high beam MERCEDES-BENZ SPRINTER 2006 Service Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 22 of 2305

Static Heater Signal

A status of9ON9indicates that the heater module

sees the9Stationary Heating Mode ON9signal after

switching on the heater with the heater timer or the

auxiliary heater switch. A status of9OFF9indicates

that the9Stationary Heating Mode ON9signal is

not present at the heater module.

Heater Booster Mode Signal

A status of9ON9indicates that the heater module

sees the9Heater Booster Mode ON9signal after

switching on the heater with the auxiliary heater

switch. A status of9OFF9indicates that the9Heater

Booster Mode ON9signal is not present at the

heater module.

3.4 INSTRUMENT CLUSTER

The Instrument Cluster has easy-to-read instru-

ments, is capable of CAN bus communication and

provides a diagnostic function. The Instrument

Cluster with analog speedometer, tachometer, fuel

and coolant temperature gauges comes in two ver-

sions.

²Speedometer with outer miles-per-hour (mph)

scale and inner kilometers-per-hour (km/h) scale.

Coolant temperature is indicated in Fahrenheit

(for US).

²Speedometer with outer kilometers-per-hour

(km/h) scale and inner miles-per-hours (mph)

scale. Coolant temperature is indicated in de-

grees Celsius (for Canada).

Below the speedometer, there is a LCD multi-

function indicator in clear view of the driver. Warn-

ing and indicator lights (based on colored light

emitting diodes) are located in the bottom of the

instrument cluster with the exception of the turn

signal indicator lights, ASR warning light and re-

serve fuel warning light. The warning lights for the

seat belt usage and parking brake/brake fluid level

are located in the line above the bottom line. The

indicator that illuminates up when the parking

brake is applied or the brake fluid level is low is

different for U.S. and Canada.

When the key is turned to the 2nd position in the

ignition, the function of the following indicator

lights is checked automatically: High Beam ON,

Preheating, airbag malfunction. In case of a broken

LED of the airbag malfunction light, the seat belt

usage warning light will flash for 6 seconds after

the function check is finished. The Instrument

Cluster is operated with the help of 4 buttons

located below the multifunction indicator. The back-

lighting for the instrument cluster uses yellow

LED's and can be adjusted electronically to daylight

and darkness.The instrument cluster includes a warning

buzzer, which sounds (in addition to a warning light

in some cases) when:

²The headlights are on with the ignition off and

the door opened.

²The driver 's seat belt is not fastened with the

ignition on.

²The key is in the ignition and the door is open.

²Critical ASSYST information is displayed in the

multifunction indicator.

3.5 POWER DOOR LOCKS/RKE

3.5.1 CENTRAL LOCKING

The Central Locking System locks all vehicle

doors if any door is locked from the inside or

mechanically locked with the key from the outside.

However, unlocking any door, in that manner, will

only unlock that particular door. The Master Door

Lock Switch on the dash enables the operator to

lock/unlock all doors. By pressing the top of the

rocker type switch once, all doors will lock. Pressing

the switch again will unlock all doors. Pressing the

lower part of the switch once will lock all doors

except the driver door. Pressing the lower part

again will unlock all doors except the driver door. If

the Central Locking System automatically unlocks

after the vehicle was attempted to be locked, at

least one door is not properly closed.

There are two LED indicators in the Master Door

Lock Switch. The left indicator is for the driver door

and the right indicator is for all passenger/cargo

doors. These will indicate if a door is ajar or if the

doors are locked. The door ajar switches are part of

the door lock motor and are mounted in the door

latch assembly.

Inside each door lock motor there is a command

switch. The command switch is operated by the

plunger and signals any change in the lock status,

locked or unlocked. Each command switch is wired

to the Central Timer Module (CTM) sometimes

referred to as the Central Locking Module. If all

doors are closed and are unlocked, and any door is

locked by the key or the interior handle, thereby

changing the command switch, all doors will be

locked. If one of the door lock motors does not reach

the end position after a locking command, it will be

detected by the CTM (command switch not in

9Locked9position) and the vehicle will be unlocked.

3.5.2 REMOTE KEYLESS ENTRY (RKE)

The SKREEM is a combination of the Remote

Keyless Entry Module and the SKIM (Sentry Key

Immobilizer Module). It is located behind the In-

strument Cluster and has an antenna that goes up

9

GENERAL INFORMATION

Page 284 of 2305

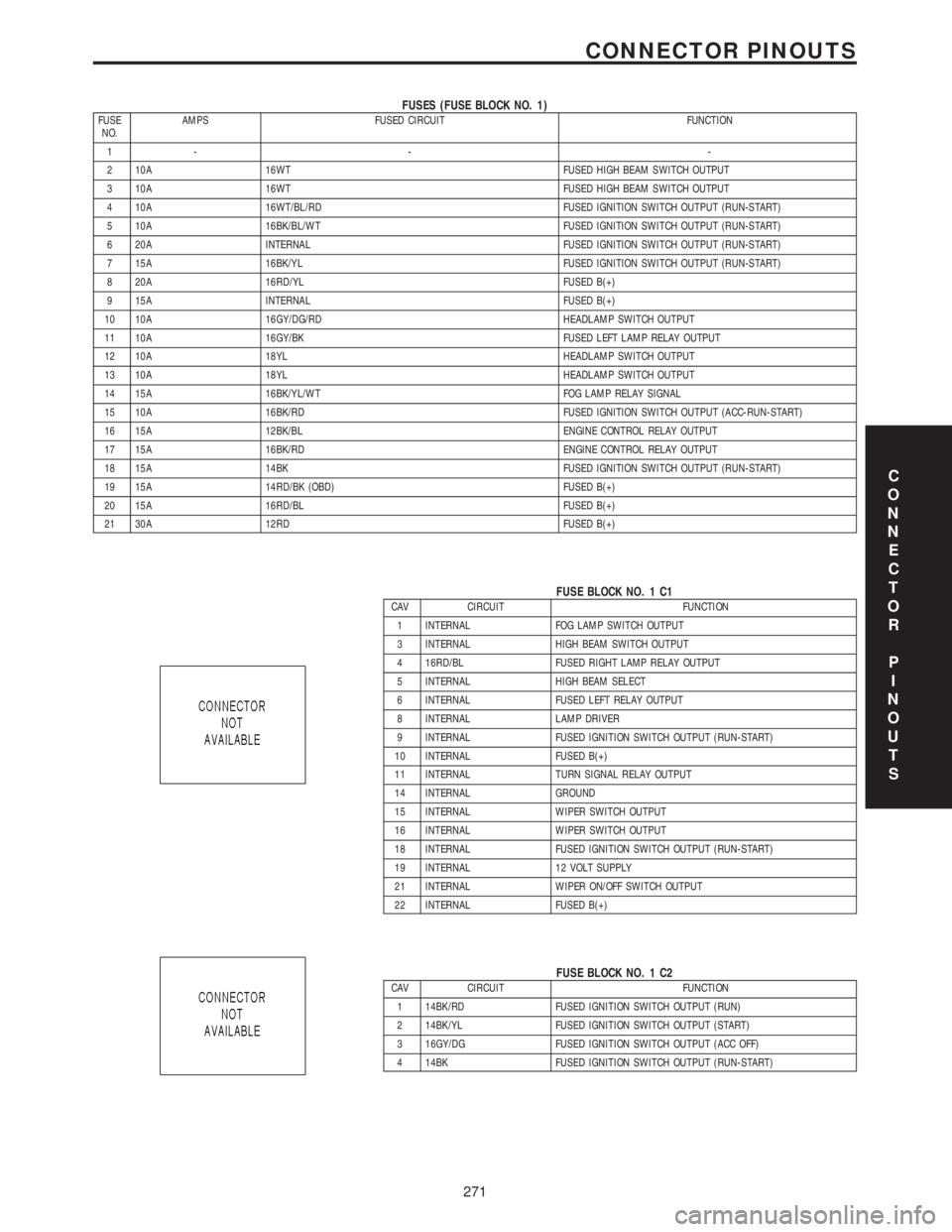

FUSES (FUSE BLOCK NO. 1)FUSE

NO.AMPS FUSED CIRCUIT FUNCTION

1- - -

2 10A 16WT FUSED HIGH BEAM SWITCH OUTPUT

3 10A 16WT FUSED HIGH BEAM SWITCH OUTPUT

4 10A 16WT/BL/RD FUSED IGNITION SWITCH OUTPUT (RUN-START)

