warning MERCEDES-BENZ SPRINTER 2006 Service Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 3 of 2305

CAUTION

ALL SERVICE AND REBUILDING INSTRUCTIONS CONTAINED HEREIN

ARE APPLICABLE TO, AND FOR THE CONVENIENCE OF, THE AUTOMOTIVE

TRADE ONLY. All test and repair procedures on components or assemblies

innon-automotive applications should be repaired in accordance with instruc-

tions supplied by the manufacturer of the total product.

Proper service and repair is important to the safe, reliable, operation of all motor vehicles. The

service procedures recommended and described in this publication were developed for pro-

fessional service personnel and are effective methods for performing vehicle repair. Following

these procedures will help assure efficient economical vehicle performance and service reli-

ability. Some of these service procedures require the use of special tools designed for specific

procedures. These special tools should be used when recommended throughout this publi-

cation.

Special attention should be exercised when working with spring or tension loaded

fasteners and devices such as E-Clips, Circlips, Snap rings, etc., as careless

removal may cause personal injury. Always wear safety goggles whenever work-

ing on vehicles or vehicle components.

It is important to note that this publication contains various CautionsandWarnings. These

should be carefully read in order to minimize the risk of personal injury, or the possibility that

improper service methods may damage the vehicle or render it unsafe. It is important to note

that these CautionsandWarnings cover only the situations and procedures Daimler-

Chrysler Corporation has encountered and recommended.

DaimlerChrysler Corporation

could not possibly know, evaluate, and advise the

service trade of all conceivable ways that

service may be performed, or of the possible hazards of each. Consequently, DaimlerChrysler

Corporation has not undertaken any such broad service review. Accordingly, anyone who uses

a service procedure, or tool, that is not recommended in this publication must assure oneself

thoroughly that neither personal safety, nor vehicle safety, be jeopardized by the service

methods they select.

For other Service and Owner Manuals for Chrysler,

Plymouth, Dodge, Dodge Truck, and Jeep

Tvehicles, Call

(800) 890-4038 or FAX (440) 572-0815 to place an order. Or, visit our website at techauthority.daimlerchrysler.com.Tech Authority Online at our website offers you serviceinformation on a subscription basis.

