fuel pump MERCEDES-BENZ SPRINTER 2006 Service Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 9 of 2305

TABLE OF CONTENTS - Continued

A/C COMPRESSOR CONTROL SHORTED LOW (ACTIVE)....................132

AIR OUTLET TEMP SENSOR HIGH OR OPEN (ACTIVE).....................134

AIR OUTLET TEMP SENSOR SHORTED LOW (ACTIVE).....................136

ATC FUNCTION TEST COOL FAILURE....................................138

ATC FUNCTION TEST FAILURE..........................................138

ATC FUNCTION TEST HEAT FAILURE.....................................138

AUX FAN RELAY CONTROL HIGH OR OPEN (ACTIVE)......................140

AUX FAN RELAY CONTROL SHORTED LOW (ACTIVE)......................142

BLOWER STAGE 1 HIGH OR OPEN (ACTIVE)..............................144

BLOWER STAGE 1 SHORTED LOW (ACTIVE)..............................146

CABIN HEATER CONTROL HIGH OR OPEN (ACTIVE).......................148

CABIN HEATER CONTROL SHORTED LOW (ACTIVE).......................150

CIRC PUMP CONTROL HIGH OR OPEN (ACTIVE)..........................152

CIRC PUMP CONTROL SHORTED LOW (ACTIVE)..........................154

EVAP TEMP SENSOR HIGH OR OPEN (ACTIVE)...........................156

EVAP TEMP SENSOR SHORTED LOW (ACTIVE)...........................158

NO COMMUNICATION BUS (ACTIVE).....................................160

NO COMMUNICATION WITH ECM (ACTIVE)...............................163

NO COMMUNICATION WITH IC (ACTIVE)..................................165

RECIRC AIR SOLENOID CONTROL HIGH OR OPEN (ACTIVE)................167

RECIRC AIR SOLENOID CONTROL SHORTED LOW (ACTIVE)................169

REFRIG PRESS SENSOR HIGH OR OPEN (ACTIVE)........................171

REFRIG PRESS SENSOR SHORTED LOW (ACTIVE)........................173

WATER CYCLE VALVE CONTROL HIGH OR OPEN (ACTIVE).................175

WATER CYCLE VALVE CONTROL SHORTED LOW (ACTIVE).................177

INSTRUMENT CLUSTER

AMBIENT TEMP SENSOR OPEN/SHORT TO BATTERY......................179

AMBIENT TEMP SENSOR SHORT TO GROUND............................181

FUEL LEVEL SENSOR OPEN/SHORT TO BATTERY.........................182

FUEL LEVEL SENSOR SHORT TO GROUND...............................184

INSTRUMENT CLUSTER INTERNAL FAILURE B1043........................185

INSTRUMENT CLUSTER INTERNAL FAILURE B1053........................186

INSTRUMENT CLUSTER OVERVOLTAGE..................................187

NO CAN COMMUNICATION WITH ABS....................................188

NO CAN COMMUNICATION WITH ECM...................................190

NO CAN COMMUNICATION WITH TCM....................................192

PREGLOW INDICATOR LAMP FAILURE...................................194

SRS INDICATOR LAMP FAILURE.........................................195

POWER DOOR LOCKS/RKE

DRIVER DOOR AJAR INDICATOR DRIVER CIRCUIT SHORT TO GROUND......196

PASSENGER DOOR AJAR INDICATOR DRIVER CIRCUIT SHORT TO GROUND .198

REPLACE CONTROL MODULE..........................................200

RKE INTERFACE CIRCUIT SHORT TO GROUND - CTM......................201

RKE INTERFACE CIRCUIT SHORT TO GROUND - SKREEM..................203

RKE INTERFACE CIRCUIT SHORT TO VOLTAGE - CTM.....................205

RKE INTERFACE CIRCUIT SHORT TO VOLTAGE - SKREEM..................206

THE ACM HAS UNLOCKED THE DOORS..................................208

UNKNOWN TROUBLE CODE UNKNOWN DTC TYPE 2......................209

*RKE INOPERATIVE....................................................210

*RKE POOR RANGE...................................................211

iv

Page 11 of 2305

TABLE OF CONTENTS - Continued

8.9VEHICLE THEFT SECURITY SYSTEM................................254

8.9.1SECURITY SYSTEM MODULE..............................254

8.9.2INTRUSION SENSORS....................................254

8.9.3SWITCHES..............................................255

8.9.4SIREN..................................................255

9.0 CONNECTOR PINOUTS................................................257

A/C AUXILIARY FAN....................................................257

AIR OUTLET TEMPERATURE SENSOR...................................257

AIRBAG CONTROL MODULE - YELLOW...................................257

AIRBAG SQUIB-DRIVER - YELLOW.......................................258

AIRBAG SQUIB-PASSENGER - YELLOW..................................258

AMBIENT TEMPERATURE SENSOR......................................258

AUTOMATIC TEMPERATURE CONTROL MODULE C1 - BROWN..............259

AUTOMATIC TEMPERATURE CONTROL MODULE C2.......................259

AUXILIARY HEATER CONTROL..........................................259

BLOWER MOTOR RESISTOR BLOCK.....................................259

BLOWER MOTOR-FRONT - BLACK.......................................260

C205 - YELLOW (DASH SIDE)...........................................260

C205 - YELLOW (MAIN BODY SIDE)......................................260

CENTRAL TIMER MODULE C1 - PINK.....................................260

CENTRAL TIMER MODULE C2 - LT. GREEN...............................261

CIRCULATION PUMP (CABIN HEATER MODULE)...........................261

CIRCULATION PUMP (REST SYSTEM)....................................261

CIRCULATION PUMP DIODE............................................261

CLOCKSPRING C2 - YELLOW...........................................262

CONTROLLER ANTILOCK BRAKE........................................262

CYLINDER LOCK SWITCH-DRIVER.......................................263

DATA LINK CONNECTOR - BLACK........................................263

DOOR LOCK MOTOR/AJAR SWITCH ASSEMBLY-DRIVER C1.................263

DOOR LOCK MOTOR/AJAR SWITCH ASSEMBLY-DRIVER C2.................263

DOOR LOCK MOTOR/AJAR SWITCH ASSEMBLY-LEFT SLIDING C1...........263

DOOR LOCK MOTOR/AJAR SWITCH ASSEMBLY-LEFT SLIDING C2...........264

DOOR LOCK MOTOR/AJAR SWITCH ASSEMBLY-PASSENGER C1............264

DOOR LOCK MOTOR/AJAR SWITCH ASSEMBLY-PASSENGER C2............264

DOOR LOCK MOTOR/AJAR SWITCH ASSEMBLY-REAR C1...................264

