Dash MERCEDES-BENZ SPRINTER 2006 User Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 1064 of 2305

WASHER RESERVOIR

DESCRIPTION

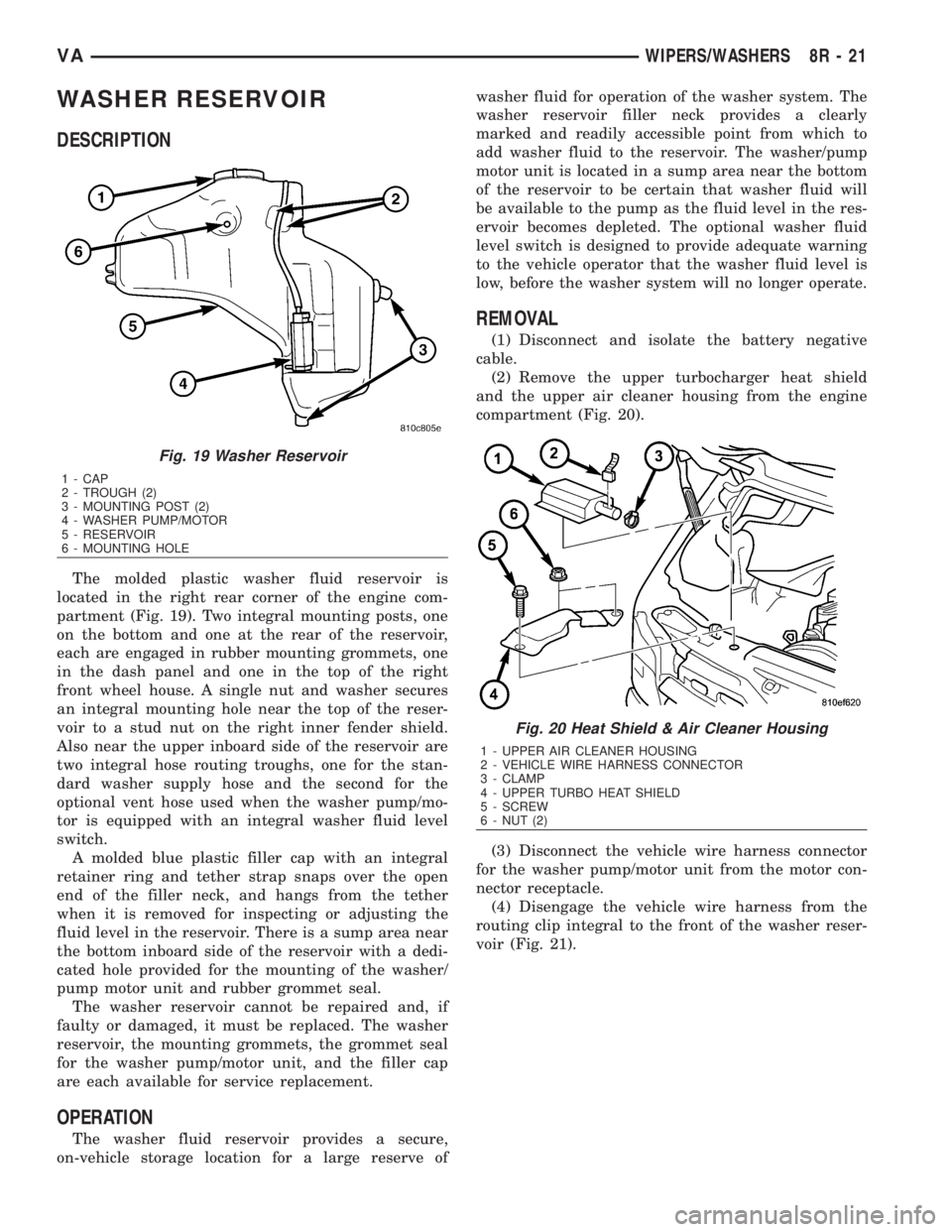

The molded plastic washer fluid reservoir is

located in the right rear corner of the engine com-

partment (Fig. 19). Two integral mounting posts, one

on the bottom and one at the rear of the reservoir,

each are engaged in rubber mounting grommets, one

in the dash panel and one in the top of the right

front wheel house. A single nut and washer secures

an integral mounting hole near the top of the reser-

voir to a stud nut on the right inner fender shield.

Also near the upper inboard side of the reservoir are

two integral hose routing troughs, one for the stan-

dard washer supply hose and the second for the

optional vent hose used when the washer pump/mo-

tor is equipped with an integral washer fluid level

switch.

A molded blue plastic filler cap with an integral

retainer ring and tether strap snaps over the open

end of the filler neck, and hangs from the tether

when it is removed for inspecting or adjusting the

fluid level in the reservoir. There is a sump area near

the bottom inboard side of the reservoir with a dedi-

cated hole provided for the mounting of the washer/

pump motor unit and rubber grommet seal.

The washer reservoir cannot be repaired and, if

faulty or damaged, it must be replaced. The washer

reservoir, the mounting grommets, the grommet seal

for the washer pump/motor unit, and the filler cap

are each available for service replacement.

OPERATION

The washer fluid reservoir provides a secure,

on-vehicle storage location for a large reserve ofwasher fluid for operation of the washer system. The

washer reservoir filler neck provides a clearly

marked and readily accessible point from which to

add washer fluid to the reservoir. The washer/pump

motor unit is located in a sump area near the bottom

of the reservoir to be certain that washer fluid will

be available to the pump as the fluid level in the res-

ervoir becomes depleted. The optional washer fluid

level switch is designed to provide adequate warning

to the vehicle operator that the washer fluid level is

low, before the washer system will no longer operate.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

