MERCEDES-BENZ SPRINTER 2006 Service Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 721 of 2305

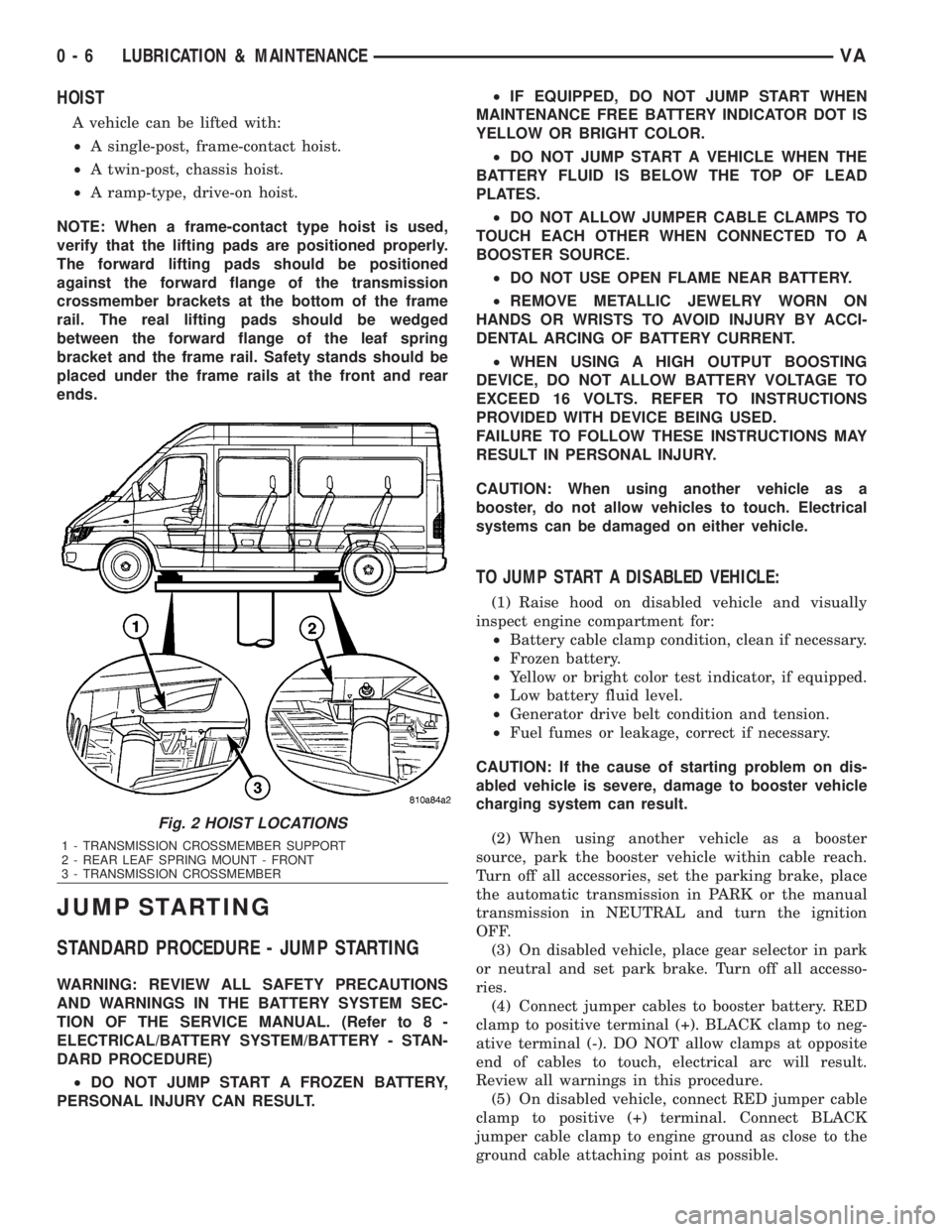

HOIST

A vehicle can be lifted with:

²A single-post, frame-contact hoist.

²A twin-post, chassis hoist.

²A ramp-type, drive-on hoist.

NOTE: When a frame-contact type hoist is used,

verify that the lifting pads are positioned properly.

The forward lifting pads should be positioned

against the forward flange of the transmission

crossmember brackets at the bottom of the frame

rail. The real lifting pads should be wedged

between the forward flange of the leaf spring

bracket and the frame rail. Safety stands should be

placed under the frame rails at the front and rear

ends.

JUMP STARTING

STANDARD PROCEDURE - JUMP STARTING

WARNING: REVIEW ALL SAFETY PRECAUTIONS

AND WARNINGS IN THE BATTERY SYSTEM SEC-

TION OF THE SERVICE MANUAL. (Refer to 8 -

ELECTRICAL/BATTERY SYSTEM/BATTERY - STAN-

DARD PROCEDURE)

²DO NOT JUMP START A FROZEN BATTERY,

PERSONAL INJURY CAN RESULT.²IF EQUIPPED, DO NOT JUMP START WHEN

MAINTENANCE FREE BATTERY INDICATOR DOT IS

YELLOW OR BRIGHT COLOR.

²DO NOT JUMP START A VEHICLE WHEN THE

BATTERY FLUID IS BELOW THE TOP OF LEAD

PLATES.

²DO NOT ALLOW JUMPER CABLE CLAMPS TO

TOUCH EACH OTHER WHEN CONNECTED TO A

BOOSTER SOURCE.

²DO NOT USE OPEN FLAME NEAR BATTERY.

²REMOVE METALLIC JEWELRY WORN ON

HANDS OR WRISTS TO AVOID INJURY BY ACCI-

DENTAL ARCING OF BATTERY CURRENT.

²WHEN USING A HIGH OUTPUT BOOSTING

DEVICE, DO NOT ALLOW BATTERY VOLTAGE TO

EXCEED 16 VOLTS. REFER TO INSTRUCTIONS

PROVIDED WITH DEVICE BEING USED.

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY

RESULT IN PERSONAL INJURY.

CAUTION: When using another vehicle as a

booster, do not allow vehicles to touch. Electrical

systems can be damaged on either vehicle.

TO JUMP START A DISABLED VEHICLE:

(1) Raise hood on disabled vehicle and visually

inspect engine compartment for:

²Battery cable clamp condition, clean if necessary.

