clock MERCEDES-BENZ SPRINTER 2010 MY10 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2010, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2010Pages: 292, PDF Size: 6.75 MB

Page 144 of 292

reduced in volume each time reverse gear

is engaged.

Refueling

G

Warning

Fuel is highly flammable. Fire, naked flames

and smoking as well as the use of auxiliary

heaters (sparks) are therefore prohibited

when handling fuel.

Switch off the

engine and the auxiliary heating

before refueling. G

Warning

Avoid any contact with fuels.

You can damage your health if your skin

comes into direct contact with fuel or if you

inhale fuel vapors.

0040Environmental note

If fuels are handled improperly, they pose a

danger to persons and the environment. Do

not allow fuels

to run into the sewage system,

the surface waters, the ground water or into

the ground.

! Filter the fuel

before transferring it to the

vehicle if you are refueling the vehicle from

barrels or containers.

This will prevent malfunctions in the fuel

system due to contaminated fuel. G

Warning

Do not use gasoline to refuel vehicles with a

diesel engine. Never

mix diesel with gasoline.

This causes damage to the fuel system and

engine and could result in the vehicle catching

fire.

! Do not use gasoline to refuel vehicles with

a diesel engine. Even small amounts of

gasoline will cause damage to the fuel

system and engine. Damage resulting from

adding gasoline is not covered by the New

Vehicle Limited Warranty. !

If the wrong fuel has been added by

mistake, do not switch on the ignition. If

you do, the fuel could enter the fuel lines.

The tank and the fuel lines must then be

drained. Inform a qualified specialist

workshop and have the tank and the fuel

lines drained completely.

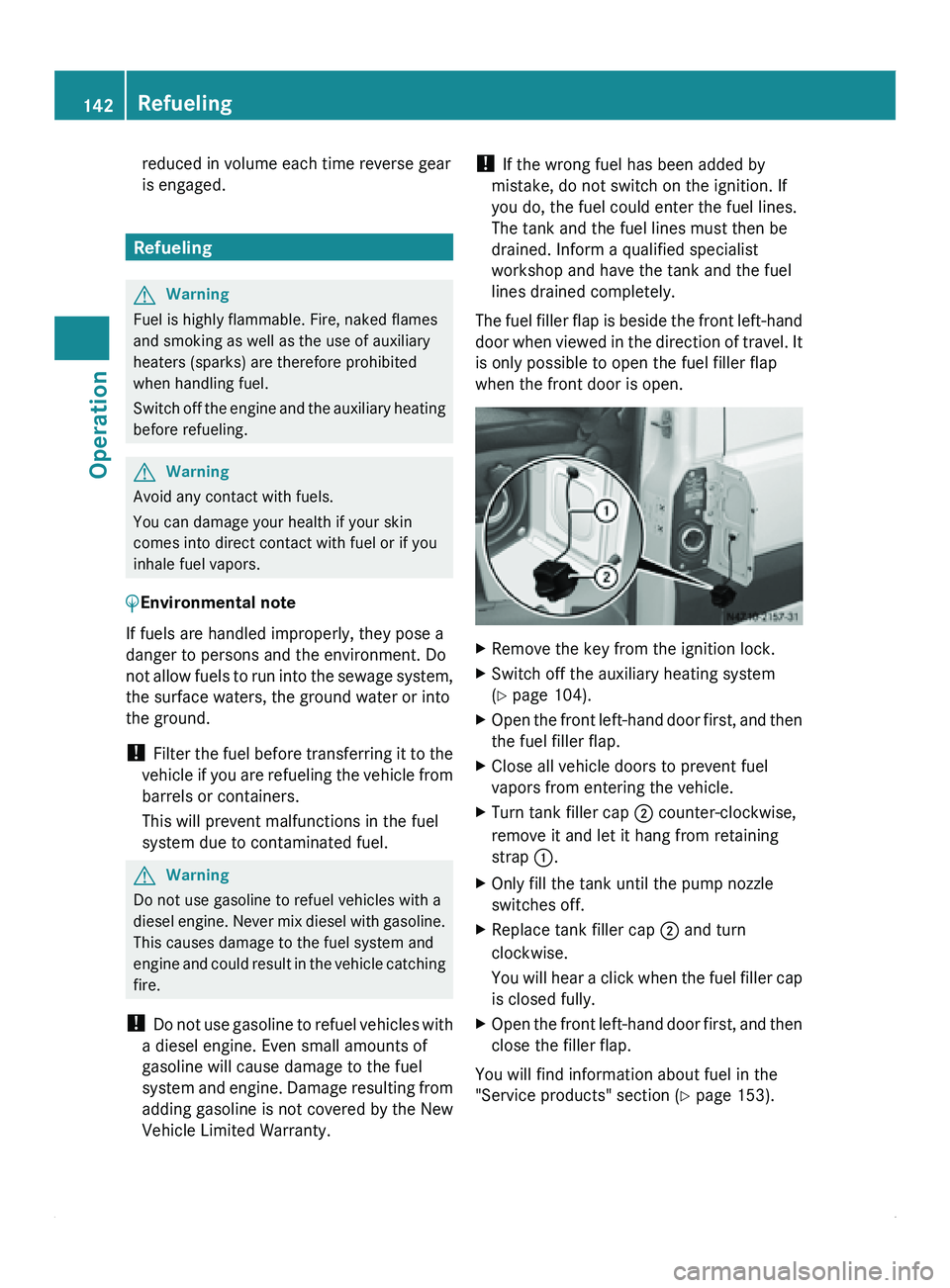

The fuel filler

flap is beside the front left-hand

door when viewed in the direction of travel. It

is only possible to open the fuel filler flap

when the front door is open. X

Remove the key from the ignition lock.