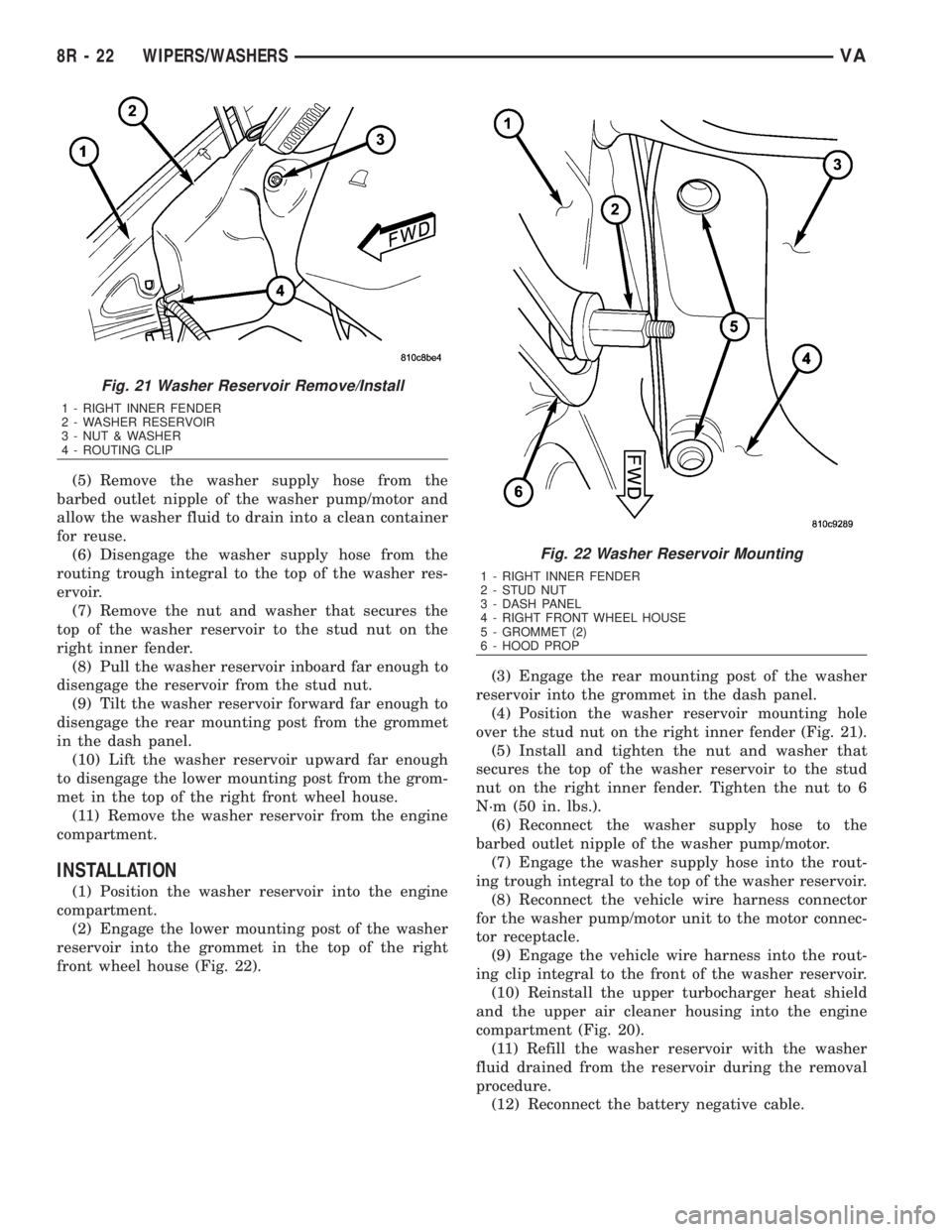

(2) Remove the upper turbocharger heat shield

and the upper air cleaner housing from the engine

compartment (Fig. 20).

(3) Disconnect the vehicle wire harness connector

for the washer pump/motor unit from the motor con-

nector receptacle.

(4) Disengage the vehicle wire harness from the

routing clip integral to the front of the washer reser-

voir (Fig. 21).

Fig. 19 Washer Reservoir

1 - CAP

2 - TROUGH (2)

3 - MOUNTING POST (2)

4 - WASHER PUMP/MOTOR

5 - RESERVOIR

6 - MOUNTING HOLE

Fig. 20 Heat Shield & Air Cleaner Housing

1 - UPPER AIR CLEANER HOUSING

2 - VEHICLE WIRE HARNESS CONNECTOR

3 - CLAMP

4 - UPPER TURBO HEAT SHIELD

5 - SCREW

6 - NUT (2)