5 10A 16BK/BL/WT FUSED IGNITION SWITCH OUTPUT (RUN-START)

6 20A INTERNAL FUSED IGNITION SWITCH OUTPUT (RUN-START)

7 15A 16BK/YL FUSED IGNITION SWITCH OUTPUT (RUN-START)

8 20A 16RD/YL FUSED B(+)

9 15A INTERNAL FUSED B(+)

10 10A 16GY/DG/RD HEADLAMP SWITCH OUTPUT

11 10A 16GY/BK FUSED LEFT LAMP RELAY OUTPUT

12 10A 18YL HEADLAMP SWITCH OUTPUT

13 10A 18YL HEADLAMP SWITCH OUTPUT

14 15A 16BK/YL/WT FOG LAMP RELAY SIGNAL

15 10A 16BK/RD FUSED IGNITION SWITCH OUTPUT (ACC-RUN-START)

16 15A 12BK/BL ENGINE CONTROL RELAY OUTPUT

17 15A 16BK/RD ENGINE CONTROL RELAY OUTPUT

18 15A 14BK FUSED IGNITION SWITCH OUTPUT (RUN-START)

19 15A 14RD/BK (OBD) FUSED B(+)

20 15A 16RD/BL FUSED B(+)

21 30A 12RD FUSED B(+)

FUSE BLOCK NO. 1 C1CAV CIRCUIT FUNCTION

1 INTERNAL FOG LAMP SWITCH OUTPUT

3 INTERNAL HIGH BEAM SWITCH OUTPUT

4 16RD/BL FUSED RIGHT LAMP RELAY OUTPUT

5 INTERNAL HIGH BEAM SELECT

6 INTERNAL FUSED LEFT RELAY OUTPUT

8 INTERNAL LAMP DRIVER

9 INTERNAL FUSED IGNITION SWITCH OUTPUT (RUN-START)

10 INTERNAL FUSED B(+)

11 INTERNAL TURN SIGNAL RELAY OUTPUT

14 INTERNAL GROUND

15 INTERNAL WIPER SWITCH OUTPUT

16 INTERNAL WIPER SWITCH OUTPUT

18 INTERNAL FUSED IGNITION SWITCH OUTPUT (RUN-START)

19 INTERNAL 12 VOLT SUPPLY

21 INTERNAL WIPER ON/OFF SWITCH OUTPUT

22 INTERNAL FUSED B(+)

FUSE BLOCK NO. 1 C2CAV CIRCUIT FUNCTION

1 14BK/RD FUSED IGNITION SWITCH OUTPUT (RUN)

2 14BK/YL FUSED IGNITION SWITCH OUTPUT (START)

3 16GY/DG FUSED IGNITION SWITCH OUTPUT (ACC OFF)

4 14BK FUSED IGNITION SWITCH OUTPUT (RUN-START)

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

271

CONNECTOR PINOUTS

Page 285 of 2305

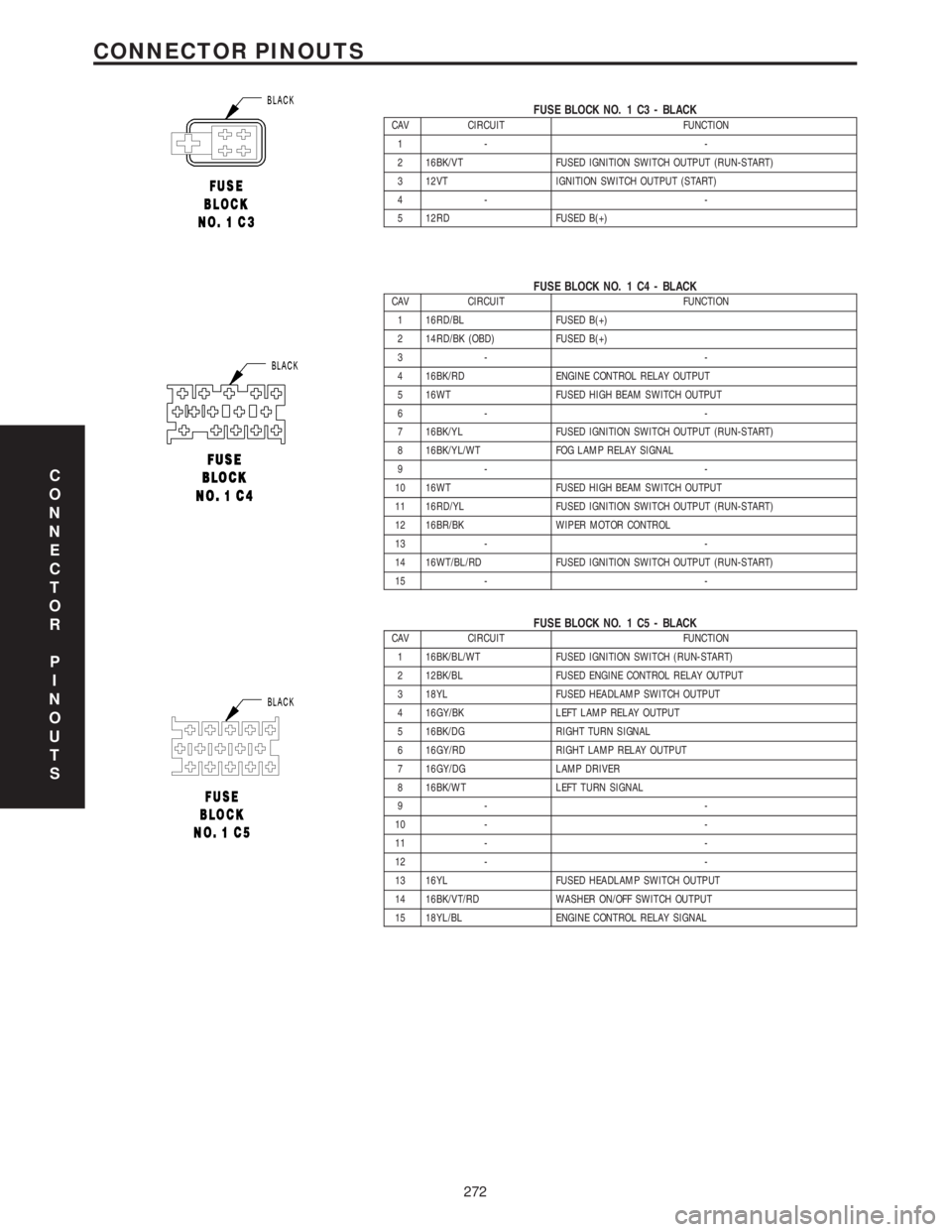

FUSE BLOCK NO. 1 C3 - BLACKCAV CIRCUIT FUNCTION

1- -

2 16BK/VT FUSED IGNITION SWITCH OUTPUT (RUN-START)