X Switch off the auxiliary heating system

(Y page 104).

X Open the front left-hand door first, and then

the fuel filler flap.

X Close all vehicle doors to prevent fuel

vapors from entering the vehicle.

X Turn tank filler cap 0047 counter-clockwise,

remove it and let it hang from retaining

strap 0046.

X Only fill the tank until the pump nozzle

switches off.

X Replace tank filler cap 0047 and turn

clockwise.

You will

hear

a click when the fuel filler cap

is closed fully.

X Open the front left-hand door first, and then

close the filler flap.

You will find information about fuel in the

"Service products" section (Y page 153). 142

Refueling

Operation

Page 145 of 292

Diesel Exhaust Fluid (DEF)

The exhaust gas aftertreatment requires a

reducing agent, Diesel

Exhaust Fluid (DEF), in

order to function correctly. G

Warning

If you open the DEF reservoir cap at high

temperatures, ammonia vapors could be

released.

Ammonia vapors have

a pungent odor and are

particularly irritating for your skin, respiratory

organs and eyes. This may result in burning

eyes, nose and throat, as well as coughing and

watering eyes.

Do not inhale ammonia vapors. G

Warning

Avoid contact with DEF.

DEF is hazardous

to health. Do not allow DEF

to come into contact with your skin. Rinse

affected areas with plenty of clean water and

consult a doctor if necessary.

0040Environmental note

Dispose of DEF in an environmentally

responsible manner.

! Only use DEF in accordance with

ISO 22241 .

The exhaust gas aftertreatment

system may otherwise be damaged.

Observe the MB Specifications for Service

Products, Sheet No. 352.0.

Damage caused by the use of other

reducing agents will result in the loss of

your New Vehicle Limited Warranty

entitlements.

! If DEF comes into contact with a painted

or aluminum surface, wash the surface off

immediately with plenty of water.

! DEF is not a diesel additive and must not

be mixed with fuel in the tank. Even small

amounts of DEF can cause engine damage.

Damage resulting from adding DEF is not

covered by the New Vehicle Limited

Warranty. i

If the DEF level drops below the reserve

level, the second warning message

(Y page 116) appears and at this point, at

the latest, you

must add at least 2.0 US gal

(7.6 l) of DEF.

You will find further information on DEF in the

"Service products" section (Y page 155).