Page 6 of 2305

TABLE OF CONTENTS

1.0 INTRODUCTION.........................................................1

1.1SYSTEM COVERAGE...............................................1

1.2SIX-STEP TROUBLESHOOTING PROCEDURE..........................1

2.0 IDENTIFICATION OF SYSTEM.............................................1

3.0 SYSTEM DESCRIPTION AND FUNCTIONAL OPERATION......................1

3.1AIRBAG SYSTEM...................................................1

3.1.1DRIVER AIRBAG............................................2

3.1.2CLOCKSPRING.............................................3

3.1.3PASSENGER AIRBAG.......................................3

3.1.4SEAT BELT TENSIONERS....................................3

3.1.5SPECIAL TOOLS............................................3

3.1.6DIAGNOSTIC TROUBLE CODES..............................4

3.1.6.1ACTIVE CODES............................................4

3.1.6.2STORED CODES...........................................4

3.2COMMUNICATION..................................................4

3.2.1COMMUNICATION K-LINES..................................4

3.2.2CAN BUS..................................................5

3.3HEATING & A/C SYSTEM............................................5

3.3.1AUTOMATIC TEMPERATURE CONTROL (ATC)..................5

3.3.1.1SYSTEM CONTROLS........................................5

3.3.1.2SYSTEM DIAGNOSTICS.....................................5

3.3.2CABIN HEATER MODULE (CHM) & HEATER BOOSTER MODULE

(HBM).....................................................7

3.3.2.1SYSTEM DESCRIPTION.....................................7

3.3.2.2VENTING THE HEATER'S EXHAUST...........................8

3.3.2.3SYSTEM DIAGNOSTICS.....................................8

3.4INSTRUMENT CLUSTER.............................................9

3.5POWER DOOR LOCKS/RKE..........................................9

3.5.1CENTRAL LOCKING.........................................9

3.5.2REMOTE KEYLESS ENTRY (RKE).............................9

3.5.3AUTO DOOR LOCKS.......................................10

3.5.4ACCIDENT RESPONSE.....................................10

3.6VEHICLE THEFT SECURITY SYSTEM (VTSS)..........................10

3.7USING THE DRBIIIT................................................11

3.8DRBIIITERROR MESSAGES.........................................11

3.9DRBIIITDOES NOT POWER UP (BLANK SCREEN)......................11

3.10DISPLAY IS NOT VISIBLE...........................................11

4.0 DISCLAIMERS, SAFETY, WARNINGS......................................11

4.1DISCLAIMERS.....................................................11

4.2SAFETY..........................................................11

4.2.1TECHNICIAN SAFETY INFORMATION.........................11

4.2.2VEHICLE PREPARATION FOR TESTING.......................12

4.2.3SERVICING SUB-ASSEMBLIES..............................12

4.2.4DRBIIITSAFETY INFORMATION.............................12

4.3WARNINGS.......................................................12

4.3.1VEHICLE DAMAGE WARNINGS..............................12

4.3.2ROAD TESTING A COMPLAINT VEHICLE......................12

i

Page 7 of 2305

TABLE OF CONTENTS - Continued

5.0 REQUIRED TOOLS AND EQUIPMENT.....................................13

6.0 GLOSSARY OF TERMS..................................................13

7.0 DIAGNOSTIC INFORMATION AND PROCEDURES...........................15

AIRBAG

AIRBAG WARNING INDICATOR - DRIVER HIGH.............................16

AIRBAG WARNING INDICATOR - DRIVER LOW..............................19

DRIVER SEAT BELT TENSIONER - INCORRECT FEEDBACK..................22

DRIVER SQUIB 1 - INCORRECT FEEDBACK................................22

INTERNAL 1...........................................................22

INTERNAL 2...........................................................22

INTERNAL 3...........................................................22

PASSENGER SEAT BELT TENSIONER - INCORRECT FEEDBACK..............22

PASSENGER SQUIB 1 - INCORRECT FEEDBACK............................22

STORED ENERGY FIRING 1..............................................22

STORED ENERGY FIRING 2..............................................22

DRIVER SEAT BELT TENSIONER CIRCUIT OPEN............................24

DRIVER SEAT BELT TENSIONER CIRCUIT SHORT..........................26

DRIVER SEAT BELT TENSIONER SHORT TO BATTERY.......................28

DRIVER SEAT BELT TENSIONER SHORT TO GROUND.......................31

DRIVER SQUIB 1 CIRCUIT OPEN.........................................33

DRIVER SQUIB 1 CIRCUIT SHORT........................................36

DRIVER SQUIB 1 SHORT TO BATTERY....................................39

DRIVER SQUIB 1 SHORT TO GROUND....................................42

LOSS OF IGNITION RUN - START.........................................45

PASSENGER SEAT BELT TENSIONER CIRCUIT OPEN.......................47

PASSENGER SEAT BELT TENSIONER CIRCUIT SHORT......................49

PASSENGER SEAT BELT TENSIONER SHORT TO BATTERY..................51

PASSENGER SEAT BELT TENSIONER SHORT TO GROUND..................54

PASSENGER SQUIB 1 CIRCUIT OPEN.....................................56

PASSENGER SQUIB 1 CIRCUIT SHORT....................................59

PASSENGER SQUIB 1 SHORT TO BATTERY................................62

PASSENGER SQUIB 1 SHORT TO GROUND................................65

*AIRBAG WARNING INDICATOR FLASHING.................................68

CABIN HEATER

A. HEATER PRE-TEST...................................................69

CIRC PUMP CONTROL OPEN............................................72

CIRC PUMP CONTROL SHORTED.........................................74

COMBUST FAN SHORTED...............................................76

COMBUST FAN SPEED INCORRECT......................................76

COMBUSTION FAN OPEN................................................76

CONTROL UNIT FAULTY.................................................77

DOSING PUMP OPEN...................................................78

DOSING PUMP SHORTED...............................................81

FAN STAGE 1 RELAY CONTROL OPEN....................................83

FAN STAGE 1 RELAY CONTROL SHORTED.................................85

FLAME DETECT PRIOR TO COMBUST.....................................87

FLAME OUT...........................................................88

NO START.............................................................88

FLAME SENSOR OPEN..................................................91

ii

Page 14 of 2305

1.0 INTRODUCTION

The procedures contained in this manual include

all the specifications, instructions and graphics

needed to diagnose Sprinter body system problems.

The diagnostics in this manual are based on the

failure condition or symptom being present at the

time of diagnosis.

Please follow the recommendations below when

choosing your diagnostic path.

1. First make sure the DRBIIItis communicating

with the appropriate modules; i.e., if the

DRBIIItdisplays a ``No Response'' or a ``Bus6

Signals Open'' condition, you must diagnose that

first.

2. Read DTC's (diagnostic trouble codes) with the

DRBIIIt.

3. If no DTC's are present, identify the customer

complaint.

4. Once the DTC or customer complaint is identi-

fied, locate the matching test in the Table of

Contents and begin to diagnose the symptom.

All component location views are in Section 8.0.

All connector pinouts are in Section 9.0. All sche-

matics are in Section 10.0. All Charts and Graphs

are in Section 11.0.

An * placed before the symptom description indi-

cates a customer complaint without a DTC.

When repairs are required, refer to the appropri-

ate service information for the proper removal and

repair procedure.

Diagnostic procedures change every year. New

diagnostic systems may be added: carryover sys-

tems may be enhanced. READ THIS MANUAL

BEFORE TRYING TO DIAGNOSE A VEHICLE

DIAGNOSTIC TROUBLE CODE. It is recom-

mended that you review the entire manual to be-

come familiar with all the new and changed diag-

nostic procedures.

This book reflects many suggested changes from

readers of past issues. After using this book, if you

have any comments or suggestions, please fill out

the form in the back of this book and mail it back to

us.

1.1 SYSTEM COVERAGE

This diagnostic procedures manual covers all

Sprinter vehicles.