3 12VT IGNITION SWITCH OUTPUT (START)

4- -

5 12RD FUSED B(+)

FUSE BLOCK NO. 1 C4 - BLACKCAV CIRCUIT FUNCTION

1 16RD/BL FUSED B(+)

2 14RD/BK (OBD) FUSED B(+)

3- -

4 16BK/RD ENGINE CONTROL RELAY OUTPUT

5 16WT FUSED HIGH BEAM SWITCH OUTPUT

6- -

7 16BK/YL FUSED IGNITION SWITCH OUTPUT (RUN-START)

8 16BK/YL/WT FOG LAMP RELAY SIGNAL

9- -

10 16WT FUSED HIGH BEAM SWITCH OUTPUT

11 16RD/YL FUSED IGNITION SWITCH OUTPUT (RUN-START)

12 16BR/BK WIPER MOTOR CONTROL

13 - -

14 16WT/BL/RD FUSED IGNITION SWITCH OUTPUT (RUN-START)

15 - -

FUSE BLOCK NO. 1 C5 - BLACKCAV CIRCUIT FUNCTION

1 16BK/BL/WT FUSED IGNITION SWITCH (RUN-START)

2 12BK/BL FUSED ENGINE CONTROL RELAY OUTPUT

3 18YL FUSED HEADLAMP SWITCH OUTPUT

4 16GY/BK LEFT LAMP RELAY OUTPUT

5 16BK/DG RIGHT TURN SIGNAL

6 16GY/RD RIGHT LAMP RELAY OUTPUT

7 16GY/DG LAMP DRIVER

8 16BK/WT LEFT TURN SIGNAL

9- -

10 - -

11 - -

12 - -

13 16YL FUSED HEADLAMP SWITCH OUTPUT

14 16BK/VT/RD WASHER ON/OFF SWITCH OUTPUT

15 18YL/BL ENGINE CONTROL RELAY SIGNAL

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

272

CONNECTOR PINOUTS

Page 292 of 2305

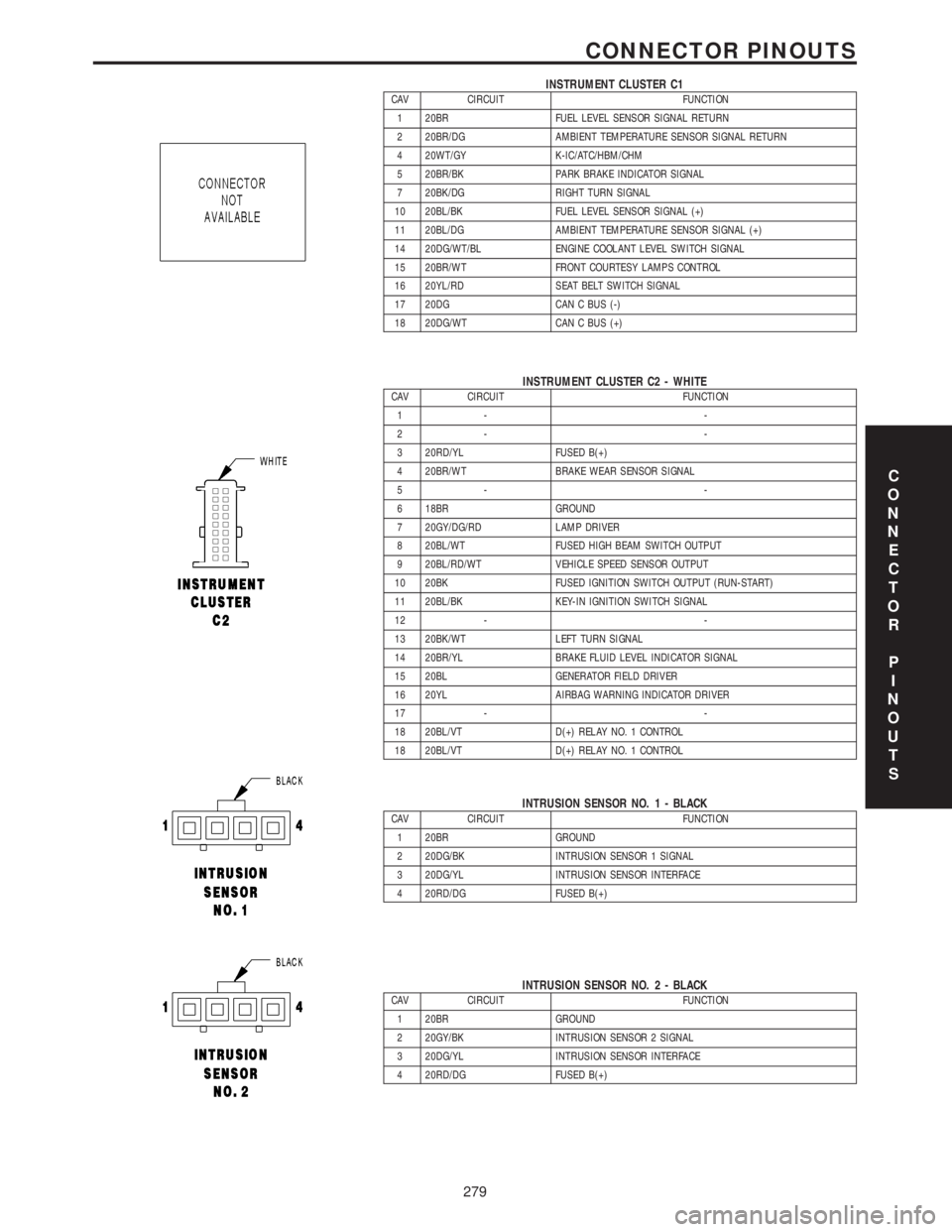

INSTRUMENT CLUSTER C1CAV CIRCUIT FUNCTION

1 20BR FUEL LEVEL SENSOR SIGNAL RETURN

2 20BR/DG AMBIENT TEMPERATURE SENSOR SIGNAL RETURN

4 20WT/GY K-IC/ATC/HBM/CHM

5 20BR/BK PARK BRAKE INDICATOR SIGNAL

7 20BK/DG RIGHT TURN SIGNAL

10 20BL/BK FUEL LEVEL SENSOR SIGNAL (+)

11 20BL/DG AMBIENT TEMPERATURE SENSOR SIGNAL (+)

14 20DG/WT/BL ENGINE COOLANT LEVEL SWITCH SIGNAL

15 20BR/WT FRONT COURTESY LAMPS CONTROL

16 20YL/RD SEAT BELT SWITCH SIGNAL

17 20DG CAN C BUS (-)

18 20DG/WT CAN C BUS (+)