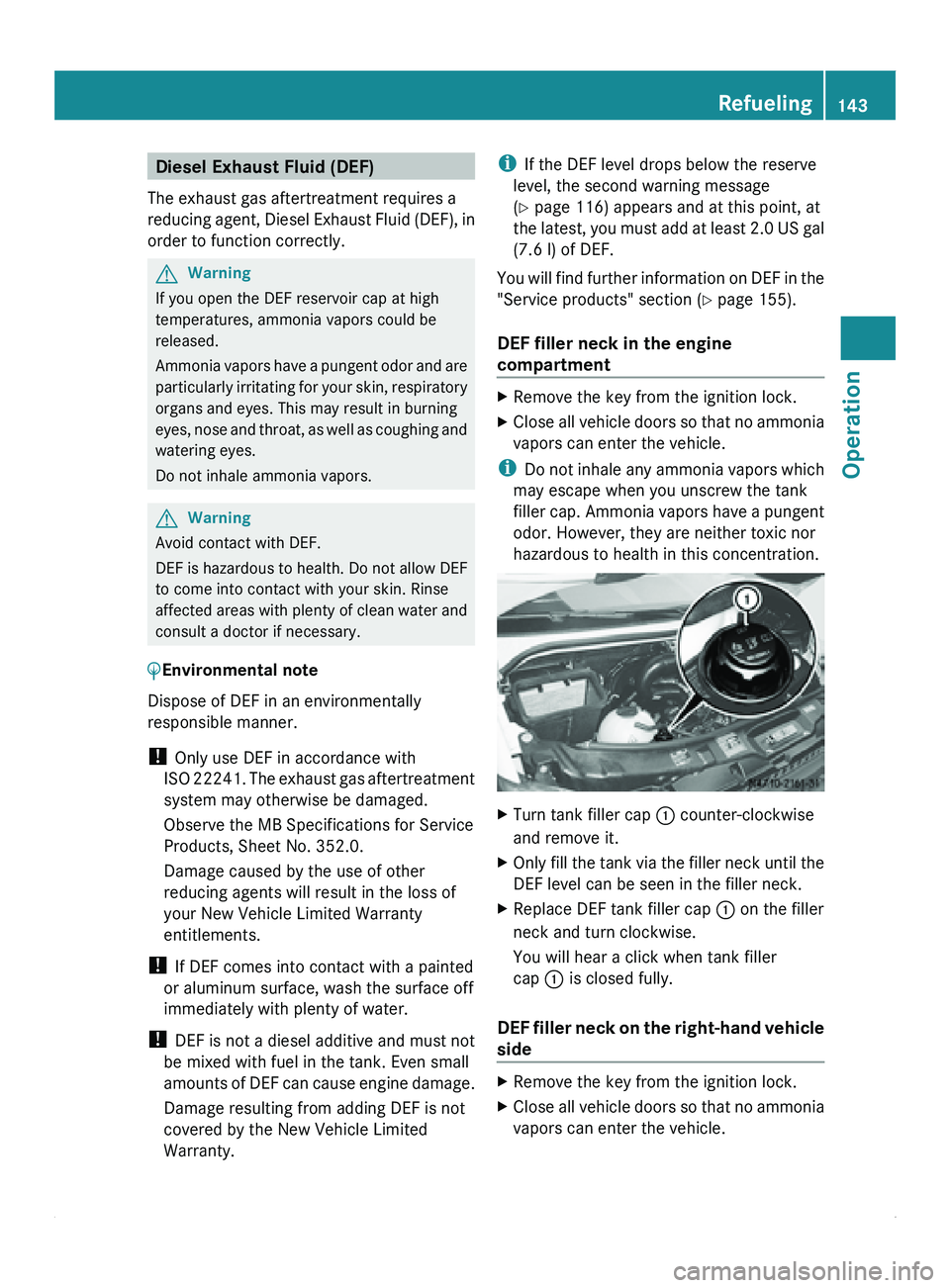

DEF filler neck in the engine

compartment X

Remove the key from the ignition lock.

X Close all

vehicle doors so that no ammonia

vapors can enter the vehicle.

i Do not inhale

any ammonia vapors which

may escape when you unscrew the tank

filler cap. Ammonia vapors have a pungent

odor. However, they are neither toxic nor

hazardous to health in this concentration. X

Turn tank filler cap 0046

counter-clockwise

and remove it.

X Only fill the tank via the filler neck until the

DEF level can be seen in the filler neck.

X Replace DEF tank filler cap 0046 on the filler

neck and turn clockwise.

You will hear a click when tank filler

cap 0046 is closed fully.

DEF filler neck on the right-hand vehicle

side X

Remove the key from the ignition lock.

X Close all vehicle doors so that no ammonia

vapors can enter the vehicle. Refueling

143

Operation Z

Page 146 of 292

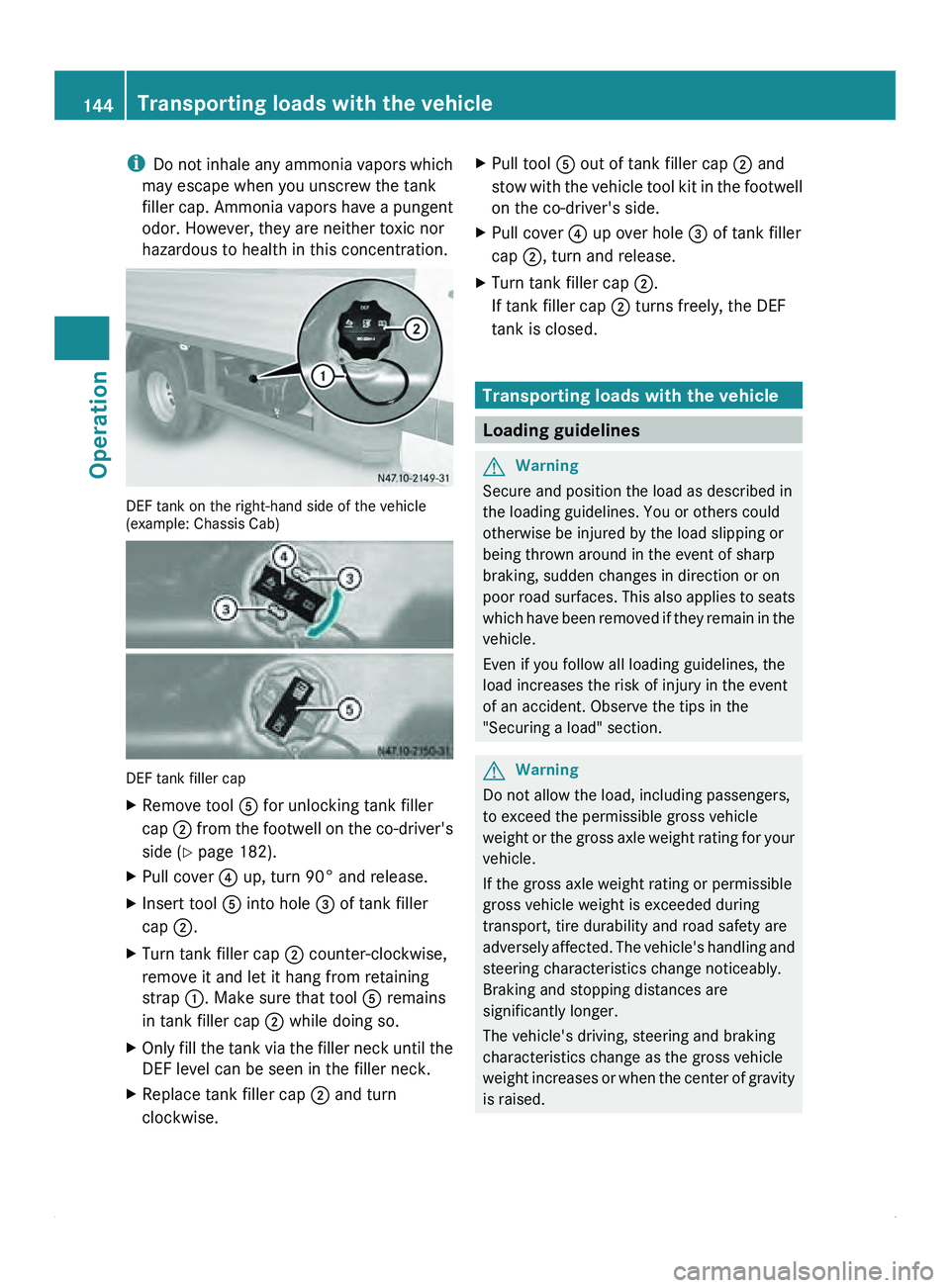

i

Do not inhale

any ammonia vapors which

may escape when you unscrew the tank

filler cap. Ammonia vapors have a pungent

odor. However, they are neither toxic nor

hazardous to health in this concentration. DEF tank on the right-hand side of the vehicle

