fuse diagram MERCEDES-BENZ SPRINTER 2006 Service Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 12 of 2305

TABLE OF CONTENTS - Continued

FUSES (FUSE BLOCK NO. 2)............................................274

FUSES (FUSE BLOCK NO. 3)............................................276

FUSES (FUSE/RELAY BLOCK)...........................................278

HOOD AJAR SWITCH - BLACK...........................................278

HORN (VTSS).........................................................278

IGNITION LOCK SWITCH - BLACK........................................278

INSTRUMENT CLUSTER C1.............................................279

INSTRUMENT CLUSTER C2 - WHITE.....................................279

INTRUSION SENSOR NO. 1 - BLACK.....................................279

INTRUSION SENSOR NO. 2 - BLACK.....................................279

INTRUSION SENSOR NO. 3 - BLACK.....................................280

MASTER DOOR LOCK SWITCH..........................................280

PANIC ALARM SWITCH - BLACK.........................................280

FUSES (PDC).........................................................281

RADIO C1 - BLACK....................................................282

RADIO C2............................................................282

RECIRCULATED AIR SOLENOID VALVE...................................282

REFRIGERANT PRESSURE SENSOR.....................................282

A/C AUXILIARY FAN RELAY (RELAY BLOCK)...............................284

CIRCULATION PUMP RELAY-CABIN HEATER MODULE (RELAY BLOCK).......284

D+ RELAY NO. 2 (RELAY BLOCK)........................................284

FAN STAGE 1 RELAY (RELAY BLOCK)....................................284

OPTIONAL EQUIPMENT RELAY (RELAY BLOCK)...........................284

REMOTE KEYLESS ENTRY ANTENNA....................................284

SEAT BELT SWITCH...................................................284

SEAT BELT TENSIONER-DRIVER - YELLOW...............................285

SEAT BELT TENSIONER-PASSENGER - YELLOW...........................285

SECURITY SYSTEM MODULE C1 - BROWN...............................285

SECURITY SYSTEM MODULE C2 - LT. GREEN.............................286

SENTRY KEY REMOTE ENTRY MODULE (SKREEM)........................286

SHIFTER ASSEMBLY - BLACK...........................................286

SIREN - BLACK.......................................................286

STEERING ANGLE SENSOR............................................287

TOWING/INTRUSION SENSOR ON/OFF SWITCH...........................287

TRANSMISSION CONTROL MODULE C1 - BLACK..........................287

TRANSMISSION CONTROL MODULE C2 - BLACK..........................288

WATER CYCLE VALVE..................................................288

WINDOW DEFOGGER-LEFT REAR.......................................288

WINDOW DEFOGGER-RIGHT REAR......................................288

10.0 SCHEMATIC DIAGRAMS................................................289

10.1AIRBAG SYSTEM.................................................289

10.2COMMUNICATION................................................290

10.2.1COMMUNICATION K-LINES................................290

10.2.2CAN BUS NETWORK......................................291

10.3HEATING & A/C...................................................292

10.3.1AUTOMATIC TEMPERATURE CONTROL (ATC)................292

10.3.2CABIN HEATER MODULE (CHM)............................293

10.3.3HEATER BOOSTER MODULE (HBM).........................294

10.4INSTRUMENT CLUSTER...........................................295

vii

Page 159 of 2305

Symptom:

BLOWER STAGE 1 SHORTED LOW (ACTIVE)

POSSIBLE CAUSES

BLOWER MOTOR FUSE

BLOWER MOTOR

BLOWER MOTOR DRIVER CIRCUIT(S) SHORTED TO GROUND

FUSED B+ CIRCUIT SHORTED TO GROUND

BLOWER MOTOR RESISTOR BLOCK

AUTOMATIC TEMPERATURE CONTROL (ATC)

TEST ACTION APPLICABILITY

1 Turn the ignition off.

Remove and inspect the Blower Motor Fuse, and replace it if necessary.

NOTE: All of the following criteria must be met in order to successfully run

the ATC Function Test.

Place the shift lever in Park.

Turn the ignition on.

With the DRBIIIt, record and erase ATC DTC's.

Start the engine. Allow the engine to reach normal operating temperature.

Set the blower to high speed.

Press the Air Conditioning switch On.

With the DRBIIIt, verify that the ambient temperature is above 59ÉF (15ÉC), the

refrigerant pressure is between 29 and 348 PSI (2 and 24 bar), the evaporator

temperature is above 36.5ÉF (2.5ÉC), and the coolant temperature is above 158ÉF

(70ÉC).

With the DRBIIItin Automatic Temperature Control (ATC), select System Tests and

select ATC Function Test. When the ATC Function Test is complete, proceed as

follows:

With the DRBIIIt, read the active ATC DTCs.

