wipers MERCEDES-BENZ SPRINTER 2006 Workshop Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 1076 of 2305

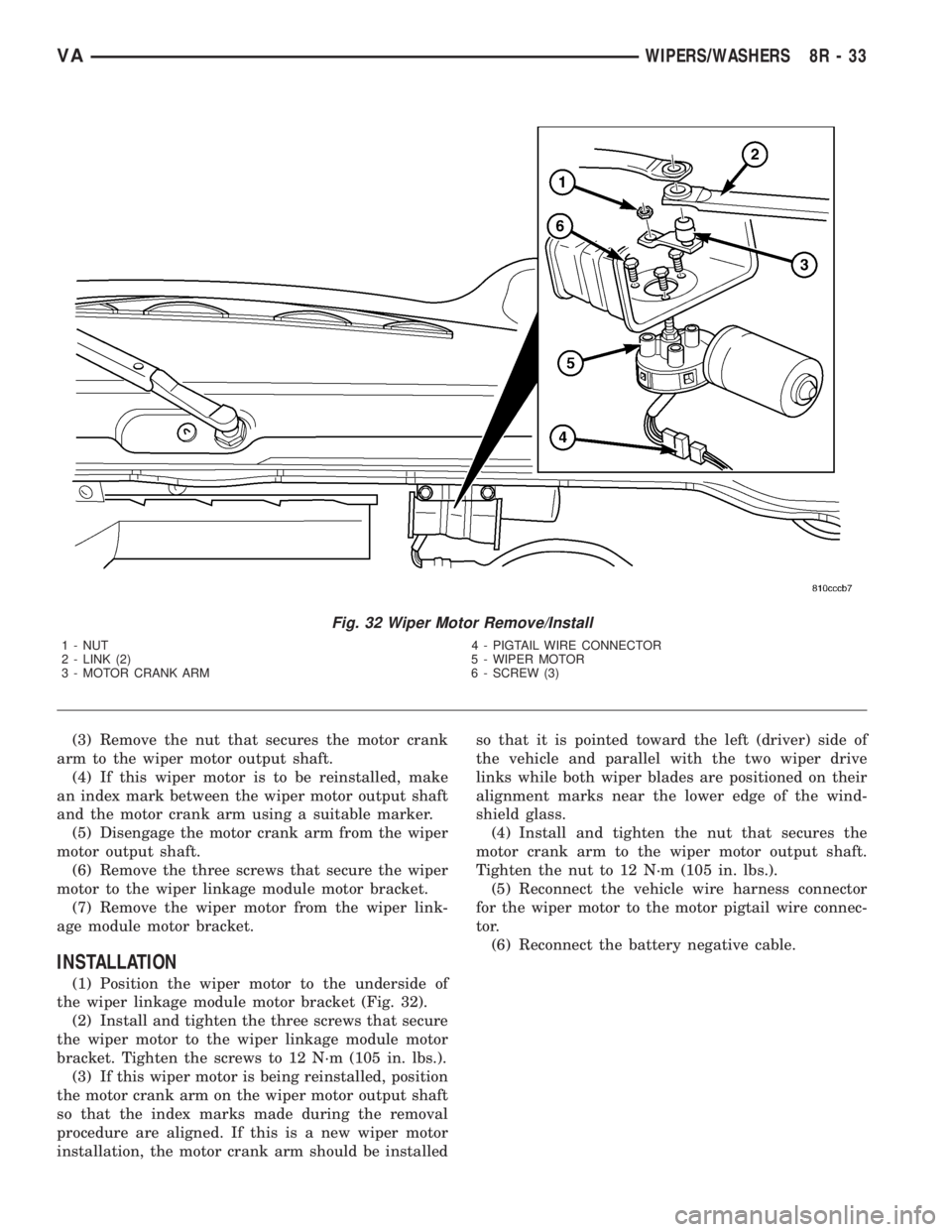

(3) Remove the nut that secures the motor crank

arm to the wiper motor output shaft.

(4) If this wiper motor is to be reinstalled, make

an index mark between the wiper motor output shaft

and the motor crank arm using a suitable marker.

(5) Disengage the motor crank arm from the wiper

motor output shaft.

(6) Remove the three screws that secure the wiper

motor to the wiper linkage module motor bracket.

(7) Remove the wiper motor from the wiper link-

age module motor bracket.

INSTALLATION

(1) Position the wiper motor to the underside of

the wiper linkage module motor bracket (Fig. 32).

(2) Install and tighten the three screws that secure

the wiper motor to the wiper linkage module motor

bracket. Tighten the screws to 12 N´m (105 in. lbs.).

(3) If this wiper motor is being reinstalled, position

the motor crank arm on the wiper motor output shaft

so that the index marks made during the removal

procedure are aligned. If this is a new wiper motor

installation, the motor crank arm should be installedso that it is pointed toward the left (driver) side of

the vehicle and parallel with the two wiper drive

links while both wiper blades are positioned on their

alignment marks near the lower edge of the wind-

shield glass.

(4) Install and tighten the nut that secures the

motor crank arm to the wiper motor output shaft.

Tighten the nut to 12 N´m (105 in. lbs.).

(5) Reconnect the vehicle wire harness connector

for the wiper motor to the motor pigtail wire connec-

tor.

(6) Reconnect the battery negative cable.

Fig. 32 Wiper Motor Remove/Install

1 - NUT 4 - PIGTAIL WIRE CONNECTOR

2 - LINK (2) 5 - WIPER MOTOR

3 - MOTOR CRANK ARM 6 - SCREW (3)