(example: Chassis Cab)

DEF tank filler cap

X

Remove tool 0086 for unlocking tank filler

cap 0047 from the

footwell on the co-driver's

side ( Y page 182).

X Pull cover 0088 up, turn 90° and release.

X Insert tool 0086 into hole 008A of tank filler

cap 0047.

X Turn tank filler cap 0047 counter-clockwise,

remove it and let it hang from retaining

strap 0046. Make sure that tool 0086 remains

in tank filler cap 0047 while doing so.

X Only fill the tank via the filler neck until the

DEF level can be seen in the filler neck.

X Replace tank filler cap 0047 and turn

clockwise. X

Pull tool 0086 out of tank filler cap 0047 and

stow with

the

vehicle tool kit in the footwell

on the co-driver's side.

X Pull cover 0088 up over hole 008A of tank filler

cap 0047, turn and release.

X Turn tank filler cap 0047.

If tank filler cap 0047 turns freely, the DEF

tank is closed. Transporting loads with the vehicle

Loading guidelines

G

Warning

Secure and position the load as described in

the loading guidelines. You or others could

otherwise be injured by the load slipping or

being thrown around in the event of sharp

braking, sudden changes in direction or on

poor road surfaces.

This also applies to seats

which have been removed if they remain in the

vehicle.

Even if you follow all loading guidelines, the

load increases the risk of injury in the event

of an accident. Observe the tips in the

"Securing a load" section. G

Warning

Do not allow the load, including passengers,

to exceed the permissible gross vehicle

weight or the

gross axle weight rating for your

vehicle.

If the gross axle weight rating or permissible

gross vehicle weight is exceeded during

transport, tire durability and road safety are

adversely affected. The vehicle's handling and

steering characteristics change noticeably.

Braking and stopping distances are

significantly longer.

The vehicle's driving, steering and braking

characteristics change as the gross vehicle

weight increases or when the center of gravity

is raised. 144

Transporting loads with the vehicle

Operation

Page 172 of 292

Only open the coolant expansion tank when

the coolant temperature is below 122 ‡

(50 †).

G

Warning

Coolant contains glycol and is therefore toxic.

Do not swallow the coolant. See a doctor

immediately if you swallow coolant.

Make sure that coolant does not come into

contact with skin,

eyes or clothing. In case of

contact with eyes, rinse immediately with

plenty of clean water. Clean affected areas of

skin and clothing with soap and water

immediately. Change any affected clothing

immediately.

X Slowly turn cap 0046 counter-clockwise and

allow the excess pressure to escape.

X Turn cap 0046 further and remove it.

X Add coolant until it is at the MAX mark.

Observe the correct coolant mixture ratio

and the required water quality

(Y page 160).

X Replace cap 0046 and tighten

it until the stop.

! Check the cooling and heating system

regularly for leaks.

If a large quantity of coolant is lost, have

the cause traced

and rectified at a qualified

specialist workshop, e.g. an authorized

Sprinter Dealer. Clutch mechanism and brake system

G

Warning

Brake fluid is hazardous to health. Do not

swallow brake fluid.

See a doctor immediately

if you swallow brake fluid.

Make sure that brake fluid does not come into

contact with skin, clothing or eyes. Rinse

affected areas with plenty of clean water and

consult a doctor if necessary.

Always wear gloves and eye protection when

topping up brake fluid. Store brake fluid only in the original closed

container and keep it out of the reach of

children. Comply with safety regulations

when handling brake fluid.

G

Warning

If the

boiling point of the brake fluid is too low,

vapor pockets may form in the brake system

when the brakes

are subjected to a heavy load

(e.g. on long downhill stretches). This would

impair braking efficiency. The vehicle's

stopping distance may then be longer. This

increases the risk of an accident.

Have the brake fluid renewed every two years.