Does the DRBIIItdisplay: BLOWER STAGE ONE SHORTED LOW?All

Ye s!Go To 2

No!Refer to the wiring diagrams located in the service information to

help isolate a possible intermittent short to ground condition.

Perform BODY VERIFICATION TEST - VER 1.

2 Turn the ignition off.

Disconnect the Blower Motor harness connector.

Connect a fused jumper wire between Battery (+) and Blower Motor cavity 1.

Connect a jumper wire between ground and Blower Motor cavity 2.

Does the Blower Motor run at full speed?All

Ye s!Go To 3

No!Replace the Blower Motor in accordance with the Service Infor-

mation. Remove and inspect the Blower Motor Fuse, and replace

it if necessary.

Perform BODY VERIFICATION TEST - VER 1.

146

HEATING & A/C

Page 233 of 2305

Symptom:

INTRUSION SENSOR 1 CIRCUIT OPEN/SHORT TO GROUND

When Monitored and Set Condition:

INTRUSION SENSOR 1 CIRCUIT OPEN/SHORT TO GROUND

When Monitored: Whenever the battery voltage is above 10.0 volts and the Security

System Module is connected.

Set Condition: The Security System Module detects the incorrect voltage on the Intrusion

Sensor circuit.

POSSIBLE CAUSES

DTC PRESENT

FUSE 2 IN FUSE BLOCK 3

FUSED B(+) WIRE OPEN

GROUND CIRCUIT OPEN

INTRUSION SENSOR 1 SIGNAL SHORTED

INTRUSION SENSOR 1 SIGNAL CIRCUIT OPEN

INTRUSION SENSOR INTERFACE WIRE SHORTED

INTRUSION SENSOR INTERFACE WIRE OPEN

INTRUSION SENSOR

TEST ACTION APPLICABILITY

1 With the DRBIIIt, record and erase DTC's.

Remove the ignition key.

Close and lock all doors and set the Vehicle Theft Security System.

Wait 1 minute.

Disarm the Vehicle Theft System.

With the DRBIIIt, read DTC's.

Does the DRBIIItdisplay the same DTC?All

Ye s!Go To 2

No!Using the wiring diagram/schematic as a guide, inspect the

wiring and connectors for an intermittent condition.

Perform BODY VERIFICATION TEST - VER 1.

2 Check Fuse 2 in Fuse Block 3.

Is the fuse open?All

Ye s!Check for a short to ground and replace the fuse.

Perform BODY VERIFICATION TEST - VER 1.

No!Go To 3

220

VEHICLE THEFT/SECURITY

Page 236 of 2305

Symptom:

INTRUSION SENSOR 2 CIRCUIT OPEN/SHORT TO GROUND

When Monitored and Set Condition:

INTRUSION SENSOR 2 CIRCUIT OPEN/SHORT TO GROUND

When Monitored: Whenever the battery voltage is above 10.0 volts and the Security

System Module is connected.

Set Condition: The Security System Module detects the incorrect voltage on the Intrusion

Sensor circuit.

POSSIBLE CAUSES

DTC PRESENT

FUSE 2 IN FUSE BLOCK 3

FUSED B(+) WIRE OPEN

GROUND CIRCUIT OPEN

INTRUSION SENSOR 2 SIGNAL SHORTED

INTRUSION SENSOR 2 SIGNAL CIRCUIT OPEN

INTRUSION SENSOR INTERFACE WIRE SHORTED

INTRUSION SENSOR INTERFACE WIRE OPEN

INTRUSION SENSOR

TEST ACTION APPLICABILITY

1 With the DRBIIIt, record and erase DTC's.

Remove the ignition key.

Close and lock all doors and set the Vehicle Theft Security System.

Wait 1 minute.

Disarm the Vehicle Theft System.

With the DRBIIIt, read DTC's.

Does the DRBIIItdisplay the same DTC?All

Ye s!Go To 2

No!Using the wiring diagram/schematic as a guide, inspect the

wiring and connectors for an intermittent condition.

Perform BODY VERIFICATION TEST - VER 1.

2 Check Fuse 2 in Fuse Block 3.

Is the fuse open?All

Ye s!Check for a short to ground and replace the fuse.

Perform BODY VERIFICATION TEST - VER 1.