DOOR LOCK MOTOR/AJAR SWITCH ASSEMBLY-REAR C2...................264

DOOR LOCK MOTOR/AJAR SWITCH ASSEMBLY-RIGHT SLIDING C1..........265

DOOR LOCK MOTOR/AJAR SWITCH ASSEMBLY-RIGHT SLIDING C2..........265

DOSING PUMP........................................................265

ENGINE CONTROL MODULE C1 (EXCEPT OBD) - BLACK...................265

ENGINE CONTROL MODULE C2 (EXCEPT OBD) - BLACK...................266

ENGINE CONTROL MODULE C2 (OBD)...................................267

ENGINE CONTROL MODULE C3 (EXCEPT OBD) - BLACK...................268

EVAPORATOR TEMPERATURE SENSOR..................................269

FUEL LEVEL SENSOR..................................................269

FUSES (FUSE BLOCK NO. 1)............................................271

FUSE BLOCK NO. 1 C1.................................................271

FUSE BLOCK NO. 1 C2.................................................271

FUSE BLOCK NO. 1 C3 - BLACK.........................................272

FUSE BLOCK NO. 1 C4 - BLACK.........................................272

FUSE BLOCK NO. 1 C5 - BLACK.........................................272

vi

Page 20 of 2305

Compres SO Accel (Compressor Shut Off - Due

To Acceleration)

The Engine Control Module transmits this data. A

status of9YES9indicates that the compressor shut

off because of an acceleration request. A status of

9NO9indicates that there is no acceleration request.

If shut off due to an acceleration request, the

compress will switch on again after 20 seconds. In

addition, the original acceleration request can no

longer exist for the ECM to acknowledge a subse-

quent request. In the event of a CAN Bus commu-

nication failure,9NO9is displayed as a substitute

value.

Compres SO W/E-Off (Compressor Shut Off -

Due to Emergency Off)

The Engine Control Module transmits this data. A

status of9YES9indicates that the compressor shut

off because of an emergency off request. A status of

9NO9indicates that there is no emergency off re-

quest. In the event of a CAN Bus communication

failure, the last stored value is displayed as a

substitute value.

Auxiliary Fan

The ATC Module transmits this data. A status of

9ON9indicates that the auxiliary fan is operational.

A status of9OFF9indicates that the auxiliary fan is

not operational. The Auxiliary Fan normally oper-

ates when refrigerant head pressure exceeds 290

PSI and coolant temperature exceeds 221ÉF. In the

event of a CAN Bus communication failure, 257ÉF is

displayed for coolant temperature (in Sensors) and

the Auxiliary Fan will run continuously.

Light PB CTRL Module

This input displays a status of9Bright9for positive

dimmer switch operation and9Dimmed9for nega-

tive dimmer switch operation. In the event of a CAN

Bus communication failure,9Bright9is displayed.

3.3.2 CABIN HEATER MODULE (CHM) &

HEATER BOOSTER MODULE (HBM)

3.3.2.1 SYSTEM DESCRIPTION

WARNING: NEVER OPERATE THE HEATER

IN AN ENCLOSED AREA THAT DOES NOT

HAVE EXHAUST VENTILATION FACILITIES.

ALWAYS VENT THE HEATER'S EXHAUST

WHEN OPERATING THE HEATER. REFER TO

(VENTING THE HEATER'S EXHAUST(

BELOW FOR PROPER EXHAUST VENTING

INSTRUCTIONS. FAILURE TO FOLLOW

THESE INSTRUCTIONS CAN RESULT IN

PERSONAL INJURY OR DEATH.

WARNING: ALLOW THE HEATER ASSEMBLY TO

COOL BEFORE PERFORMING A COMPONENT

INSPECTION/REPAIR/REPLACEMENT. FAILURE

TO FOLLOW THESE INSTRUCTIONS CAN

RESULT IN PERSONAL INJURY OR DEATH.

WARNING: ALWAYS DISCONNECT THE

VEHICLE'S BATTERY PRIOR TO

PERFORMING ANY TYPE OF WORK ON THE

HEATER ASSEMBLY. FAILURE TO FOLLOW

THESE INSTRUCTIONS CAN RESULT IN

PERSONAL INJURY OR DEATH.

WARNING: NEVER ATTEMPT TO REPAIR THE

HEATER ASSEMBLY OR ANY OF ITS

INTERNAL COMPONENTS. ALWAYS

PERFORM HEATER COMPONENT

REPLACEMENT IN ACCORDANCE WITH THE

SERVICE INFORMATION. FAILURE TO

FOLLOW THESE INSTRUCTIONS CAN

RESULT IN PERSONAL INJURY OR DEATH.

CAUTION: Always Perform The Heater

Pre-Test (In The Diagnostic Procedures) Prior

To Performing Any Other Test On The Heater

For The Test Result To Be Valid.

NOTE: Do not disconnect the vehicle's

battery or the heater's main power-supply

while the heater is in operation or in

run-down mode. Failure to follow these

instructions may result in excess emissions

from the heater.

NOTE: Failure to prime the Dosing Pump

after draining the fuel line will prevent heater

activation during the first attempt to start the

unit. This may also set a Diagnostic Trouble

Code (DTC) in the control unit's memory. Do

not perform the Dosing Pump Priming

Procedure if an attempt was made to start the

heater without priming the Dosing Pump

first. This will put excess fuel in the heater

module and cause smoke to emit from the

heater's exhaust pipe when heater activation

occurs.

NOTE: Waxed fuel can obstruct the fuel line

and reduce flow. Check for the appropriate

winter grade fuel and replace as necessary.

The Cabin Heater Assembly and Heater Booster

Assembly are supplemental type heaters designed

to pre-heat the engine's coolant in order to supply

the vehicle's occupants with heat prior to the engine

7

GENERAL INFORMATION

Page 21 of 2305

reaching operating temperature. The heater's con-

trol unit controls and monitors combustion opera-

tion through various inputs and outputs that are

contained inside the heater assembly. The supple-

mental heater connects to the vehicle's heater hoses

and uses a separate fuel supply line and fuel pump

that connects to the vehicle's fuel tank. Unlike the

Heater Booster, the Cabin Heater Assembly has an

integral coolant pump which allows heater opera-

tion without the vehicle's engine running. In addi-

tion, a programmable timer module can also be

added to this system. Neither the Cabin Heater

Assembly nor the Heater Booster Assembly are

connected to the CAN Bus. Communication be-

tween the heater's control unit and the DRBIIIt

occurs through the Diagnostic Link Connector

(DLC) via a K-Line.