VAWIPERS/WASHERS 8R - 33

Page 1077 of 2305

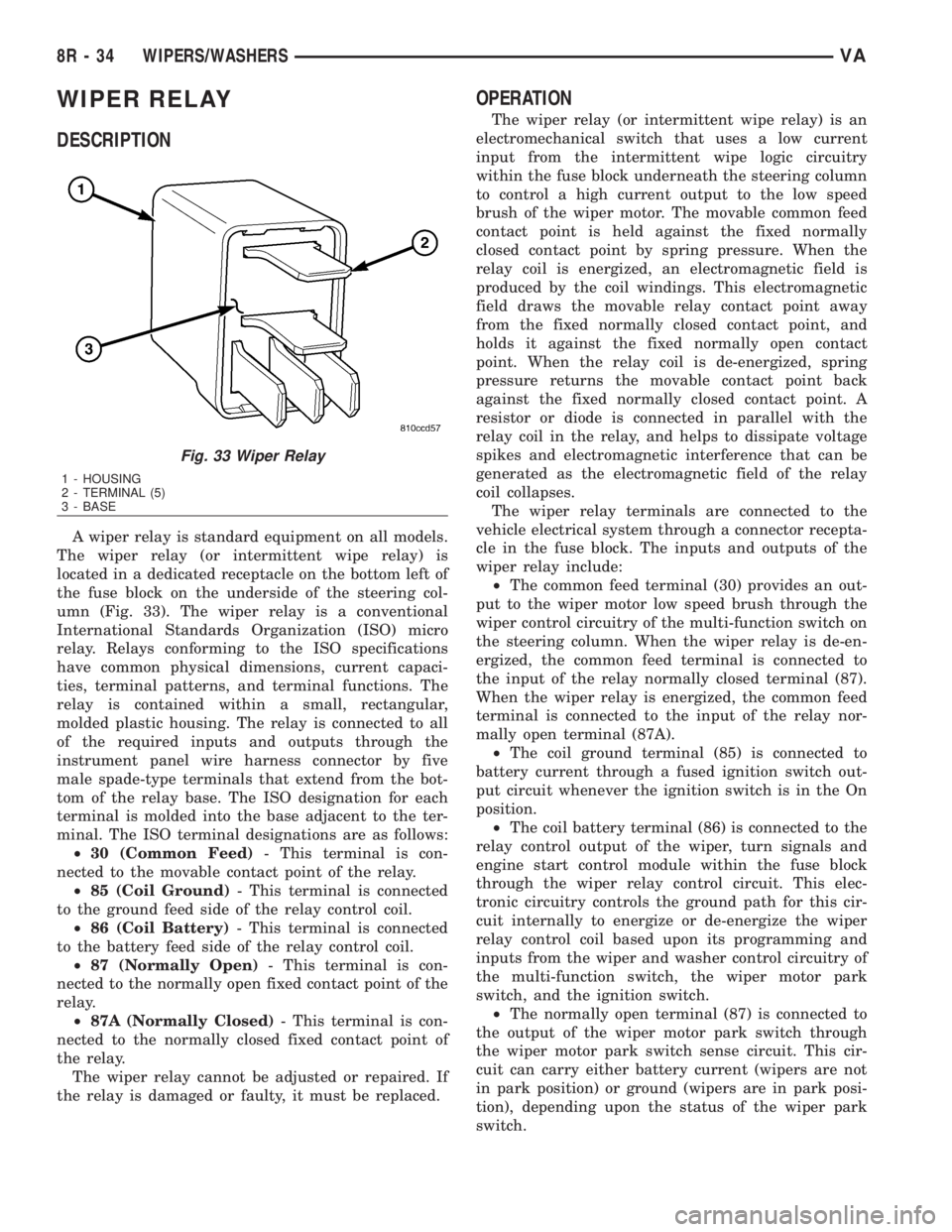

WIPER RELAY

DESCRIPTION

A wiper relay is standard equipment on all models.

The wiper relay (or intermittent wipe relay) is

located in a dedicated receptacle on the bottom left of

the fuse block on the underside of the steering col-

umn (Fig. 33). The wiper relay is a conventional

International Standards Organization (ISO) micro

relay. Relays conforming to the ISO specifications

have common physical dimensions, current capaci-

ties, terminal patterns, and terminal functions. The

relay is contained within a small, rectangular,

molded plastic housing. The relay is connected to all

of the required inputs and outputs through the

instrument panel wire harness connector by five

male spade-type terminals that extend from the bot-

tom of the relay base. The ISO designation for each

terminal is molded into the base adjacent to the ter-

minal. The ISO terminal designations are as follows:

²30 (Common Feed)- This terminal is con-

nected to the movable contact point of the relay.

²85 (Coil Ground)- This terminal is connected

to the ground feed side of the relay control coil.

²86 (Coil Battery)- This terminal is connected

to the battery feed side of the relay control coil.

²87 (Normally Open)- This terminal is con-

nected to the normally open fixed contact point of the

relay.

²87A (Normally Closed)- This terminal is con-

nected to the normally closed fixed contact point of

the relay.

The wiper relay cannot be adjusted or repaired. If

the relay is damaged or faulty, it must be replaced.

OPERATION

The wiper relay (or intermittent wipe relay) is an

electromechanical switch that uses a low current

input from the intermittent wipe logic circuitry

within the fuse block underneath the steering column

to control a high current output to the low speed

brush of the wiper motor. The movable common feed

contact point is held against the fixed normally

closed contact point by spring pressure. When the

relay coil is energized, an electromagnetic field is

produced by the coil windings. This electromagnetic

field draws the movable relay contact point away

from the fixed normally closed contact point, and

holds it against the fixed normally open contact

point. When the relay coil is de-energized, spring

pressure returns the movable contact point back

against the fixed normally closed contact point. A

resistor or diode is connected in parallel with the

relay coil in the relay, and helps to dissipate voltage

spikes and electromagnetic interference that can be

generated as the electromagnetic field of the relay

coil collapses.

The wiper relay terminals are connected to the

vehicle electrical system through a connector recepta-

cle in the fuse block. The inputs and outputs of the

wiper relay include:

²The common feed terminal (30) provides an out-

put to the wiper motor low speed brush through the

wiper control circuitry of the multi-function switch on

the steering column. When the wiper relay is de-en-

ergized, the common feed terminal is connected to

the input of the relay normally closed terminal (87).

When the wiper relay is energized, the common feed

terminal is connected to the input of the relay nor-

mally open terminal (87A).

²The coil ground terminal (85) is connected to

battery current through a fused ignition switch out-

put circuit whenever the ignition switch is in the On

position.

²The coil battery terminal (86) is connected to the

relay control output of the wiper, turn signals and

engine start control module within the fuse block

through the wiper relay control circuit. This elec-

tronic circuitry controls the ground path for this cir-

cuit internally to energize or de-energize the wiper

relay control coil based upon its programming and

inputs from the wiper and washer control circuitry of

the multi-function switch, the wiper motor park

switch, and the ignition switch.

²The normally open terminal (87) is connected to

the output of the wiper motor park switch through

the wiper motor park switch sense circuit. This cir-

cuit can carry either battery current (wipers are not

in park position) or ground (wipers are in park posi-

tion), depending upon the status of the wiper park

switch.

Fig. 33 Wiper Relay

1 - HOUSING

2 - TERMINAL (5)

3 - BASE

8R - 34 WIPERS/WASHERSVA

Page 1078 of 2305

²The normally closed terminal (87A) is connected

to battery current through a fused ignition switch

output circuit whenever the ignition switch is in the

On position.

The wiper relay can be diagnosed using conven-

tional diagnostic tools and methods.

REMOVAL

WARNING: To avoid personal injury or death, on

vehicles equipped with airbags, disable the supple-

mental restraint system before attempting any

steering wheel, steering column, airbag, seat belt

tensioner, or instrument panel component diagno-

sis or service. Disconnect and isolate the battery

negative (ground) cable, then wait two minutes for

the system capacitor to discharge before perform-

ing further diagnosis or service. This is the only

sure way to disable the supplemental restraint sys-

tem. Failure to take the proper precautions could

result in accidental airbag deployment.