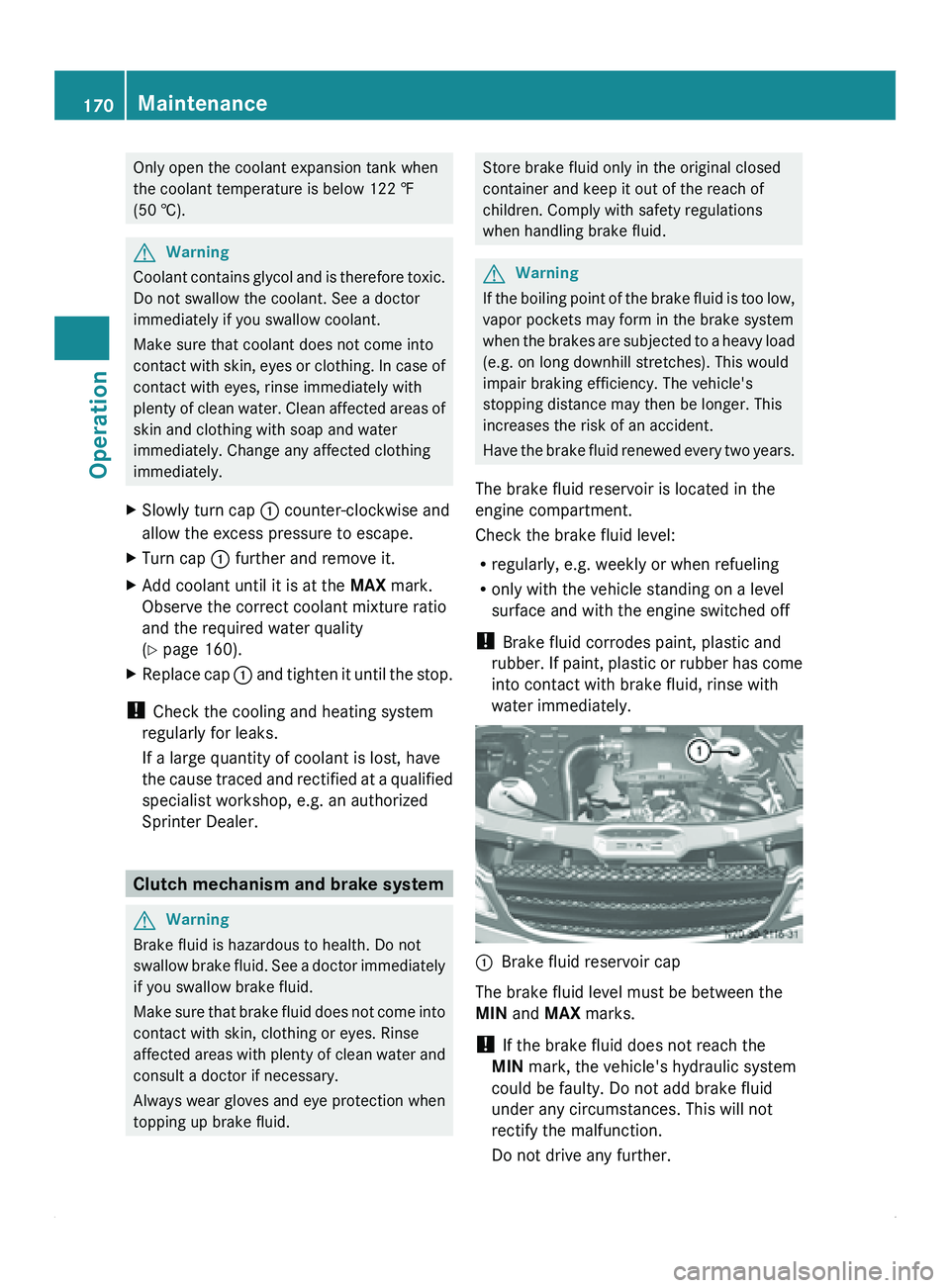

The brake fluid reservoir is located in the

engine compartment.

Check the brake fluid level:

R regularly, e.g. weekly or when refueling

R only with the vehicle standing on a level

surface and with the engine switched off

! Brake fluid corrodes paint, plastic and

rubber. If paint, plastic or rubber has come

into contact with brake fluid, rinse with

water immediately. 0046

Brake fluid reservoir cap

The brake fluid level must be between the

MIN and

MAX marks.

! If the brake fluid does not reach the

MIN mark, the vehicle's hydraulic system

could be faulty. Do not add brake fluid

under any circumstances. This will not

rectify the malfunction.

Do not drive any further. 170

Maintenance

Operation

Page 184 of 292

Vehicle equipment

i Diese Betriebsanleitung beschreibt alle

Modelle, Serien- und

Sonderausstattungen

Ihres Fahrzeugs, die zum Zeitpunkt des

Redaktionsschlusses dieser

Betriebsanleitung erhältlich waren.