1.2 SIX-STEP TROUBLESHOOTING

PROCEDURE

Diagnosis of the body system is done in six basic

steps:

²verification of complaint

²verification of any related symptoms

²symptom analysis

²problem isolation

²repair of isolated problem

²verification of proper operation

2.0 IDENTIFICATION OF

SYSTEM

The vehicle systems that are part of the ``body''

system are:

²Airbag

²Automatic Temperature Control

²Communication

²Instrument Cluster

²Power Door Locks/RKE

²Vehicle Theft Security System (VTSS)

²Wiper/Rain Sensor

3.0 SYSTEM DESCRIPTION AND

FUNCTIONAL OPERATION

The body system on the Sprinter consists of a

combination of modules that communicate with

each other using the CAN Bus (controller area

network). Through the CAN Bus, information about

the operation of vehicle components and circuits is

relayed quickly to the appropriate modules. Since

the CAN bus network is for intermodule communi-

cation only, the DRBIIItutilizes K-Lines to estab-

lish communications with each module. It is impor-

tant to note the CAN bus circuits are by no means

tied to the K-Lines. They are completely separate

from each other. For additional information on the

CAN bus and the K-Lines, refer to the Communi-

cation section of this general information.

3.1 AIRBAG SYSTEM

The Sprinter Airbag System contains the follow-

ing components:

²Airbag Control Module (ACM)

²Airbag Warning Indicator (SRS)

²Driver Airbags

²Clockspring

²Passenger Airbag

²Driver Seat Belt Tensioners

²Passenger Seat Belt Tensioners

The Airbag Control Module (ACM) has five major

functions: onboard diagnostics, determine the se-

verity of impacts, squib deployment and Accident

Response, K-Line communications. The ACM is

1

GENERAL INFORMATION

Page 15 of 2305

secured to the floor under the Driver seat and

receives power from the Fuse Block No. 1. When-

ever the ignition key is turned to the run or start

position, the ACM performs a system test. The ACM

cannot be repaired or adjusted.

The microprocessor in the ACM monitors the

internal and external airbag system electrical cir-

cuits to determine the system readiness. When a

monitored system is determine to be out of range,

the ACM will set both active and stored diagnostic

trouble codes (DTC). The ACM also contains an

energy-storage capacitor. This capacitor stores

enough electrical energy to deploy the front airbag

components for two seconds following a battery

disconnect or failure during an impact.

The Accelerometer in the ACM is used to sense

the rate of vehicle deceleration, provide verification

of the direction and severity of an impact. When the

preprogrammed conditions are met, the ACM sends

an electrical signal to deploy the appropriate front

airbag system components and a deployment noti-

fication.

To provide an accident response notification, the

ACM is hardwired to the Central Timer module

(CTM) and Engine Control Module (ECM). When a

deployment occurs the ACM provides a 50ms 10.0

volt pulse to the CTM and ECM. When the Accident

Report notification signal is received the CTM un-

locks the door locks and the ECM stalls the engine.

The Accident signal will set a DTC in the CTM and

the door locks will not work until the DTC has been

erased. The ECM will set a DTC if the Accident

Report circuit is shorted to battery voltage. The

ACM saves the deployment record and after three

deployments the ACM must be replaced. The

DRBIIItcan be used to test the Accident Report

Notification feature: select the SYSTEM TEST from

the ACM main menu. Then select the Analog Crash

Output System Test.

The ACM is hardwired to the Instrument Cluster

(MIC) to control Warning Indicator (SRS indicator).

When DTCs becomes activate, the ACM illuminates

the Warning Indicator by pulling the indicator

circuit low. The SRS indicator is the only point at

which the customer can observe symptoms of a

system malfunction.

As part of the system test the ACM illuminates

the Warning Indicator on for 4.0 second bulb test.

After the lamp check, if the indicator turns off, it

means that the ACM has checked the system and

found it to be free of discernible malfunctions.

NON-CRITICAL DTCs

If the lamp comes on and stays on for a period

longer than 4.0 seconds (about 10.0 seconds) is

usually a stored DTC (intermittent problem) in the

system.

CRITICAL DTCs

DTCs that could lead to a condition where the

safety devises may not deploy or incorrectly deploy.

In the event of such a DTC, the safety of the vehicle

occupants can no longer be guaranteed. If the lamp

remains on, there could be an active DTC in the

system. Some DTCs, Internal Module and squib

DTCs, will keep the indicator illuminated even if

the codes are no longer active.

ACM NOT CONFIGURED FOR PASSENGER

AIRBAG AND TENSIONER

If after replacing the ACM the Airbag Warning

Indicator flashes continuously the ACM must be

configured for the Passenger Airbag and Tensioner.

Select Miscellaneous from the ACM main menu and

configure the Passenger Airbag Tensioner squibs.

WARNING:THE AIRBAG SYSTEM IS A

SENSITIVE, COMPLEX ELECTROMECHANICAL

UNIT. BEFORE ATTEMPTING TO DIAGNOSE OR

SERVICE ANY AIRBAG SYSTEM OR RELATED

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENTS YOU MUST

FIRST DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE. WAIT

TWO MINUTES FOR THE SYSTEM CAPACITOR

TO DISCHARGE BEFORE FURTHER SYSTEM

SERVICE. THIS IS THE ONLY SURE WAY TO

DISABLE THE AIRBAG SYSTEM. FAILURE TO

DO THIS COULD RESULT IN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, NEVER STRIKE OR KICK THE

AIRBAG CONTROL MODULE, AS IT CAN

DAMAGE THE IMPACT SENSOR OR AFFECT

ITS CALIBRATION.