VAWIPERS/WASHERS 8R - 21

Page 1065 of 2305

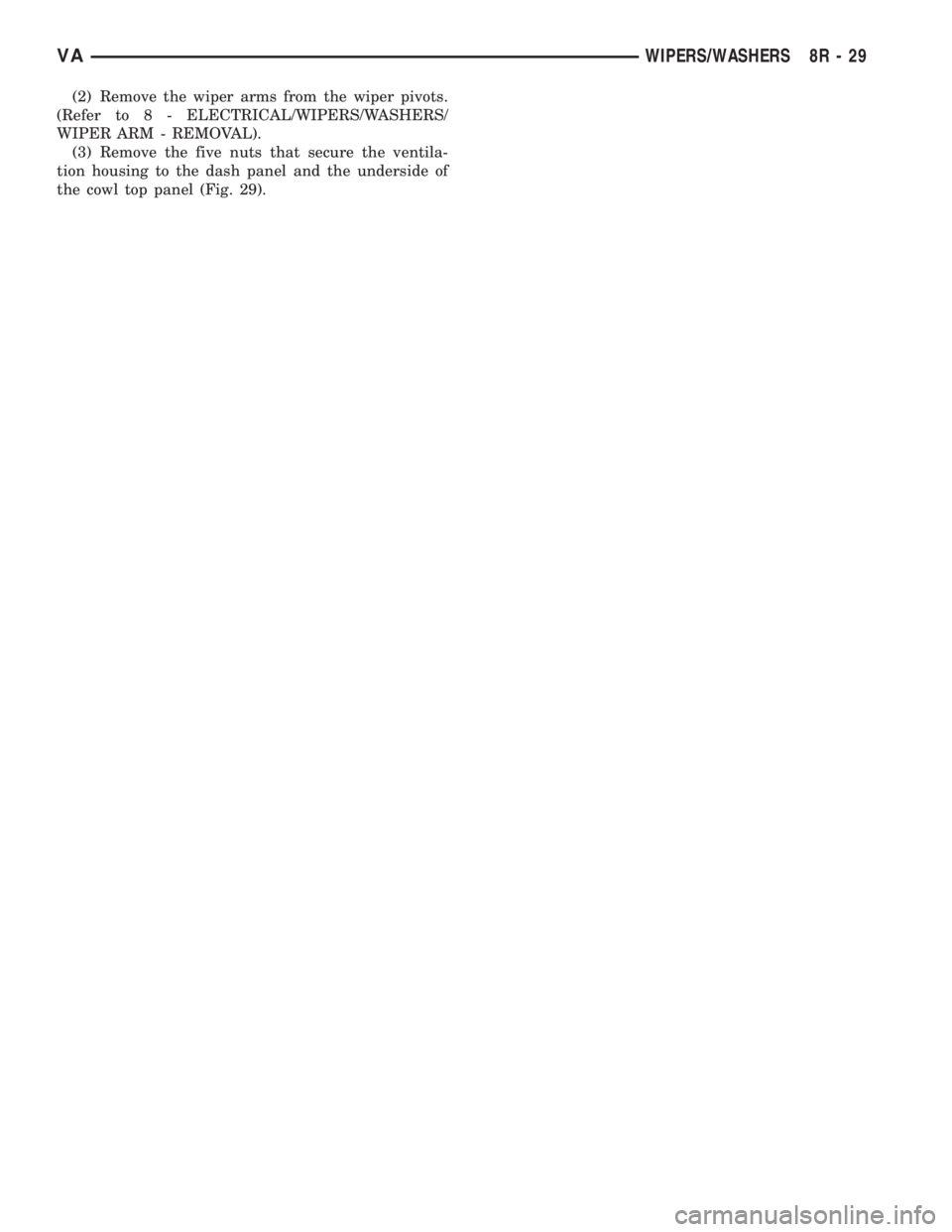

(5) Remove the washer supply hose from the

barbed outlet nipple of the washer pump/motor and

allow the washer fluid to drain into a clean container

for reuse.

(6) Disengage the washer supply hose from the

routing trough integral to the top of the washer res-

ervoir.

(7) Remove the nut and washer that secures the

top of the washer reservoir to the stud nut on the

right inner fender.

(8) Pull the washer reservoir inboard far enough to

disengage the reservoir from the stud nut.

(9) Tilt the washer reservoir forward far enough to

disengage the rear mounting post from the grommet

in the dash panel.

(10) Lift the washer reservoir upward far enough

to disengage the lower mounting post from the grom-

met in the top of the right front wheel house.

(11) Remove the washer reservoir from the engine

compartment.

INSTALLATION

(1) Position the washer reservoir into the engine

compartment.

(2) Engage the lower mounting post of the washer

reservoir into the grommet in the top of the right

front wheel house (Fig. 22).(3) Engage the rear mounting post of the washer

reservoir into the grommet in the dash panel.

(4) Position the washer reservoir mounting hole

over the stud nut on the right inner fender (Fig. 21).

(5) Install and tighten the nut and washer that

secures the top of the washer reservoir to the stud

nut on the right inner fender. Tighten the nut to 6

N´m (50 in. lbs.).

(6) Reconnect the washer supply hose to the

barbed outlet nipple of the washer pump/motor.

(7) Engage the washer supply hose into the rout-

ing trough integral to the top of the washer reservoir.

(8) Reconnect the vehicle wire harness connector

for the washer pump/motor unit to the motor connec-

tor receptacle.

(9) Engage the vehicle wire harness into the rout-

ing clip integral to the front of the washer reservoir.

(10) Reinstall the upper turbocharger heat shield

and the upper air cleaner housing into the engine

compartment (Fig. 20).

(11) Refill the washer reservoir with the washer

fluid drained from the reservoir during the removal

procedure.

(12) Reconnect the battery negative cable.

Fig. 21 Washer Reservoir Remove/Install

1 - RIGHT INNER FENDER

2 - WASHER RESERVOIR

3 - NUT & WASHER

4 - ROUTING CLIP

Fig. 22 Washer Reservoir Mounting

1 - RIGHT INNER FENDER

2 - STUD NUT

3 - DASH PANEL

4 - RIGHT FRONT WHEEL HOUSE

5 - GROMMET (2)

6 - HOOD PROP

8R - 22 WIPERS/WASHERSVA

Page 1072 of 2305

(2) Remove the wiper arms from the wiper pivots.

(Refer to 8 - ELECTRICAL/WIPERS/WASHERS/

WIPER ARM - REMOVAL).

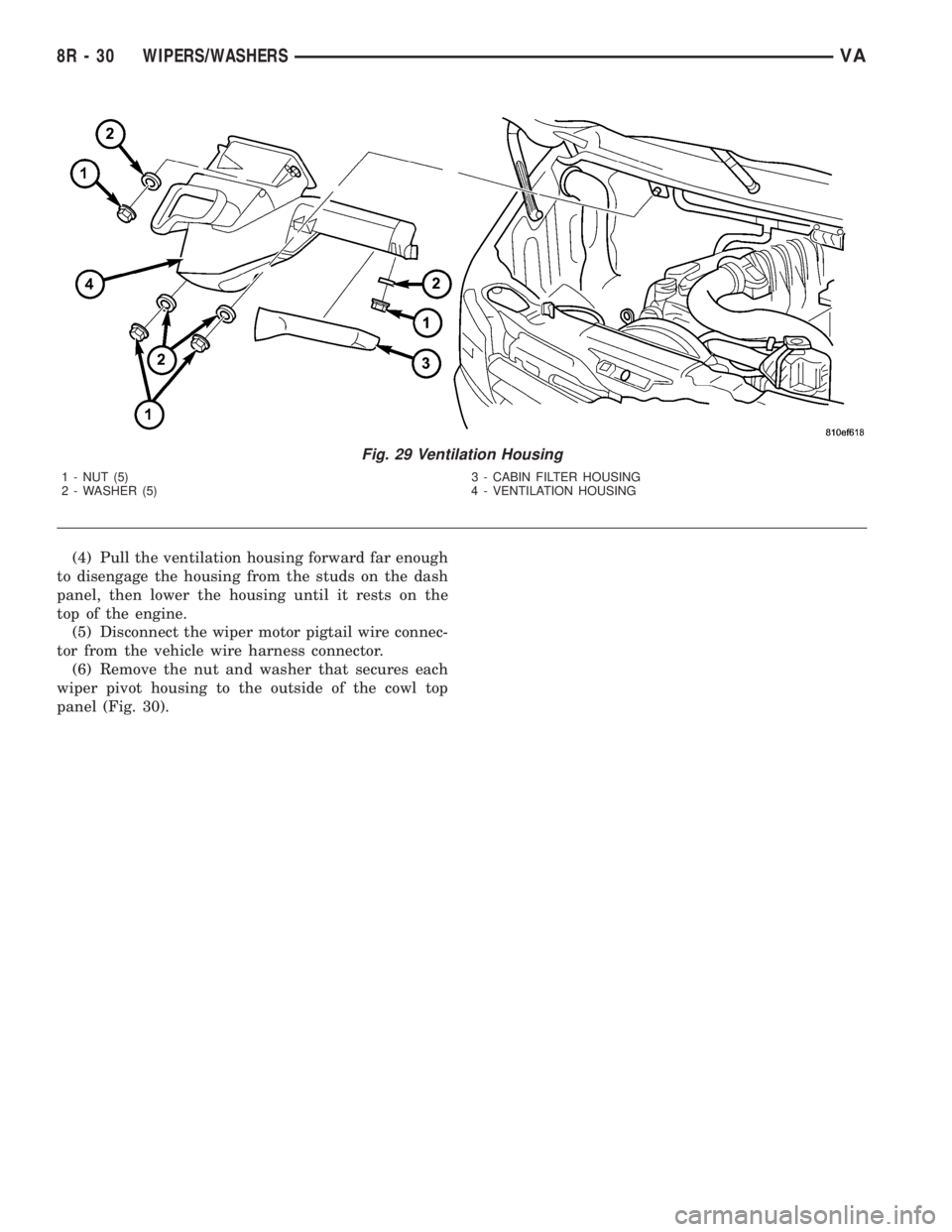

(3) Remove the five nuts that secure the ventila-

tion housing to the dash panel and the underside of

the cowl top panel (Fig. 29).