Länderspezifische Abweichungen sind

möglich. Beachten Sie, dass Ihr Fahrzeug

nicht mit allen beschriebenen Funktionen

ausgestattet sein könnte. Dies betrifft auch

sicherheitsrelevante Systeme und

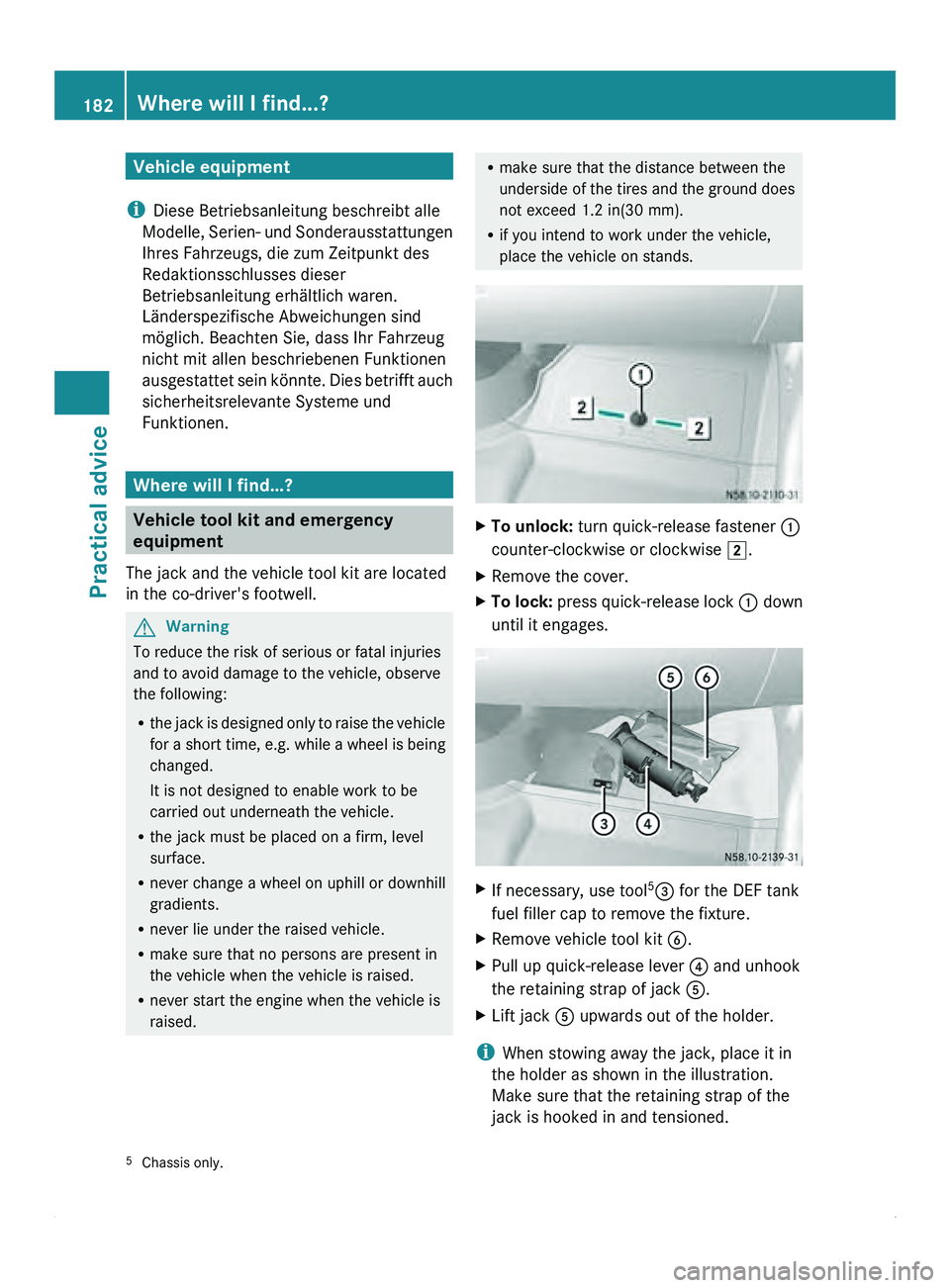

Funktionen. Where will I find...?

Vehicle tool kit and emergency

equipment

The jack and the vehicle tool kit are located

in the co-driver's footwell. G

Warning

To reduce the risk of serious or fatal injuries

and to avoid damage to the vehicle, observe

the following:

R the jack is

designed only to raise the vehicle

for a short time, e.g. while a wheel is being

changed.

It is not designed to enable work to be

carried out underneath the vehicle.

R the jack must be placed on a firm, level

surface.

R never change a wheel on uphill or downhill

gradients.

R never lie under the raised vehicle.

R make sure that no persons are present in

the vehicle when the vehicle is raised.

R never start the engine when the vehicle is

raised. R

make sure that the distance between the

underside

of the

tires and the ground does

not exceed 1.2 in(30 mm).

R if you intend to work under the vehicle,

place the vehicle on stands. X

To unlock: turn quick-release fastener

0046

counter-clockwise or clockwise 004B.

X Remove the cover.

X To lock: press quick-release lock

0046 down

until it engages. X

If necessary, use tool 5

008A for the DEF tank

fuel filler cap to remove the fixture.

X Remove vehicle tool kit 0087.

X Pull up quick-release lever 0088 and unhook

the retaining strap of jack 0086.

X Lift jack 0086 upwards out of the holder.

i When stowing away the jack, place it in

the holder as shown in the illustration.

Make sure that the retaining strap of the

jack is hooked in and tensioned.

5 Chassis only.182

Where will I find...?