No!Go To 3

223

VEHICLE THEFT/SECURITY

Page 239 of 2305

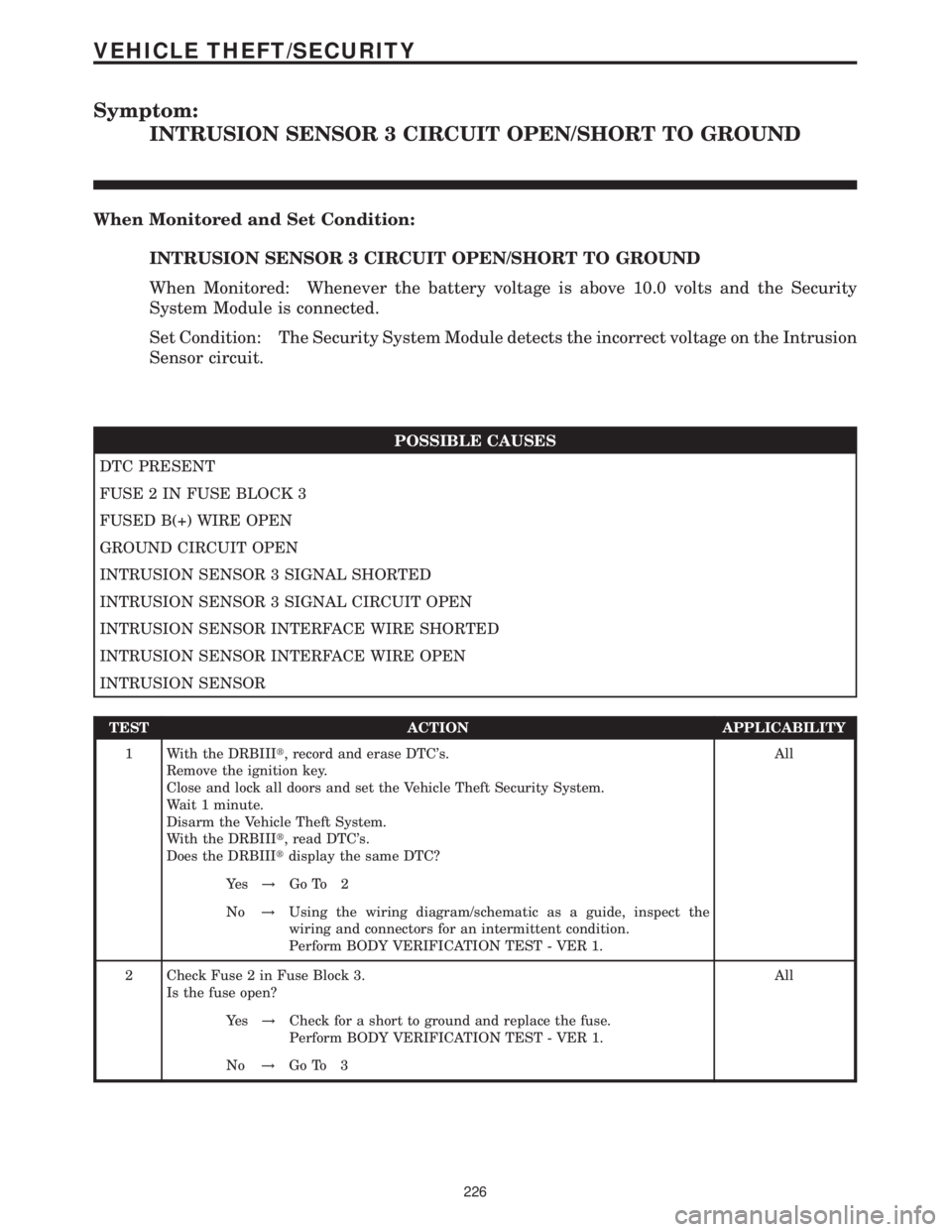

Symptom:

INTRUSION SENSOR 3 CIRCUIT OPEN/SHORT TO GROUND

When Monitored and Set Condition:

INTRUSION SENSOR 3 CIRCUIT OPEN/SHORT TO GROUND

When Monitored: Whenever the battery voltage is above 10.0 volts and the Security

System Module is connected.

Set Condition: The Security System Module detects the incorrect voltage on the Intrusion

Sensor circuit.

POSSIBLE CAUSES

DTC PRESENT

FUSE 2 IN FUSE BLOCK 3

FUSED B(+) WIRE OPEN

GROUND CIRCUIT OPEN

INTRUSION SENSOR 3 SIGNAL SHORTED

INTRUSION SENSOR 3 SIGNAL CIRCUIT OPEN

INTRUSION SENSOR INTERFACE WIRE SHORTED

INTRUSION SENSOR INTERFACE WIRE OPEN

INTRUSION SENSOR

TEST ACTION APPLICABILITY

1 With the DRBIIIt, record and erase DTC's.

Remove the ignition key.

Close and lock all doors and set the Vehicle Theft Security System.

Wait 1 minute.

Disarm the Vehicle Theft System.

With the DRBIIIt, read DTC's.

Does the DRBIIItdisplay the same DTC?All

Ye s!Go To 2

No!Using the wiring diagram/schematic as a guide, inspect the

wiring and connectors for an intermittent condition.