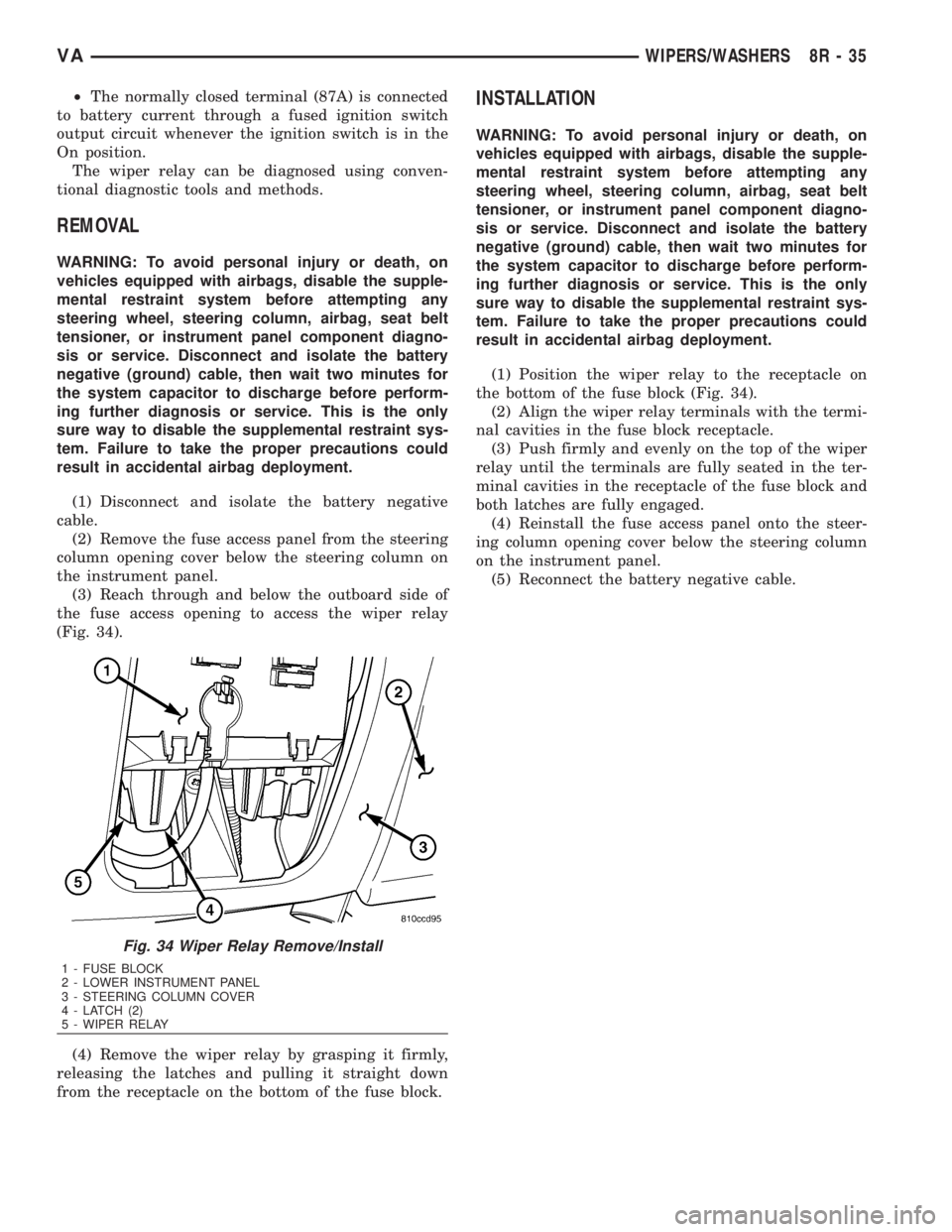

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the fuse access panel from the steering

column opening cover below the steering column on

the instrument panel.

(3) Reach through and below the outboard side of

the fuse access opening to access the wiper relay

(Fig. 34).

(4) Remove the wiper relay by grasping it firmly,

releasing the latches and pulling it straight down

from the receptacle on the bottom of the fuse block.

INSTALLATION

WARNING: To avoid personal injury or death, on

vehicles equipped with airbags, disable the supple-

mental restraint system before attempting any

steering wheel, steering column, airbag, seat belt

tensioner, or instrument panel component diagno-

sis or service. Disconnect and isolate the battery

negative (ground) cable, then wait two minutes for

the system capacitor to discharge before perform-

ing further diagnosis or service. This is the only

sure way to disable the supplemental restraint sys-

tem. Failure to take the proper precautions could

result in accidental airbag deployment.

(1) Position the wiper relay to the receptacle on

the bottom of the fuse block (Fig. 34).

(2) Align the wiper relay terminals with the termi-

nal cavities in the fuse block receptacle.

(3) Push firmly and evenly on the top of the wiper

relay until the terminals are fully seated in the ter-

minal cavities in the receptacle of the fuse block and

both latches are fully engaged.

(4) Reinstall the fuse access panel onto the steer-

ing column opening cover below the steering column

on the instrument panel.

(5) Reconnect the battery negative cable.

Fig. 34 Wiper Relay Remove/Install

1 - FUSE BLOCK

2 - LOWER INSTRUMENT PANEL

3 - STEERING COLUMN COVER

4 - LATCH (2)