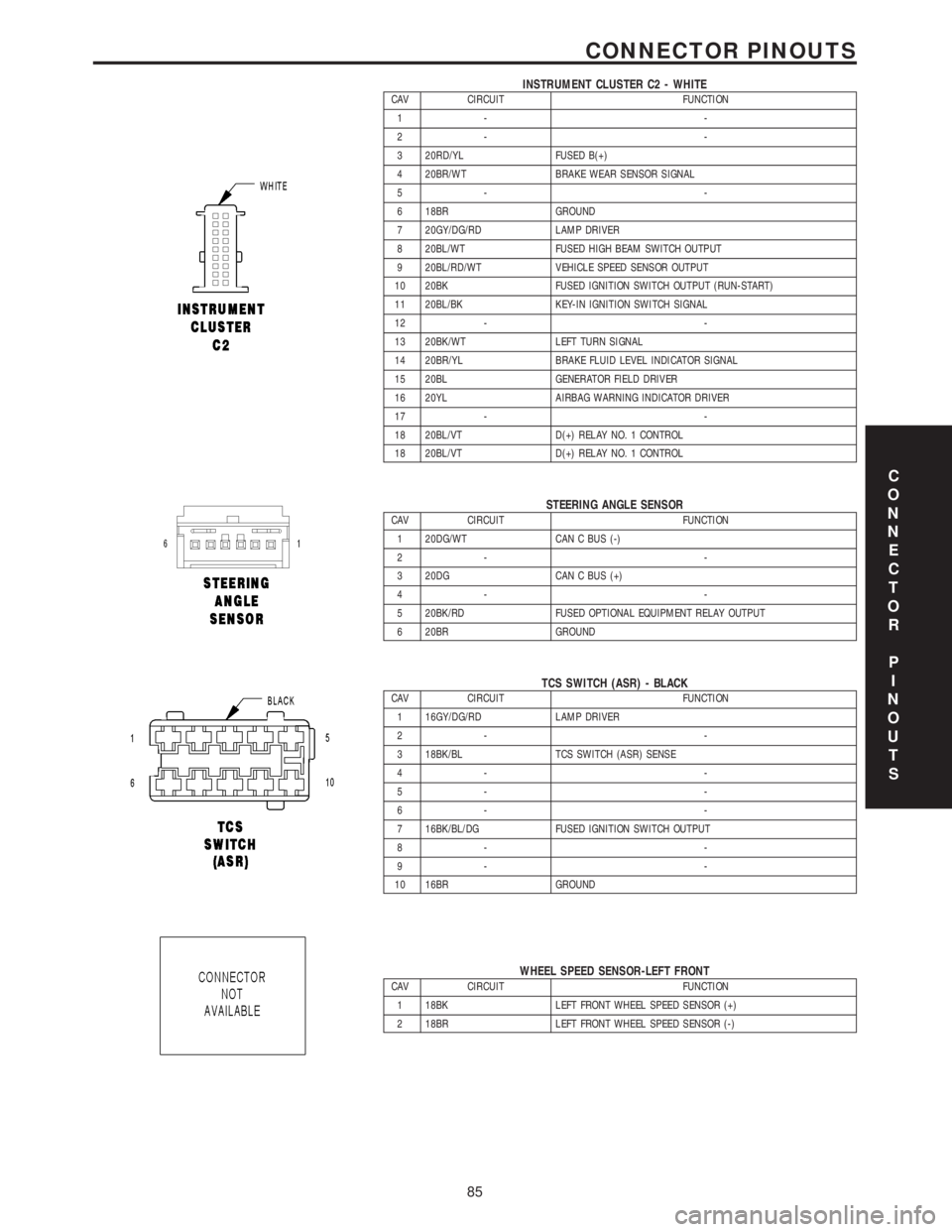

INSTRUMENT CLUSTER C2 - WHITECAV CIRCUIT FUNCTION

1- -

2- -

3 20RD/YL FUSED B(+)

4 20BR/WT BRAKE WEAR SENSOR SIGNAL

5- -

6 18BR GROUND

7 20GY/DG/RD LAMP DRIVER

8 20BL/WT FUSED HIGH BEAM SWITCH OUTPUT

9 20BL/RD/WT VEHICLE SPEED SENSOR OUTPUT

10 20BK FUSED IGNITION SWITCH OUTPUT (RUN-START)

11 20BL/BK KEY-IN IGNITION SWITCH SIGNAL

12 - -

13 20BK/WT LEFT TURN SIGNAL

14 20BR/YL BRAKE FLUID LEVEL INDICATOR SIGNAL

15 20BL GENERATOR FIELD DRIVER

16 20YL AIRBAG WARNING INDICATOR DRIVER

17 - -

18 20BL/VT D(+) RELAY NO. 1 CONTROL

18 20BL/VT D(+) RELAY NO. 1 CONTROL

INTRUSION SENSOR NO. 1 - BLACKCAV CIRCUIT FUNCTION

1 20BR GROUND

2 20DG/BK INTRUSION SENSOR 1 SIGNAL

3 20DG/YL INTRUSION SENSOR INTERFACE

4 20RD/DG FUSED B(+)

INTRUSION SENSOR NO. 2 - BLACKCAV CIRCUIT FUNCTION

1 20BR GROUND

2 20GY/BK INTRUSION SENSOR 2 SIGNAL

3 20DG/YL INTRUSION SENSOR INTERFACE

4 20RD/DG FUSED B(+)

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

279

CONNECTOR PINOUTS

Page 406 of 2305

INSTRUMENT CLUSTER C2 - WHITECAV CIRCUIT FUNCTION

1- -

2- -

3 20RD/YL FUSED B(+)

4 20BR/WT BRAKE WEAR SENSOR SIGNAL

5- -

6 18BR GROUND

7 20GY/DG/RD LAMP DRIVER

8 20BL/WT FUSED HIGH BEAM SWITCH OUTPUT

9 20BL/RD/WT VEHICLE SPEED SENSOR OUTPUT

10 20BK FUSED IGNITION SWITCH OUTPUT (RUN-START)

11 20BL/BK KEY-IN IGNITION SWITCH SIGNAL

12 - -

13 20BK/WT LEFT TURN SIGNAL

14 20BR/YL BRAKE FLUID LEVEL INDICATOR SIGNAL

15 20BL GENERATOR FIELD DRIVER

16 20YL AIRBAG WARNING INDICATOR DRIVER

17 - -

18 20BL/VT D(+) RELAY NO. 1 CONTROL

18 20BL/VT D(+) RELAY NO. 1 CONTROL

STEERING ANGLE SENSORCAV CIRCUIT FUNCTION

1 20DG/WT CAN C BUS (-)

2- -

3 20DG CAN C BUS (+)

4- -

5 20BK/RD FUSED OPTIONAL EQUIPMENT RELAY OUTPUT

6 20BR GROUND

TCS SWITCH (ASR) - BLACKCAV CIRCUIT FUNCTION

1 16GY/DG/RD LAMP DRIVER

2- -

3 18BK/BL TCS SWITCH (ASR) SENSE

4- -

5- -

6- -

7 16BK/BL/DG FUSED IGNITION SWITCH OUTPUT

8- -

9- -

10 16BR GROUND

WHEEL SPEED SENSOR-LEFT FRONTCAV CIRCUIT FUNCTION

1 18BK LEFT FRONT WHEEL SPEED SENSOR (+)

2 18BR LEFT FRONT WHEEL SPEED SENSOR (-)