²Frozen battery.

²Yellow or bright color test indicator, if equipped.

²Low battery fluid level.

²Generator drive belt condition and tension.

²Fuel fumes or leakage, correct if necessary.

CAUTION: If the cause of starting problem on dis-

abled vehicle is severe, damage to booster vehicle

charging system can result.

(2) When using another vehicle as a booster

source, park the booster vehicle within cable reach.

Turn off all accessories, set the parking brake, place

the automatic transmission in PARK or the manual

transmission in NEUTRAL and turn the ignition

OFF.

(3) On disabled vehicle, place gear selector in park

or neutral and set park brake. Turn off all accesso-

ries.

(4) Connect jumper cables to booster battery. RED

clamp to positive terminal (+). BLACK clamp to neg-

ative terminal (-). DO NOT allow clamps at opposite

end of cables to touch, electrical arc will result.

Review all warnings in this procedure.

(5) On disabled vehicle, connect RED jumper cable

clamp to positive (+) terminal. Connect BLACK

jumper cable clamp to engine ground as close to the

ground cable attaching point as possible.

Fig. 2 HOIST LOCATIONS

1 - TRANSMISSION CROSSMEMBER SUPPORT

2 - REAR LEAF SPRING MOUNT - FRONT

3 - TRANSMISSION CROSSMEMBER

0 - 6 LUBRICATION & MAINTENANCEVA

Page 722 of 2305

(6) Start the engine in the vehicle which has the

booster battery, let the engine idle a few minutes,

then start the engine in the vehicle with the dis-

charged battery.

CAUTION: Do not crank starter motor on disabled

vehicle for more than 15 seconds, starter will over-

heat and could fail.

(7) Allow battery in disabled vehicle to charge to

at least 12.4 volts (75% charge) before attempting to

start engine. If engine does not start within 15 sec-

onds, stop cranking engine and allow starter to cool

(15 min.), before cranking again.

DISCONNECT CABLE CLAMPS AS FOLLOWS:

²Disconnect BLACK cable clamp from engine

ground on disabled vehicle.

²When using a Booster vehicle, disconnect

BLACK cable clamp from battery negative terminal.

Disconnect RED cable clamp from battery positive

terminal.

²Disconnect RED cable clamp from battery posi-

tive terminal on disabled vehicle.

TOWING

STANDARD PROCEDURE - TOWING

WARNING: Do not tow the vehicle if the key cannot

be turned in the ignition lock. If the key cannot be

turned, the ignition lock remains locked and the

vehicle cannot be steered. With the engine not run-

ning there is no power assistance for the braking

and steering systems. In this case, it is important to

keep in mind that a considerably higher degree of

effort is necessary to brake and steer the vehicle.

The vehicle must not be towed with the front axle

raised and the key in position 2 in the ignition lock

as the drive wheels could then lock due to the

acceleration skid control (ASR)

If the Engine is Damaged

For towing distances up to 30 miles (about 50

km)

²Shift selector lever in ªNº position.

²Do not exceed a towing speed of 30 m.p.h. (50

km/h).

For towing distances greater than 30 mile

(about 50 km)

²Remove the propeller shafts leading to the drive

axles. The vehicle can be towed without restriction.

If the Transmission is Damaged

²Remove the propeller shafts leading to the drive

axles. The vehicle can be towed without restriction.

If the Front Axle is Damaged

²Raise the front axle.

²Observe the same towing restrictions as for

engine damage.

If the Rear Axle is Damaged

²Raise the rear axle.

NOTE: Comply with local legal regulations regard-

ing towing vehicles.

SAFETY PRECAUTIONS

NOTE: The following safety precautions must be

observed when towing a vehicle.

²Secure loose and protruding parts.

²Always use a safety chain system that is inde-

pendent of the lifting and towing equipment.

²Do not allow towing equipment to contact the

disabled vehicle's fuel tank.

²Do not allow anyone under the disabled vehicle

while it is lifted by the towing device.

²Do not allow passengers to ride in a vehicle

being towed.

²Always observe state and local laws regarding

towing regulations.

²Do not tow a vehicle in a manner that could

jeopardize the safety of the operator, pedestrians or

other motorists.

²Do not attach tow chains, T-hooks, J-hooks, or a

tow sling to a bumper, steering linkage, drive shafts

or a non-reinforced frame hole.

²Remove exhaust pipe tips that interfere with the

tow sling and crossbar

²Padding should be placed between the tow sling/

crossbar and any painted surfaces

²When placing tow hooks on the rear axle, posi-

tion them so they do not damage the brake tubing or

hoses

²Do not tow the vehicle by connecting to the front

or rear shock absorbers

²Do not tow a heavily loaded vehicle. Damage to

the vehicle may result. Use a flatbed device to trans-

port a loaded vehicle.

GROUND CLEARANCE

CAUTION: If vehicle is towed with wheels removed,

install lug nuts to retain brake drums.

A towed vehicle should be raised until lifted wheels

are a minimum 100 mm (4 in) from the ground. Be

sure there is adequate ground clearance at the oppo-

site end of the vehicle, especially when towing over

rough terrain, steep rises in the road or if the vehicle

is equipped with air dams, spoilers, and/or ground

VALUBRICATION & MAINTENANCE 0 - 7

Page 723 of 2305

effect panels. If necessary, remove the wheels from

the lifted end of the vehicle and lower the vehicle

closer to the ground, to increase the ground clearance

at the opposite end of the vehicle. Install lug nuts on

wheel attaching studs to retain brake drums.

RAMP ANGLE

If a vehicle with flat-bed towing equipment is used,

the approach ramp angle should not exceed 15

degrees.

TOWING WHEN KEYS ARE NOT AVAILABLE

When the vehicle is locked and keys are not avail-

able, use a flat bed hauler. A Wheel-lift or Sling-type

device can be used provided all the wheels are lifted

off the ground using tow dollies.

MAINTENANCE SCHEDULES

DESCRIPTION

The use of special lubricant additives is not recom-

mended. The use of such additives may affect the

warranty rights. With regard to legal stipulations

concerning emissions control, please note that

engines have to be serviced and adjusted in accor-

dance with special instructions and using special

measuring equipment. Modifications to or interfer-

ence with the emissions control systems are not per-

missible.