5 - WIPER RELAY

VAWIPERS/WASHERS 8R - 35

Page 1080 of 2305

WIRING

TABLE OF CONTENTS

page page

WIRING DIAGRAM INFORMATION....... 8W-01-1

COMPONENT INDEX.................. 8W-02-1

POWER DISTRIBUTION............... 8W-10-1

FUSE BLOCK........................ 8W-11-1

GROUND DISTRIBUTION.............. 8W-15-1

BUS COMMUNICATIONS.............. 8W-18-1

CHARGING SYSTEM.................. 8W-20-1

STARTING SYSTEM.................. 8W-21-1

FUEL/IGNITION SYSTEM.............. 8W-30-1

TRANSMISSION CONTROL SYSTEM..... 8W-31-1

VEHICLE SPEED CONTROL............ 8W-33-1

ANTILOCK BRAKES................... 8W-35-1

VEHICLE THEFT SECURITY SYSTEM..... 8W-39-1

INSTRUMENT CLUSTER............... 8W-40-1

HORN/CIGAR LIGHTER................ 8W-41-1

AIR CONDITIONING-HEATER........... 8W-42-1

AIRBAG SYSTEM.................... 8W-43-1

INTERIOR LIGHTING.................. 8W-44-1CENTRAL TIMER MODULE............. 8W-45-1

AUDIO SYSTEM..................... 8W-47-1

REAR WINDOW DEFOGGER............ 8W-48-1

FRONT LIGHTING.................... 8W-50-1

REAR LIGHTING..................... 8W-51-1

TURN SIGNALS...................... 8W-52-1

WIPERS............................ 8W-53-1

TRAILER TOW....................... 8W-54-1

NAVIGATION/TELECOMMUNICATIONS.... 8W-55-1

POWER WINDOWS................... 8W-60-1

POWER DOOR LOCKS................ 8W-61-1

POWER MIRRORS................... 8W-62-1

POWER SEATS...................... 8W-63-1

SPLICE INFORMATION................ 8W-70-1

CONNECTOR PIN-OUTS............... 8W-80-1

CONNECTOR/GROUND/SPLICE

LOCATION........................ 8W-91-1

POWER DISTRIBUTION............... 8W-97-1 VAWIRING 8W - 1

Page 1086 of 2305

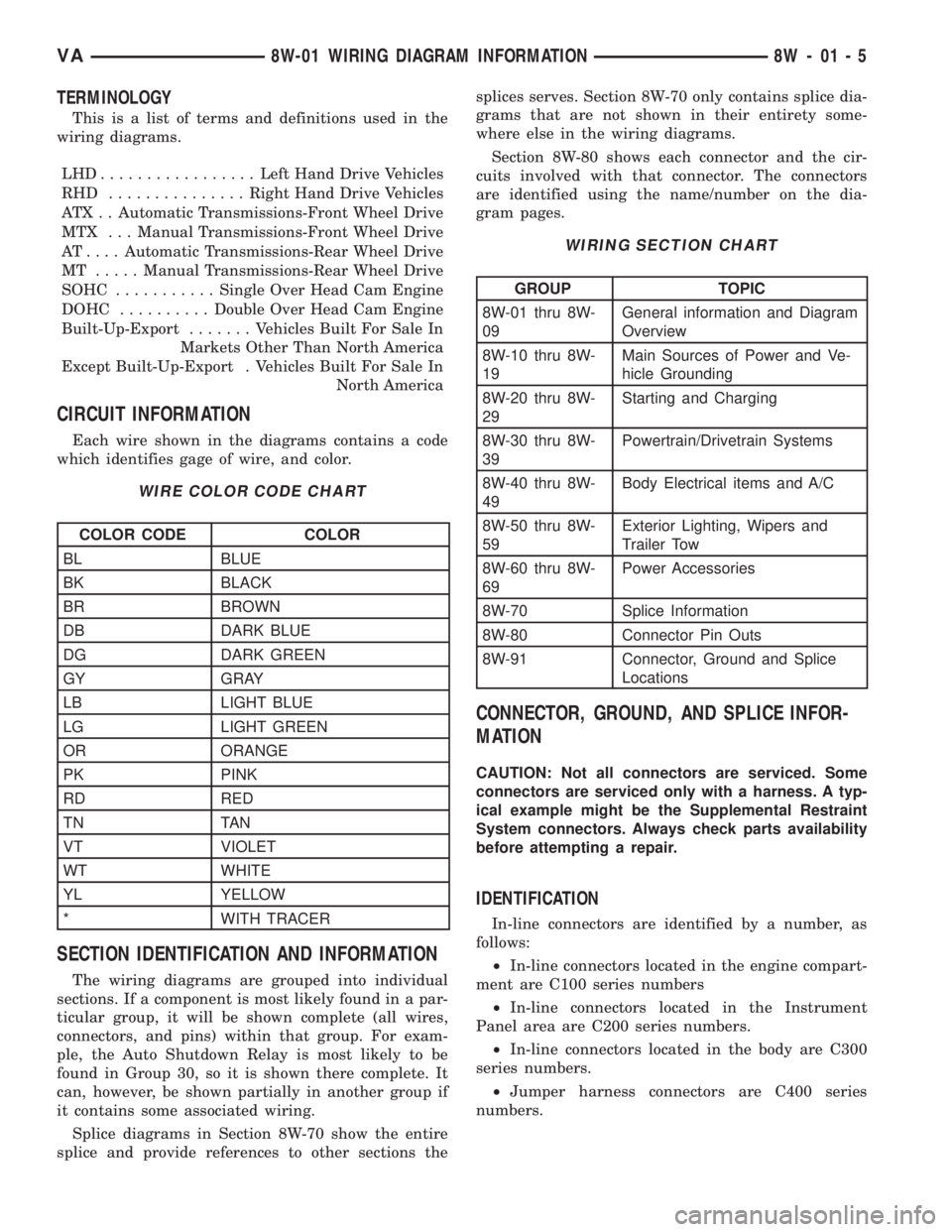

TERMINOLOGY

This is a list of terms and definitions used in the

wiring diagrams.

LHD.................Left Hand Drive Vehicles

RHD ...............Right Hand Drive Vehicles

ATX . . Automatic Transmissions-Front Wheel Drive

MTX . . . Manual Transmissions-Front Wheel Drive

AT....Automatic Transmissions-Rear Wheel Drive

MT .....Manual Transmissions-Rear Wheel Drive

SOHC...........Single Over Head Cam Engine

DOHC..........Double Over Head Cam Engine

Built-Up-Export....... Vehicles Built For Sale In

Markets Other Than North America

Except Built-Up-Export . Vehicles Built For Sale In

North America

CIRCUIT INFORMATION

Each wire shown in the diagrams contains a code

which identifies gage of wire, and color.

WIRE COLOR CODE CHART

COLOR CODE COLOR

BL BLUE

BK BLACK

BR BROWN

DB DARK BLUE

DG DARK GREEN

GY GRAY

LB LIGHT BLUE

LG LIGHT GREEN

OR ORANGE

PK PINK

RD RED

TN TAN

VT VIOLET

WT WHITE

YL YELLOW

* WITH TRACER

SECTION IDENTIFICATION AND INFORMATION

The wiring diagrams are grouped into individual

sections. If a component is most likely found in a par-

ticular group, it will be shown complete (all wires,

connectors, and pins) within that group. For exam-

ple, the Auto Shutdown Relay is most likely to be

found in Group 30, so it is shown there complete. It

can, however, be shown partially in another group if

it contains some associated wiring.

Splice diagrams in Section 8W-70 show the entire

splice and provide references to other sections thesplices serves. Section 8W-70 only contains splice dia-

grams that are not shown in their entirety some-

where else in the wiring diagrams.

Section 8W-80 shows each connector and the cir-

cuits involved with that connector. The connectors

are identified using the name/number on the dia-

gram pages.

WIRING SECTION CHART

GROUP TOPIC

8W-01 thru 8W-

09General information and Diagram

Overview

8W-10 thru 8W-

19Main Sources of Power and Ve-

hicle Grounding

8W-20 thru 8W-

29Starting and Charging

8W-30 thru 8W-

39Powertrain/Drivetrain Systems

8W-40 thru 8W-

49Body Electrical items and A/C

8W-50 thru 8W-

59Exterior Lighting, Wipers and

Trailer Tow

8W-60 thru 8W-

69Power Accessories

8W-70 Splice Information

8W-80 Connector Pin Outs

8W-91 Connector, Ground and Splice

Locations

CONNECTOR, GROUND, AND SPLICE INFOR-

MATION

CAUTION: Not all connectors are serviced. Some

connectors are serviced only with a harness. A typ-

ical example might be the Supplemental Restraint

System connectors. Always check parts availability

before attempting a repair.

IDENTIFICATION

In-line connectors are identified by a number, as

follows:

²In-line connectors located in the engine compart-

ment are C100 series numbers

²In-line connectors located in the Instrument

Panel area are C200 series numbers.

²In-line connectors located in the body are C300

series numbers.

²Jumper harness connectors are C400 series

numbers.