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

85

CONNECTOR PINOUTS

Page 688 of 2305

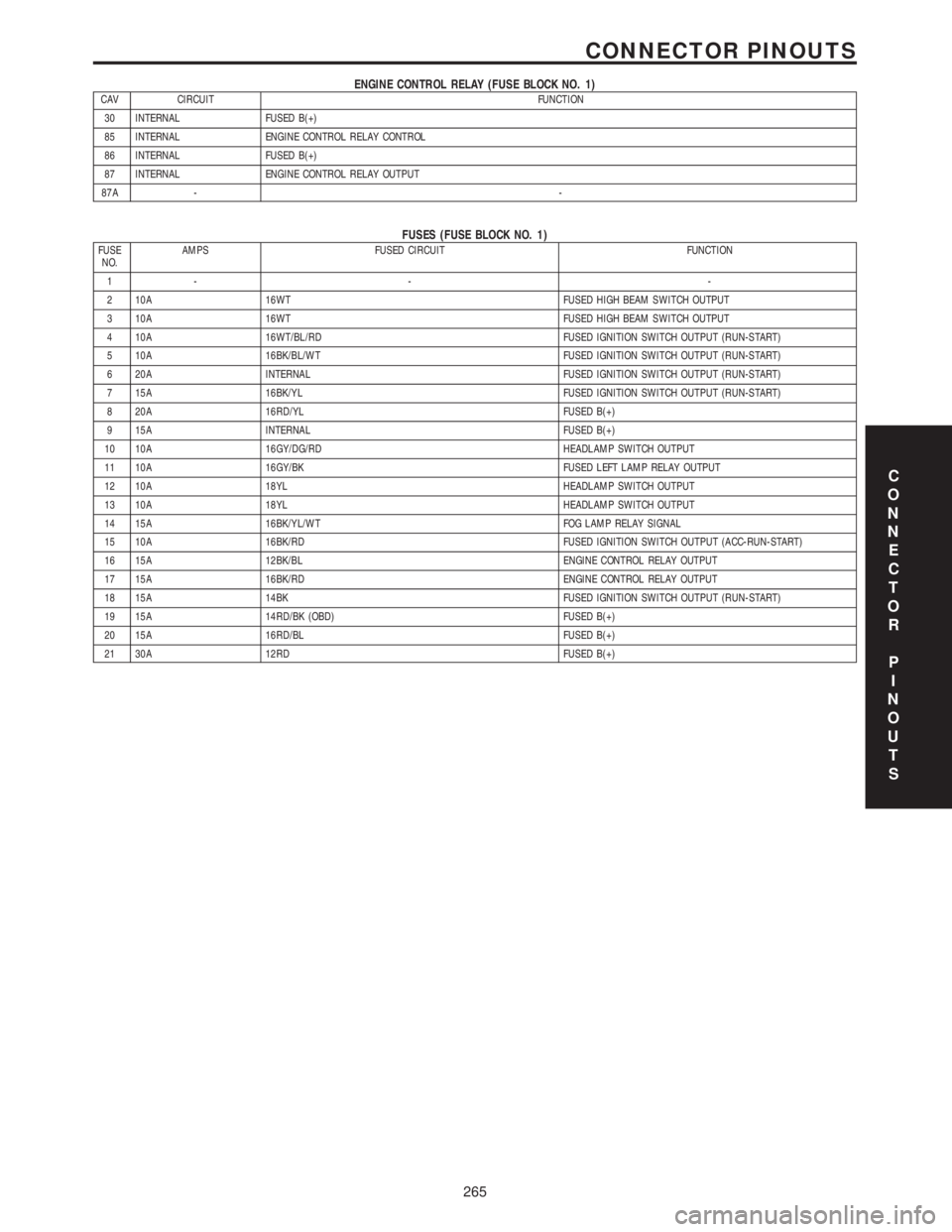

ENGINE CONTROL RELAY (FUSE BLOCK NO. 1)CAV CIRCUIT FUNCTION

30 INTERNAL FUSED B(+)

85 INTERNAL ENGINE CONTROL RELAY CONTROL

86 INTERNAL FUSED B(+)

87 INTERNAL ENGINE CONTROL RELAY OUTPUT

87A --

FUSES (FUSE BLOCK NO. 1)FUSE

NO.AMPS FUSED CIRCUIT FUNCTION

1- - -

2 10A 16WT FUSED HIGH BEAM SWITCH OUTPUT

3 10A 16WT FUSED HIGH BEAM SWITCH OUTPUT

4 10A 16WT/BL/RD FUSED IGNITION SWITCH OUTPUT (RUN-START)

5 10A 16BK/BL/WT FUSED IGNITION SWITCH OUTPUT (RUN-START)

6 20A INTERNAL FUSED IGNITION SWITCH OUTPUT (RUN-START)

7 15A 16BK/YL FUSED IGNITION SWITCH OUTPUT (RUN-START)

8 20A 16RD/YL FUSED B(+)

9 15A INTERNAL FUSED B(+)

10 10A 16GY/DG/RD HEADLAMP SWITCH OUTPUT

11 10A 16GY/BK FUSED LEFT LAMP RELAY OUTPUT

12 10A 18YL HEADLAMP SWITCH OUTPUT

13 10A 18YL HEADLAMP SWITCH OUTPUT

14 15A 16BK/YL/WT FOG LAMP RELAY SIGNAL

15 10A 16BK/RD FUSED IGNITION SWITCH OUTPUT (ACC-RUN-START)

16 15A 12BK/BL ENGINE CONTROL RELAY OUTPUT

17 15A 16BK/RD ENGINE CONTROL RELAY OUTPUT

18 15A 14BK FUSED IGNITION SWITCH OUTPUT (RUN-START)

19 15A 14RD/BK (OBD) FUSED B(+)

20 15A 16RD/BL FUSED B(+)

21 30A 12RD FUSED B(+)

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

265

CONNECTOR PINOUTS

Page 708 of 2305

FASTENER IDENTIFICATION

DESCRIPTION

The SAE bolt strength grades range from grade 2

to grade 8. The higher the grade number, the greater

the bolt strength. Identification is determined by the

line marks on the top of each bolt head. The actual

bolt strength grade corresponds to the number of line

marks plus 2. The most commonly used metric bolt

strength classes are 9.8 and 10.9. The metric

strength class identification number is imprinted on

the head of the bolt. The higher the class number,

the greater the bolt strength. Some metric nuts are

imprinted with a single-digit strength class on the

nut face. Refer to the Fastener Identification and

Fastener Strength Charts (Fig. 2) and (Fig. 3).