3.3.2.2 VENTING THE HEATER'S EXHAUST

WARNING: NEVER OPERATE THE HEATER

IN AN ENCLOSED AREA THAT DOES NOT

HAVE EXHAUST VENTILATION FACILITIES.

ALWAYS VENT THE HEATER'S EXHAUST

WHEN OPERATING THE HEATER. FAILURE

TO FOLLOW THESE INSTRUCTIONS CAN

RESULT IN PERSONAL INJURY OR DEATH.

WARNING:

ALLOW THE HEATER ASSEMBLY TO

COOL BEFORE PERFORMING A COMPONENT

INSPECTION/REPAIR/REPLACEMENT. FAILURE

TO FOLLOW THESE INSTRUCTIONS CAN

RESULT IN PERSONAL INJURY OR DEATH.

CAUTION: When using a powered exhaust

ventilation system, do not attach the exhaust

ventilation hose directly to the heater's

exhaust pipe. Too much suction can prevent

heater operation.

When using a powered exhaust ventilation sys-

tem, affix the ventilation hose to the heater's ex-

haust pipe or to the vehicle in such a manor that the

end of the ventilation hose remains approximately

three inches away from the end of the heater's

exhaust pipe.

When using a non-powered exhaust ventilation

system, affix the ventilation hose directly to the

heater's exhaust pipe.

3.3.2.3 SYSTEM DIAGNOSTICS

CAUTION: Always Perform The Heater

Pre-Test (In The Diagnostic Procedures) Prior

To Performing Any Other Test For The Test

Result To Be Valid.

Fault detection is through stored Diagnostic

Trouble Codes (DTCs). DTCs are displayed by the

DRBIIIt. The heater's control unit will store up to

five DTCs in its memory. If the control unit detects

a new fault in the system, one that is not already

stored in its memory, it will clear the oldest of the

five stored DTCs, and it will store the new fault's

DTC. If the control unit detects a reoccurrence of a

stored fault, it will overwrite that fault's DTC with

the most recent occurrence.

DIAGNOSTIC TIPS

SENSOR VALUES

Operating Voltage

The normal range for the Operating Voltage is from

10 volts to 15 volts. The value indicates the voltage

at the heater 's Fused B+ terminal.

Heating Capacity

The normal range for the heating capacity is from

0% to 100%. The value indicates the momentary

output of the auxiliary heater in % of the maximum

output.

Coolant Temperature

The value indicates the current coolant tempera-

ture.

Flame Sensor Resistance

The normal range for the Flame Sensor is from 750

ohms to 2270 ohms. The value indicates the mo-

mentary resistance of the Flame Sensor.

INPUT/OUTPUT STATUS

Dosing Pump

A status of9ON9indicates that the Dosing Pump is

operational. A status of9OFF9indicates the Dosing

Pump is not operational.

Glow Pin

A status of9ON9indicates that the Glow Pin is

energized. A status of9OFF9indicates the Glow Pin

is not energized.

Combustion Fan

A status of9ON9indicates that the Combustion Fan

is operational. A status of9OFF9indicates the

Combustion Fan is not operational.

Circulation Pump

A status of9ON9indicates that the Circulation

Pump is operational. A status of9OFF9indicates the

Circulation Pump is not operational.

Front End Blower

A status of9ON9indicates that the Blower Motor is

operational. A status of9OFF9indicates the Blower

Motor is not operational.