VA8W-01 WIRING DIAGRAM INFORMATION 8W - 01 - 5

Page 1382 of 2305

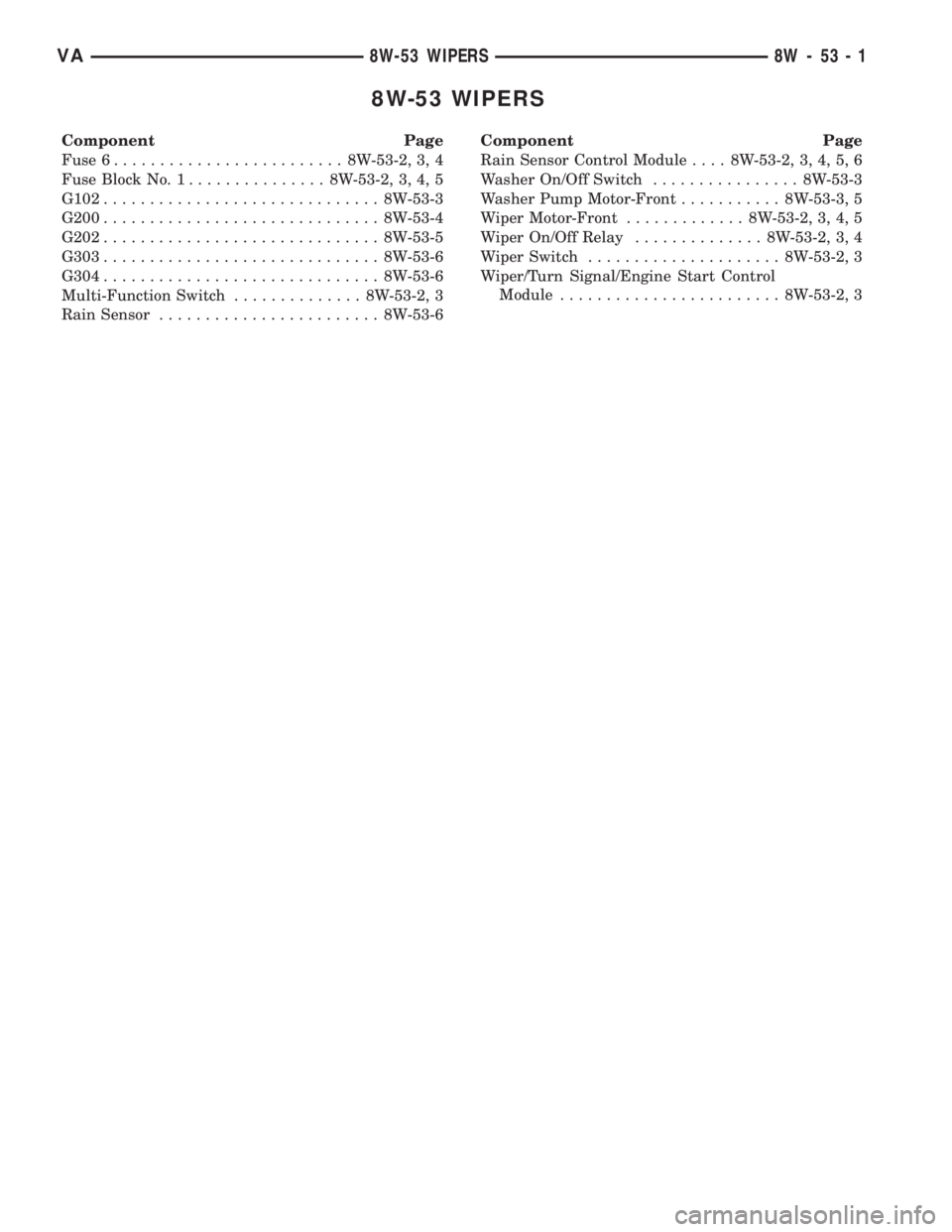

8W-53 WIPERS

Component Page

Fuse 6......................... 8W-53-2, 3, 4

Fuse Block No. 1............... 8W-53-2, 3, 4, 5

G102.............................. 8W-53-3

G200.............................. 8W-53-4

G202.............................. 8W-53-5

G303.............................. 8W-53-6

G304.............................. 8W-53-6

Multi-Function Switch.............. 8W-53-2, 3

Rain Sensor........................ 8W-53-6Component Page

Rain Sensor Control Module.... 8W-53-2, 3, 4, 5, 6

Washer On/Off Switch................ 8W-53-3

Washer Pump Motor-Front........... 8W-53-3, 5

Wiper Motor-Front............. 8W-53-2, 3, 4, 5

Wiper On/Off Relay.............. 8W-53-2, 3, 4

Wiper Switch..................... 8W-53-2, 3

Wiper/Turn Signal/Engine Start Control

Module........................ 8W-53-2, 3

VA8W-53 WIPERS 8W - 53 - 1

Page 2028 of 2305

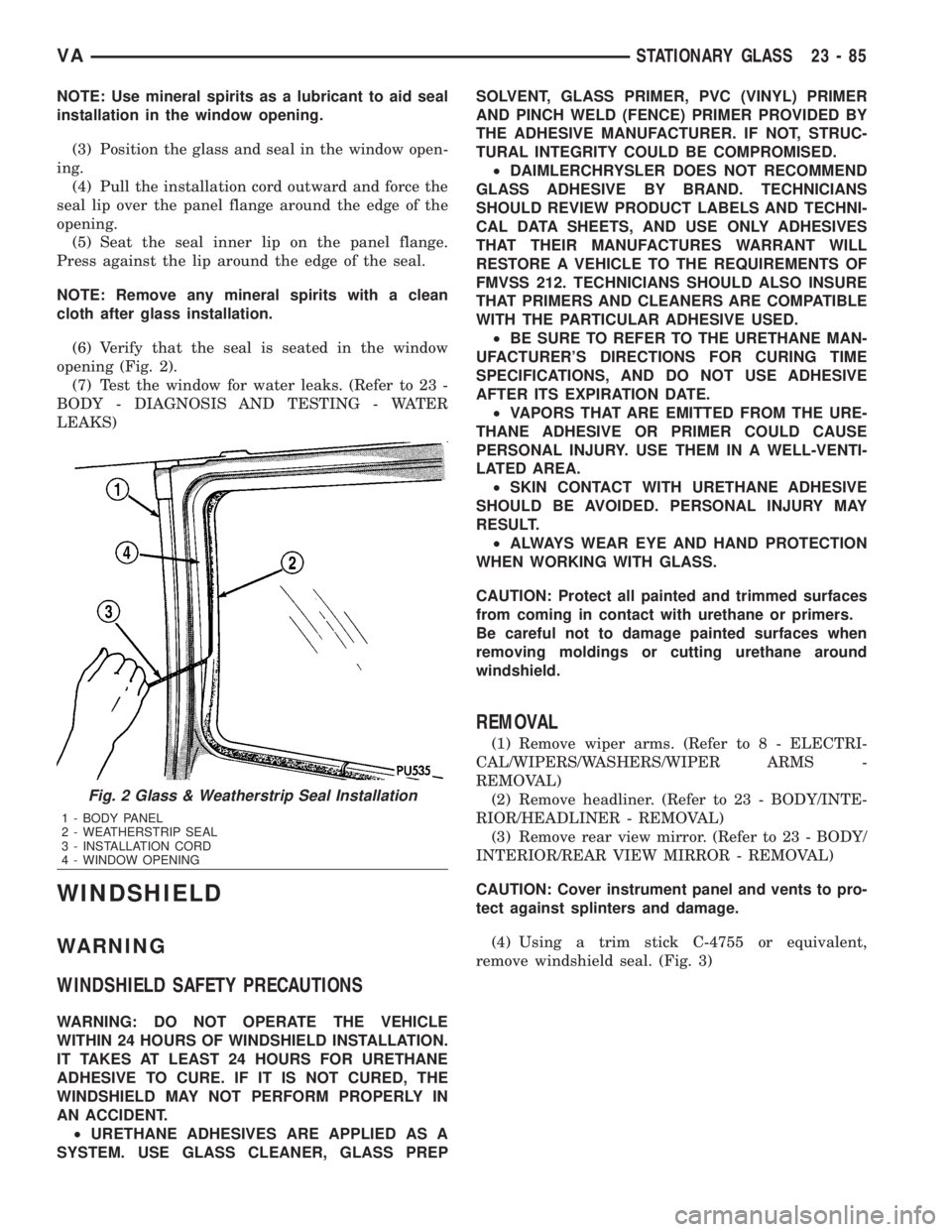

NOTE: Use mineral spirits as a lubricant to aid seal

installation in the window opening.

(3) Position the glass and seal in the window open-

ing.

(4) Pull the installation cord outward and force the

seal lip over the panel flange around the edge of the

opening.

(5) Seat the seal inner lip on the panel flange.

Press against the lip around the edge of the seal.

NOTE: Remove any mineral spirits with a clean

cloth after glass installation.

(6) Verify that the seal is seated in the window

opening (Fig. 2).

(7) Test the window for water leaks. (Refer to 23 -

BODY - DIAGNOSIS AND TESTING - WATER

LEAKS)

WINDSHIELD

WARNING

WINDSHIELD SAFETY PRECAUTIONS

WARNING: DO NOT OPERATE THE VEHICLE

WITHIN 24 HOURS OF WINDSHIELD INSTALLATION.

IT TAKES AT LEAST 24 HOURS FOR URETHANE

ADHESIVE TO CURE. IF IT IS NOT CURED, THE

WINDSHIELD MAY NOT PERFORM PROPERLY IN

AN ACCIDENT.