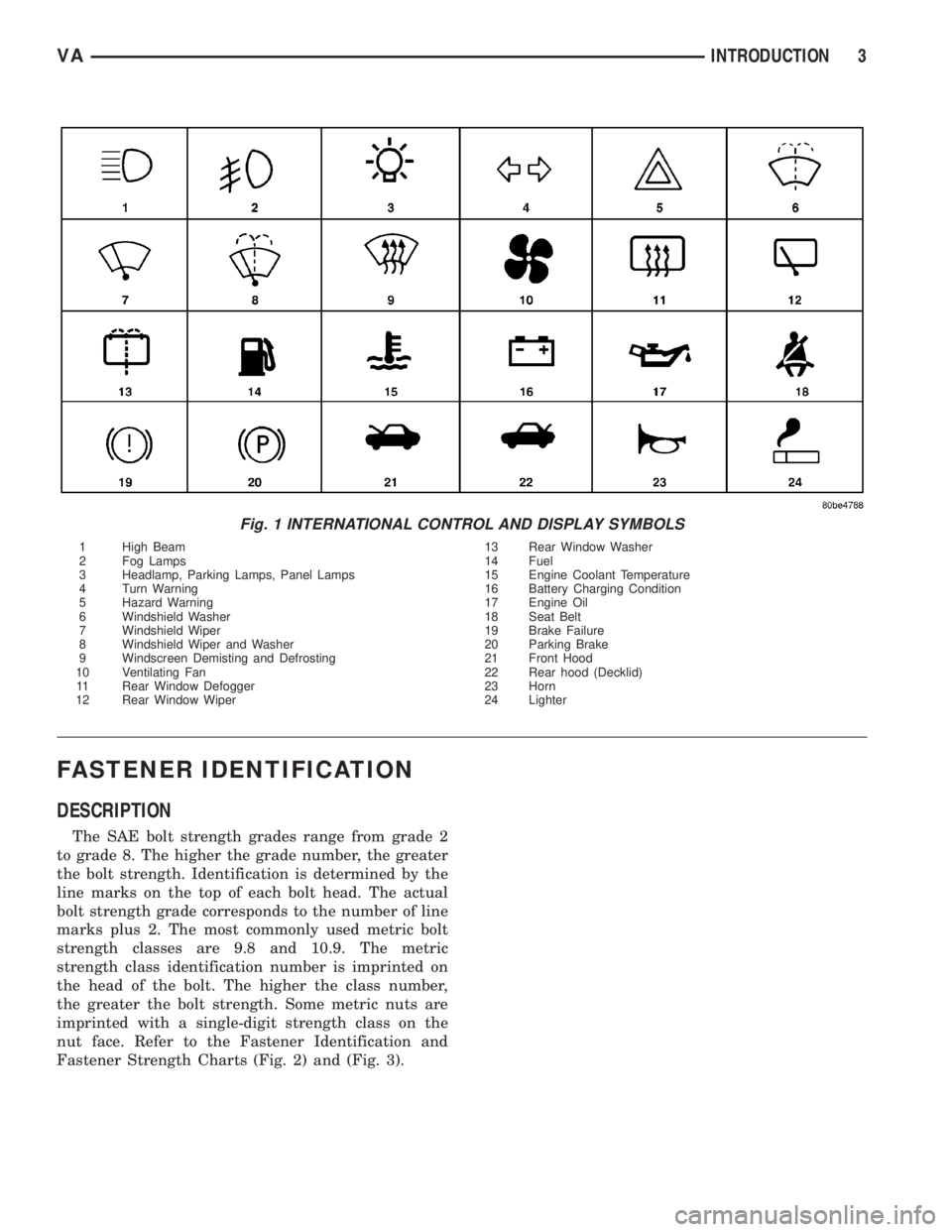

Fig. 1 INTERNATIONAL CONTROL AND DISPLAY SYMBOLS

1 High Beam 13 Rear Window Washer

2 Fog Lamps 14 Fuel

3 Headlamp, Parking Lamps, Panel Lamps 15 Engine Coolant Temperature

4 Turn Warning 16 Battery Charging Condition

5 Hazard Warning 17 Engine Oil

6 Windshield Washer 18 Seat Belt

7 Windshield Wiper 19 Brake Failure

8 Windshield Wiper and Washer 20 Parking Brake

9 Windscreen Demisting and Defrosting 21 Front Hood

10 Ventilating Fan 22 Rear hood (Decklid)

11 Rear Window Defogger 23 Horn

12 Rear Window Wiper 24 Lighter

VAINTRODUCTION 3

Page 920 of 2305

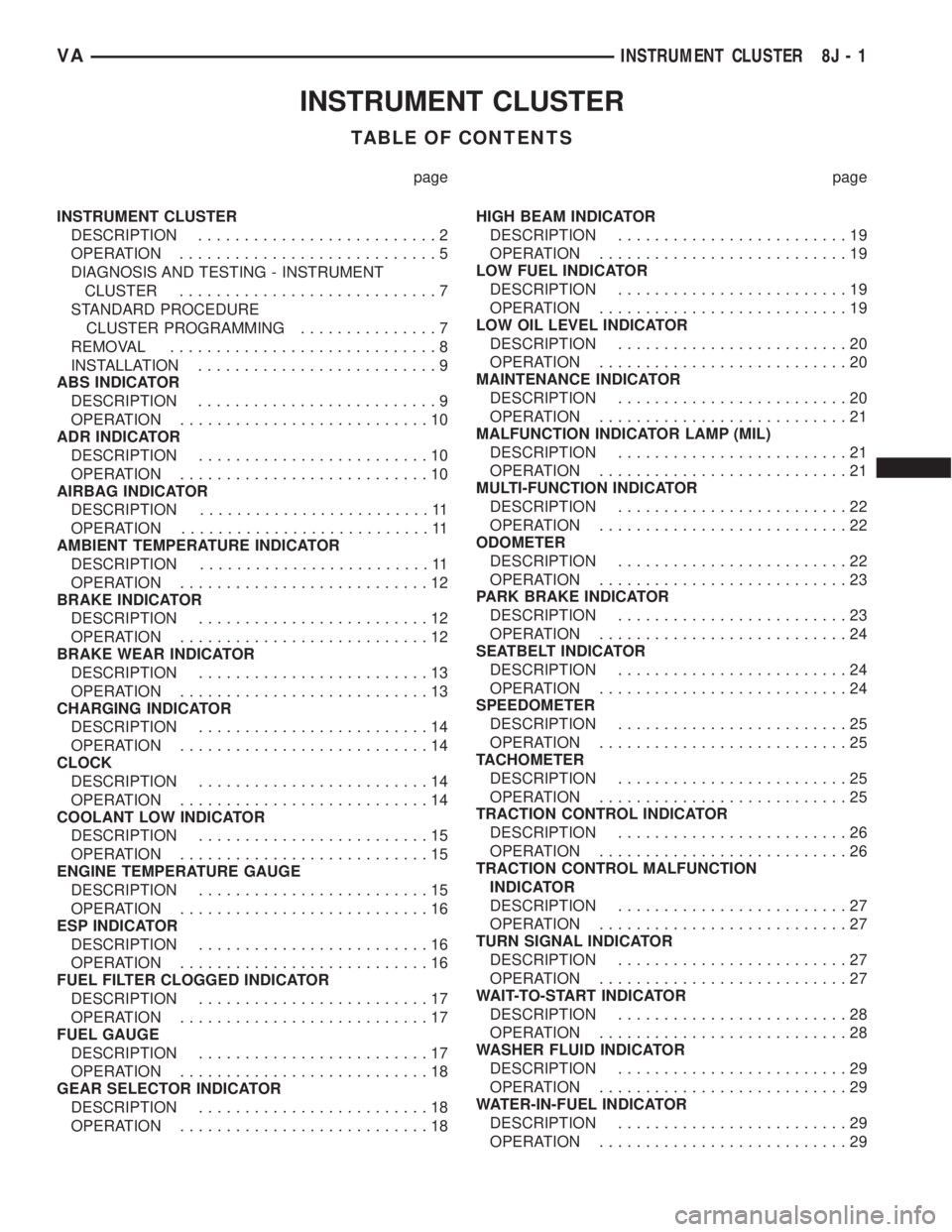

INSTRUMENT CLUSTER

TABLE OF CONTENTS

page page

INSTRUMENT CLUSTER

DESCRIPTION..........................2

OPERATION............................5

DIAGNOSIS AND TESTING - INSTRUMENT

CLUSTER............................7

STANDARD PROCEDURE

CLUSTER PROGRAMMING...............7

REMOVAL.............................8

INSTALLATION..........................9

ABS INDICATOR

DESCRIPTION..........................9

OPERATION...........................10

ADR INDICATOR

DESCRIPTION.........................10

OPERATION...........................10

AIRBAG INDICATOR

DESCRIPTION.........................11

OPERATION...........................11

AMBIENT TEMPERATURE INDICATOR

DESCRIPTION.........................11

OPERATION...........................12

BRAKE INDICATOR

DESCRIPTION.........................12

OPERATION...........................12

BRAKE WEAR INDICATOR

DESCRIPTION.........................13

OPERATION...........................13

CHARGING INDICATOR

DESCRIPTION.........................14

OPERATION...........................14

CLOCK

DESCRIPTION.........................14

OPERATION...........................14

COOLANT LOW INDICATOR

DESCRIPTION.........................15

OPERATION...........................15

ENGINE TEMPERATURE GAUGE

DESCRIPTION.........................15

OPERATION...........................16

ESP INDICATOR

DESCRIPTION.........................16

OPERATION...........................16

FUEL FILTER CLOGGED INDICATOR

DESCRIPTION.........................17

OPERATION...........................17

FUEL GAUGE

DESCRIPTION.........................17

OPERATION...........................18

GEAR SELECTOR INDICATOR

DESCRIPTION.........................18

OPERATION...........................18HIGH BEAM INDICATOR

DESCRIPTION.........................19

OPERATION...........................19

LOW FUEL INDICATOR

DESCRIPTION.........................19

OPERATION...........................19

LOW OIL LEVEL INDICATOR

DESCRIPTION.........................20

OPERATION...........................20

MAINTENANCE INDICATOR

DESCRIPTION.........................20

OPERATION...........................21

MALFUNCTION INDICATOR LAMP (MIL)

DESCRIPTION.........................21

OPERATION...........................21

MULTI-FUNCTION INDICATOR

DESCRIPTION.........................22

OPERATION...........................22

ODOMETER

DESCRIPTION.........................22

OPERATION...........................23

PARK BRAKE INDICATOR

DESCRIPTION.........................23

OPERATION...........................24

SEATBELT INDICATOR

DESCRIPTION.........................24

OPERATION...........................24

SPEEDOMETER

DESCRIPTION.........................25

OPERATION...........................25

TACHOMETER

DESCRIPTION.........................25

OPERATION...........................25

TRACTION CONTROL INDICATOR

DESCRIPTION.........................26

OPERATION...........................26

TRACTION CONTROL MALFUNCTION

INDICATOR

DESCRIPTION.........................27

OPERATION...........................27

TURN SIGNAL INDICATOR

DESCRIPTION.........................27

OPERATION...........................27

WAIT-TO-START INDICATOR

DESCRIPTION.........................28

OPERATION...........................28

WASHER FLUID INDICATOR

DESCRIPTION.........................29

OPERATION...........................29

WATER-IN-FUEL INDICATOR