VAWIPERS/WASHERS 8R - 29

Page 1073 of 2305

(4) Pull the ventilation housing forward far enough

to disengage the housing from the studs on the dash

panel, then lower the housing until it rests on the

top of the engine.

(5) Disconnect the wiper motor pigtail wire connec-

tor from the vehicle wire harness connector.

(6) Remove the nut and washer that secures each

wiper pivot housing to the outside of the cowl top

panel (Fig. 30).

Fig. 29 Ventilation Housing

1 - NUT (5) 3 - CABIN FILTER HOUSING

2 - WASHER (5) 4 - VENTILATION HOUSING

8R - 30 WIPERS/WASHERSVA

Page 1074 of 2305

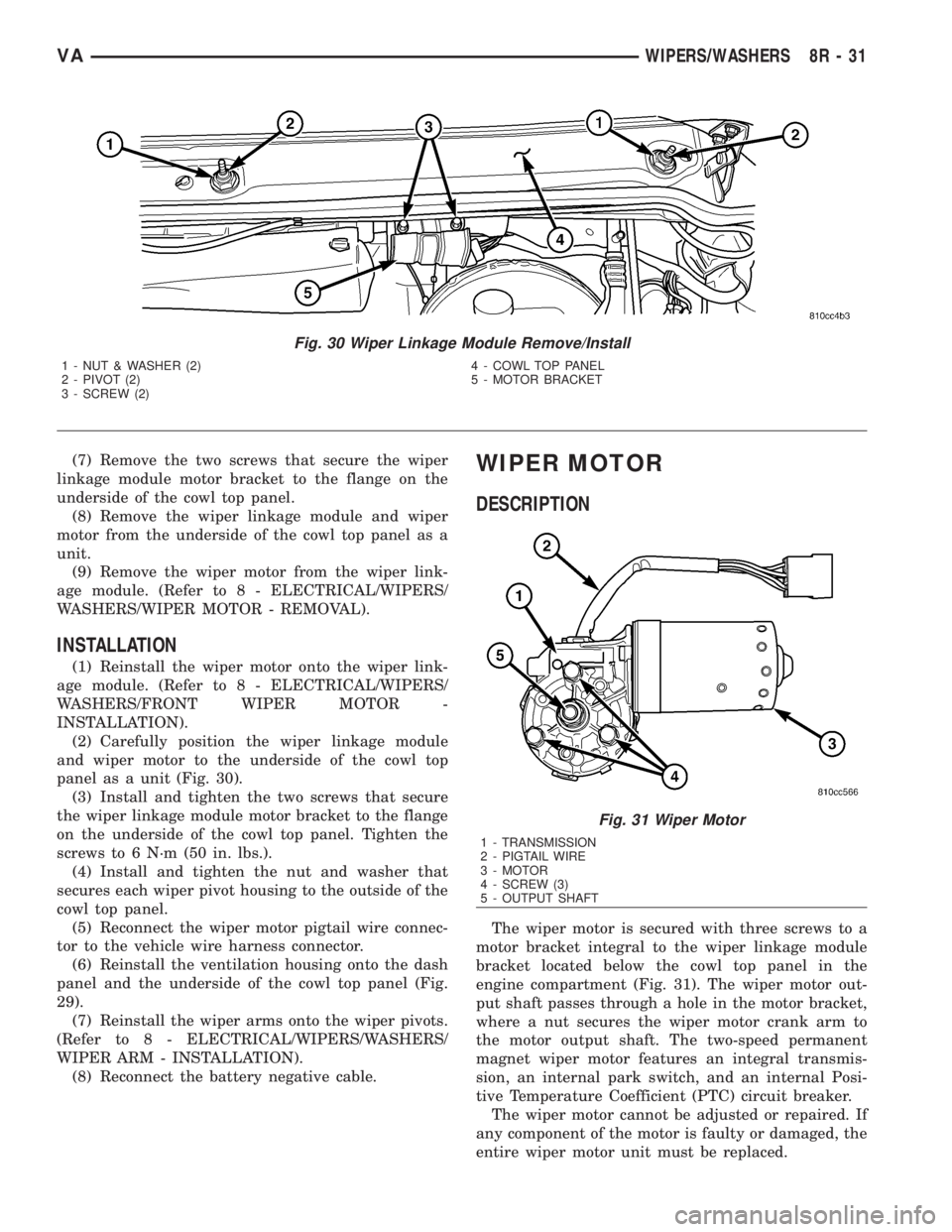

(7) Remove the two screws that secure the wiper

linkage module motor bracket to the flange on the

underside of the cowl top panel.

(8) Remove the wiper linkage module and wiper

motor from the underside of the cowl top panel as a

unit.

(9) Remove the wiper motor from the wiper link-

age module. (Refer to 8 - ELECTRICAL/WIPERS/

WASHERS/WIPER MOTOR - REMOVAL).

INSTALLATION

(1) Reinstall the wiper motor onto the wiper link-

age module. (Refer to 8 - ELECTRICAL/WIPERS/

WASHERS/FRONT WIPER MOTOR -

INSTALLATION).

(2) Carefully position the wiper linkage module

and wiper motor to the underside of the cowl top

panel as a unit (Fig. 30).

(3) Install and tighten the two screws that secure

the wiper linkage module motor bracket to the flange

on the underside of the cowl top panel. Tighten the

screws to 6 N´m (50 in. lbs.).

(4) Install and tighten the nut and washer that

secures each wiper pivot housing to the outside of the

cowl top panel.

(5) Reconnect the wiper motor pigtail wire connec-

tor to the vehicle wire harness connector.

(6) Reinstall the ventilation housing onto the dash

panel and the underside of the cowl top panel (Fig.

29).

(7) Reinstall the wiper arms onto the wiper pivots.

(Refer to 8 - ELECTRICAL/WIPERS/WASHERS/

WIPER ARM - INSTALLATION).

