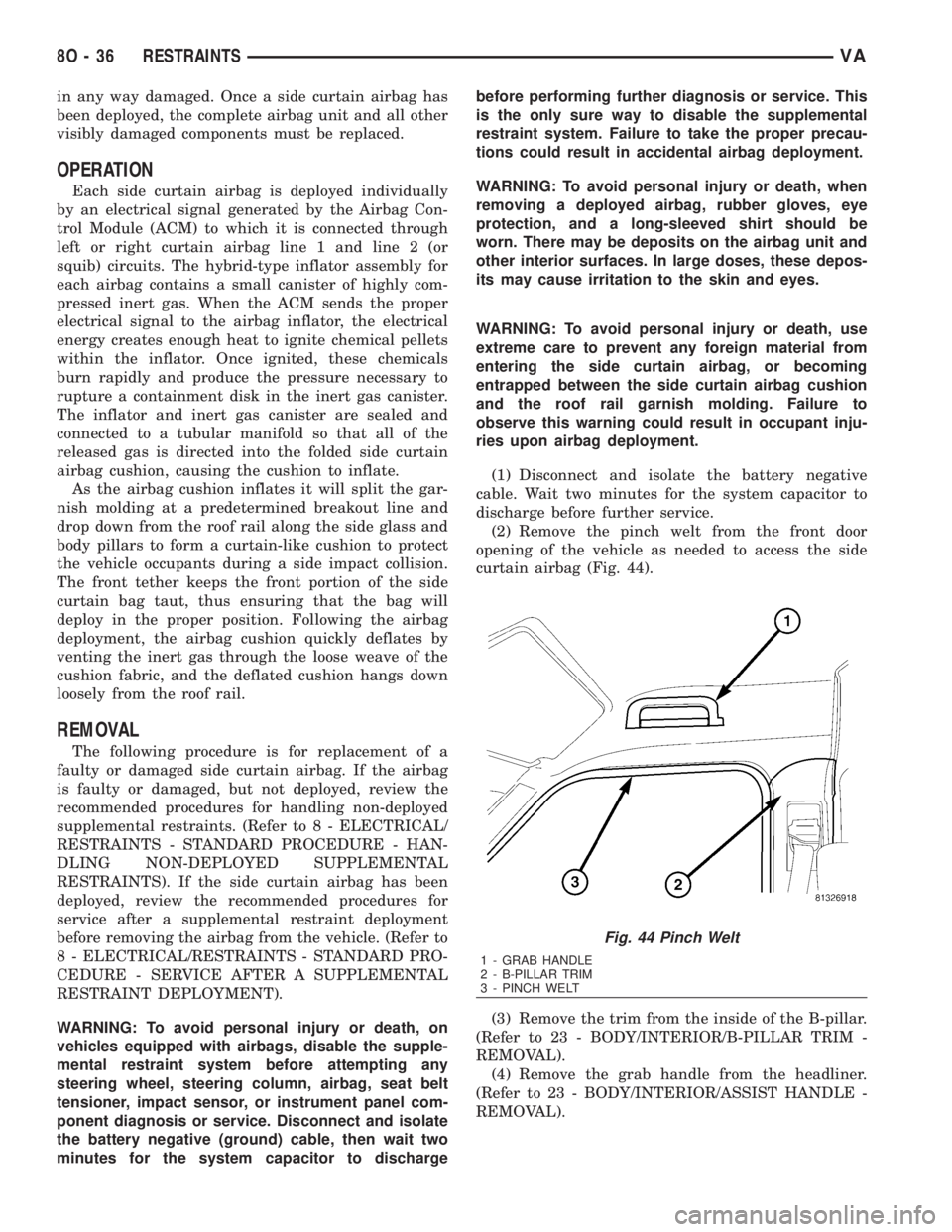

(7) Remove the two screws that secure the seat

belt turning loop height adjuster to the upper inner

B-pillar (Fig. 42).