MAINTENANCE - WITHOUT ASSYST MAINTE-

NANCE COMPUTER

Maintenance Intervals

²Oil service ±Normal Operationevery 10,000

miles or 16,000 km or 12 months.

²Maintenance service every 30,000 miles or

48,000 km.

Additional work must be carried out at yearly

intervals.

MAINTENANCE - WITH ASSYST MAINTENANCE

COMPUTER

ASSYST provides information on the best possible

timing for maintenance work.

When the next maintenance service is due, this

will be indicated in the multi-function display with

the wrench icon symbol displayed in km/miles or

days.

²One wrench icon showing indicates Oil Service

is necessary.

²Two wrench icons showing indicates Mainte-

nance Service is necessary ± displayed in km/miles or

days.

If the display shows the number of days, a clock

symbol will also appear in the multi-function display.You should have the maintenance performed

within the stated period/distance.

The service indicator will be reset after an oil ser-

vice and/or maintenance service has been performed.

REGULAR CHECK - UPS

To maintain the safe operation of the vehicle, it is

recommended that the following tasks be performed

on a regular basis (i.e. weekly or whenever the vehi-

cle is refueled). Check:

²Engine oil level

²Brake system - fluid level

²Battery - acid level

²Windshield washer system and headlamp clean-

ing system - fluid level

²Mechanical assemblies (e.g. engine, transmis-

sion, etc.) - check for leaks

²Condition of tires and tires pressures

²All exterior lights

SPECIAL MAINTENANCE REQUIREMENTS

If bodies built by manufacturers other than

DaimlerChrysler Corporation are fitted to the vehi-

cle, the maintenance requirements and lubrication

intervals specified by the body manufacturer must be

adhered to, in addition to all standard maintenance

requirements.

Coolant

Corrosion inhibitor/antifreeze concentration in the

coolant should be checked before the onset of winter

(once year in countries with high prevailing temper-

atures).

Replace the coolant every five years or 100,000

miles.

Dust Filter for Heating / Ventilation Replacement

The dust filter and the tailgate interior filter are to

be renewed during routine maintenance service. If

operating conditions are dusty, these filters should be

renewed more frequently.

ENGINE OIL CHANGE AND FILTER REPLACEMENT

At a minimum, change the engine oil and oil filter

once a year ± even if the vehicle mileage per year is

extremely low. For standard oil service schedules

refer to the chapter oil service and maintenance ser-

vice.

Once a Year

Select the viscosity of the engine oil (SAE classes)

according to the outside air temperature.

Only use engine oil approved by DaimlerChrysler

Corporation if following the ASSYST system guide-

lines.

0 - 8 LUBRICATION & MAINTENANCEVA

Page 724 of 2305

SCOPE OF WORK FOR MAINTENANCE SERVICE

Oil Service

²Engine: Oil change and filter replacement

Check fluid levels of the following system, refill as neces-

sary.

²If fluid is lost, trace and eliminate cause - as a

separate order.

²Power-assisted steering

Lubrication work:

²Trailer tow hitch (original equipment)

Maintenance

²ASSYST maintenance computer reset

Function check

²Signalling system, warning and indicator lamps

²Headlamps, exterior lighting

²Windshield wipers, windshield washer system

Check for leaks and damage

²Check for abrasion points and ensure that lines

are correctly routed!

²All lines and hoses, sensor cables

²Rubber boots on front axle drive shafts, rubber

boots on front axle suspension ball joints, shock

absorbers

²Check fluid levels for the following systems, cor-

rect as necessary

NOTE: Should there be a loss of fluid which cannot

be explained by regular use, trace and eliminate the

cause.

²Engine cooling system. Check corrosion inhibi-

tor/antifreeze, refill as necessary.

²Hydraulic brake system

²Battery

²Windshield washer system

Engine

²Fuel filter renewal - Every oil service

²Air cleaner with maintenance indicator:

²Check degree of contamination.

²Air cleaner filter element renewed as necessary.

Chassis and body

²Trailer coupling: Check operation, play and

retaining fixtures

²Secondary rubber springs: Visual check

²Tire pressures: Correct as necessary, including

spare tire

²Check thickness of brake pads

²Brake test

²Check condition of steering mechanism

²Heating/ventilation dust filter renewal

ADDITIONAL MAINTENANCE WORK

Automatic transmission once only at 80,000 miles / 128000

km

²Oil and filter change

During every second maintenance service

²Air cleaner without maintenance indicator:

²Air cleaner filter element renewal

²Check poly-V-belt for wear and signs of damage

During every fourth maintenance service

²Change rear axle fluid

ADDITIONAL MAINTENANCE WORK AFTER YEARS

Every 2 years

²Change brake fluid.

Every 3 years

²Air cleaner filter element renewal (note installa-

tion date)