Practical advice

Page 187 of 292

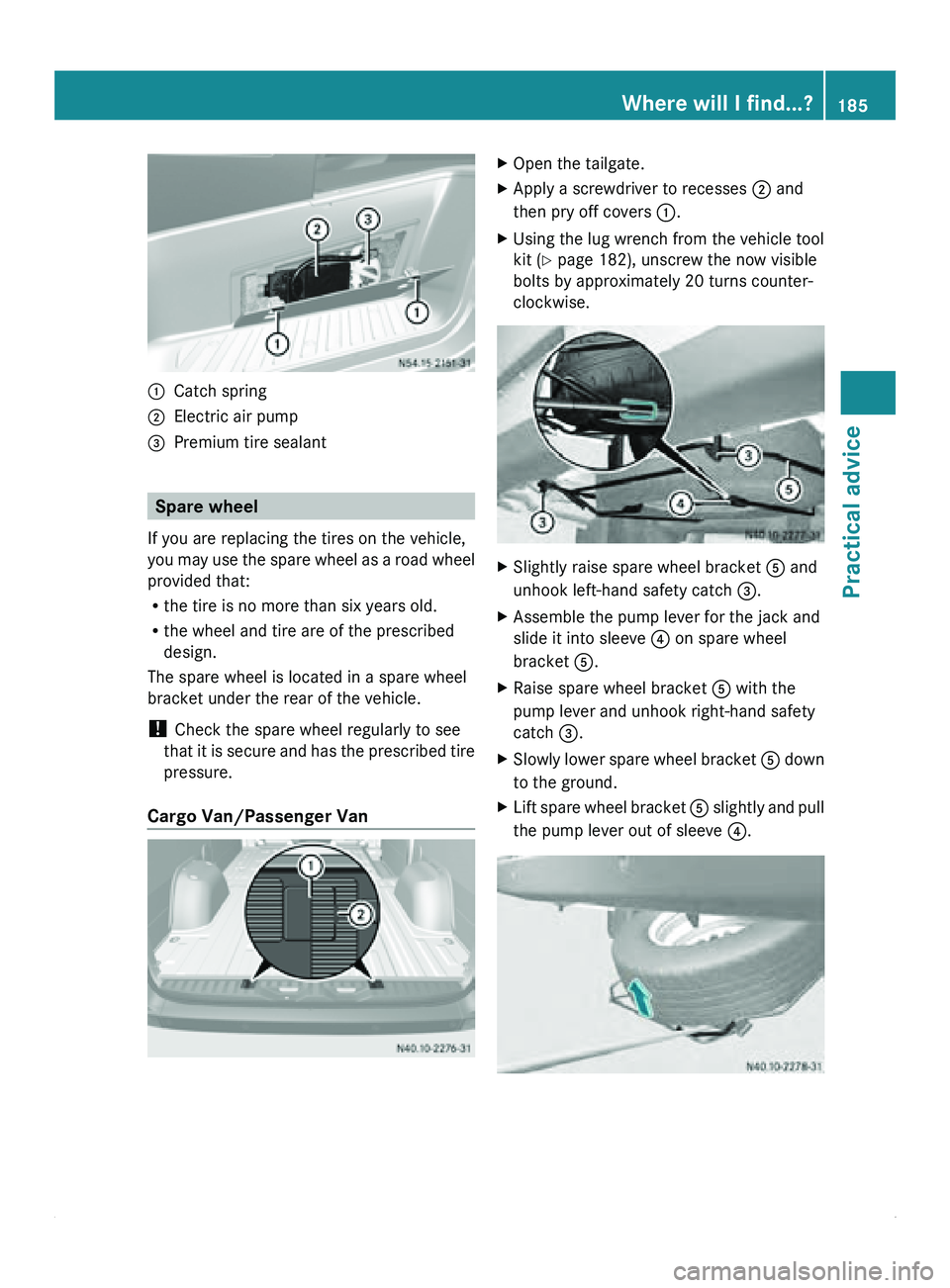

0046

Catch spring

0047 Electric air pump

008A Premium tire sealant Spare wheel

If you are replacing the tires on the vehicle,

you may use

the spare wheel as a road wheel

provided that:

R the tire is no more than six years old.

R the wheel and tire are of the prescribed

design.

The spare wheel is located in a spare wheel

bracket under the rear of the vehicle.

! Check the spare wheel regularly to see

that it is secure and has the prescribed tire

pressure.

Cargo Van/Passenger Van X

Open the tailgate.

X Apply a screwdriver to recesses 0047 and

then pry off covers 0046.

X Using the lug wrench from the vehicle tool

kit ( Y page 182), unscrew the now visible

bolts by approximately 20 turns counter-

clockwise. X

Slightly raise spare wheel bracket 0086 and

unhook left-hand safety catch 008A.

X Assemble the pump lever for the jack and

slide it into sleeve 0088 on spare wheel

bracket 0086.

X Raise spare wheel bracket 0086 with the

pump lever and unhook right-hand safety

catch 008A.

X Slowly lower spare wheel bracket 0086 down

to the ground.

X Lift spare

wheel bracket 0086 slightly and

pull

the pump lever out of sleeve 0088. Where will I find...?