WARNING: IF AN AIRBAG CONTROL

MODULE IS ACCIDENTALLY DROPPED

DURING SERVICE, THE MODULE MUST BE

SCRAPPED AND REPLACED WITH A NEW

UNIT. FAILURE TO TAKE THE PROPER

PRECAUTIONS COULD RESULT IN

ACCIDENTAL AIRBAG DEPLOYMENT AND

PERSONAL INJURY OR DEATH.

3.1.1 DRIVER AIRBAG

The airbag protective trim cover is the most

visible part of the driver side airbag system. The

airbag is mounted directly to the steering wheel.

Located under the trim cover are the airbag cushion

and the airbag cushion supporting components.

2

GENERAL INFORMATION

Page 16 of 2305

When supplied with the proper electrical signal, the

inflator discharged the gas directly into the cush-

ion. The airbag cannot be repaired, and must be

replaced if deployed or in any way damaged.

WARNING: THE DRIVER AIRBAG MODULE

CONTAINS ARGON GAS PRESSURIZED TO

OVER 17236.89 Kpa (2500 PSI). DO NOT

ATTEMPT TO DISMANTLE AN AIRBAG

MODULE OR TAMPER WITH ITS INFLATOR.

DO NOT PUNCTURE, INCINERATE, OR

BRING INTO CONTACT WITH ELECTRICITY.

DO NOT STORE AT TEMPERATURE

EXCEEDING 93ÉC (200ÉF). REPLACE AIRBAG

SYSTEM COMPONENTS ONLY WITH PARTS

SPECIFIED IN THE CHRYSLER MOPAR

PARTS CATALOG. SUBSTITUTE PARTS MAY

APPEAR INTER-CHANGEABLE, BUT

INTERNAL DIFFERENCES MAY RESULT IN

INFERIOR OCCUPANT PROTECTION. THE

FASTENERS, SCREWS, AND BOLTS

ORIGINALLY USED FOR THE AIRBAG

SYSTEM COMPONENTS HAVE SPECIAL

COATINGS AND ARE SPECIFICALLY

DESIGNED FOR THE AIRBAG SYSTEM. THEY

MUST NEVER BE REPLACED WITH ANY

SUBSTITUTES. ANY TIME A NEW FASTENER

IS NEEDED, REPLACE IT WITH THE

CORRECT FASTENERS PROVIDED IN THE

SERVICE PACKAGE OR SPECIFIED IN THE

MOPAR PARTS CATALOG. FAILURE TO

TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG

DEPLOYMENT AND PERSONAL INJURY OR

DEATH.

3.1.2 CLOCKSPRING

The clockspring is mounted on the steering col-

umn under the steering wheel. This assembly con-

sists of a plastic housing which contains a flat,

ribbon-like, electrically conductive tape that winds

and unwinds with the steering wheel rotation. The

clockspring is used to maintain a continuous elec-

trical circuit between the instrument panel wiring

and the driver airbag and the horn. The clockspring

must be properly centered when it is reinstalled on

the steering column following any service proce-

dure, or it could be damaged. The clockspring can-

not be repaired and it must be replaced.

3.1.3 PASSENGER AIRBAG

The Passenger Airbag is optional equipment.

When supplied with the proper electrical signal the

passenger airbag inflator discharges the gas di-rectly into the cushion. The airbag module cannot

be repaired, and must be replaced if deployed or in

any way damaged.

WARNING: THE PASSENGER AIRBAG

MODULE CONTAINS ARGON GAS

PRESSURIZED TO 17236.89 Kpa (2500 PSI).

DO NOT ATTEMPT TO DISMANTLE AN

AIRBAG MODULE OR TAMPER WITH ITS

INFLATOR. DO NOT PUNCTURE,

INCINERATE, OR BRING INTO CONTACT

WITH ELECTRICITY. DO NOT STORE AT

TEMPERATURE EXCEEDING 93ÉC (200ÉF).

REPLACE AIRBAG SYSTEM COMPONENTS

ONLY WITH PARTS SPECIFIED IN THE

MOPAR PARTS CATALOG. SUBSTITUTE

PARTS MAY APPEAR INTER-CHANGEABLE,

BUT INTERNAL DIFFERENCES MAY RESULT

IN INFERIOR OCCUPANT PROTECTION. THE

FASTENERS, SCREWS, AND BOLTS

ORIGINALLY USED FOR THE AIRBAG

SYSTEM COMPONENTS HAVE SPECIAL

COATINGS AND ARE SPECIFICALLY

DESIGNED FOR THE AIRBAG SYSTEM. THEY

MUST NEVER BE REPLACED WITH ANY

SUBSTITUTES. ANY TIME A NEW FASTENER

IS NEEDED, REPLACE IT WITH THE

CORRECT FASTENERS PROVIDED IN THE

SERVICE PACKAGE OR SPECIFIED IN THE

MOPAR PARTS CATALOG. FAILURE TO

TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG

DEPLOYMENT AND PERSONAL INJURY OR

DEATH.