Every 15 years or 100,000 miles

²Coolant renewal

²Note coolant composition

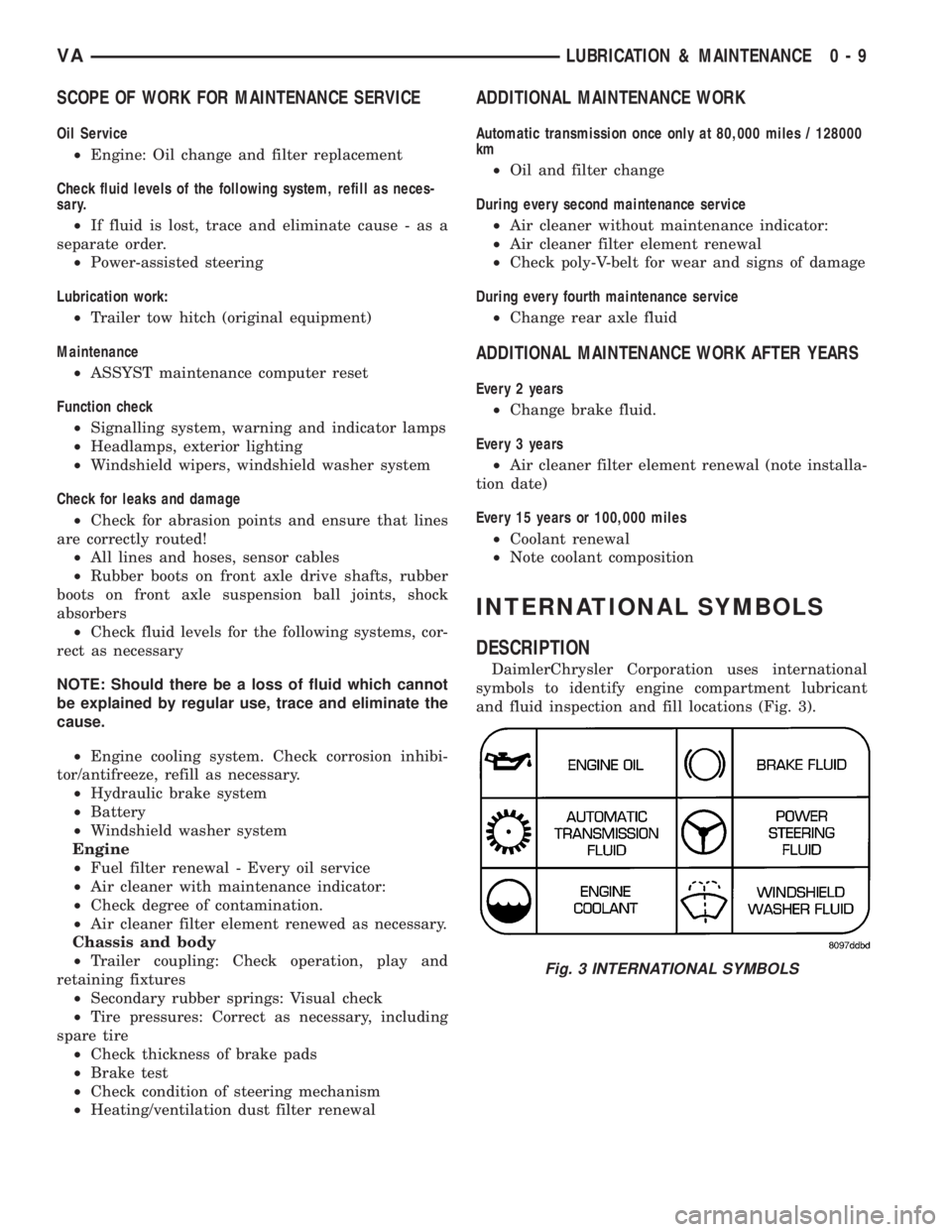

INTERNATIONAL SYMBOLS

DESCRIPTION

DaimlerChrysler Corporation uses international

symbols to identify engine compartment lubricant

and fluid inspection and fill locations (Fig. 3).

Fig. 3 INTERNATIONAL SYMBOLS

VALUBRICATION & MAINTENANCE 0 - 9

Page 725 of 2305

Page 726 of 2305

SUSPENSION

TABLE OF CONTENTS

page page

FRONT.................................1

REAR..................................11WHEEL ALIGNMENT......................17

FRONT

TABLE OF CONTENTS

page page

FRONT

SPECIFICATIONS - TORQUE CHART.........1

SPECIAL TOOLS

FRONT SUSPENSION...................2

BUSHINGS

REMOVAL.............................3

INSTALLATION..........................3

HUB / BEARING

DIAGNOSIS AND TESTING -...............4

REMOVAL.............................4

INSTALLATION..........................5

KNUCKLE

REMOVAL.............................5

INSTALLATION..........................6

LOWER BALL JOINT

REMOVAL.............................6

INSTALLATION..........................6

LOWER CONTROL ARM

REMOVAL.............................6

INSTALLATION..........................7SPRING

REMOVAL.............................7

INSTALLATION..........................8

SPRING CLAMP PLATES

REMOVAL.............................8

INSTALLATION..........................9

SPRING STOP PLATES

REMOVAL.............................9

INSTALLATION..........................9

STABILIZER BAR

DESCRIPTION..........................9

OPERATION............................9

REMOVAL.............................9

INSTALLATION..........................9

STABILIZER LINK

REMOVAL.............................10

INSTALLATION.........................10

STRUT

REMOVAL.............................10

INSTALLATION.........................10

FRONT

SPECIFICATIONS - TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Lower Ball Joint To Steer-