Fig. 40 Turning Loop Height Adjuster

1 - HEIGHT ADJUSTER TRIM

2 - LUG

3 - HEIGHT ADJUSTER

4 - DRIVER

Fig. 41 Front Seat Belt Turning Loop

1 - HEIGHT ADJUSTER

2 - NUT

3 - FRONT SEAT BELT

Fig. 42 Seat Belt Turning Loop Adjuster Remove/

Install

1 - SCREW (2)

2 - ADJUSTER

3 - B-PILLAR

8O - 34 RESTRAINTSVA

Page 1026 of 2305

(8) Remove the seat belt turning loop height

adjuster from the inner B-pillar.

INSTALLATION

WARNING: To avoid personal injury or death, on

vehicles equipped with airbags, disable the supple-

mental restraint system before attempting any

steering wheel, steering column, airbag, seat belt

tensioner, or instrument panel component diagno-

sis or service. Disconnect and isolate the battery

negative (ground) cable, then wait two minutes for

the system capacitor to discharge before perform-

ing further diagnosis or service. This is the only

sure way to disable the supplemental restraint sys-

tem. Failure to take the proper precautions could

result in accidental airbag deployment.

WARNING: To avoid personal injury or death, during

and following any seat belt service, carefully

inspect all seat belts, buckles, mounting hardware,

retractors, and anchors for proper installation, oper-

ation, or damage. Replace any belt that is cut,

frayed, or torn. Straighten any belt that is twisted.

Tighten any loose fasteners. Replace any belt that

has a damaged or inoperative buckle or retractor.

Replace any belt that has a bent or damaged latch

plate or anchor plate. Never attempt to repair a seat

belt component. Always replace damaged or faulty

seat belt components with the correct, new and

unused replacement parts listed in the

DaimlerChrysler Mopar Parts Catalog.

(1) Position the seat belt turning loop height

adjuster onto the inner B-pillar (Fig. 42).

(2) Install and tighten the two screws that secure

the seat belt turning loop height adjuster to the

upper inner B-pillar. Tighten the screws to 35 N´m

(26 ft. lbs.).

(3) Position the front seat belt turning loop onto

the height adjuster on the upper B-pillar (Fig. 41).

(4) Install and tighten the nut that secures the

front seat belt turning loop to the height adjuster.

Tighten the nut to 35 N´m (26 ft. lbs.).

(5) Position the height adjuster trim to the upper

B-pillar so that the driver on the back of the trim

engages the lug of the height adjuster (Fig. 40).

(6) Reinstall the trim panel onto the inside of the

B-pillar. (Refer to 23 - BODY/INTERIOR/B-PILLAR

TRIM - INSTALLATION).

(7) Reconnect the battery negative cable.