(8) Reconnect the battery negative cable.

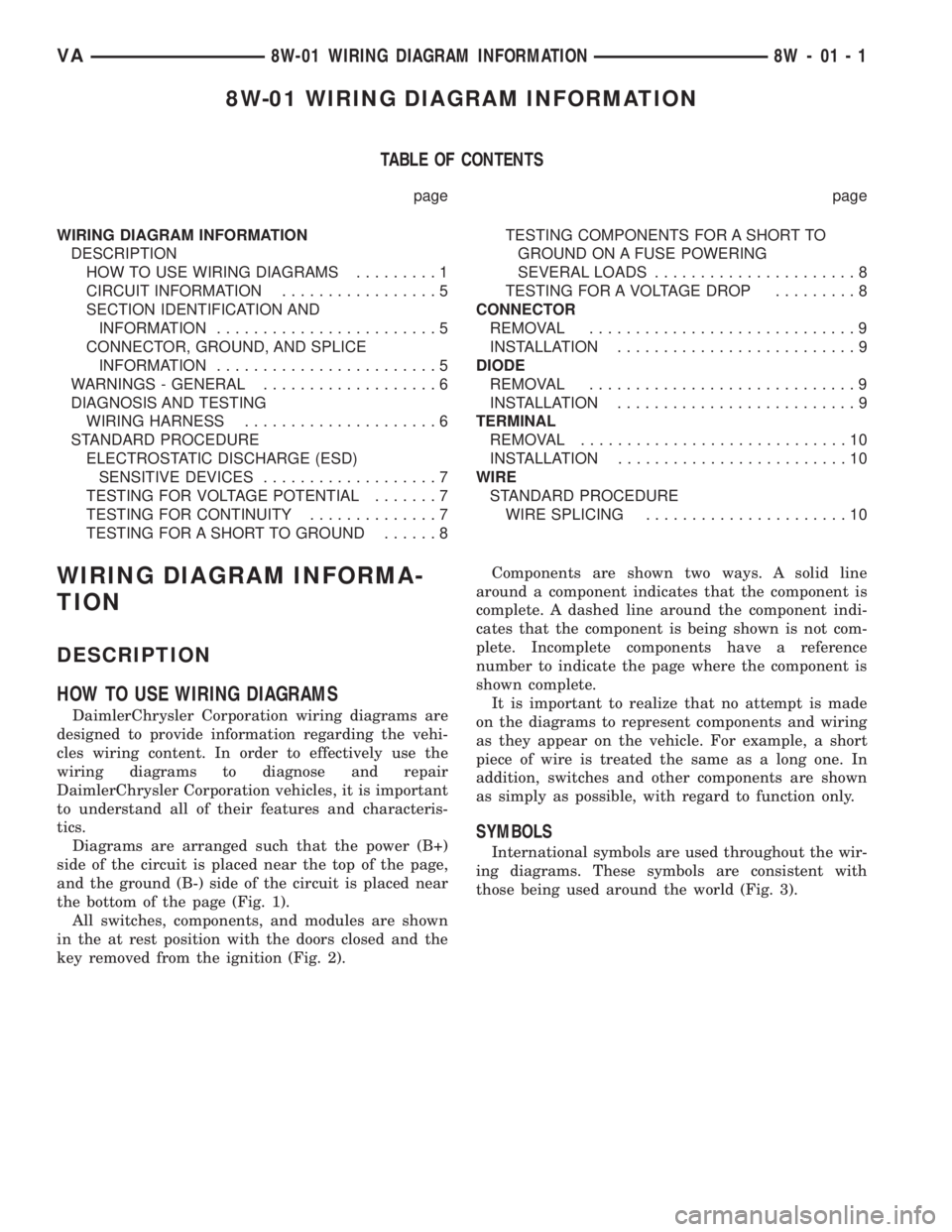

WIPER MOTOR

DESCRIPTION

The wiper motor is secured with three screws to a

motor bracket integral to the wiper linkage module

bracket located below the cowl top panel in the

engine compartment (Fig. 31). The wiper motor out-

put shaft passes through a hole in the motor bracket,

where a nut secures the wiper motor crank arm to

the motor output shaft. The two-speed permanent

magnet wiper motor features an integral transmis-

sion, an internal park switch, and an internal Posi-

tive Temperature Coefficient (PTC) circuit breaker.

The wiper motor cannot be adjusted or repaired. If

any component of the motor is faulty or damaged, the

entire wiper motor unit must be replaced.

Fig. 30 Wiper Linkage Module Remove/Install

1 - NUT & WASHER (2) 4 - COWL TOP PANEL

2 - PIVOT (2) 5 - MOTOR BRACKET

3 - SCREW (2)

Fig. 31 Wiper Motor

1 - TRANSMISSION

2 - PIGTAIL WIRE

3 - MOTOR

4 - SCREW (3)

5 - OUTPUT SHAFT

VAWIPERS/WASHERS 8R - 31

Page 1082 of 2305

8W-01 WIRING DIAGRAM INFORMATION

TABLE OF CONTENTS

page page

WIRING DIAGRAM INFORMATION

DESCRIPTION

HOW TO USE WIRING DIAGRAMS.........1

CIRCUIT INFORMATION.................5

SECTION IDENTIFICATION AND

INFORMATION........................5

CONNECTOR, GROUND, AND SPLICE

INFORMATION........................5

WARNINGS - GENERAL...................6

DIAGNOSIS AND TESTING

WIRING HARNESS.....................6

STANDARD PROCEDURE

ELECTROSTATIC DISCHARGE (ESD)

SENSITIVE DEVICES...................7

TESTING FOR VOLTAGE POTENTIAL.......7

TESTING FOR CONTINUITY..............7

TESTING FOR A SHORT TO GROUND......8TESTING COMPONENTS FOR A SHORT TO

GROUND ON A FUSE POWERING

SEVERAL LOADS......................8

TESTING FOR A VOLTAGE DROP.........8

CONNECTOR

REMOVAL.............................9

INSTALLATION..........................9

DIODE

REMOVAL.............................9

INSTALLATION..........................9

TERMINAL

REMOVAL.............................10

INSTALLATION.........................10

WIRE

STANDARD PROCEDURE

WIRE SPLICING......................10

WIRING DIAGRAM INFORMA-

TION

DESCRIPTION

HOW TO USE WIRING DIAGRAMS

DaimlerChrysler Corporation wiring diagrams are

designed to provide information regarding the vehi-

cles wiring content. In order to effectively use the

wiring diagrams to diagnose and repair

DaimlerChrysler Corporation vehicles, it is important

to understand all of their features and characteris-

tics.