8

GENERAL INFORMATION

Page 101 of 2305

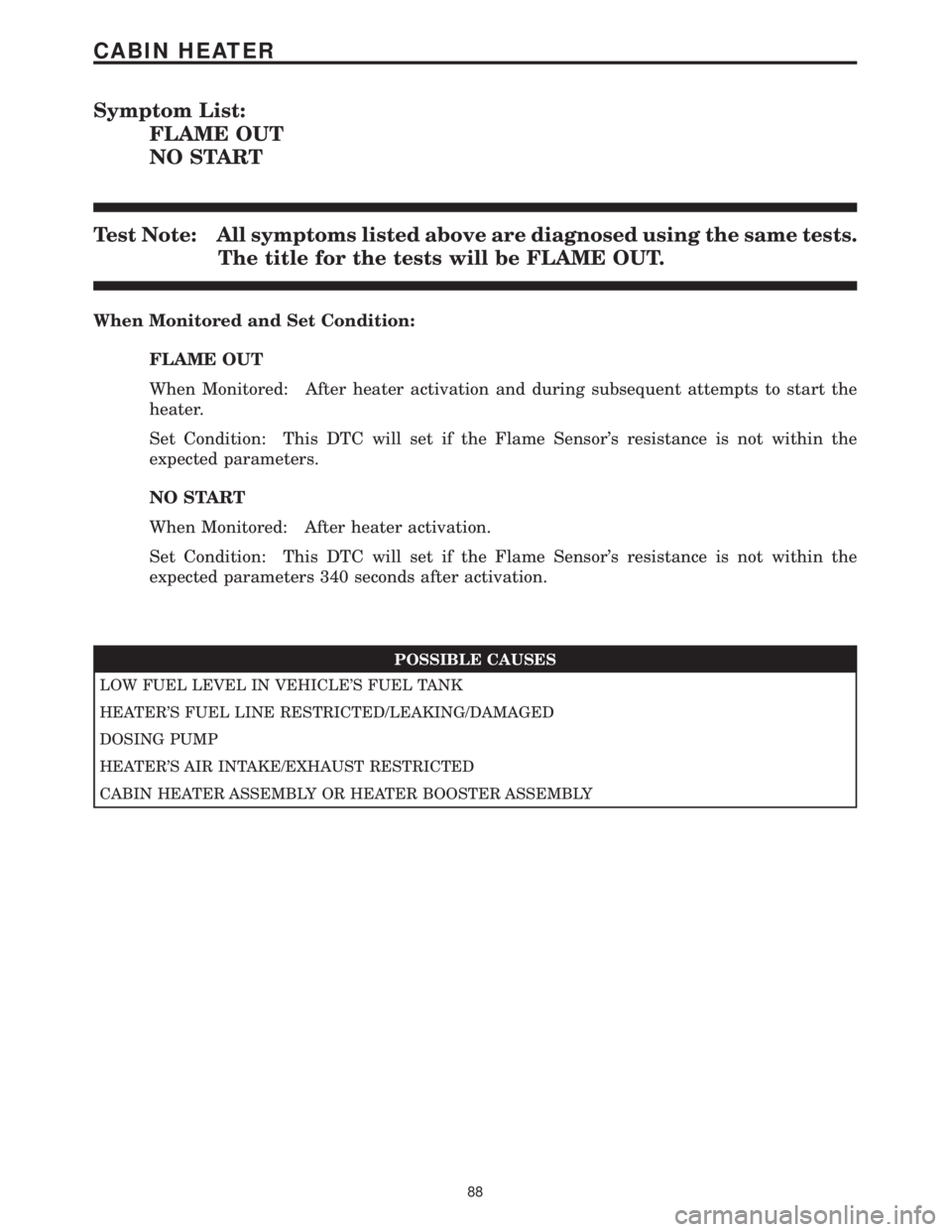

Symptom List:

FLAME OUT

NO START

Test Note: All symptoms listed above are diagnosed using the same tests.

The title for the tests will be FLAME OUT.

When Monitored and Set Condition:

FLAME OUT

When Monitored: After heater activation and during subsequent attempts to start the

heater.

Set Condition: This DTC will set if the Flame Sensor's resistance is not within the

expected parameters.

NO START

When Monitored: After heater activation.

Set Condition: This DTC will set if the Flame Sensor's resistance is not within the

expected parameters 340 seconds after activation.

POSSIBLE CAUSES

LOW FUEL LEVEL IN VEHICLE'S FUEL TANK

HEATER'S FUEL LINE RESTRICTED/LEAKING/DAMAGED

DOSING PUMP

HEATER'S AIR INTAKE/EXHAUST RESTRICTED

CABIN HEATER ASSEMBLY OR HEATER BOOSTER ASSEMBLY

88

CABIN HEATER

Page 103 of 2305

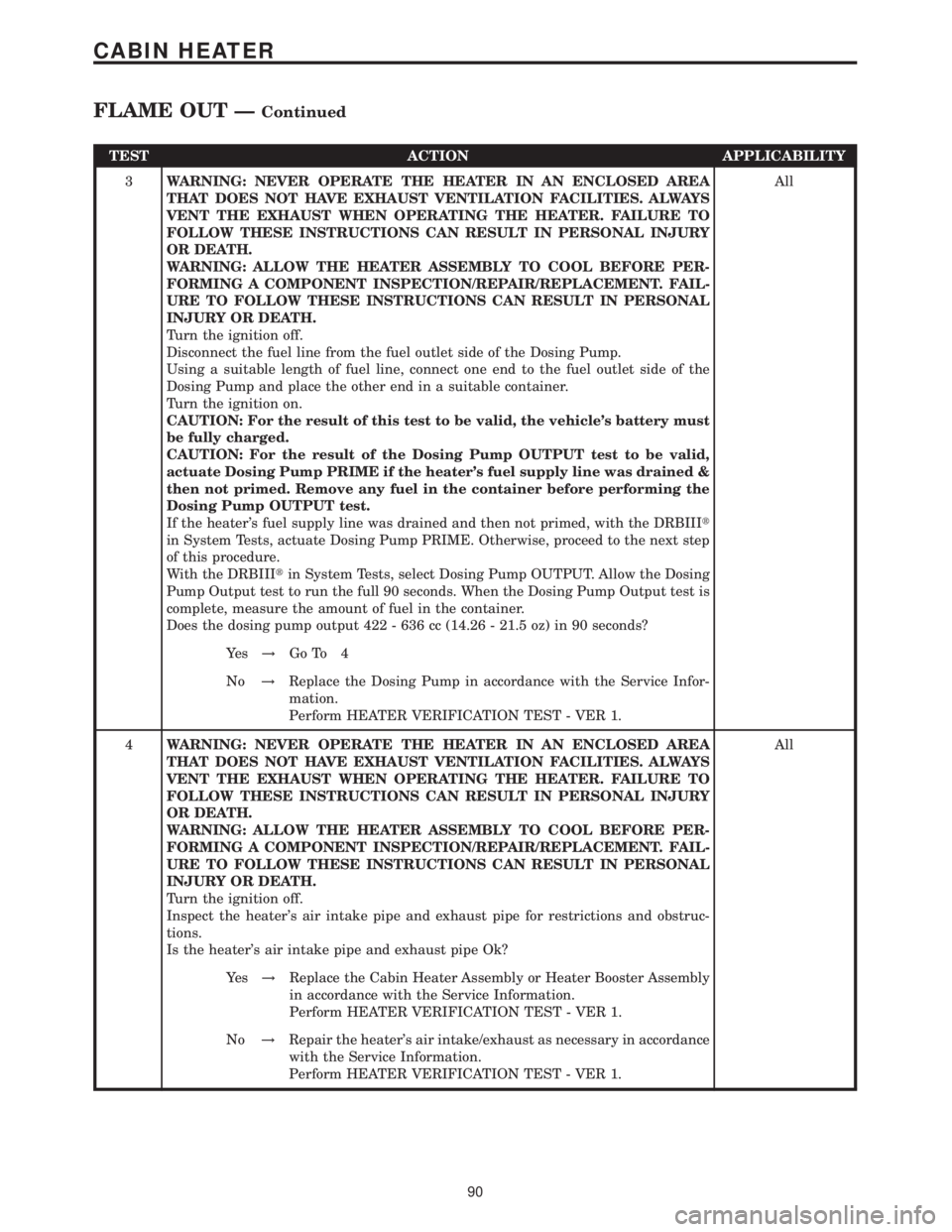

TEST ACTION APPLICABILITY

3WARNING: NEVER OPERATE THE HEATER IN AN ENCLOSED AREA

THAT DOES NOT HAVE EXHAUST VENTILATION FACILITIES. ALWAYS

VENT THE EXHAUST WHEN OPERATING THE HEATER. FAILURE TO

FOLLOW THESE INSTRUCTIONS CAN RESULT IN PERSONAL INJURY

OR DEATH.