ing Knuckle280 206 Ð

Strut To Steering Knuckle 185 136 Ð

Strut To Body 100 74 Ð

Bottom Spring Clamp

Plate To Front Axle

M12 X 1.5 Bolt130 96 Ð

VASUSPENSION 2 - 1

Page 727 of 2305

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Bottom Spring Clamp

Plate To Front Axle

M10 Bolt65 48 Ð

Sway Bar Clamp To The

Front Axle30 22 Ð

Hexagon Socket Bolt For

Clamping Nut To Adjust

Wheel Bearing Play12 9 106

Lower Control Arm To

Front Axle Beam150 110 Ð

Stop Plate For Lower

Control Arm60 44 Ð

Outer Tie Rod End Nut 130 96 Ð

Outer Tie Rod End Nut

Jam Nut50 37 Ð

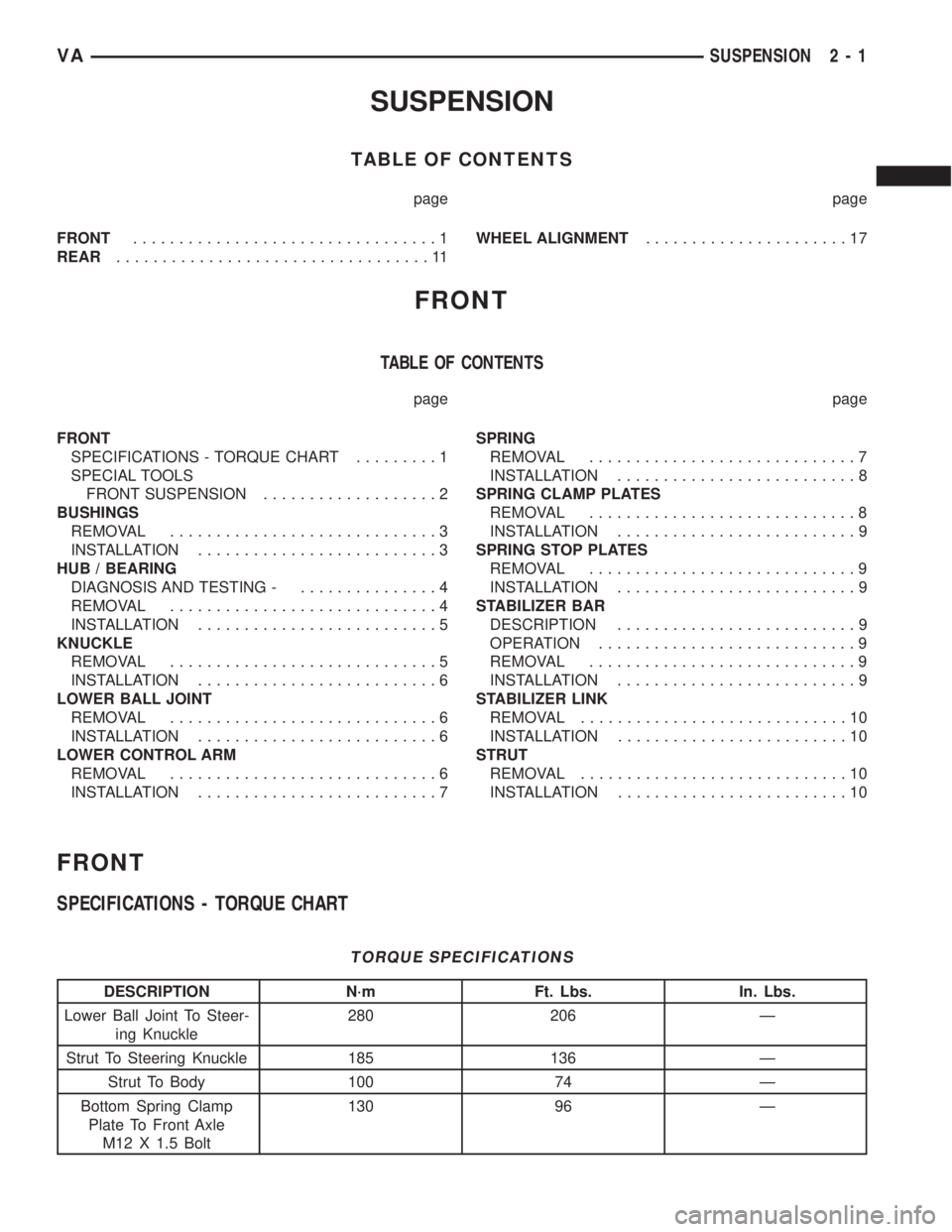

SPECIAL TOOLS

FRONT SUSPENSION

SPECIAL TOOL CROSS REFERENCE CHART

MB

TOOL #MILLER

TOOL #DESCRIPTION

N/A 9288 LEAF SPRING WEDGE

BLOCK

N/A 9294 LOWER BALL JOINT RE-

MOVE/INSTALLER

N/A 9302 BUSHING REMOVER /IN-

STALLER

N/A C-3894-A PULLER TIE ROD

730 589

02 33 009282 BALL JOINT SEPARA-

TOR

N/A C-4212F BALL JOINT PRESS

Puller Tie Rod C-3894-A

BALL JOINT PRESS - C-4212F

LOWER BALL JOINT REMOVE / INSTALL - 9294

2 - 2 FRONTVA

Page 728 of 2305

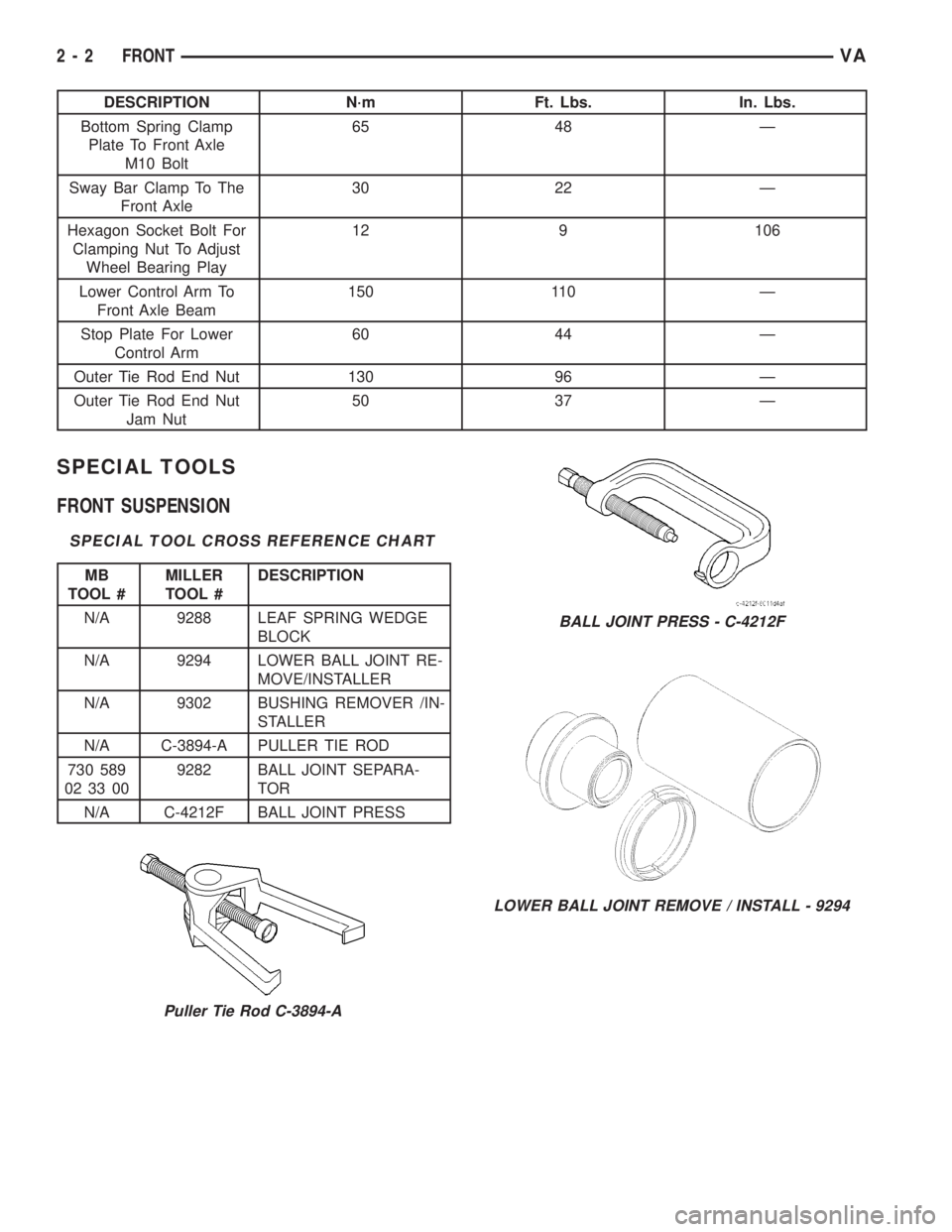

BUSHINGS

REMOVAL

(1) Remove the lower control arm (Refer to 2 -

SUSPENSION/FRONT/LOWER CONTROL ARM -

REMOVAL).