Diagrams are arranged such that the power (B+)

side of the circuit is placed near the top of the page,

and the ground (B-) side of the circuit is placed near

the bottom of the page (Fig. 1).

All switches, components, and modules are shown

in the at rest position with the doors closed and the

key removed from the ignition (Fig. 2).Components are shown two ways. A solid line

around a component indicates that the component is

complete. A dashed line around the component indi-

cates that the component is being shown is not com-

plete. Incomplete components have a reference

number to indicate the page where the component is

shown complete.

It is important to realize that no attempt is made

on the diagrams to represent components and wiring

as they appear on the vehicle. For example, a short

piece of wire is treated the same as a long one. In

addition, switches and other components are shown

as simply as possible, with regard to function only.

SYMBOLS

International symbols are used throughout the wir-

ing diagrams. These symbols are consistent with

those being used around the world (Fig. 3).

VA8W-01 WIRING DIAGRAM INFORMATION 8W - 01 - 1

Page 1431 of 2305

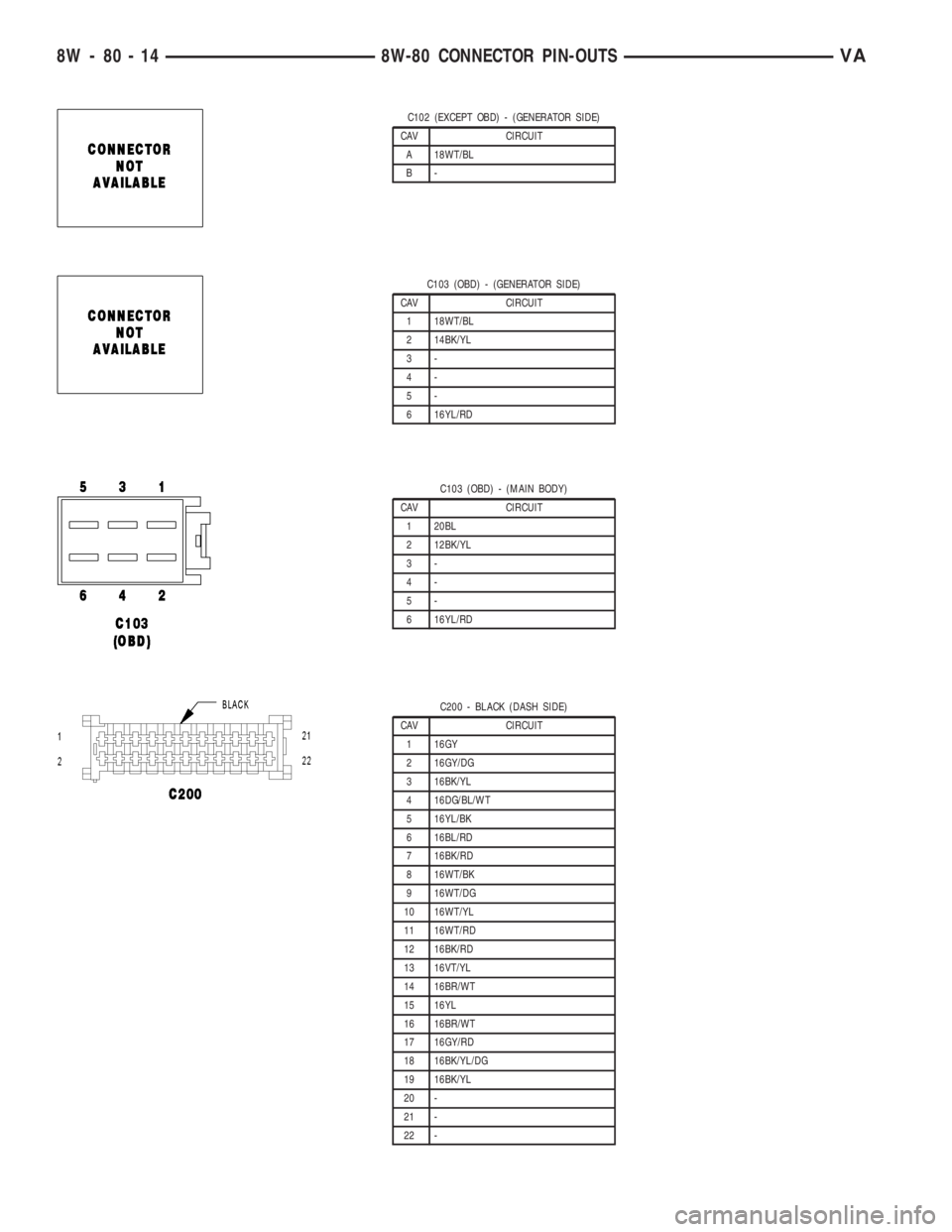

C102 (EXCEPT OBD) - (GENERATOR SIDE)

CAV CIRCUIT

A 18WT/BL

B-

C103 (OBD) - (GENERATOR SIDE)

CAV CIRCUIT

1 18WT/BL

2 14BK/YL

3-

4-

5-

6 16YL/RD

C103 (OBD) - (MAIN BODY)

CAV CIRCUIT

1 20BL

2 12BK/YL

3-

4-

5-

6 16YL/RD

C200 - BLACK (DASH SIDE)