SIDE CURTAIN AIRBAG

DESCRIPTION

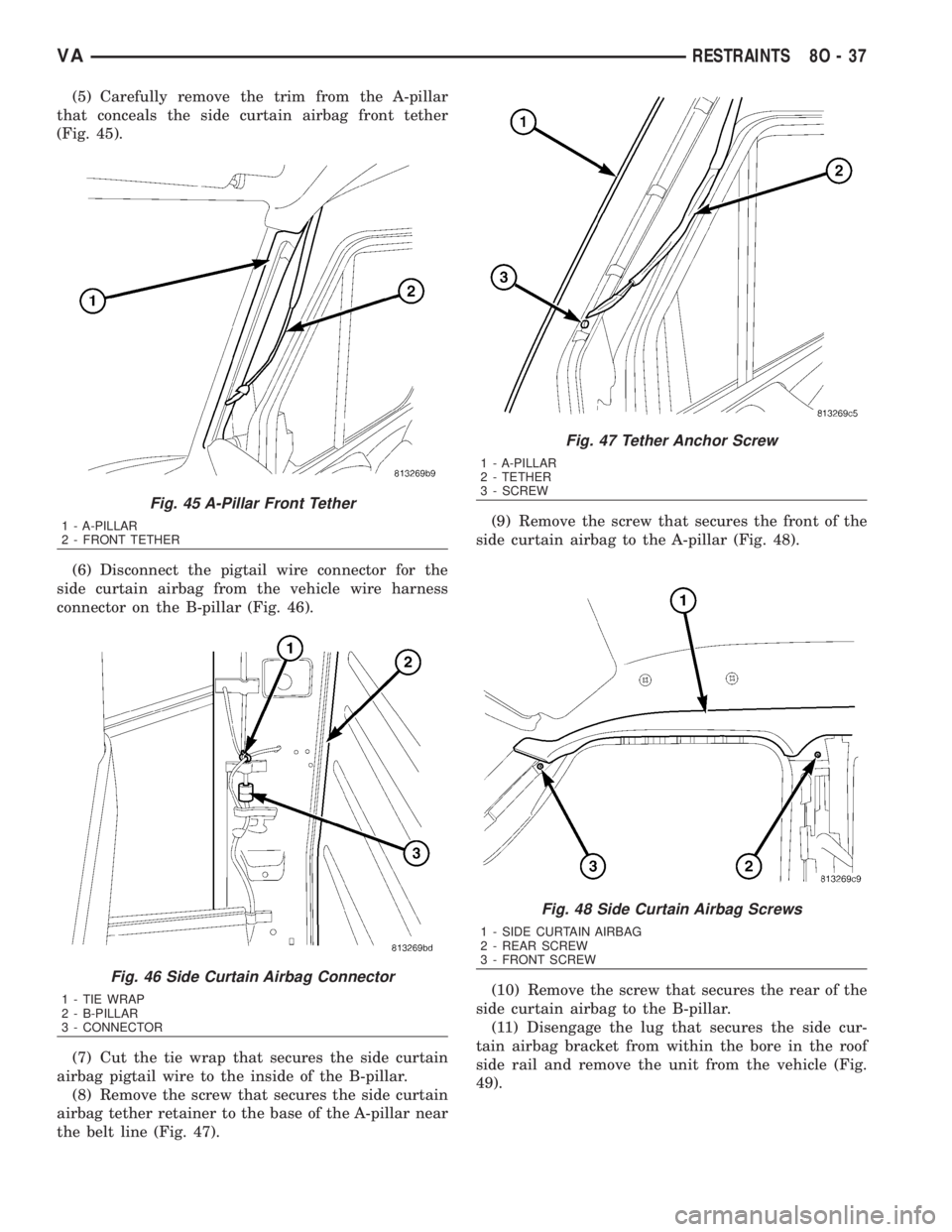

Optional side curtain airbags are available for this

model when it is also equipped with dual front air-

bags. These airbags are passive, inflatable, Supple-

mental Restraint System (SRS) components (Fig. 43).

This system is designed to reduce injuries to the

vehicle occupants in the event of a side impact colli-

sion.

Vehicles equipped with side curtain airbags have

two individually controlled curtain airbag units.

These airbag units are concealed and mounted above

the front door openings where they are each secured

to one of the roof side rails. Each folded airbag cush-

ion is contained within a channel in the molded plas-

tic garnish molding that extends along the roof rail

from the A-pillar at the front of the vehicle to just

behind the B-pillar. A tether extends down the A-pil-

lar from the front of the airbag cushion, where it is

secured to the base of the pillar near the belt line

with a screw.

The hybrid-type inflator for each airbag is con-

nected to the airbag cushion by a tubular manifold.

The inflator bracket and the airbag cushion channel

are located with a stamped metal lug to a bore in the

roof rail, then secured with screws at the A-pillar in

the front and the B-pillar in the rear. A two-wire pig-

tail wire is routed from the airbag inflator down the

B-pillar where it connects the unit to a take out of

the vehicle body wire harness with a keyed and

latched connector insulator.