²URETHANE ADHESIVES ARE APPLIED AS A

SYSTEM. USE GLASS CLEANER, GLASS PREPSOLVENT, GLASS PRIMER, PVC (VINYL) PRIMER

AND PINCH WELD (FENCE) PRIMER PROVIDED BY

THE ADHESIVE MANUFACTURER. IF NOT, STRUC-

TURAL INTEGRITY COULD BE COMPROMISED.

²DAIMLERCHRYSLER DOES NOT RECOMMEND

GLASS ADHESIVE BY BRAND. TECHNICIANS

SHOULD REVIEW PRODUCT LABELS AND TECHNI-

CAL DATA SHEETS, AND USE ONLY ADHESIVES

THAT THEIR MANUFACTURES WARRANT WILL

RESTORE A VEHICLE TO THE REQUIREMENTS OF

FMVSS 212. TECHNICIANS SHOULD ALSO INSURE

THAT PRIMERS AND CLEANERS ARE COMPATIBLE

WITH THE PARTICULAR ADHESIVE USED.

²BE SURE TO REFER TO THE URETHANE MAN-

UFACTURER'S DIRECTIONS FOR CURING TIME

SPECIFICATIONS, AND DO NOT USE ADHESIVE

AFTER ITS EXPIRATION DATE.

²VAPORS THAT ARE EMITTED FROM THE URE-

THANE ADHESIVE OR PRIMER COULD CAUSE

PERSONAL INJURY. USE THEM IN A WELL-VENTI-

LATED AREA.

²SKIN CONTACT WITH URETHANE ADHESIVE

SHOULD BE AVOIDED. PERSONAL INJURY MAY

RESULT.

²ALWAYS WEAR EYE AND HAND PROTECTION

WHEN WORKING WITH GLASS.

CAUTION: Protect all painted and trimmed surfaces

from coming in contact with urethane or primers.

Be careful not to damage painted surfaces when

removing moldings or cutting urethane around

windshield.

REMOVAL

(1) Remove wiper arms. (Refer to 8 - ELECTRI-

CAL/WIPERS/WASHERS/WIPER ARMS -

REMOVAL)

(2) Remove headliner. (Refer to 23 - BODY/INTE-

RIOR/HEADLINER - REMOVAL)

(3) Remove rear view mirror. (Refer to 23 - BODY/

INTERIOR/REAR VIEW MIRROR - REMOVAL)

CAUTION: Cover instrument panel and vents to pro-

tect against splinters and damage.

(4) Using a trim stick C-4755 or equivalent,

remove windshield seal. (Fig. 3)

Fig. 2 Glass & Weatherstrip Seal Installation

1 - BODY PANEL

2 - WEATHERSTRIP SEAL

3 - INSTALLATION CORD

4 - WINDOW OPENING

VASTATIONARY GLASS 23 - 85

Page 2032 of 2305

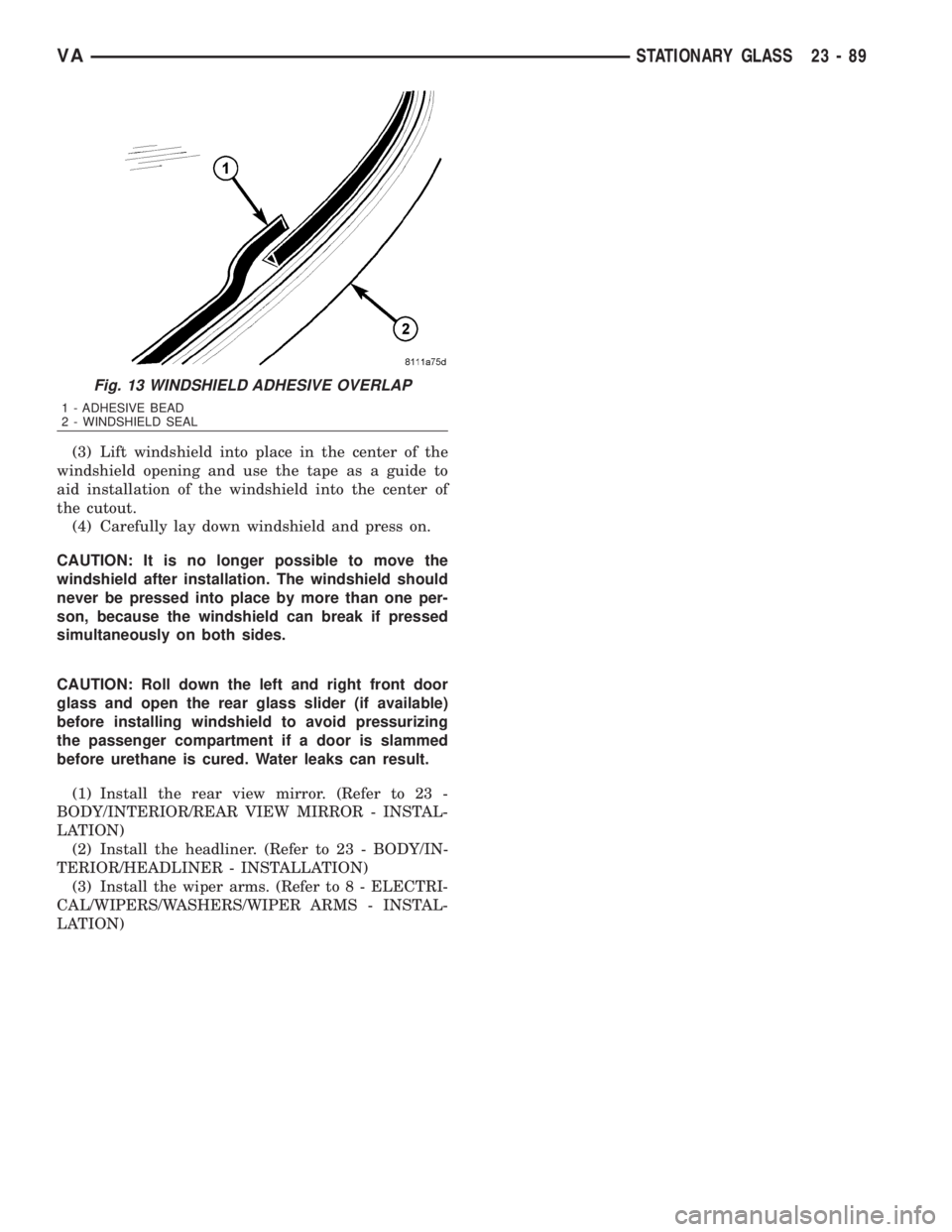

(3) Lift windshield into place in the center of the

windshield opening and use the tape as a guide to

aid installation of the windshield into the center of

the cutout.

(4) Carefully lay down windshield and press on.

CAUTION: It is no longer possible to move the

windshield after installation. The windshield should

never be pressed into place by more than one per-

son, because the windshield can break if pressed

simultaneously on both sides.

CAUTION: Roll down the left and right front door

glass and open the rear glass slider (if available)

before installing windshield to avoid pressurizing

the passenger compartment if a door is slammed

before urethane is cured. Water leaks can result.