DESCRIPTION.........................29

OPERATION...........................29

VAINSTRUMENT CLUSTER 8J - 1

Page 922 of 2305

Located between the rear cover and the cluster

hood is the cluster housing. The molded plastic clus-

ter housing serves as the carrier for the cluster elec-

tronic circuit board and circuitry, the cluster

connector receptacles, the gauges, a Light Emitting

Diode (LED) for each cluster indicator and general

illumination lamp, the multi-function indicator LCD

unit, electronic tone generators, the cluster overlay,

the gauge pointers, the multi-function indicator

switches and the four switch push buttons.

The cluster overlay is a laminated plastic unit. The

dark, visible, outer surface of the overlay is marked

with all of the gauge dial faces and graduations, but

this layer is also translucent. The darkness of this

outer layer prevents the cluster from appearing clut-

tered or busy by concealing the cluster indicators

that are not illuminated, while the translucence of

this layer allows those indicators and icons that are

illuminated to be readily visible. The underlying

layer of the overlay is opaque and allows light from

the LED for each of the various indicators and illu-

mination lamps behind it to be visible through the

outer layer of the overlay only through predeter-

mined cutouts. A rectangular opening in the overlay

at the base of the speedometer provides a window

through which the illuminated multi-function indica-

tor LCD unit can be viewed.

Several versions of the EMIC module are offered

on this model. These versions accommodate all of the

variations of optional equipment and regulatory

requirements for the various markets in which the

vehicle will be offered. The microprocessor-based

EMIC utilizes integrated circuitry, Electrically Eras-

able Programmable Read Only Memory (EEPROM)

type memory storage, information carried on the

Controller Area Network (CAN) data bus, along with

several hard wired analog and multiplexed inputs to

monitor systems, sensors and switches throughout

the vehicle.

In response to those inputs, the hardware and soft-

ware of the EMIC allow it to control and integrate

many electronic functions and features of the vehicle

through both hard wired outputs and the transmis-

sion of electronic message outputs to other electronic

modules in the vehicle over the CAN data bus. (Refer

to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/COMMUNICATION - DESCRIPTION -

CAN BUS).

Besides typical instrument cluster gauge and indi-

cator support, the electronic functions and features

that the EMIC supports or controls include the fol-

lowing:

²Active Service System- In vehicles equipped

with the Active Service SYSTem (ASSYST) engine oil

maintenance indicator option, the EMIC electronic

circuit board includes a second dedicated micropro-

cessor. This second microprocessor evaluates various

data including time, mileage, and driving conditionsto calculate the required engine oil service intervals,

and provides both visual and audible alerts to the

vehicle operator when certain engine oil maintenance

services are required.

²Audible Warnings- The EMIC electronic cir-

cuit board is equipped with an audible tone generator

and programming that allows it to provide various

audible alerts to the vehicle operator, including buzz-

ing and chime tones. An audible contactless elec-

tronic relay is also soldered onto the circuit board to

produce audible clicks that is synchronized with turn

signal indicator flashing to emulate the sounds of a

conventional turn signal or hazard warning flasher.

These audible clicks can occur at one of two rates to

emulate both normal and bulb-out turn or hazard

flasher operation. (Refer to 8 - ELECTRICAL/

CHIME/BUZZER - DESCRIPTION).

²Panel Lamps Dimming Control- The EMIC

provides a hard wired 12-volt Pulse-Width Modulated

(PWM) output that synchronizes the dimming level

of all panel lamps dimmer controlled lamps with that

of the cluster general illumination lamps and multi-

function indicator.