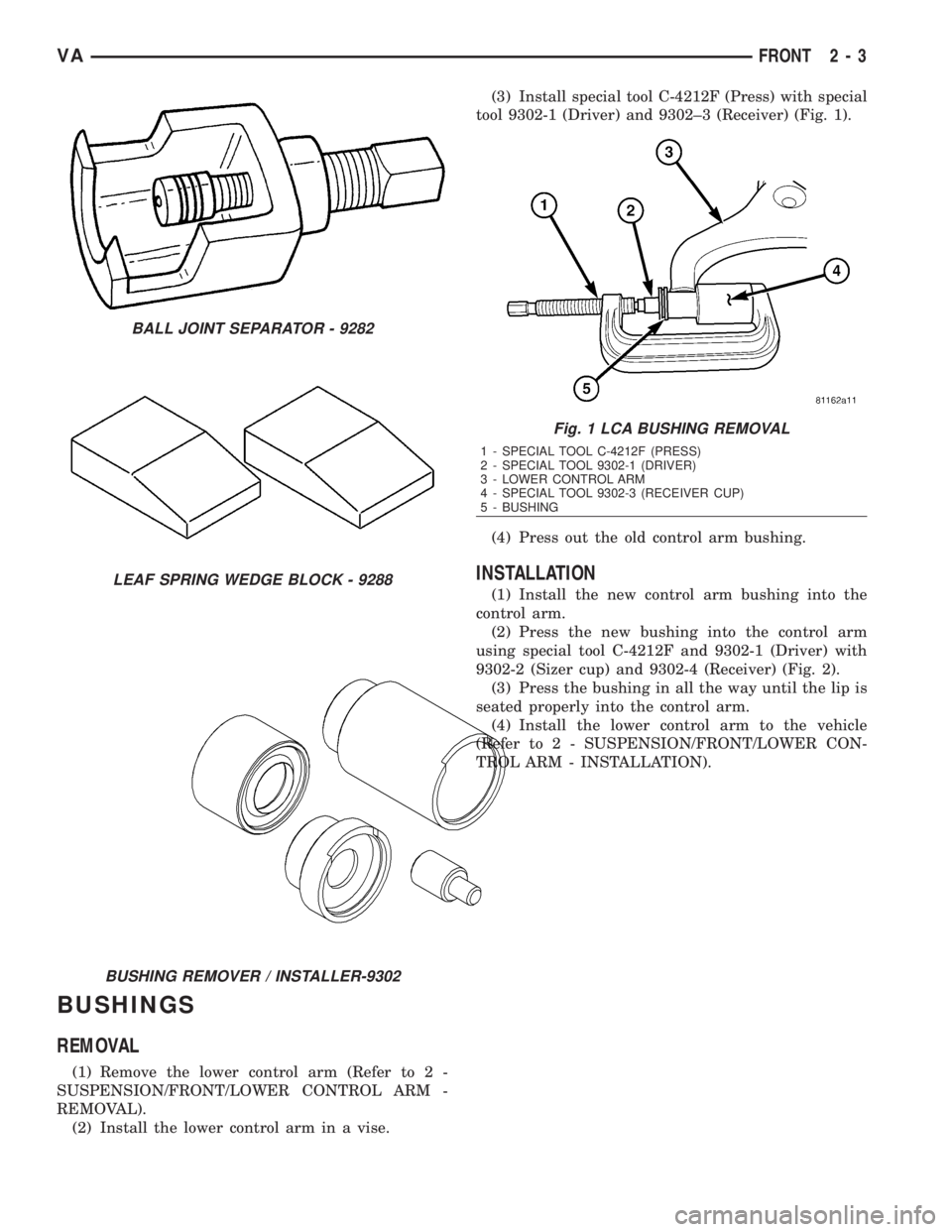

(2) Install the lower control arm in a vise.(3) Install special tool C-4212F (Press) with special

tool 9302-1 (Driver) and 9302±3 (Receiver) (Fig. 1).

(4) Press out the old control arm bushing.