(1) Install the rear view mirror. (Refer to 23 -

BODY/INTERIOR/REAR VIEW MIRROR - INSTAL-

LATION)

(2) Install the headliner. (Refer to 23 - BODY/IN-

TERIOR/HEADLINER - INSTALLATION)

(3) Install the wiper arms. (Refer to 8 - ELECTRI-

CAL/WIPERS/WASHERS/WIPER ARMS - INSTAL-

LATION)

Fig. 13 WINDSHIELD ADHESIVE OVERLAP

1 - ADHESIVE BEAD

2 - WINDSHIELD SEAL

VASTATIONARY GLASS 23 - 89

Page 2085 of 2305

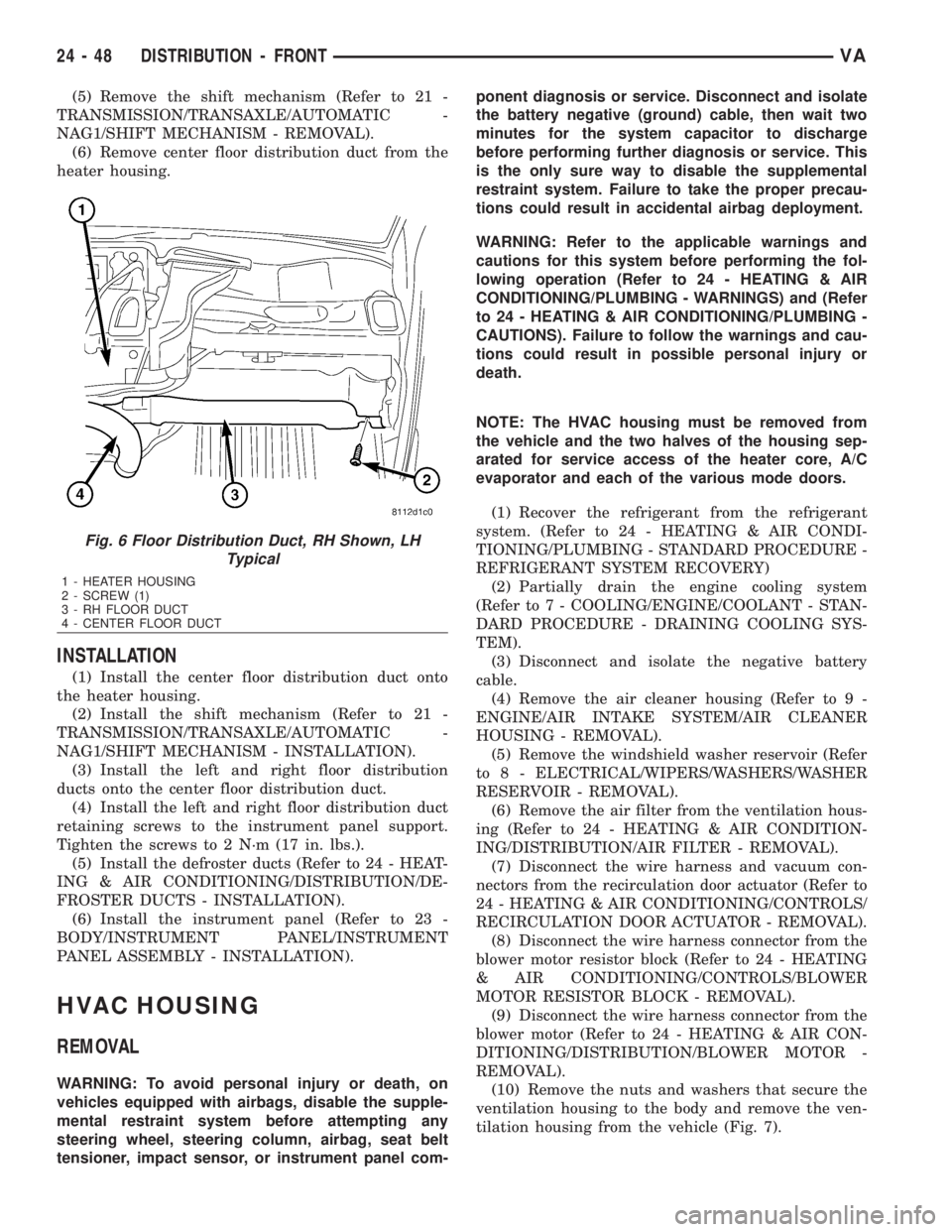

(5) Remove the shift mechanism (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC -

NAG1/SHIFT MECHANISM - REMOVAL).

(6) Remove center floor distribution duct from the

heater housing.

INSTALLATION

(1) Install the center floor distribution duct onto

the heater housing.

(2) Install the shift mechanism (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC -

NAG1/SHIFT MECHANISM - INSTALLATION).

(3) Install the left and right floor distribution

ducts onto the center floor distribution duct.

(4) Install the left and right floor distribution duct

retaining screws to the instrument panel support.

Tighten the screws to 2 N´m (17 in. lbs.).

(5) Install the defroster ducts (Refer to 24 - HEAT-

ING & AIR CONDITIONING/DISTRIBUTION/DE-

FROSTER DUCTS - INSTALLATION).

(6) Install the instrument panel (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL ASSEMBLY - INSTALLATION).

HVAC HOUSING

REMOVAL

WARNING: To avoid personal injury or death, on

vehicles equipped with airbags, disable the supple-

mental restraint system before attempting any

steering wheel, steering column, airbag, seat belt

tensioner, impact sensor, or instrument panel com-ponent diagnosis or service. Disconnect and isolate

the battery negative (ground) cable, then wait two

minutes for the system capacitor to discharge

before performing further diagnosis or service. This

is the only sure way to disable the supplemental

restraint system. Failure to take the proper precau-

tions could result in accidental airbag deployment.

WARNING: Refer to the applicable warnings and

cautions for this system before performing the fol-

lowing operation (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - WARNINGS) and (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

CAUTIONS). Failure to follow the warnings and cau-

tions could result in possible personal injury or

death.

NOTE: The HVAC housing must be removed from

the vehicle and the two halves of the housing sep-

arated for service access of the heater core, A/C

evaporator and each of the various mode doors.

(1) Recover the refrigerant from the refrigerant

system. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT SYSTEM RECOVERY)

(2) Partially drain the engine cooling system

(Refer to 7 - COOLING/ENGINE/COOLANT - STAN-

DARD PROCEDURE - DRAINING COOLING SYS-

TEM).

(3) Disconnect and isolate the negative battery

cable.

(4) Remove the air cleaner housing (Refer to 9 -

ENGINE/AIR INTAKE SYSTEM/AIR CLEANER

HOUSING - REMOVAL).

(5) Remove the windshield washer reservoir (Refer

to 8 - ELECTRICAL/WIPERS/WASHERS/WASHER

RESERVOIR - REMOVAL).

(6) Remove the air filter from the ventilation hous-

ing (Refer to 24 - HEATING & AIR CONDITION-

ING/DISTRIBUTION/AIR FILTER - REMOVAL).

(7) Disconnect the wire harness and vacuum con-

nectors from the recirculation door actuator (Refer to

24 - HEATING & AIR CONDITIONING/CONTROLS/

RECIRCULATION DOOR ACTUATOR - REMOVAL).

(8) Disconnect the wire harness connector from the

blower motor resistor block (Refer to 24 - HEATING

& AIR CONDITIONING/CONTROLS/BLOWER

MOTOR RESISTOR BLOCK - REMOVAL).

(9) Disconnect the wire harness connector from the

blower motor (Refer to 24 - HEATING & AIR CON-

DITIONING/DISTRIBUTION/BLOWER MOTOR -

REMOVAL).

(10) Remove the nuts and washers that secure the

ventilation housing to the body and remove the ven-

tilation housing from the vehicle (Fig. 7).