The side curtain airbag unit cannot be adjusted or

repaired and must be replaced if deployed, faulty, or

Fig. 43 Side Curtain Airbag

1 - GRAB HANDLE

2 - B-PILLAR TRIM

3 - SIDE CURTAIN AIRBAG

VARESTRAINTS 8O - 35

Page 1027 of 2305

in any way damaged. Once a side curtain airbag has

been deployed, the complete airbag unit and all other

visibly damaged components must be replaced.

OPERATION

Each side curtain airbag is deployed individually

by an electrical signal generated by the Airbag Con-

trol Module (ACM) to which it is connected through

left or right curtain airbag line 1 and line 2 (or

squib) circuits. The hybrid-type inflator assembly for

each airbag contains a small canister of highly com-

pressed inert gas. When the ACM sends the proper

electrical signal to the airbag inflator, the electrical

energy creates enough heat to ignite chemical pellets

within the inflator. Once ignited, these chemicals

burn rapidly and produce the pressure necessary to

rupture a containment disk in the inert gas canister.

The inflator and inert gas canister are sealed and

connected to a tubular manifold so that all of the

released gas is directed into the folded side curtain

airbag cushion, causing the cushion to inflate.

As the airbag cushion inflates it will split the gar-

nish molding at a predetermined breakout line and

drop down from the roof rail along the side glass and

body pillars to form a curtain-like cushion to protect

the vehicle occupants during a side impact collision.

The front tether keeps the front portion of the side

curtain bag taut, thus ensuring that the bag will

deploy in the proper position. Following the airbag

deployment, the airbag cushion quickly deflates by

venting the inert gas through the loose weave of the

cushion fabric, and the deflated cushion hangs down

loosely from the roof rail.

REMOVAL

The following procedure is for replacement of a

faulty or damaged side curtain airbag. If the airbag

is faulty or damaged, but not deployed, review the

recommended procedures for handling non-deployed

supplemental restraints. (Refer to 8 - ELECTRICAL/

RESTRAINTS - STANDARD PROCEDURE - HAN-

DLING NON-DEPLOYED SUPPLEMENTAL

RESTRAINTS). If the side curtain airbag has been

deployed, review the recommended procedures for

service after a supplemental restraint deployment

before removing the airbag from the vehicle. (Refer to

8 - ELECTRICAL/RESTRAINTS - STANDARD PRO-

CEDURE - SERVICE AFTER A SUPPLEMENTAL

RESTRAINT DEPLOYMENT).

WARNING: To avoid personal injury or death, on

vehicles equipped with airbags, disable the supple-

mental restraint system before attempting any

steering wheel, steering column, airbag, seat belt

tensioner, impact sensor, or instrument panel com-

ponent diagnosis or service. Disconnect and isolate

the battery negative (ground) cable, then wait two

minutes for the system capacitor to dischargebefore performing further diagnosis or service. This

is the only sure way to disable the supplemental

restraint system. Failure to take the proper precau-

tions could result in accidental airbag deployment.

WARNING: To avoid personal injury or death, when

removing a deployed airbag, rubber gloves, eye

protection, and a long-sleeved shirt should be

worn. There may be deposits on the airbag unit and

other interior surfaces. In large doses, these depos-

its may cause irritation to the skin and eyes.

WARNING: To avoid personal injury or death, use

extreme care to prevent any foreign material from

entering the side curtain airbag, or becoming

entrapped between the side curtain airbag cushion

and the roof rail garnish molding. Failure to

observe this warning could result in occupant inju-

ries upon airbag deployment.

(1) Disconnect and isolate the battery negative

cable. Wait two minutes for the system capacitor to

discharge before further service.

(2) Remove the pinch welt from the front door

opening of the vehicle as needed to access the side

curtain airbag (Fig. 44).

(3) Remove the trim from the inside of the B-pillar.

(Refer to 23 - BODY/INTERIOR/B-PILLAR TRIM -

REMOVAL).

(4) Remove the grab handle from the headliner.

(Refer to 23 - BODY/INTERIOR/ASSIST HANDLE -

REMOVAL).