Perform BODY VERIFICATION TEST - VER 1.

2 Check Fuse 2 in Fuse Block 3.

Is the fuse open?All

Ye s!Check for a short to ground and replace the fuse.

Perform BODY VERIFICATION TEST - VER 1.

No!Go To 3

226

VEHICLE THEFT/SECURITY

Page 248 of 2305

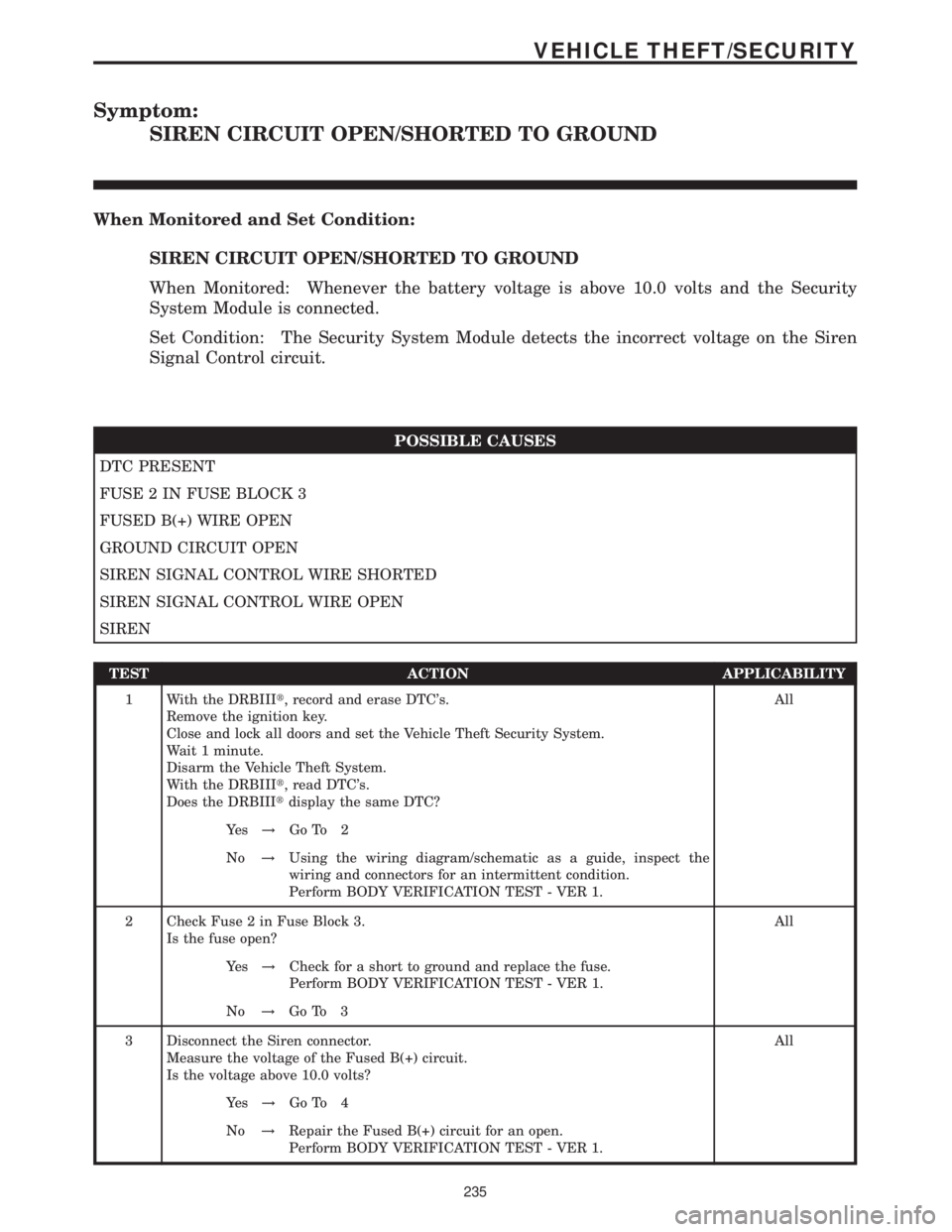

Symptom:

SIREN CIRCUIT OPEN/SHORTED TO GROUND

When Monitored and Set Condition:

SIREN CIRCUIT OPEN/SHORTED TO GROUND

When Monitored: Whenever the battery voltage is above 10.0 volts and the Security

System Module is connected.

Set Condition: The Security System Module detects the incorrect voltage on the Siren

Signal Control circuit.

POSSIBLE CAUSES

DTC PRESENT

FUSE 2 IN FUSE BLOCK 3

FUSED B(+) WIRE OPEN

GROUND CIRCUIT OPEN

SIREN SIGNAL CONTROL WIRE SHORTED

SIREN SIGNAL CONTROL WIRE OPEN

SIREN

TEST ACTION APPLICABILITY

1 With the DRBIIIt, record and erase DTC's.

Remove the ignition key.