WARNING: ALLOW THE HEATER ASSEMBLY TO COOL BEFORE PER-

FORMING A COMPONENT INSPECTION/REPAIR/REPLACEMENT. FAIL-

URE TO FOLLOW THESE INSTRUCTIONS CAN RESULT IN PERSONAL

INJURY OR DEATH.

Turn the ignition off.

Disconnect the fuel line from the fuel outlet side of the Dosing Pump.

Using a suitable length of fuel line, connect one end to the fuel outlet side of the

Dosing Pump and place the other end in a suitable container.

Turn the ignition on.

CAUTION: For the result of this test to be valid, the vehicle's battery must

be fully charged.

CAUTION: For the result of the Dosing Pump OUTPUT test to be valid,

actuate Dosing Pump PRIME if the heater's fuel supply line was drained &

then not primed. Remove any fuel in the container before performing the

Dosing Pump OUTPUT test.

If the heater's fuel supply line was drained and then not primed, with the DRBIIIt

in System Tests, actuate Dosing Pump PRIME. Otherwise, proceed to the next step

of this procedure.

With the DRBIIItin System Tests, select Dosing Pump OUTPUT. Allow the Dosing

Pump Output test to run the full 90 seconds. When the Dosing Pump Output test is

complete, measure the amount of fuel in the container.

Does the dosing pump output 422 - 636 cc (14.26 - 21.5 oz) in 90 seconds?All

Ye s!Go To 4

No!Replace the Dosing Pump in accordance with the Service Infor-

mation.

Perform HEATER VERIFICATION TEST - VER 1.

4WARNING: NEVER OPERATE THE HEATER IN AN ENCLOSED AREA

THAT DOES NOT HAVE EXHAUST VENTILATION FACILITIES. ALWAYS

VENT THE EXHAUST WHEN OPERATING THE HEATER. FAILURE TO

FOLLOW THESE INSTRUCTIONS CAN RESULT IN PERSONAL INJURY

OR DEATH.

WARNING: ALLOW THE HEATER ASSEMBLY TO COOL BEFORE PER-

FORMING A COMPONENT INSPECTION/REPAIR/REPLACEMENT. FAIL-

URE TO FOLLOW THESE INSTRUCTIONS CAN RESULT IN PERSONAL

INJURY OR DEATH.

Turn the ignition off.

Inspect the heater's air intake pipe and exhaust pipe for restrictions and obstruc-

tions.

Is the heater's air intake pipe and exhaust pipe Ok?All

Ye s!Replace the Cabin Heater Assembly or Heater Booster Assembly

in accordance with the Service Information.

Perform HEATER VERIFICATION TEST - VER 1.

No!Repair the heater's air intake/exhaust as necessary in accordance

with the Service Information.

Perform HEATER VERIFICATION TEST - VER 1.

90

CABIN HEATER

FLAME OUT ÐContinued

Page 195 of 2305

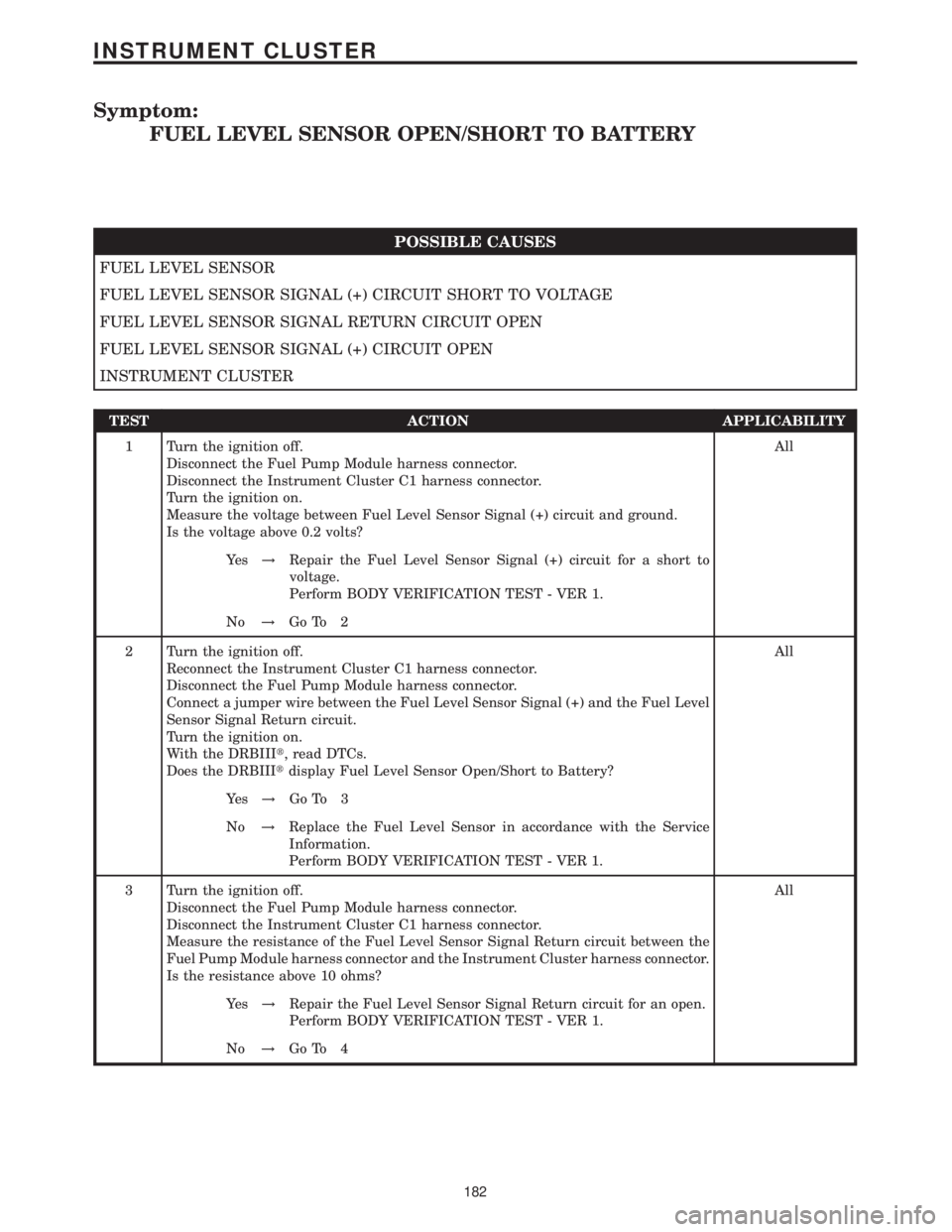

Symptom:

FUEL LEVEL SENSOR OPEN/SHORT TO BATTERY

POSSIBLE CAUSES

FUEL LEVEL SENSOR

FUEL LEVEL SENSOR SIGNAL (+) CIRCUIT SHORT TO VOLTAGE

FUEL LEVEL SENSOR SIGNAL RETURN CIRCUIT OPEN

FUEL LEVEL SENSOR SIGNAL (+) CIRCUIT OPEN

INSTRUMENT CLUSTER

TEST ACTION APPLICABILITY

1 Turn the ignition off.

Disconnect the Fuel Pump Module harness connector.