Fig. 44 Pinch Welt

1 - GRAB HANDLE

2 - B-PILLAR TRIM

3 - PINCH WELT

8O - 36 RESTRAINTSVA

Page 1028 of 2305

(5) Carefully remove the trim from the A-pillar

that conceals the side curtain airbag front tether

(Fig. 45).

(6) Disconnect the pigtail wire connector for the

side curtain airbag from the vehicle wire harness

connector on the B-pillar (Fig. 46).

(7) Cut the tie wrap that secures the side curtain

airbag pigtail wire to the inside of the B-pillar.

(8) Remove the screw that secures the side curtain

airbag tether retainer to the base of the A-pillar near

the belt line (Fig. 47).(9) Remove the screw that secures the front of the

side curtain airbag to the A-pillar (Fig. 48).

(10) Remove the screw that secures the rear of the

side curtain airbag to the B-pillar.

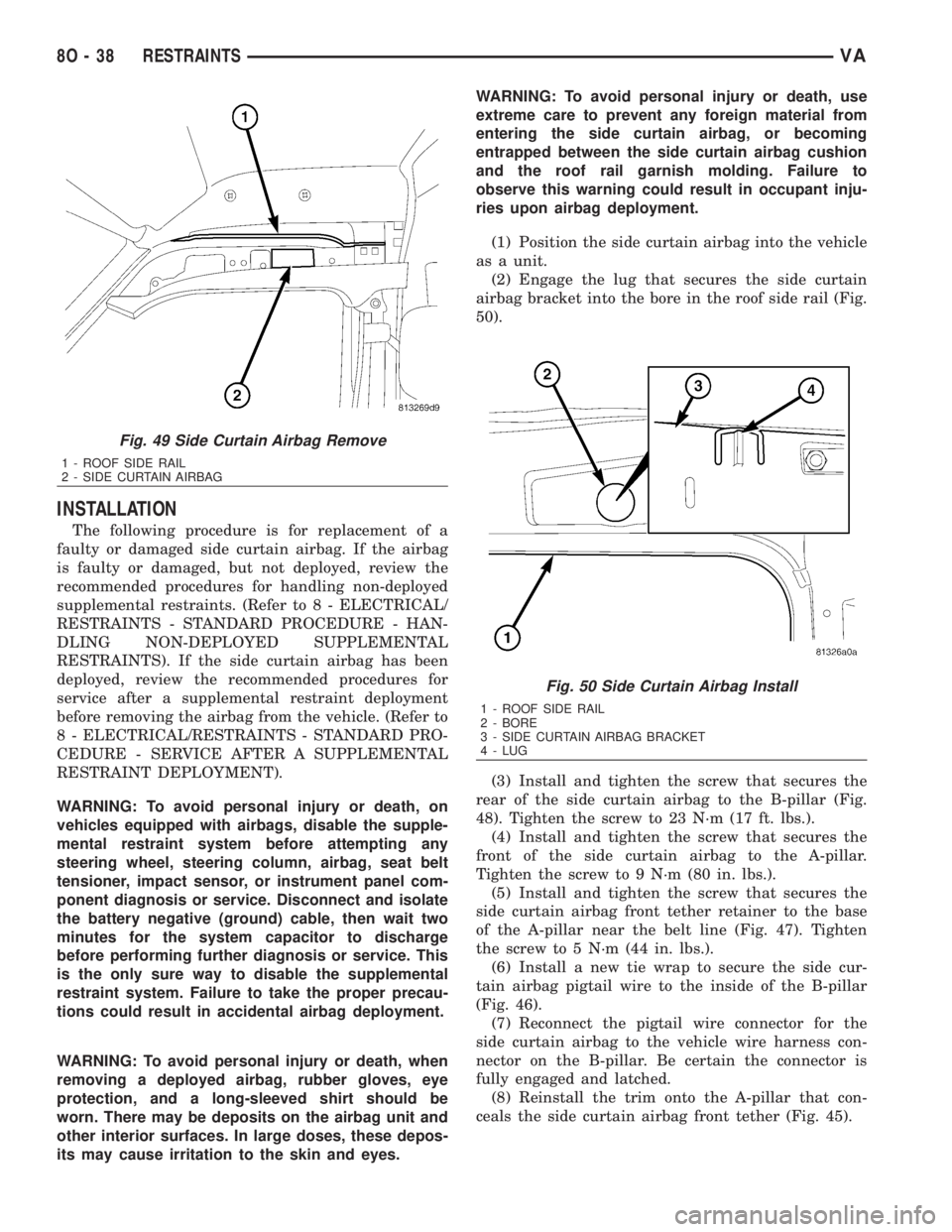

(11) Disengage the lug that secures the side cur-

tain airbag bracket from within the bore in the roof

side rail and remove the unit from the vehicle (Fig.

49).

Fig. 45 A-Pillar Front Tether

1 - A-PILLAR

2 - FRONT TETHER

Fig. 46 Side Curtain Airbag Connector

1 - TIE WRAP

2 - B-PILLAR

3 - CONNECTOR

Fig. 47 Tether Anchor Screw

1 - A-PILLAR

2 - TETHER

3 - SCREW

Fig. 48 Side Curtain Airbag Screws

1 - SIDE CURTAIN AIRBAG

2 - REAR SCREW

3 - FRONT SCREW

VARESTRAINTS 8O - 37

Page 1029 of 2305

INSTALLATION

The following procedure is for replacement of a

faulty or damaged side curtain airbag. If the airbag

is faulty or damaged, but not deployed, review the

recommended procedures for handling non-deployed

supplemental restraints. (Refer to 8 - ELECTRICAL/

RESTRAINTS - STANDARD PROCEDURE - HAN-

DLING NON-DEPLOYED SUPPLEMENTAL

RESTRAINTS). If the side curtain airbag has been

deployed, review the recommended procedures for

service after a supplemental restraint deployment

before removing the airbag from the vehicle. (Refer to

8 - ELECTRICAL/RESTRAINTS - STANDARD PRO-

CEDURE - SERVICE AFTER A SUPPLEMENTAL