3.1.4 SEAT BELT TENSIONERS

Front seat belt systems incorporate a Driver and

optional Passenger Seat Belt Tensioner Retractors.

At the onset of an impact event each tensioner uses

a pyrotechnic device, which is triggered simulta-

neously with the front airbags, to rapidly retract

the seat belts. With the slack removed, the occu-

pant's forward motion in an impact will be reduced

as will the likelihood of contacting interior compo-

nents. After an impact that deploys the airbag, the

seat belt tensioner assembly must be replaced. The

ACM module monitors the Seat Belt Tensioners

circuit resistance and reports active and stored

DTCs if any problem is found. Follow all of the

safety procedures when servicing tensioner.

3.1.5 SPECIAL TOOLS

Airbag load tools 8310 and 8443 are used in some

airbag diagnostic test. The load tools contain fixed

resistive loads, jumpers and adapters. The fixed

3

GENERAL INFORMATION

Page 20 of 2305

Compres SO Accel (Compressor Shut Off - Due

To Acceleration)

The Engine Control Module transmits this data. A

status of9YES9indicates that the compressor shut

off because of an acceleration request. A status of

9NO9indicates that there is no acceleration request.

If shut off due to an acceleration request, the

compress will switch on again after 20 seconds. In

addition, the original acceleration request can no

longer exist for the ECM to acknowledge a subse-

quent request. In the event of a CAN Bus commu-

nication failure,9NO9is displayed as a substitute

value.

Compres SO W/E-Off (Compressor Shut Off -

Due to Emergency Off)

The Engine Control Module transmits this data. A

status of9YES9indicates that the compressor shut

off because of an emergency off request. A status of

9NO9indicates that there is no emergency off re-

quest. In the event of a CAN Bus communication

failure, the last stored value is displayed as a

substitute value.

Auxiliary Fan

The ATC Module transmits this data. A status of

9ON9indicates that the auxiliary fan is operational.

A status of9OFF9indicates that the auxiliary fan is

not operational. The Auxiliary Fan normally oper-

ates when refrigerant head pressure exceeds 290

PSI and coolant temperature exceeds 221ÉF. In the

event of a CAN Bus communication failure, 257ÉF is

displayed for coolant temperature (in Sensors) and

the Auxiliary Fan will run continuously.

Light PB CTRL Module

This input displays a status of9Bright9for positive

dimmer switch operation and9Dimmed9for nega-

tive dimmer switch operation. In the event of a CAN

Bus communication failure,9Bright9is displayed.

3.3.2 CABIN HEATER MODULE (CHM) &

HEATER BOOSTER MODULE (HBM)

3.3.2.1 SYSTEM DESCRIPTION

WARNING: NEVER OPERATE THE HEATER

IN AN ENCLOSED AREA THAT DOES NOT

HAVE EXHAUST VENTILATION FACILITIES.

ALWAYS VENT THE HEATER'S EXHAUST

WHEN OPERATING THE HEATER. REFER TO

(VENTING THE HEATER'S EXHAUST(

BELOW FOR PROPER EXHAUST VENTING

INSTRUCTIONS. FAILURE TO FOLLOW

THESE INSTRUCTIONS CAN RESULT IN

PERSONAL INJURY OR DEATH.

WARNING: ALLOW THE HEATER ASSEMBLY TO

COOL BEFORE PERFORMING A COMPONENT

INSPECTION/REPAIR/REPLACEMENT. FAILURE

TO FOLLOW THESE INSTRUCTIONS CAN

RESULT IN PERSONAL INJURY OR DEATH.

WARNING: ALWAYS DISCONNECT THE

VEHICLE'S BATTERY PRIOR TO

PERFORMING ANY TYPE OF WORK ON THE

HEATER ASSEMBLY. FAILURE TO FOLLOW

THESE INSTRUCTIONS CAN RESULT IN

PERSONAL INJURY OR DEATH.

WARNING: NEVER ATTEMPT TO REPAIR THE

HEATER ASSEMBLY OR ANY OF ITS

INTERNAL COMPONENTS. ALWAYS

PERFORM HEATER COMPONENT

REPLACEMENT IN ACCORDANCE WITH THE

SERVICE INFORMATION. FAILURE TO

FOLLOW THESE INSTRUCTIONS CAN

RESULT IN PERSONAL INJURY OR DEATH.

CAUTION: Always Perform The Heater

Pre-Test (In The Diagnostic Procedures) Prior

To Performing Any Other Test On The Heater

For The Test Result To Be Valid.

NOTE: Do not disconnect the vehicle's

battery or the heater's main power-supply

while the heater is in operation or in

run-down mode. Failure to follow these

instructions may result in excess emissions

from the heater.

NOTE: Failure to prime the Dosing Pump

after draining the fuel line will prevent heater

activation during the first attempt to start the

unit. This may also set a Diagnostic Trouble

Code (DTC) in the control unit's memory. Do

not perform the Dosing Pump Priming

Procedure if an attempt was made to start the

heater without priming the Dosing Pump

first. This will put excess fuel in the heater

module and cause smoke to emit from the

heater's exhaust pipe when heater activation

occurs.