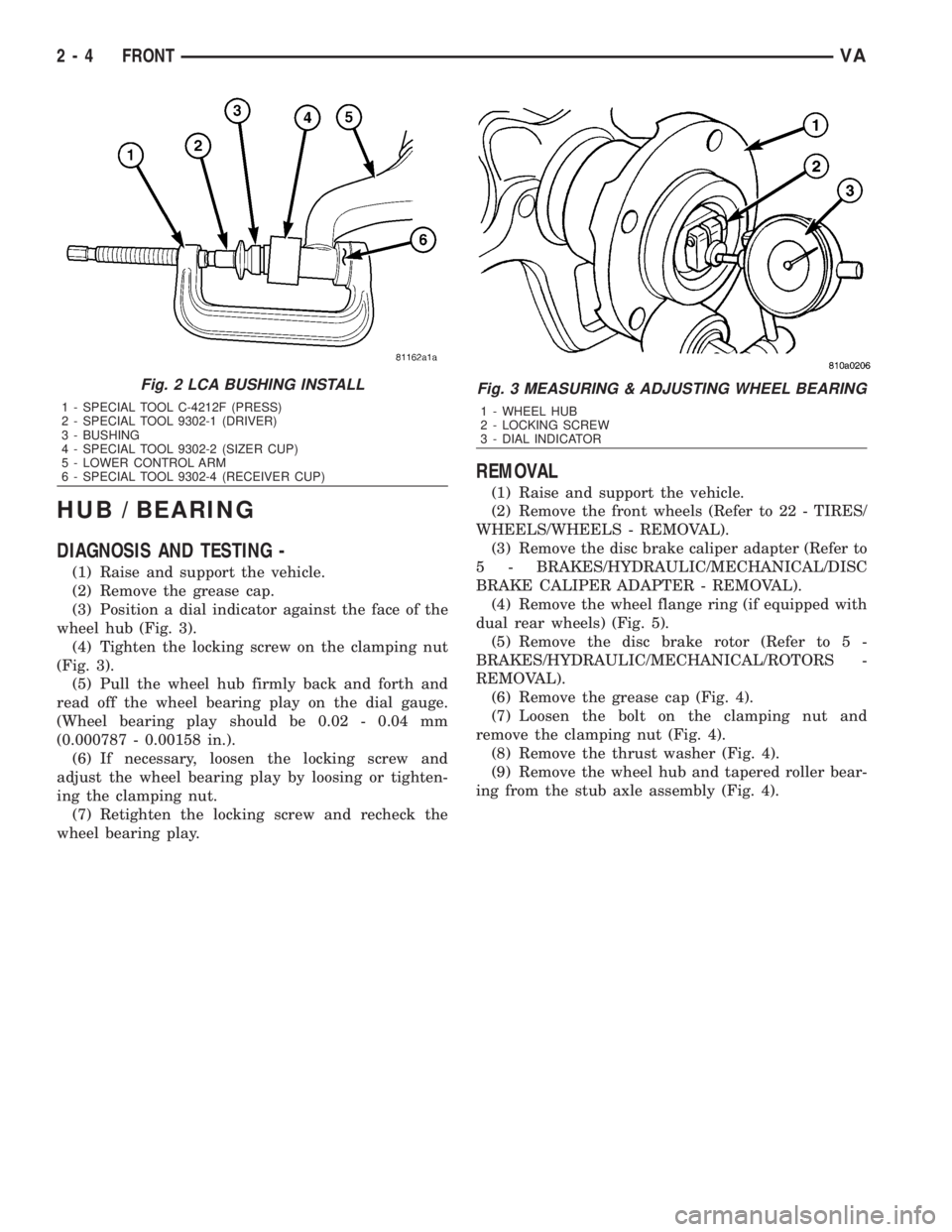

INSTALLATION

(1) Install the new control arm bushing into the

control arm.

(2) Press the new bushing into the control arm

using special tool C-4212F and 9302-1 (Driver) with

9302-2 (Sizer cup) and 9302-4 (Receiver) (Fig. 2).

(3) Press the bushing in all the way until the lip is

seated properly into the control arm.

(4) Install the lower control arm to the vehicle

(Refer to 2 - SUSPENSION/FRONT/LOWER CON-

TROL ARM - INSTALLATION).

BALL JOINT SEPARATOR - 9282

LEAF SPRING WEDGE BLOCK - 9288

BUSHING REMOVER / INSTALLER-9302

Fig. 1 LCA BUSHING REMOVAL

1 - SPECIAL TOOL C-4212F (PRESS)

2 - SPECIAL TOOL 9302-1 (DRIVER)

3 - LOWER CONTROL ARM

4 - SPECIAL TOOL 9302-3 (RECEIVER CUP)