RESTRAINT DEPLOYMENT).

WARNING: To avoid personal injury or death, on

vehicles equipped with airbags, disable the supple-

mental restraint system before attempting any

steering wheel, steering column, airbag, seat belt

tensioner, impact sensor, or instrument panel com-

ponent diagnosis or service. Disconnect and isolate

the battery negative (ground) cable, then wait two

minutes for the system capacitor to discharge

before performing further diagnosis or service. This

is the only sure way to disable the supplemental

restraint system. Failure to take the proper precau-

tions could result in accidental airbag deployment.

WARNING: To avoid personal injury or death, when

removing a deployed airbag, rubber gloves, eye

protection, and a long-sleeved shirt should be

worn. There may be deposits on the airbag unit and

other interior surfaces. In large doses, these depos-

its may cause irritation to the skin and eyes.WARNING: To avoid personal injury or death, use

extreme care to prevent any foreign material from

entering the side curtain airbag, or becoming

entrapped between the side curtain airbag cushion

and the roof rail garnish molding. Failure to

observe this warning could result in occupant inju-

ries upon airbag deployment.

(1) Position the side curtain airbag into the vehicle

as a unit.

(2) Engage the lug that secures the side curtain

airbag bracket into the bore in the roof side rail (Fig.

50).

(3) Install and tighten the screw that secures the

rear of the side curtain airbag to the B-pillar (Fig.

48). Tighten the screw to 23 N´m (17 ft. lbs.).

(4) Install and tighten the screw that secures the

front of the side curtain airbag to the A-pillar.

Tighten the screw to 9 N´m (80 in. lbs.).

(5) Install and tighten the screw that secures the

side curtain airbag front tether retainer to the base

of the A-pillar near the belt line (Fig. 47). Tighten

the screw to 5 N´m (44 in. lbs.).