Disconnect the Instrument Cluster C1 harness connector.

Turn the ignition on.

Measure the voltage between Fuel Level Sensor Signal (+) circuit and ground.

Is the voltage above 0.2 volts?All

Ye s!Repair the Fuel Level Sensor Signal (+) circuit for a short to

voltage.

Perform BODY VERIFICATION TEST - VER 1.

No!Go To 2

2 Turn the ignition off.

Reconnect the Instrument Cluster C1 harness connector.

Disconnect the Fuel Pump Module harness connector.

Connect a jumper wire between the Fuel Level Sensor Signal (+) and the Fuel Level

Sensor Signal Return circuit.

Turn the ignition on.

With the DRBIIIt, read DTCs.

Does the DRBIIItdisplay Fuel Level Sensor Open/Short to Battery?All

Ye s!Go To 3

No!Replace the Fuel Level Sensor in accordance with the Service

Information.

Perform BODY VERIFICATION TEST - VER 1.

3 Turn the ignition off.

Disconnect the Fuel Pump Module harness connector.

Disconnect the Instrument Cluster C1 harness connector.

Measure the resistance of the Fuel Level Sensor Signal Return circuit between the

Fuel Pump Module harness connector and the Instrument Cluster harness connector.

Is the resistance above 10 ohms?All

Ye s!Repair the Fuel Level Sensor Signal Return circuit for an open.

Perform BODY VERIFICATION TEST - VER 1.

No!Go To 4

182

INSTRUMENT CLUSTER

Page 196 of 2305

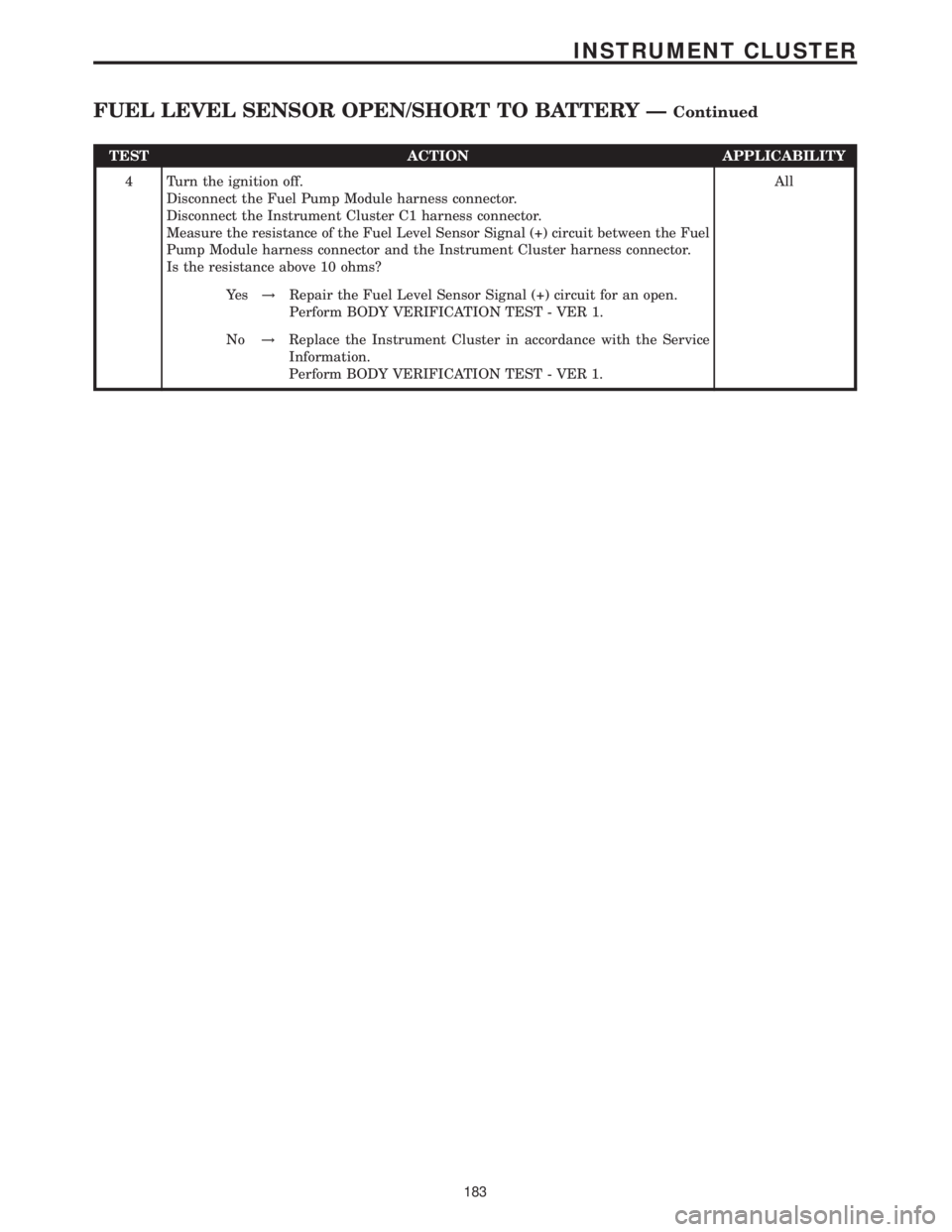

TEST ACTION APPLICABILITY

4 Turn the ignition off.

Disconnect the Fuel Pump Module harness connector.

Disconnect the Instrument Cluster C1 harness connector.

Measure the resistance of the Fuel Level Sensor Signal (+) circuit between the Fuel

Pump Module harness connector and the Instrument Cluster harness connector.