CAV CIRCUIT

1 16GY

2 16GY/DG

3 16BK/YL

4 16DG/BL/WT

5 16YL/BK

6 16BL/RD

7 16BK/RD

8 16WT/BK

9 16WT/DG

10 16WT/YL

11 16WT/RD

12 16BK/RD

13 16VT/YL

14 16BR/WT

15 16YL

16 16BR/WT

17 16GY/RD

18 16BK/YL/DG

19 16BK/YL

20 -

21 -

22 -

8W - 80 - 14 8W-80 CONNECTOR PIN-OUTSVA

Page 1432 of 2305

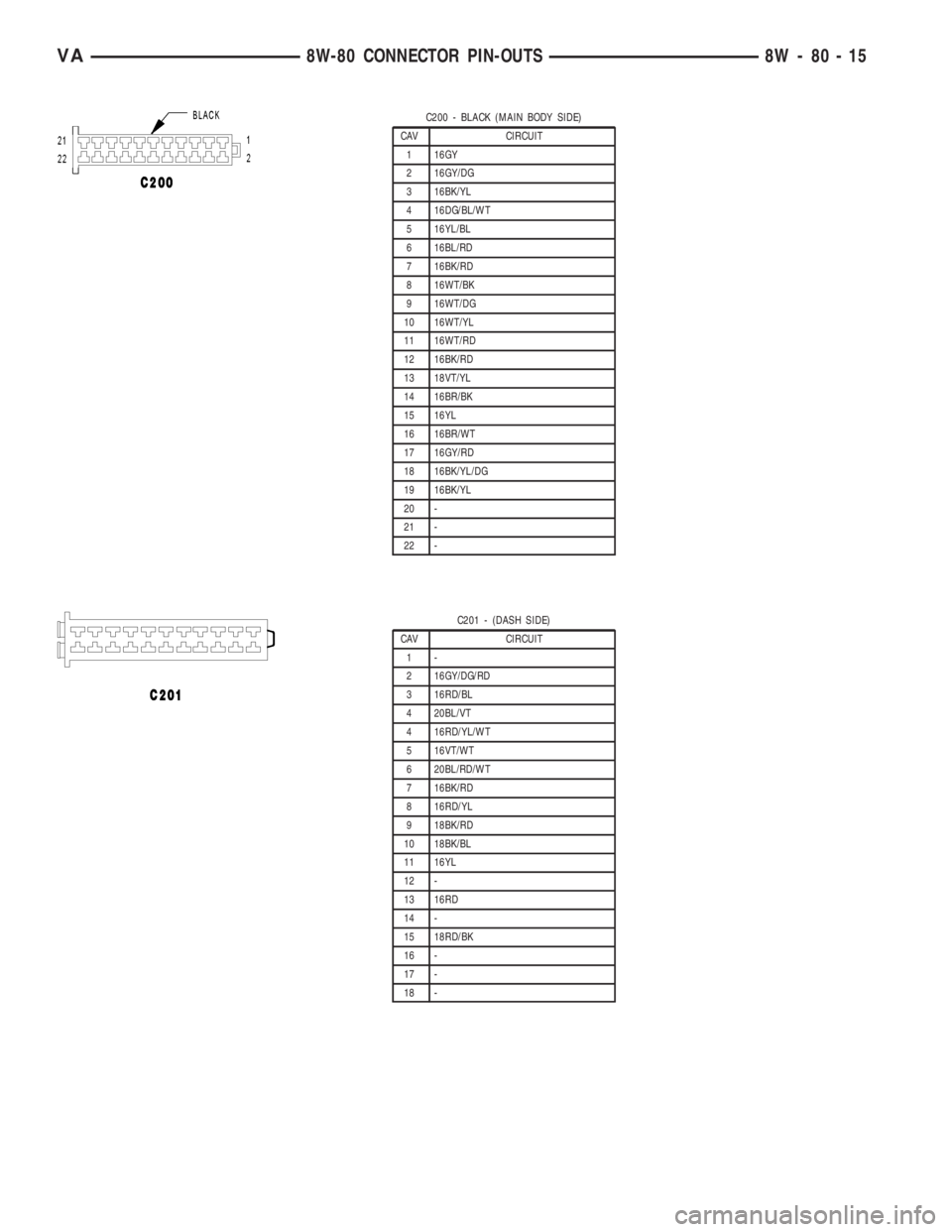

C200 - BLACK (MAIN BODY SIDE)

CAV CIRCUIT

1 16GY

2 16GY/DG

3 16BK/YL

4 16DG/BL/WT

5 16YL/BL

6 16BL/RD

7 16BK/RD

8 16WT/BK

9 16WT/DG

10 16WT/YL

11 16WT/RD

12 16BK/RD

13 18VT/YL

14 16BR/BK

15 16YL

16 16BR/WT

17 16GY/RD

18 16BK/YL/DG

19 16BK/YL

20 -

21 -

22 -

C201 - (DASH SIDE)