NOTE: Waxed fuel can obstruct the fuel line

and reduce flow. Check for the appropriate

winter grade fuel and replace as necessary.

The Cabin Heater Assembly and Heater Booster

Assembly are supplemental type heaters designed

to pre-heat the engine's coolant in order to supply

the vehicle's occupants with heat prior to the engine

7

GENERAL INFORMATION

Page 21 of 2305

reaching operating temperature. The heater's con-

trol unit controls and monitors combustion opera-

tion through various inputs and outputs that are

contained inside the heater assembly. The supple-

mental heater connects to the vehicle's heater hoses

and uses a separate fuel supply line and fuel pump

that connects to the vehicle's fuel tank. Unlike the

Heater Booster, the Cabin Heater Assembly has an

integral coolant pump which allows heater opera-

tion without the vehicle's engine running. In addi-

tion, a programmable timer module can also be

added to this system. Neither the Cabin Heater

Assembly nor the Heater Booster Assembly are

connected to the CAN Bus. Communication be-

tween the heater's control unit and the DRBIIIt

occurs through the Diagnostic Link Connector

(DLC) via a K-Line.

3.3.2.2 VENTING THE HEATER'S EXHAUST

WARNING: NEVER OPERATE THE HEATER

IN AN ENCLOSED AREA THAT DOES NOT

HAVE EXHAUST VENTILATION FACILITIES.

ALWAYS VENT THE HEATER'S EXHAUST

WHEN OPERATING THE HEATER. FAILURE

TO FOLLOW THESE INSTRUCTIONS CAN

RESULT IN PERSONAL INJURY OR DEATH.

WARNING:

ALLOW THE HEATER ASSEMBLY TO

COOL BEFORE PERFORMING A COMPONENT

INSPECTION/REPAIR/REPLACEMENT. FAILURE

TO FOLLOW THESE INSTRUCTIONS CAN

RESULT IN PERSONAL INJURY OR DEATH.

CAUTION: When using a powered exhaust

ventilation system, do not attach the exhaust

ventilation hose directly to the heater's

exhaust pipe. Too much suction can prevent

heater operation.

When using a powered exhaust ventilation sys-

tem, affix the ventilation hose to the heater's ex-

haust pipe or to the vehicle in such a manor that the

end of the ventilation hose remains approximately

three inches away from the end of the heater's

exhaust pipe.

When using a non-powered exhaust ventilation

system, affix the ventilation hose directly to the

heater's exhaust pipe.

3.3.2.3 SYSTEM DIAGNOSTICS

CAUTION: Always Perform The Heater

Pre-Test (In The Diagnostic Procedures) Prior

To Performing Any Other Test For The Test

Result To Be Valid.

Fault detection is through stored Diagnostic

Trouble Codes (DTCs). DTCs are displayed by the

DRBIIIt. The heater's control unit will store up to

five DTCs in its memory. If the control unit detects

a new fault in the system, one that is not already

stored in its memory, it will clear the oldest of the

five stored DTCs, and it will store the new fault's

DTC. If the control unit detects a reoccurrence of a

stored fault, it will overwrite that fault's DTC with

the most recent occurrence.

DIAGNOSTIC TIPS

SENSOR VALUES

Operating Voltage

The normal range for the Operating Voltage is from

10 volts to 15 volts. The value indicates the voltage

at the heater 's Fused B+ terminal.

Heating Capacity

The normal range for the heating capacity is from

0% to 100%. The value indicates the momentary

output of the auxiliary heater in % of the maximum

output.

Coolant Temperature

The value indicates the current coolant tempera-

ture.

Flame Sensor Resistance

The normal range for the Flame Sensor is from 750

ohms to 2270 ohms. The value indicates the mo-

mentary resistance of the Flame Sensor.

INPUT/OUTPUT STATUS

Dosing Pump

A status of9ON9indicates that the Dosing Pump is

operational. A status of9OFF9indicates the Dosing

Pump is not operational.

Glow Pin

A status of9ON9indicates that the Glow Pin is

energized. A status of9OFF9indicates the Glow Pin

is not energized.

Combustion Fan

A status of9ON9indicates that the Combustion Fan

is operational. A status of9OFF9indicates the

Combustion Fan is not operational.

Circulation Pump

A status of9ON9indicates that the Circulation

Pump is operational. A status of9OFF9indicates the

Circulation Pump is not operational.

Front End Blower

A status of9ON9indicates that the Blower Motor is

operational. A status of9OFF9indicates the Blower

Motor is not operational.

8

GENERAL INFORMATION

Page 22 of 2305

Static Heater Signal

A status of9ON9indicates that the heater module

sees the9Stationary Heating Mode ON9signal after

switching on the heater with the heater timer or the

auxiliary heater switch. A status of9OFF9indicates

that the9Stationary Heating Mode ON9signal is

not present at the heater module.

Heater Booster Mode Signal

A status of9ON9indicates that the heater module

sees the9Heater Booster Mode ON9signal after

switching on the heater with the auxiliary heater

switch. A status of9OFF9indicates that the9Heater

Booster Mode ON9signal is not present at the

heater module.