Close and lock all doors and set the Vehicle Theft Security System.

Wait 1 minute.

Disarm the Vehicle Theft System.

With the DRBIIIt, read DTC's.

Does the DRBIIItdisplay the same DTC?All

Ye s!Go To 2

No!Using the wiring diagram/schematic as a guide, inspect the

wiring and connectors for an intermittent condition.

Perform BODY VERIFICATION TEST - VER 1.

2 Check Fuse 2 in Fuse Block 3.

Is the fuse open?All

Ye s!Check for a short to ground and replace the fuse.

Perform BODY VERIFICATION TEST - VER 1.

No!Go To 3

3 Disconnect the Siren connector.

Measure the voltage of the Fused B(+) circuit.

Is the voltage above 10.0 volts?All

Ye s!Go To 4

No!Repair the Fused B(+) circuit for an open.

Perform BODY VERIFICATION TEST - VER 1.

235

VEHICLE THEFT/SECURITY

Page 422 of 2305

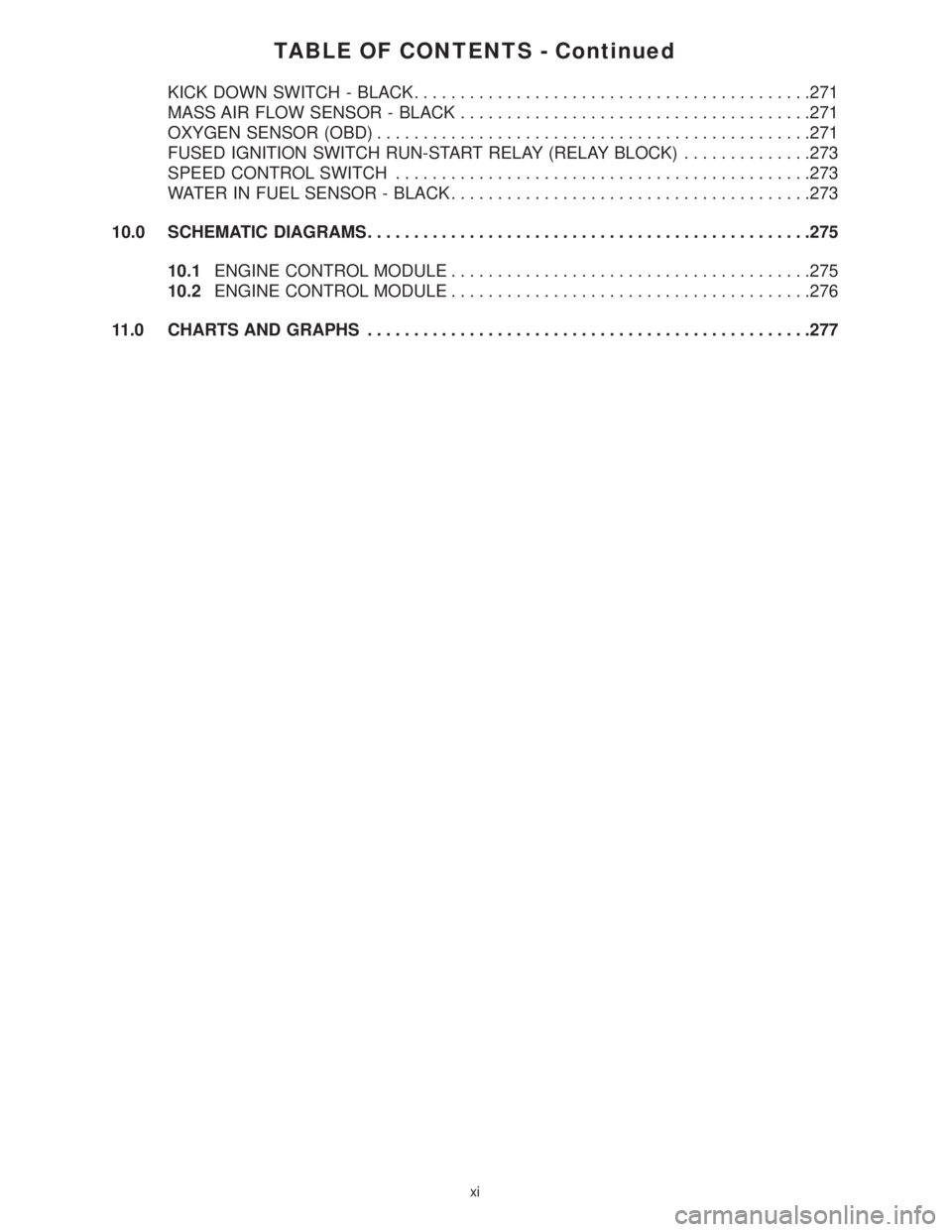

TABLE OF CONTENTS - Continued

KICK DOWN SWITCH - BLACK...........................................271