CAV CIRCUIT

1-

2 16GY/DG/RD

3 16RD/BL

4 20BL/VT

4 16RD/YL/WT

5 16VT/WT

6 20BL/RD/WT

7 16BK/RD

8 16RD/YL

9 18BK/RD

10 18BK/BL

11 16YL

12 -

13 16RD

14 -

15 18RD/BK

16 -

17 -

18 -

VA8W-80 CONNECTOR PIN-OUTS 8W - 80 - 15

Page 1433 of 2305

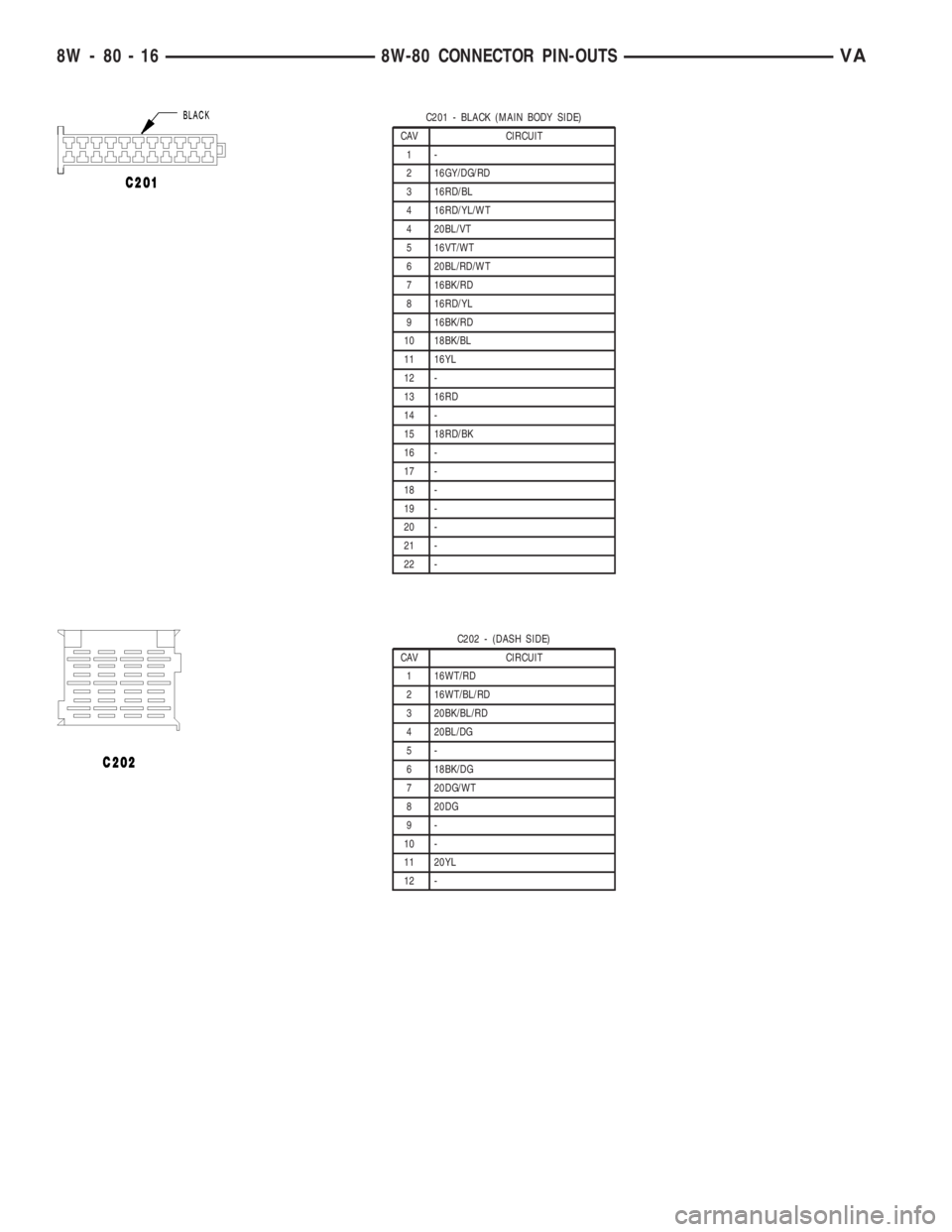

C201 - BLACK (MAIN BODY SIDE)

CAV CIRCUIT

1-

2 16GY/DG/RD

3 16RD/BL

4 16RD/YL/WT

4 20BL/VT

5 16VT/WT

6 20BL/RD/WT

7 16BK/RD

8 16RD/YL

9 16BK/RD

10 18BK/BL

11 16YL

12 -

13 16RD

14 -

15 18RD/BK

16 -

17 -

18 -

19 -

20 -

21 -

22 -

C202 - (DASH SIDE)

CAV CIRCUIT

1 16WT/RD

2 16WT/BL/RD

3 20BK/BL/RD

4 20BL/DG

5-

6 18BK/DG

7 20DG/WT

8 20DG

9-

10 -

11 20YL

12 -

8W - 80 - 16 8W-80 CONNECTOR PIN-OUTSVA

Page 1434 of 2305

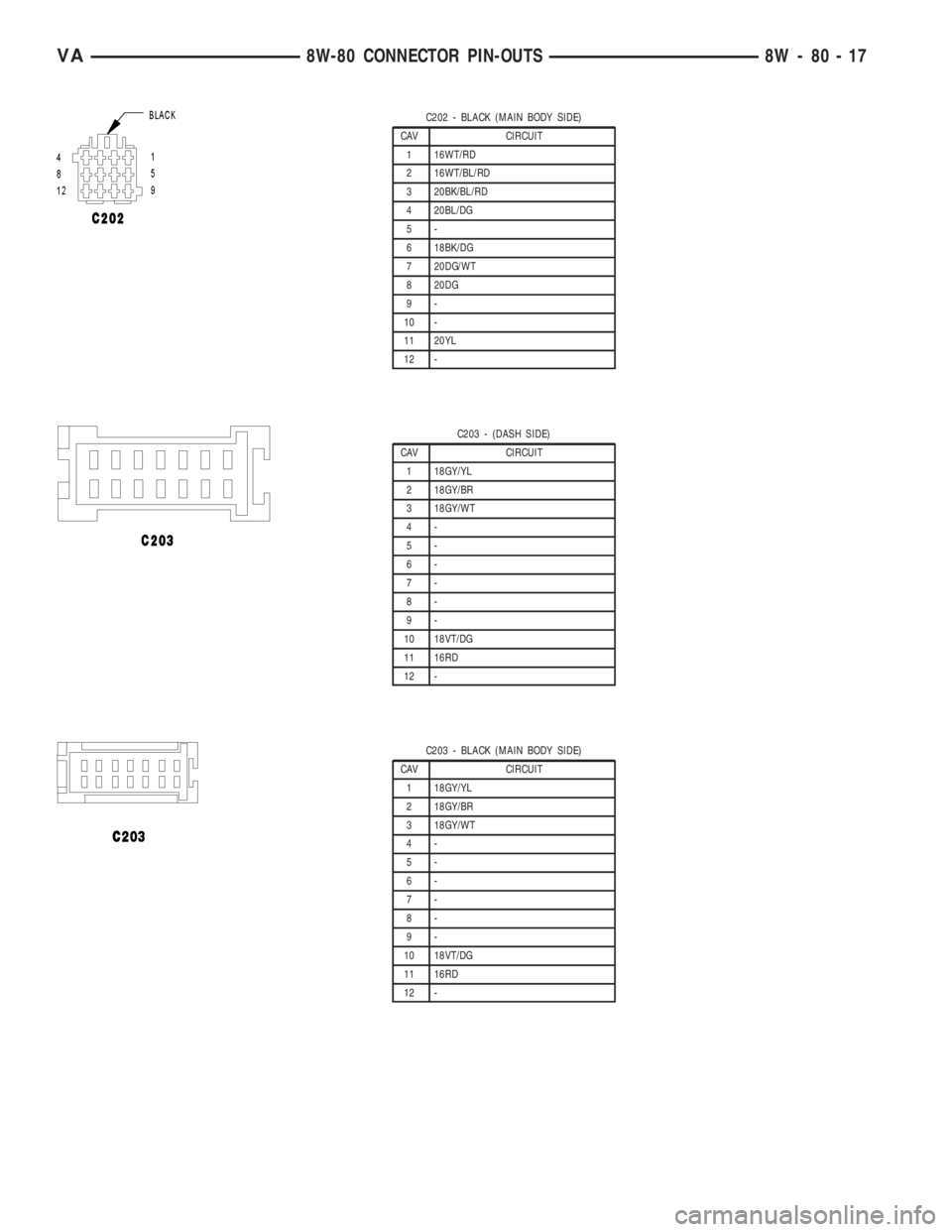

C202 - BLACK (MAIN BODY SIDE)

CAV CIRCUIT

1 16WT/RD

2 16WT/BL/RD

3 20BK/BL/RD

4 20BL/DG

5-

6 18BK/DG

7 20DG/WT

8 20DG

9-

10 -

11 20YL

12 -

C203 - (DASH SIDE)

CAV CIRCUIT

1 18GY/YL

2 18GY/BR

3 18GY/WT

4-

5-

6-

7-

8-

9-

10 18VT/DG

11 16RD

12 -

C203 - BLACK (MAIN BODY SIDE)

CAV CIRCUIT

1 18GY/YL

2 18GY/BR

3 18GY/WT

4-

5-

6-

7-

8-

9-

10 18VT/DG

11 16RD

12 -

VA8W-80 CONNECTOR PIN-OUTS 8W - 80 - 17