3.4 INSTRUMENT CLUSTER

The Instrument Cluster has easy-to-read instru-

ments, is capable of CAN bus communication and

provides a diagnostic function. The Instrument

Cluster with analog speedometer, tachometer, fuel

and coolant temperature gauges comes in two ver-

sions.

²Speedometer with outer miles-per-hour (mph)

scale and inner kilometers-per-hour (km/h) scale.

Coolant temperature is indicated in Fahrenheit

(for US).

²Speedometer with outer kilometers-per-hour

(km/h) scale and inner miles-per-hours (mph)

scale. Coolant temperature is indicated in de-

grees Celsius (for Canada).

Below the speedometer, there is a LCD multi-

function indicator in clear view of the driver. Warn-

ing and indicator lights (based on colored light

emitting diodes) are located in the bottom of the

instrument cluster with the exception of the turn

signal indicator lights, ASR warning light and re-

serve fuel warning light. The warning lights for the

seat belt usage and parking brake/brake fluid level

are located in the line above the bottom line. The

indicator that illuminates up when the parking

brake is applied or the brake fluid level is low is

different for U.S. and Canada.

When the key is turned to the 2nd position in the

ignition, the function of the following indicator

lights is checked automatically: High Beam ON,

Preheating, airbag malfunction. In case of a broken

LED of the airbag malfunction light, the seat belt

usage warning light will flash for 6 seconds after

the function check is finished. The Instrument

Cluster is operated with the help of 4 buttons

located below the multifunction indicator. The back-

lighting for the instrument cluster uses yellow

LED's and can be adjusted electronically to daylight

and darkness.The instrument cluster includes a warning

buzzer, which sounds (in addition to a warning light

in some cases) when:

²The headlights are on with the ignition off and

the door opened.

²The driver 's seat belt is not fastened with the

ignition on.

²The key is in the ignition and the door is open.

²Critical ASSYST information is displayed in the

multifunction indicator.

3.5 POWER DOOR LOCKS/RKE

3.5.1 CENTRAL LOCKING

The Central Locking System locks all vehicle

doors if any door is locked from the inside or

mechanically locked with the key from the outside.

However, unlocking any door, in that manner, will

only unlock that particular door. The Master Door

Lock Switch on the dash enables the operator to

lock/unlock all doors. By pressing the top of the

rocker type switch once, all doors will lock. Pressing

the switch again will unlock all doors. Pressing the

lower part of the switch once will lock all doors

except the driver door. Pressing the lower part

again will unlock all doors except the driver door. If

the Central Locking System automatically unlocks

after the vehicle was attempted to be locked, at

least one door is not properly closed.

There are two LED indicators in the Master Door

Lock Switch. The left indicator is for the driver door

and the right indicator is for all passenger/cargo

doors. These will indicate if a door is ajar or if the

doors are locked. The door ajar switches are part of

the door lock motor and are mounted in the door

latch assembly.

Inside each door lock motor there is a command

switch. The command switch is operated by the

plunger and signals any change in the lock status,

locked or unlocked. Each command switch is wired

to the Central Timer Module (CTM) sometimes

referred to as the Central Locking Module. If all

doors are closed and are unlocked, and any door is

locked by the key or the interior handle, thereby

changing the command switch, all doors will be

locked. If one of the door lock motors does not reach

the end position after a locking command, it will be

detected by the CTM (command switch not in

9Locked9position) and the vehicle will be unlocked.