Is the resistance above 10 ohms?All

Ye s!Repair the Fuel Level Sensor Signal (+) circuit for an open.

Perform BODY VERIFICATION TEST - VER 1.

No!Replace the Instrument Cluster in accordance with the Service

Information.

Perform BODY VERIFICATION TEST - VER 1.

183

INSTRUMENT CLUSTER

FUEL LEVEL SENSOR OPEN/SHORT TO BATTERY ÐContinued

Page 197 of 2305

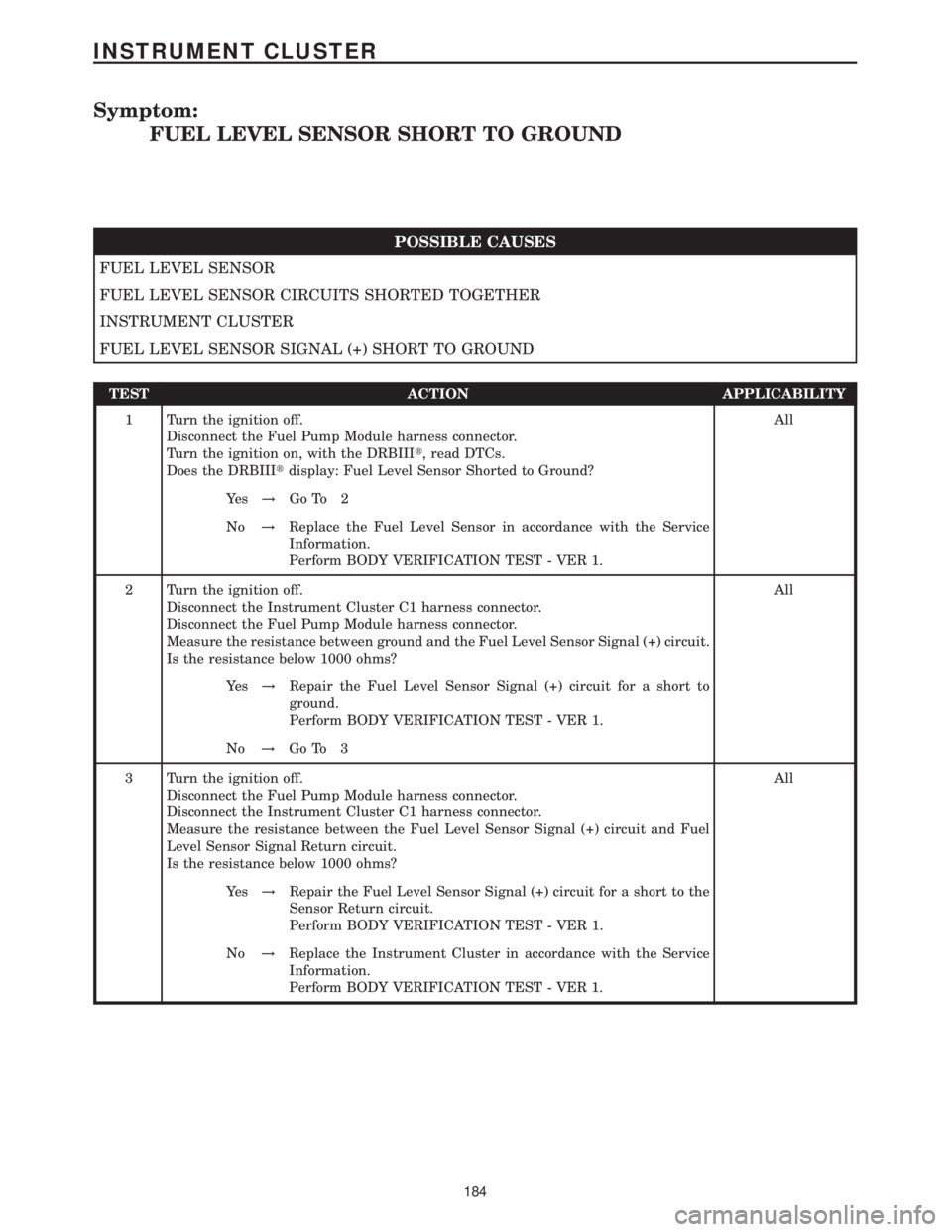

Symptom:

FUEL LEVEL SENSOR SHORT TO GROUND

POSSIBLE CAUSES

FUEL LEVEL SENSOR

FUEL LEVEL SENSOR CIRCUITS SHORTED TOGETHER

INSTRUMENT CLUSTER

FUEL LEVEL SENSOR SIGNAL (+) SHORT TO GROUND

TEST ACTION APPLICABILITY

1 Turn the ignition off.

Disconnect the Fuel Pump Module harness connector.

Turn the ignition on, with the DRBIIIt, read DTCs.

Does the DRBIIItdisplay: Fuel Level Sensor Shorted to Ground?All

Ye s!Go To 2

No!Replace the Fuel Level Sensor in accordance with the Service

Information.

Perform BODY VERIFICATION TEST - VER 1.

2 Turn the ignition off.

Disconnect the Instrument Cluster C1 harness connector.

Disconnect the Fuel Pump Module harness connector.

Measure the resistance between ground and the Fuel Level Sensor Signal (+) circuit.

Is the resistance below 1000 ohms?All

Ye s!Repair the Fuel Level Sensor Signal (+) circuit for a short to

ground.

Perform BODY VERIFICATION TEST - VER 1.

No!Go To 3

3 Turn the ignition off.

Disconnect the Fuel Pump Module harness connector.

Disconnect the Instrument Cluster C1 harness connector.

Measure the resistance between the Fuel Level Sensor Signal (+) circuit and Fuel

Level Sensor Signal Return circuit.

Is the resistance below 1000 ohms?All

Ye s!Repair the Fuel Level Sensor Signal (+) circuit for a short to the

Sensor Return circuit.

Perform BODY VERIFICATION TEST - VER 1.

No!Replace the Instrument Cluster in accordance with the Service

Information.

Perform BODY VERIFICATION TEST - VER 1.