5 - BUSHING

VAFRONT 2 - 3

Page 729 of 2305

HUB / BEARING

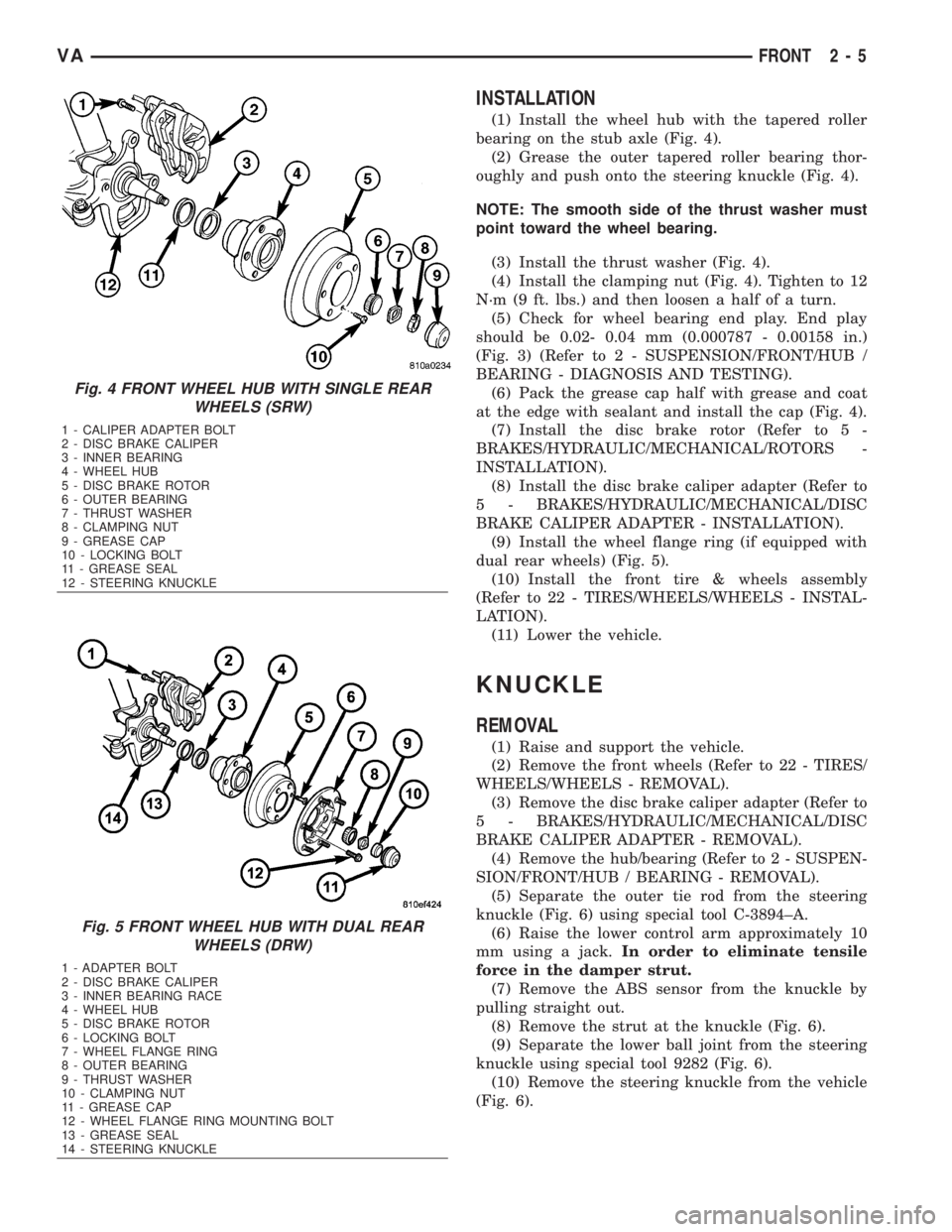

DIAGNOSIS AND TESTING -

(1) Raise and support the vehicle.

(2) Remove the grease cap.

(3) Position a dial indicator against the face of the

wheel hub (Fig. 3).

(4) Tighten the locking screw on the clamping nut

(Fig. 3).

(5) Pull the wheel hub firmly back and forth and

read off the wheel bearing play on the dial gauge.

(Wheel bearing play should be 0.02 - 0.04 mm

(0.000787 - 0.00158 in.).

(6) If necessary, loosen the locking screw and

adjust the wheel bearing play by loosing or tighten-

ing the clamping nut.

(7) Retighten the locking screw and recheck the

wheel bearing play.

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the front wheels (Refer to 22 - TIRES/

WHEELS/WHEELS - REMOVAL).

(3) Remove the disc brake caliper adapter (Refer to

5 - BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPER ADAPTER - REMOVAL).

(4) Remove the wheel flange ring (if equipped with

dual rear wheels) (Fig. 5).

(5) Remove the disc brake rotor (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/ROTORS -

REMOVAL).

(6) Remove the grease cap (Fig. 4).

(7) Loosen the bolt on the clamping nut and

remove the clamping nut (Fig. 4).

(8) Remove the thrust washer (Fig. 4).

(9) Remove the wheel hub and tapered roller bear-

ing from the stub axle assembly (Fig. 4).

Fig. 2 LCA BUSHING INSTALL

1 - SPECIAL TOOL C-4212F (PRESS)

2 - SPECIAL TOOL 9302-1 (DRIVER)

3 - BUSHING

4 - SPECIAL TOOL 9302-2 (SIZER CUP)

5 - LOWER CONTROL ARM

6 - SPECIAL TOOL 9302-4 (RECEIVER CUP)

Fig. 3 MEASURING & ADJUSTING WHEEL BEARING

1 - WHEEL HUB

2 - LOCKING SCREW

3 - DIAL INDICATOR

2 - 4 FRONTVA

Page 730 of 2305

INSTALLATION

(1) Install the wheel hub with the tapered roller

bearing on the stub axle (Fig. 4).

(2) Grease the outer tapered roller bearing thor-

oughly and push onto the steering knuckle (Fig. 4).

NOTE: The smooth side of the thrust washer must

point toward the wheel bearing.

(3) Install the thrust washer (Fig. 4).

(4) Install the clamping nut (Fig. 4). Tighten to 12

N´m (9 ft. lbs.) and then loosen a half of a turn.

(5) Check for wheel bearing end play. End play

should be 0.02- 0.04 mm (0.000787 - 0.00158 in.)

(Fig. 3) (Refer to 2 - SUSPENSION/FRONT/HUB /

BEARING - DIAGNOSIS AND TESTING).

(6) Pack the grease cap half with grease and coat

at the edge with sealant and install the cap (Fig. 4).

(7) Install the disc brake rotor (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/ROTORS -

INSTALLATION).

(8) Install the disc brake caliper adapter (Refer to

5 - BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPER ADAPTER - INSTALLATION).

(9) Install the wheel flange ring (if equipped with

dual rear wheels) (Fig. 5).

(10) Install the front tire & wheels assembly

(Refer to 22 - TIRES/WHEELS/WHEELS - INSTAL-

LATION).

(11) Lower the vehicle.

KNUCKLE

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the front wheels (Refer to 22 - TIRES/

WHEELS/WHEELS - REMOVAL).

(3) Remove the disc brake caliper adapter (Refer to

5 - BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPER ADAPTER - REMOVAL).

(4) Remove the hub/bearing (Refer to 2 - SUSPEN-

SION/FRONT/HUB / BEARING - REMOVAL).

(5) Separate the outer tie rod from the steering

knuckle (Fig. 6) using special tool C-3894±A.

(6) Raise the lower control arm approximately 10

mm using a jack.In order to eliminate tensile

force in the damper strut.

(7) Remove the ABS sensor from the knuckle by

pulling straight out.

(8) Remove the strut at the knuckle (Fig. 6).

(9) Separate the lower ball joint from the steering

knuckle using special tool 9282 (Fig. 6).

(10) Remove the steering knuckle from the vehicle

(Fig. 6).

Fig. 4 FRONT WHEEL HUB WITH SINGLE REAR

WHEELS (SRW)

1 - CALIPER ADAPTER BOLT

2 - DISC BRAKE CALIPER

3 - INNER BEARING

4 - WHEEL HUB

5 - DISC BRAKE ROTOR

6 - OUTER BEARING

7 - THRUST WASHER

8 - CLAMPING NUT

9 - GREASE CAP

10 - LOCKING BOLT

11 - GREASE SEAL

12 - STEERING KNUCKLE

Fig. 5 FRONT WHEEL HUB WITH DUAL REAR

WHEELS (DRW)

1 - ADAPTER BOLT

2 - DISC BRAKE CALIPER

3 - INNER BEARING RACE

4 - WHEEL HUB

5 - DISC BRAKE ROTOR

6 - LOCKING BOLT

7 - WHEEL FLANGE RING

8 - OUTER BEARING

9 - THRUST WASHER

10 - CLAMPING NUT

11 - GREASE CAP

12 - WHEEL FLANGE RING MOUNTING BOLT

13 - GREASE SEAL

14 - STEERING KNUCKLE

VAFRONT 2 - 5