(6) Install a new tie wrap to secure the side cur-

tain airbag pigtail wire to the inside of the B-pillar

(Fig. 46).

(7) Reconnect the pigtail wire connector for the

side curtain airbag to the vehicle wire harness con-

nector on the B-pillar. Be certain the connector is

fully engaged and latched.

(8) Reinstall the trim onto the A-pillar that con-

ceals the side curtain airbag front tether (Fig. 45).

Fig. 49 Side Curtain Airbag Remove

1 - ROOF SIDE RAIL

2 - SIDE CURTAIN AIRBAG

Fig. 50 Side Curtain Airbag Install

1 - ROOF SIDE RAIL

2 - BORE

3 - SIDE CURTAIN AIRBAG BRACKET

4 - LUG

8O - 38 RESTRAINTSVA

Page 1030 of 2305

(9) Reinstall the grab handle onto the headliner.

(Refer to 23 - BODY/INTERIOR/ASSIST HANDLE -

INSTALLATION).

(10) Reinstall the trim onto the inside of the B-pil-

lar. (Refer to 23 - BODY/INTERIOR/B-PILLAR TRIM

- INSTALLATION).

(11) Reinstall the pinch welt to the front door

opening (Fig. 44).

(12) Do not reconnect the battery negative cable at

this time. The supplemental restraint system verifi-

cation test procedure should be performed following

service of any supplemental restraint system compo-

nent. (Refer to 8 - ELECTRICAL/RESTRAINTS -

STANDARD PROCEDURE - VERIFICATION TEST).