MASS AIR FLOW SENSOR - BLACK......................................271

OXYGEN SENSOR (OBD)...............................................271

FUSED IGNITION SWITCH RUN-START RELAY (RELAY BLOCK)..............273

SPEED CONTROL SWITCH.............................................273

WATER IN FUEL SENSOR - BLACK.......................................273

10.0 SCHEMATIC DIAGRAMS................................................275

10.1ENGINE CONTROL MODULE.......................................275

10.2ENGINE CONTROL MODULE.......................................276

11.0 CHARTS AND GRAPHS................................................277

xi

Page 660 of 2305

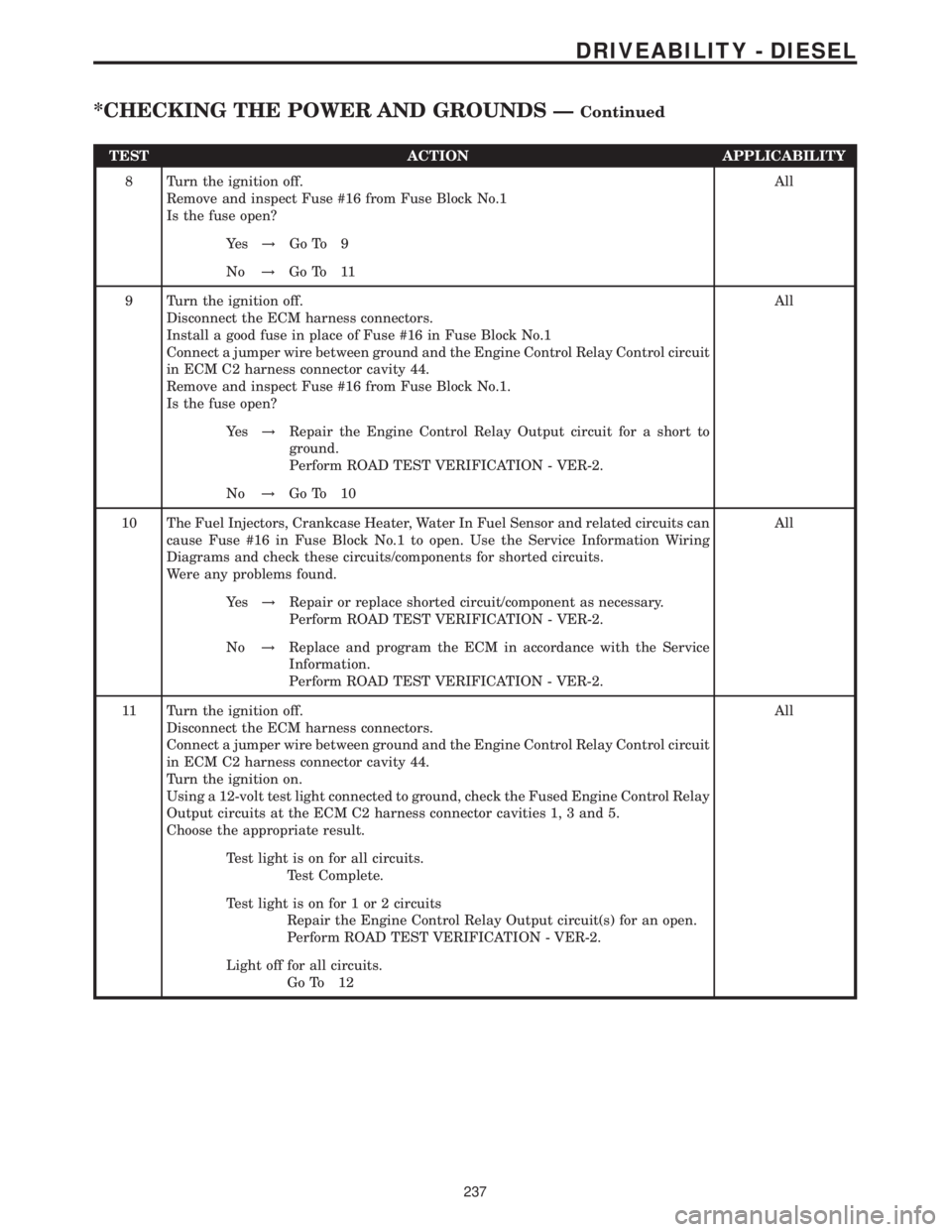

TEST ACTION APPLICABILITY

8 Turn the ignition off.

Remove and inspect Fuse #16 from Fuse Block No.1

Is the fuse open?All

Ye s!Go To 9

No!Go To 11

9 Turn the ignition off.

Disconnect the ECM harness connectors.