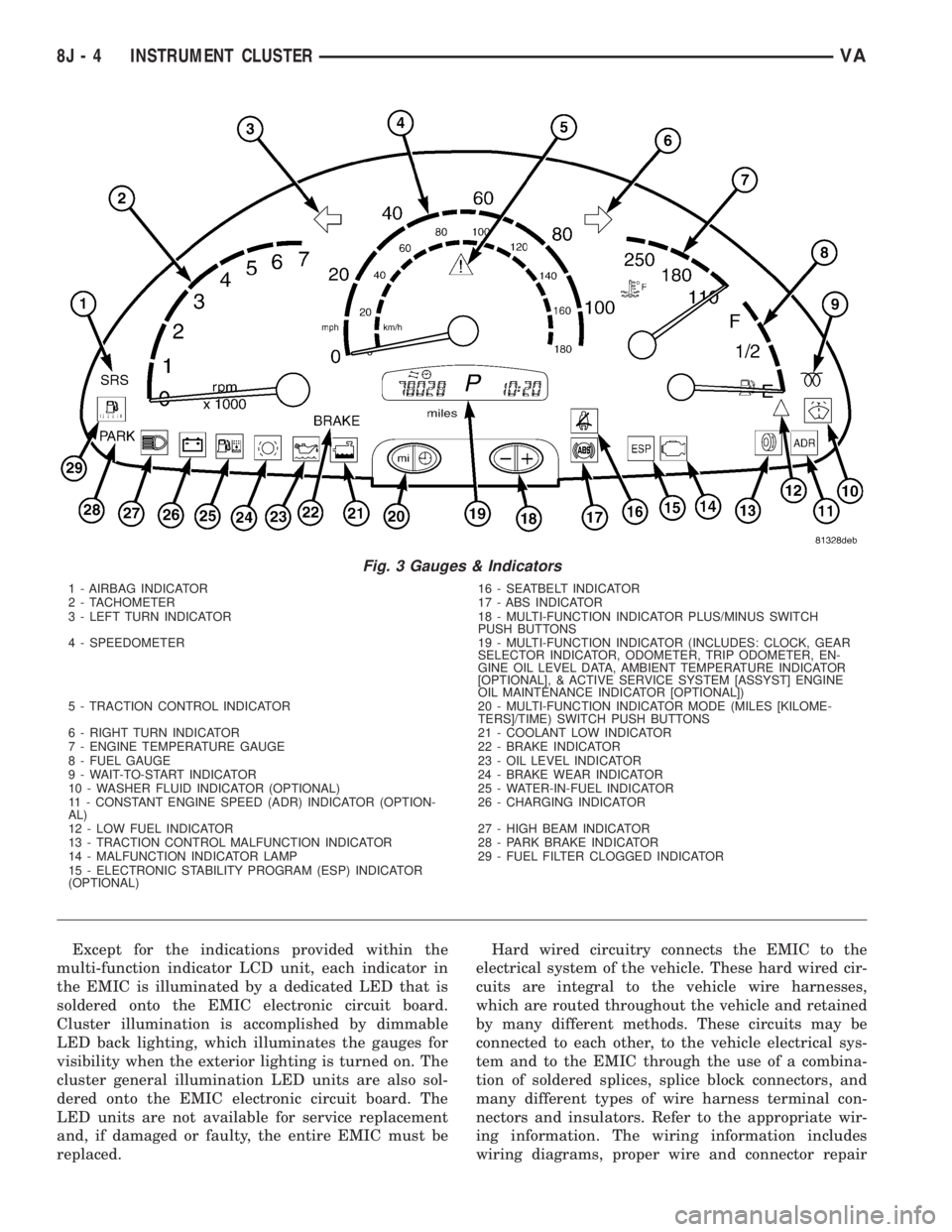

The EMIC houses four analog gauges and has pro-

visions for up to nineteen indicators (Fig. 3). The

EMIC includes the following analog gauges:

²Coolant Temperature Gauge

²Fuel Gauge

²Speedometer

²Tachometer

The EMIC includes provisions for the following

indicators (Fig. 3):

²Airbag (SRS) Indicator

²Antilock Brake System (ABS) Indicator

²Brake Indicator

²Brake Wear Indicator

²Charging Indicator

²Clogged Fuel Filter Indicator

²Constant Engine Speed (ADR) Indicator

²Coolant Low Indicator

²Electronic Stability Program (ESP) Indica-

tor

²High Beam Indicator

²Low Fuel Indicator

²Malfunction Indicator Lamp (MIL)

²Multi-Function Indicator (LCD)

²Park Brake Indicator

²Seatbelt Indicator

²Traction Control (ASR) Indicator

²Traction Control (ASR) Malfunction Indica-

tor

²Turn Signal (Right and Left) Indicators

²Washer Fluid Indicator

²Wait-To-Start Indicator

²Water-In-Fuel Indicator

VAINSTRUMENT CLUSTER 8J - 3

Page 923 of 2305

Except for the indications provided within the

multi-function indicator LCD unit, each indicator in

the EMIC is illuminated by a dedicated LED that is

soldered onto the EMIC electronic circuit board.

Cluster illumination is accomplished by dimmable

LED back lighting, which illuminates the gauges for

visibility when the exterior lighting is turned on. The

cluster general illumination LED units are also sol-

dered onto the EMIC electronic circuit board. The

LED units are not available for service replacement

and, if damaged or faulty, the entire EMIC must be

replaced.Hard wired circuitry connects the EMIC to the

electrical system of the vehicle. These hard wired cir-

cuits are integral to the vehicle wire harnesses,

which are routed throughout the vehicle and retained

by many different methods. These circuits may be

connected to each other, to the vehicle electrical sys-

tem and to the EMIC through the use of a combina-

tion of soldered splices, splice block connectors, and

many different types of wire harness terminal con-

nectors and insulators. Refer to the appropriate wir-

ing information. The wiring information includes

wiring diagrams, proper wire and connector repair

Fig. 3 Gauges & Indicators

1 - AIRBAG INDICATOR 16 - SEATBELT INDICATOR

2 - TACHOMETER 17 - ABS INDICATOR

3 - LEFT TURN INDICATOR 18 - MULTI-FUNCTION INDICATOR PLUS/MINUS SWITCH

PUSH BUTTONS

4 - SPEEDOMETER 19 - MULTI-FUNCTION INDICATOR (INCLUDES: CLOCK, GEAR

SELECTOR INDICATOR, ODOMETER, TRIP ODOMETER, EN-

GINE OIL LEVEL DATA, AMBIENT TEMPERATURE INDICATOR

[OPTIONAL], & ACTIVE SERVICE SYSTEM [ASSYST] ENGINE

OIL MAINTENANCE INDICATOR [OPTIONAL])

5 - TRACTION CONTROL INDICATOR 20 - MULTI-FUNCTION INDICATOR MODE (MILES [KILOME-

TERS]/TIME) SWITCH PUSH BUTTONS

6 - RIGHT TURN INDICATOR 21 - COOLANT LOW INDICATOR

7 - ENGINE TEMPERATURE GAUGE 22 - BRAKE INDICATOR

8 - FUEL GAUGE 23 - OIL LEVEL INDICATOR

9 - WAIT-TO-START INDICATOR 24 - BRAKE WEAR INDICATOR

10 - WASHER FLUID INDICATOR (OPTIONAL) 25 - WATER-IN-FUEL INDICATOR

11 - CONSTANT ENGINE SPEED (ADR) INDICATOR (OPTION-

AL)26 - CHARGING INDICATOR

12 - LOW FUEL INDICATOR 27 - HIGH BEAM INDICATOR

13 - TRACTION CONTROL MALFUNCTION INDICATOR 28 - PARK BRAKE INDICATOR

14 - MALFUNCTION INDICATOR LAMP 29 - FUEL FILTER CLOGGED INDICATOR

15 - ELECTRONIC STABILITY PROGRAM (ESP) INDICATOR

(OPTIONAL)

8J - 4 INSTRUMENT CLUSTERVA