184

INSTRUMENT CLUSTER

Page 259 of 2305

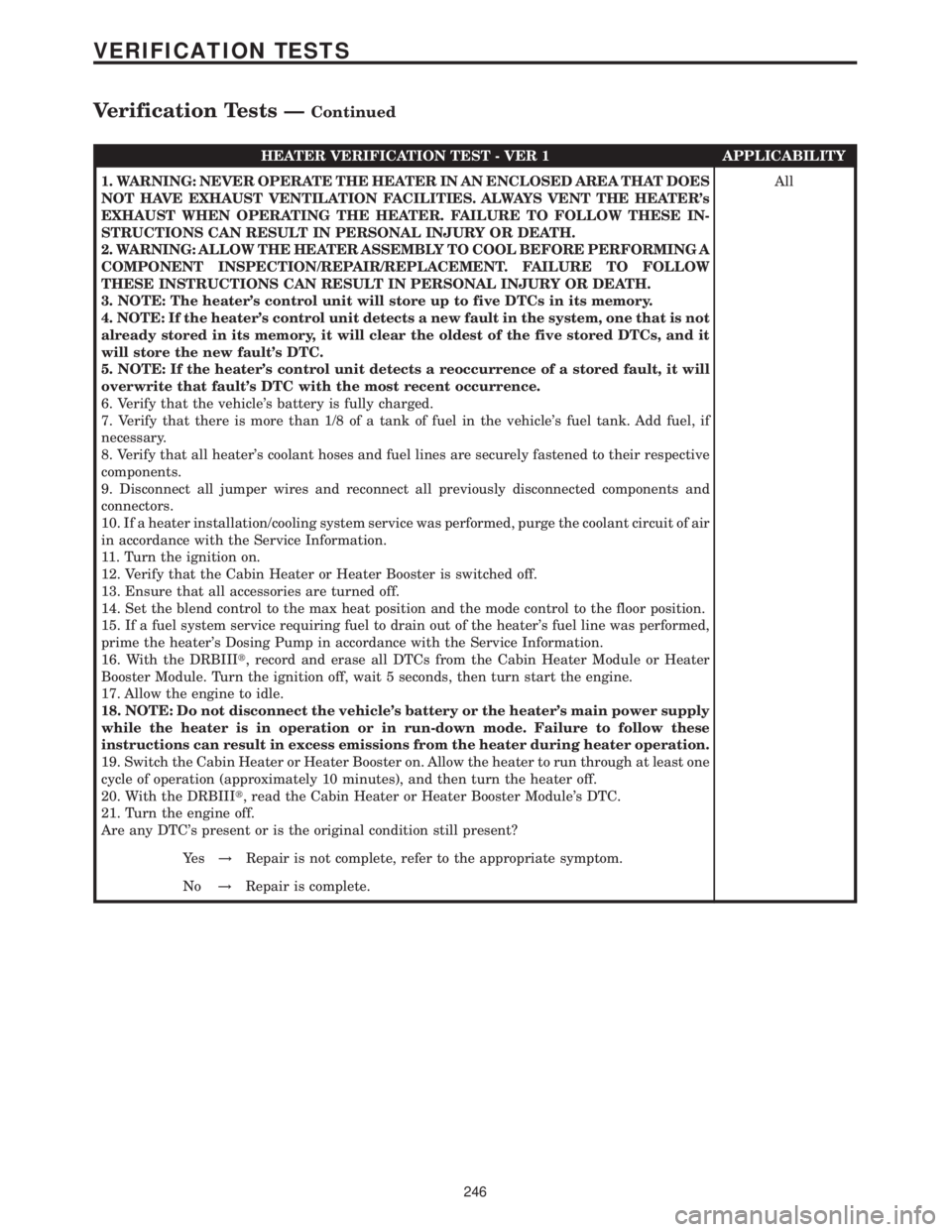

HEATER VERIFICATION TEST - VER 1 APPLICABILITY

1. WARNING: NEVER OPERATE THE HEATER IN AN ENCLOSED AREA THAT DOES

NOT HAVE EXHAUST VENTILATION FACILITIES. ALWAYS VENT THE HEATER's

EXHAUST WHEN OPERATING THE HEATER. FAILURE TO FOLLOW THESE IN-

STRUCTIONS CAN RESULT IN PERSONAL INJURY OR DEATH.

2. WARNING: ALLOW THE HEATER ASSEMBLY TO COOL BEFORE PERFORMING A

COMPONENT INSPECTION/REPAIR/REPLACEMENT. FAILURE TO FOLLOW

THESE INSTRUCTIONS CAN RESULT IN PERSONAL INJURY OR DEATH.

3. NOTE: The heater's control unit will store up to five DTCs in its memory.

4. NOTE: If the heater's control unit detects a new fault in the system, one that is not

already stored in its memory, it will clear the oldest of the five stored DTCs, and it

will store the new fault's DTC.

5. NOTE: If the heater's control unit detects a reoccurrence of a stored fault, it will

overwrite that fault's DTC with the most recent occurrence.

6. Verify that the vehicle's battery is fully charged.

7. Verify that there is more than 1/8 of a tank of fuel in the vehicle's fuel tank. Add fuel, if

necessary.

8. Verify that all heater's coolant hoses and fuel lines are securely fastened to their respective

components.

9. Disconnect all jumper wires and reconnect all previously disconnected components and

connectors.

10. If a heater installation/cooling system service was performed, purge the coolant circuit of air

in accordance with the Service Information.

11. Turn the ignition on.

12. Verify that the Cabin Heater or Heater Booster is switched off.

13. Ensure that all accessories are turned off.

14. Set the blend control to the max heat position and the mode control to the floor position.

15. If a fuel system service requiring fuel to drain out of the heater's fuel line was performed,

prime the heater's Dosing Pump in accordance with the Service Information.

16. With the DRBIIIt, record and erase all DTCs from the Cabin Heater Module or Heater

Booster Module. Turn the ignition off, wait 5 seconds, then turn start the engine.

17. Allow the engine to idle.

18. NOTE: Do not disconnect the vehicle's battery or the heater's main power supply

while the heater is in operation or in run-down mode. Failure to follow these

instructions can result in excess emissions from the heater during heater operation.

19. Switch the Cabin Heater or Heater Booster on. Allow the heater to run through at least one

cycle of operation (approximately 10 minutes), and then turn the heater off.

20. With the DRBIIIt, read the Cabin Heater or Heater Booster Module's DTC.

21. Turn the engine off.

Are any DTC's present or is the original condition still present?All

Ye s!Repair is not complete, refer to the appropriate symptom.

No!Repair is complete.

246

VERIFICATION TESTS

Verification Tests ÐContinued