Install a good fuse in place of Fuse #16 in Fuse Block No.1

Connect a jumper wire between ground and the Engine Control Relay Control circuit

in ECM C2 harness connector cavity 44.

Remove and inspect Fuse #16 from Fuse Block No.1.

Is the fuse open?All

Ye s!Repair the Engine Control Relay Output circuit for a short to

ground.

Perform ROAD TEST VERIFICATION - VER-2.

No!Go To 10

10 The Fuel Injectors, Crankcase Heater, Water In Fuel Sensor and related circuits can

cause Fuse #16 in Fuse Block No.1 to open. Use the Service Information Wiring

Diagrams and check these circuits/components for shorted circuits.

Were any problems found.All

Ye s!Repair or replace shorted circuit/component as necessary.

Perform ROAD TEST VERIFICATION - VER-2.

No!Replace and program the ECM in accordance with the Service

Information.

Perform ROAD TEST VERIFICATION - VER-2.

11 Turn the ignition off.

Disconnect the ECM harness connectors.

Connect a jumper wire between ground and the Engine Control Relay Control circuit

in ECM C2 harness connector cavity 44.

Turn the ignition on.

Using a 12-volt test light connected to ground, check the Fused Engine Control Relay

Output circuits at the ECM C2 harness connector cavities 1, 3 and 5.

Choose the appropriate result.All

Test light is on for all circuits.

Test Complete.

Test light is on for 1 or 2 circuits

Repair the Engine Control Relay Output circuit(s) for an open.

Perform ROAD TEST VERIFICATION - VER-2.

Light off for all circuits.

Go To 12

237

DRIVEABILITY - DIESEL

*CHECKING THE POWER AND GROUNDS ÐContinued

Page 854 of 2305

CHIME / BUZZER

TABLE OF CONTENTS

page page

CHIME/BUZZER

DESCRIPTION..........................1

OPERATION............................1DIAGNOSIS AND TESTING - CHIME

WARNING SYSTEM.....................2

CHIME / BUZZER

DESCRIPTION

A chime warning system is standard factory-in-

stalled equipment. The chime warning system uses a

chime tone generator and a contactless relay that are

soldered onto the electronic circuit board inside the

ElectroMechanical Instrument Cluster (EMIC) to

provide audible indications of various vehicle condi-

tions that may require the attention of the vehicle

operator or occupants. The microprocessor-based

EMIC utilizes electronic messages received from

other modules in the vehicle over the Controller Area

Network (CAN) data bus network along with hard

wired inputs to the cluster to monitor many sensors

and switches throughout the vehicle. In response to

those inputs, the circuitry and internal programming

of the EMIC allow it to control audible outputs that

are produced through its on-board chime tone gener-

ator and contactless relay.

The EMIC circuitry and its chime tone generator

are capable of producing the following audible out-

puts:

²Single Chime Tone- A single, extended ªbeep-

likeº chime tone is issued as a seat belt reminder.

²Fast Rate Repetitive Chime Tone- Repeated

ªbeep-likeº tones that are issued at a fast rate as an

audible alert and to support various visual warnings.

²Slow Rate Repetitive Click Tone- Repeated

ªclick-likeº tones that are issued at a slow rate to

emulate turn signal and hazard flasher operation.

²Fast Rate Repetitive Click Tone- Repeated

ªclick-likeº tones that are issued at a fast rate to

emulate turn signal flasher operation with a bulb

out.

Hard wired circuitry connects the EMIC and the

various chime warning switch and sensor inputs to

their respective modules and to each other through

the electrical system of the vehicle. These hard wired

circuits are integral to the vehicle wire harness,

which is routed throughout the vehicle and retained

by many different methods. These circuits may be

connected to each other, to the vehicle electrical sys-

tem and to the EMIC through the use of a combina-

tion of soldered splices, splice block connectors, andmany different types of wire harness terminal con-

nectors and insulators. Refer to the appropriate wir-

ing information. The wiring information includes

wiring diagrams, proper wire and connector repair

procedures, further details on wire harness routing

and retention, as well as pin-out and location views

for the various wire harness connectors, splices and

grounds.

The EMIC chime tone generator and contactless

relay cannot be adjusted or repaired. If the chime

tone generator or contactless relay are damaged or

faulty, the entire EMIC unit must be replaced.

OPERATION

The chime warning system components operate on

battery current received through a non-switched

fused B(+) circuit so that the system may operate

regardless of the ignition switch position. The Elec-

troMechanical Instrument Cluster (EMIC) also mon-

itors the ignition switch position so that some chime

features will only occur with ignition switch in the

On position, while others occur regardless of the igni-

tion switch position.