SIDE IMPACT SENSOR

DESCRIPTION

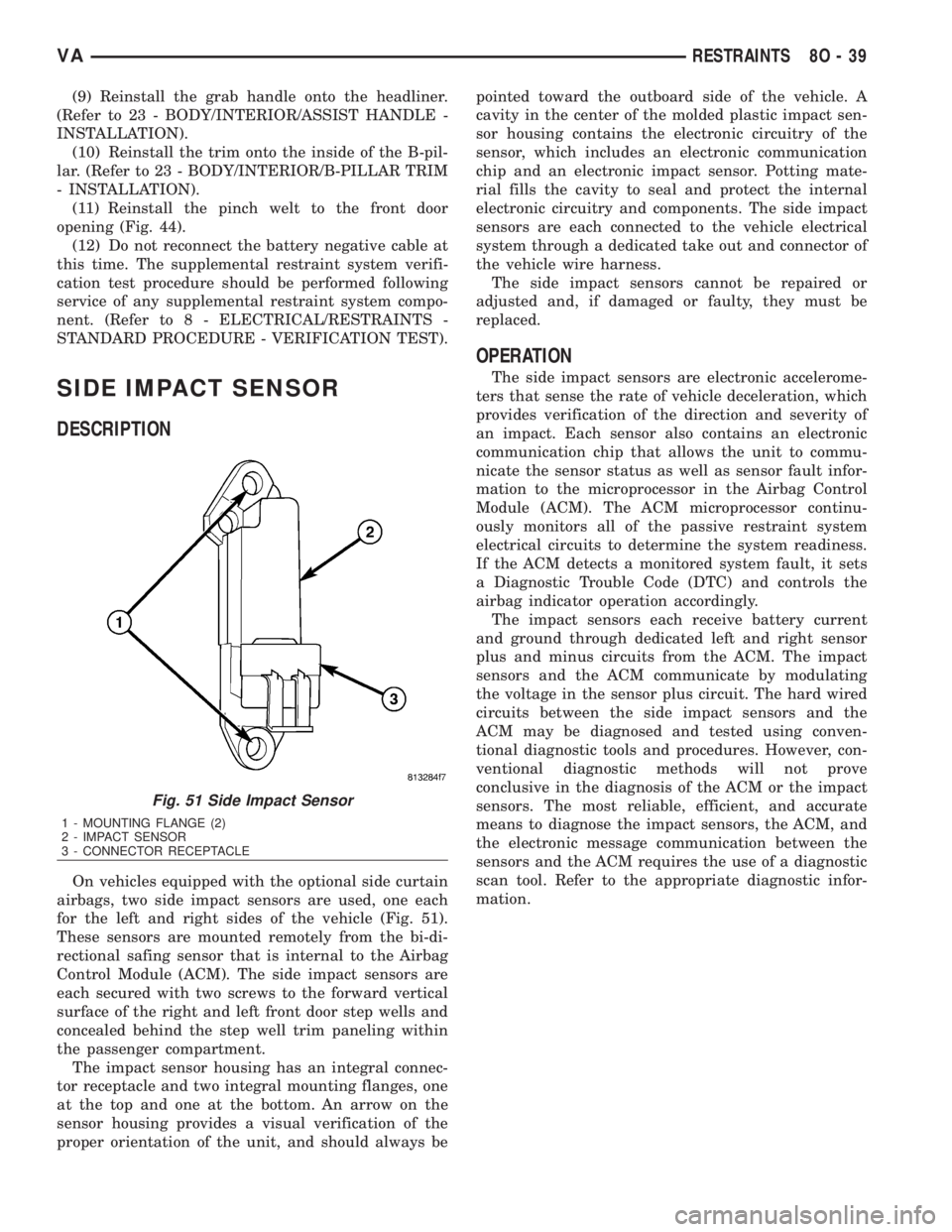

On vehicles equipped with the optional side curtain

airbags, two side impact sensors are used, one each

for the left and right sides of the vehicle (Fig. 51).

These sensors are mounted remotely from the bi-di-

rectional safing sensor that is internal to the Airbag

Control Module (ACM). The side impact sensors are

each secured with two screws to the forward vertical

surface of the right and left front door step wells and

concealed behind the step well trim paneling within

the passenger compartment.

The impact sensor housing has an integral connec-

tor receptacle and two integral mounting flanges, one

at the top and one at the bottom. An arrow on the

sensor housing provides a visual verification of the

proper orientation of the unit, and should always bepointed toward the outboard side of the vehicle. A

cavity in the center of the molded plastic impact sen-

sor housing contains the electronic circuitry of the

sensor, which includes an electronic communication

chip and an electronic impact sensor. Potting mate-

rial fills the cavity to seal and protect the internal

electronic circuitry and components. The side impact

sensors are each connected to the vehicle electrical

system through a dedicated take out and connector of

the vehicle wire harness.

The side impact sensors cannot be repaired or

adjusted and, if damaged or faulty, they must be

replaced.

OPERATION

The side impact sensors are electronic accelerome-

ters that sense the rate of vehicle deceleration, which

provides verification of the direction and severity of

an impact. Each sensor also contains an electronic

communication chip that allows the unit to commu-

nicate the sensor status as well as sensor fault infor-

mation to the microprocessor in the Airbag Control

Module (ACM). The ACM microprocessor continu-

ously monitors all of the passive restraint system

electrical circuits to determine the system readiness.

If the ACM detects a monitored system fault, it sets

a Diagnostic Trouble Code (DTC) and controls the

airbag indicator operation accordingly.

The impact sensors each receive battery current

and ground through dedicated left and right sensor

plus and minus circuits from the ACM. The impact

sensors and the ACM communicate by modulating

the voltage in the sensor plus circuit. The hard wired

circuits between the side impact sensors and the

ACM may be diagnosed and tested using conven-

tional diagnostic tools and procedures. However, con-

ventional diagnostic methods will not prove

conclusive in the diagnosis of the ACM or the impact

sensors. The most reliable, efficient, and accurate

means to diagnose the impact sensors, the ACM, and

the electronic message communication between the

sensors and the ACM requires the use of a diagnostic

scan tool. Refer to the appropriate diagnostic infor-

mation.

Fig. 51 Side Impact Sensor

1 - MOUNTING FLANGE (2)

2 - IMPACT SENSOR

3 - CONNECTOR RECEPTACLE

VARESTRAINTS 8O - 39