3.5.2 REMOTE KEYLESS ENTRY (RKE)

The SKREEM is a combination of the Remote

Keyless Entry Module and the SKIM (Sentry Key

Immobilizer Module). It is located behind the In-

strument Cluster and has an antenna that goes up

9

GENERAL INFORMATION

Page 24 of 2305

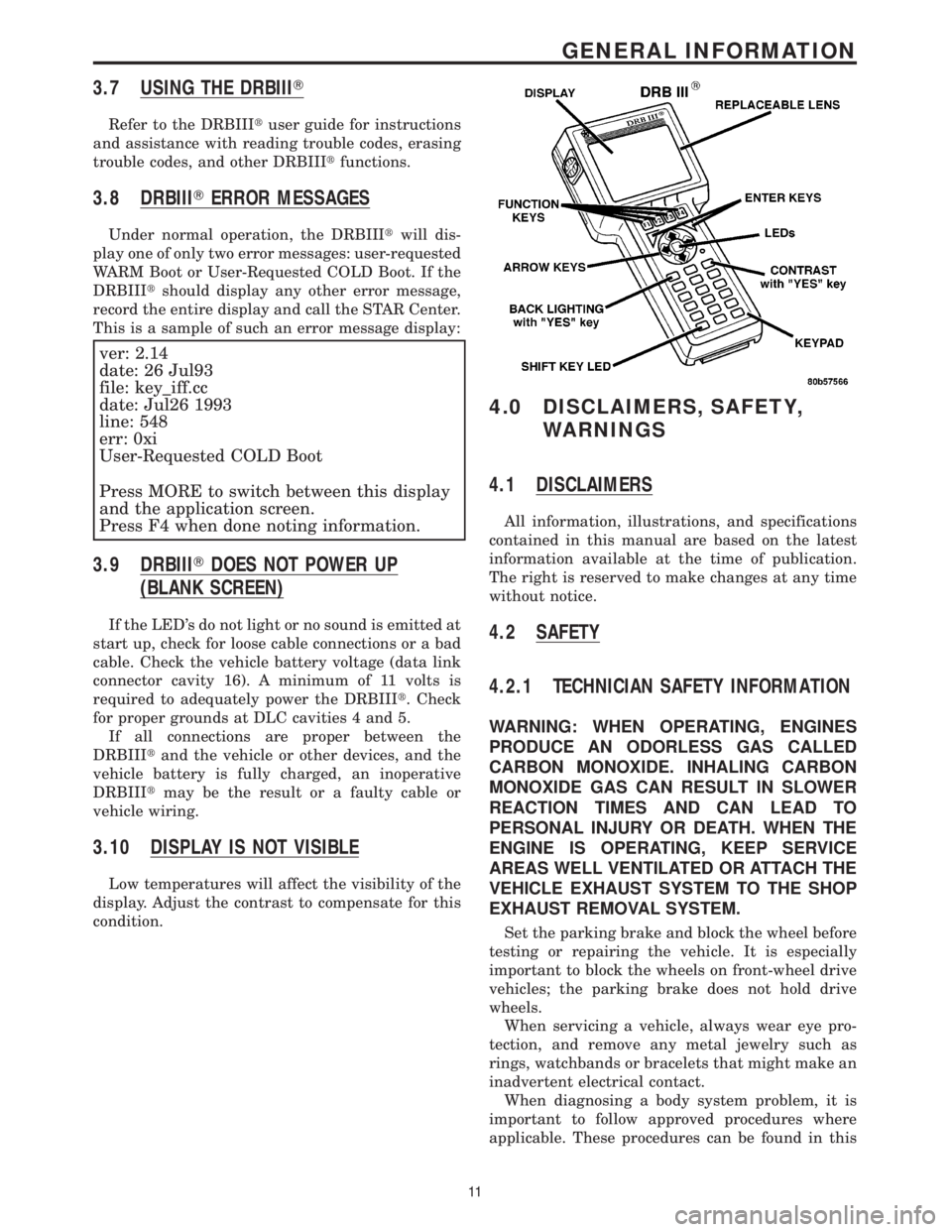

3.7 USING THE DRBIIIT

Refer to the DRBIIItuser guide for instructions

and assistance with reading trouble codes, erasing

trouble codes, and other DRBIIItfunctions.

3.8 DRBIIITERROR MESSAGES

Under normal operation, the DRBIIItwill dis-

play one of only two error messages: user-requested

WARM Boot or User-Requested COLD Boot. If the

DRBIIItshould display any other error message,

record the entire display and call the STAR Center.

This is a sample of such an error message display:

ver: 2.14

date: 26 Jul93

file: key_iff.cc

date: Jul26 1993

line: 548

err: 0xi

User-Requested COLD Boot

Press MORE to switch between this display

and the application screen.

Press F4 when done noting information.

3.9 DRBIIITDOES NOT POWER UP

(BLANK SCREEN)

If the LED's do not light or no sound is emitted at

start up, check for loose cable connections or a bad

cable. Check the vehicle battery voltage (data link

connector cavity 16). A minimum of 11 volts is

required to adequately power the DRBIIIt. Check

for proper grounds at DLC cavities 4 and 5.

If all connections are proper between the

DRBIIItand the vehicle or other devices, and the

vehicle battery is fully charged, an inoperative

DRBIIItmay be the result or a faulty cable or

vehicle wiring.

3.10 DISPLAY IS NOT VISIBLE

Low temperatures will affect the visibility of the

display. Adjust the contrast to compensate for this

condition.

4.0 DISCLAIMERS, SAFETY,

WARNINGS

4.1 DISCLAIMERS

All information, illustrations, and specifications

contained in this manual are based on the latest

information available at the time of publication.

The right is reserved to make changes at any time

without notice.

4.2 SAFETY

4.2.1 TECHNICIAN SAFETY INFORMATION

WARNING: WHEN OPERATING, ENGINES

PRODUCE AN ODORLESS GAS CALLED

CARBON MONOXIDE. INHALING CARBON

MONOXIDE GAS CAN RESULT IN SLOWER

REACTION TIMES AND CAN LEAD TO

PERSONAL INJURY OR DEATH. WHEN THE

ENGINE IS OPERATING, KEEP SERVICE

AREAS WELL VENTILATED OR ATTACH THE

VEHICLE EXHAUST SYSTEM TO THE SHOP

EXHAUST REMOVAL SYSTEM.

Set the parking brake and block the wheel before

testing or repairing the vehicle. It is especially

important to block the wheels on front-wheel drive

vehicles; the parking brake does not hold drive

wheels.

When servicing a vehicle, always wear eye pro-

tection, and remove any metal jewelry such as

rings, watchbands or bracelets that might make an

inadvertent electrical contact.

When diagnosing a body system problem, it is

important to follow approved procedures where

applicable. These procedures can be found in this

11

GENERAL INFORMATION