The chime warning system provides an audible

indication to the vehicle operator or occupants under

the following conditions:

²Engine Oil Level Low Warning- Each time

the ignition switch is turned to the On position, the

EMIC chime tone generator will generate a fast rate

repetitive chime tone if electronic messages are

received over the Controller Area Network (CAN)

data bus from the Engine Control Module (ECM)

indicating that the engine level is too low. The ECM

uses internal programming and hard wired inputs

from the engine oil level and temperature sensor to

determine the engine oil level. This audible warning

occurs in concert with the visual warning provided by

the multi-function indicator in the cluster.

²Fasten Seat Belt Reminder- Each time the

ignition switch is turned to the On position, the

EMIC chime tone generator will generate a single

extended chime tone for a duration of about six sec-

onds, or until the driver side front seat belt is fas-

tened, whichever occurs first. The EMIC uses

internal programming and a hard wired input from

the driver side front seat belt switch to determine

VACHIME/BUZZER 8B - 1

Page 903 of 2305

relays which allows battery current to flow to the

rear window defogger grid lines. The heated grid

lines heat the rear glass to help clear the rear win-

dow surfaces of fog or frost.

The electric backlight (EBL) system is controlled

by the EBL timing circuity, which is integral to the

rear window defogger module. A yellow indicator in

the switch will illuminate to indicate when the EBL

system is turned on.

NOTE: The EBL system turns off automatically after

approximately 10 minutes of initial operation. Each

following activation cycle of the EBL system will

last approximately five minutes.

The EBL system will be automatically turned off

after a programmed time interval of about ten min-

utes. After the initial time interval has expired, if the

rear window defogger switch is pressed to the On

position again during the same ignition cycle, the

EBL system will automatically turn off after about

five minutes.

The EBL system will automatically shut off if the

ignition switch is turned to the Off position, or it can

be turned off manually by pressing the defogger

switch a second time.

DIAGNOSIS AND TESTING

ELECTRIC BACKLIGHT (EBL) SYSTEM

NOTE: Illumination of the defogger switch indicator

lamp means that there is electrical current available

at the output of the rear window defogger logic cir-

cuitry, but does not confirm that the electrical cur-

rent is reaching the rear glass heating grid lines.

NOTE: For circuit descriptions and diagrams of the

EBL system, refer to 8W - WIRING DIAGRAM

INFORMATION.

Operation of the electrical backlight (EBL) system

can be confirmed by the following:

(1) Turn the ignition switch to the On position. Set

the rear window defogger switch in the On position.

The rear window defogger operation can be checked

by feeling the rear window glass. A distinct difference

in temperature between the grid lines and the adja-

cent clear glass should be detected within three to

four minutes of operation.

(2) If a temperature difference is not detected, use

a 12-volt DC voltmeter and contact the rear glass

heating grid terminal B with the negative lead, and

terminal A with the positive lead (Fig. 2). The volt-

meter should read battery voltage. If the voltmeter

does not read battery voltage, check the following:²Confirm that the ignition switch is in the On

position.

²Make sure that the rear glass heating grid feed

wires and ground wires are connected to the window

terminals. Confirm that the ground wires have conti-

nuity to ground.

²Check that fuse 7 (15 amp) in fuse block #1 and

fuse 10 (30 amp) in the fuse/relay block are OK. The

fuses must be tight in there receptacles and all elec-

trical connections must be secure.

(3) When the above steps have been completed and

the rear glass heating grid is still inoperative, one or

more of the following is faulty.

²Rear window defogger switch in the instrument

panel.

²Rear window defogger (EBL) relays in the fuse/

relay block.

²Rear window defogger (EBL) relay control circu-

ity in the rear window defogger module.

²Check for a loose wire connector or a wire

pushed out of a connector.

²Rear window grid lines (all grid lines would

have to be broken, or the power feed or ground wire

not connected, for the entire heating grid to be inop-

erative).

(4) If the system operation has been verified but

the defogger switch indicator does not illuminate,

check for voltage at the defogger indicator from the

rear window defogger module when the defogger

switch is activated. If power is present, replace the

rear window defogger switch.

(5) If broken defogger grid lines are suspected, use

a 12-volt DC voltmeter and contact terminal B with

the negative lead and each rear glass heating grid

line at it's mid-point with the positive lead. The volt-

meter should read approximately 6 volts at each grid

line mid-point C. If the voltmeter does not read

approximately 6 volts, repair the open grid line(s)

(Refer to 8 - ELECTRICAL/HEATED GLASS/REAR

WINDOW DEFOGGER GRID - STANDARD PROCE-

DURE).

8G - 2 HEATED GLASSVA