Fig. 6 Floor Distribution Duct, RH Shown, LH

Typical

1 - HEATER HOUSING

2 - SCREW (1)

3 - RH FLOOR DUCT

4 - CENTER FLOOR DUCT

24 - 48 DISTRIBUTION - FRONTVA

Page 2088 of 2305

(12) Install the two bolts that secure the refriger-

ant line terminal block to the A/C evaporator.

Tighten the bolts to 5 N´m (45 in. lbs.).

(13) Unplug or remove the tape from the heater

core hoses and tubes.

(14) Connect the heater hoses to the heater core

tubes and install the heater hose clamps.

(15) Install the ventilation housing to the dash

panel.

(16) Install the nuts and washers that secure the

ventilation housing to the dash panel. Tighten the

nuts to 5 N´m (45 in. lbs.).

(17) Connect the wire harness connectors to the

blower motor, blower motor resistor block and the

recirculation door actuator.

(18) Connect the vacuum harness connector to the

recirculation door actuator.

(19) Install the air filter into the ventilation hous-

ing (Refer to 24 - HEATING & AIR CONDITION-

ING/DISTRIBUTION/AIR FILTER -

INSTALLATION).

(20) Install the windshield washer reservoir (Refer

to 8 - ELECTRICAL/WIPERS/WASHERS/WASHER

RESERVOIR - INSTALLATION).

(21) Install the air cleaner housing (Refer to 9 -

ENGINE/AIR INTAKE SYSTEM/AIR CLEANER

HOUSING - INSTALLATION).

(22) Reconnect the negative battery cable.

(23) If the heater core is being replaced, flush the

cooling system (Refer to 7 - COOLING - STANDARD

PROCEDURE - COOLING SYSTEM CLEANING/

REVERSE FLUSHING).

(24) Refill the engine cooling system (Refer to 7 -

COOLING/ENGINE/COOLANT - STANDARD PRO-

CEDURE - COOLANT SYSTEM FILL).

(25) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE).

(26) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE).

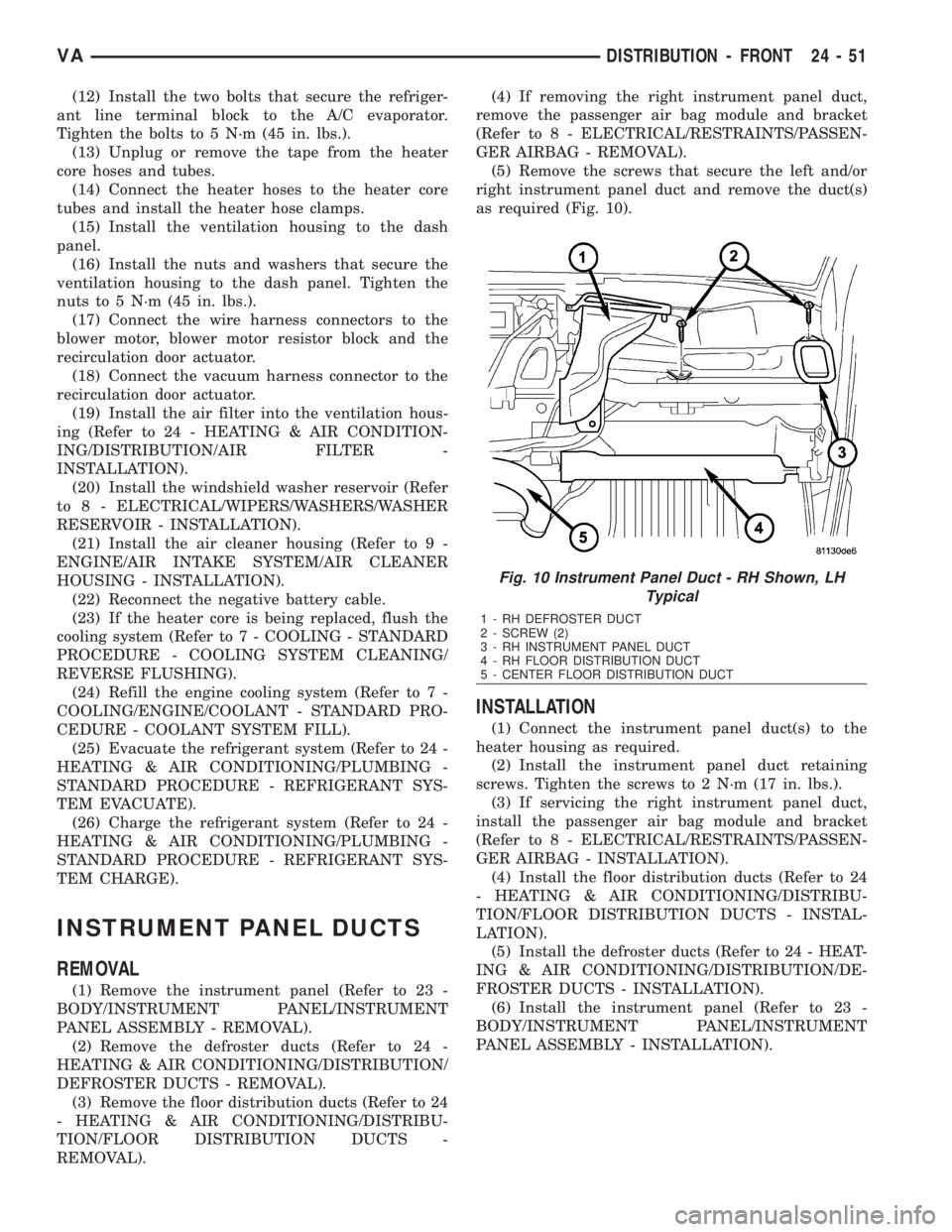

INSTRUMENT PANEL DUCTS

REMOVAL

(1) Remove the instrument panel (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL ASSEMBLY - REMOVAL).

(2) Remove the defroster ducts (Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

DEFROSTER DUCTS - REMOVAL).

(3) Remove the floor distribution ducts (Refer to 24

- HEATING & AIR CONDITIONING/DISTRIBU-

TION/FLOOR DISTRIBUTION DUCTS -

REMOVAL).(4) If removing the right instrument panel duct,

remove the passenger air bag module and bracket

(Refer to 8 - ELECTRICAL/RESTRAINTS/PASSEN-

GER AIRBAG - REMOVAL).

(5) Remove the screws that secure the left and/or

right instrument panel duct and remove the duct(s)

as required (Fig. 10).

INSTALLATION

(1) Connect the instrument panel duct(s) to the

heater housing as required.

(2) Install the instrument panel duct retaining

screws. Tighten the screws to 2 N´m (17 in. lbs.).

(3) If servicing the right instrument panel duct,

install the passenger air bag module and bracket

(Refer to 8 - ELECTRICAL/RESTRAINTS/PASSEN-

GER AIRBAG - INSTALLATION).

(4) Install the floor distribution ducts (Refer to 24

- HEATING & AIR CONDITIONING/DISTRIBU-

TION/FLOOR DISTRIBUTION DUCTS - INSTAL-

LATION).

(5) Install the defroster ducts (Refer to 24 - HEAT-

ING & AIR CONDITIONING/DISTRIBUTION/DE-

FROSTER DUCTS - INSTALLATION).

(6) Install the instrument panel (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL ASSEMBLY - INSTALLATION).

Fig. 10 Instrument Panel Duct - RH Shown, LH

Typical

1 - RH DEFROSTER DUCT

2 - SCREW (2)

3 - RH INSTRUMENT PANEL DUCT

4 - RH FLOOR DISTRIBUTION DUCT

5 - CENTER FLOOR DISTRIBUTION DUCT

VADISTRIBUTION - FRONT 24 - 51