185

Practical advice Z

Page 226 of 292

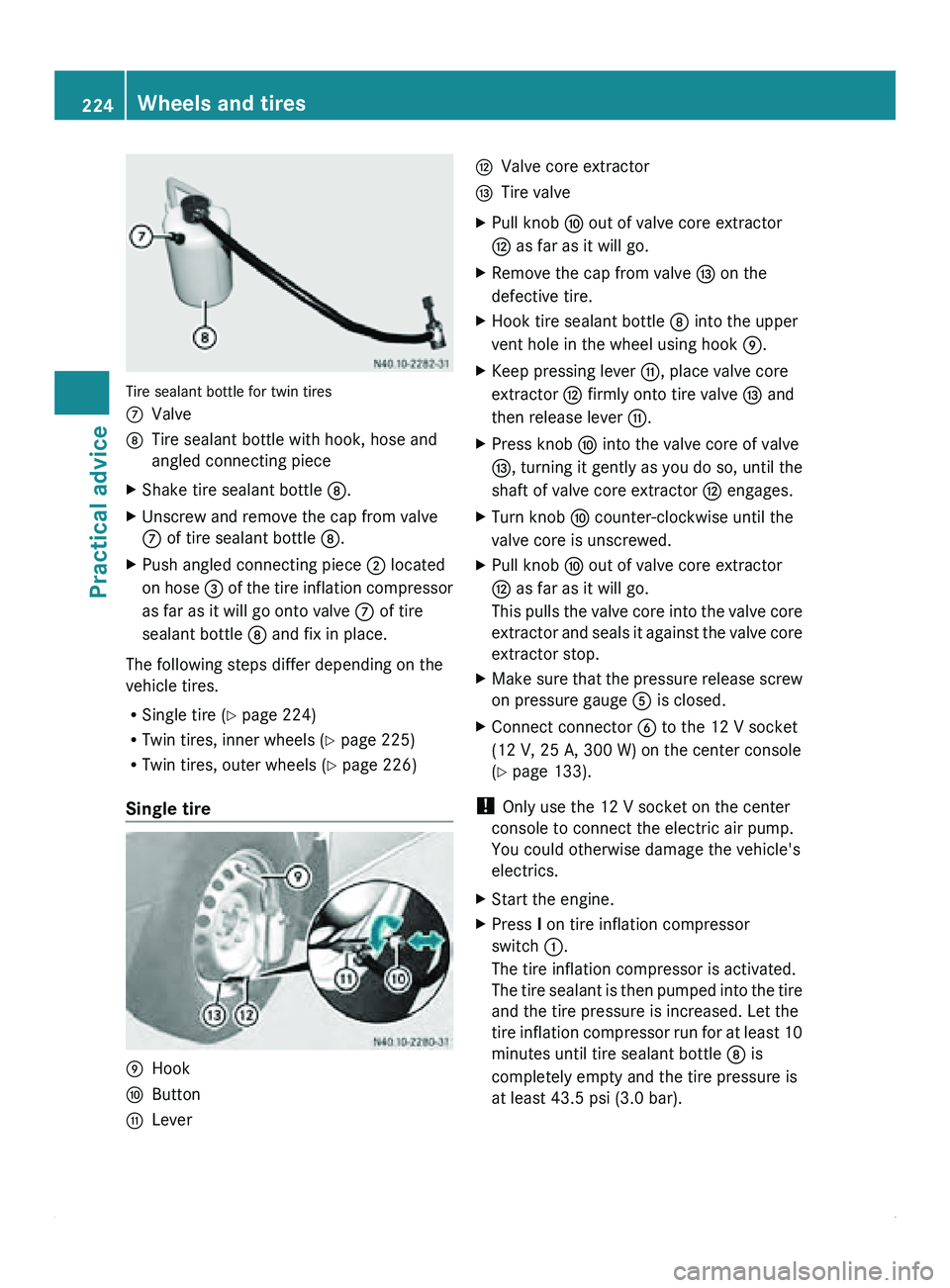

Tire sealant bottle for twin tires

006E

Valve

006F Tire sealant bottle with hook, hose and

angled connecting piece

X Shake tire sealant bottle 006F.

X Unscrew and remove the cap from valve

006E of tire sealant bottle 006F.

X Push angled connecting piece 0047 located

on hose 008A

of the tire inflation compressor

as far as it will go onto valve 006E of tire

sealant bottle 006F and fix in place.

The following steps differ depending on the

vehicle tires.

R Single tire (Y page 224)

R Twin tires, inner wheels ( Y page 225)

R Twin tires, outer wheels (

Y page 226)

Single tire 0070

Hook

0071 Button

0072 Lever 0073

Valve core extractor

0074 Tire valve

X Pull knob 0071 out of valve core extractor

0073 as far as it will go.

X Remove the cap from valve 0074 on the

defective tire.

X Hook tire sealant bottle 006F into the upper

vent hole in the wheel using hook 0070.

X Keep pressing lever 0072, place valve core

extractor 0073 firmly onto tire valve 0074 and

then release lever 0072.

X Press knob 0071 into the valve core of valve

0074, turning it gently as you do so, until the

shaft of valve core extractor 0073 engages.

X Turn knob 0071 counter-clockwise until the

valve core is unscrewed.

X Pull knob 0071 out of valve core extractor

0073 as far as it will go.

This pulls

the

valve core into the valve core

extractor and seals it against the valve core

extractor stop.

X Make sure that the pressure release screw

on pressure gauge 0086 is closed.

X Connect connector 0087 to the 12 V socket

(12 V, 25 A, 300 W) on the center console

(Y page 133).

! Only use the 12 V socket on the center

console to connect the electric air pump.

You could otherwise damage the vehicle's

electrics.

X Start the engine.

X Press I on tire inflation compressor

switch 0046.

The tire inflation compressor is activated.

The tire sealant

is then pumped into the tire

and the tire pressure is increased. Let the

tire inflation compressor run for at least 10

minutes until tire sealant bottle 006F is

completely empty and the tire pressure is

at least 43.5 psi (3.0 bar). 224

Wheels and tires

Practical advice

Page 227 of 292

!

Do not run

the electric air pump for longer

than 20 minutes without a break; otherwise

it may overheat.

The air pump can be used again once it has

cooled down.

X Inflate the tire using the tire inflation

compressor until the recommended tire

pressure ( Y page 281) is reached.

X Then, press 0 on tire inflation compressor

switch 0046.

The tire inflation compressor is

deactivated.

X Slide knob 0071 quickly to the stop in valve

core extractor 0073.

X Turn knob 0071 clockwise

until

the valve core

is firmly screwed into tire valve 0074.

i Do not pull the valve core extractor from

the tire valve while the valve core is

unscrewed from

the

tire valve. Tire sealant

could otherwise escape and make you

dirty.

The tire sealant is water-soluble. If tire

sealant escapes, you can wash it away with

water.

X Press lever 0072 and pull

valve core extractor

0073 from tire valve 0074.

X Screw the valve cap onto tire valve 0074.

After filling with tire sealant, ( Y page 228).

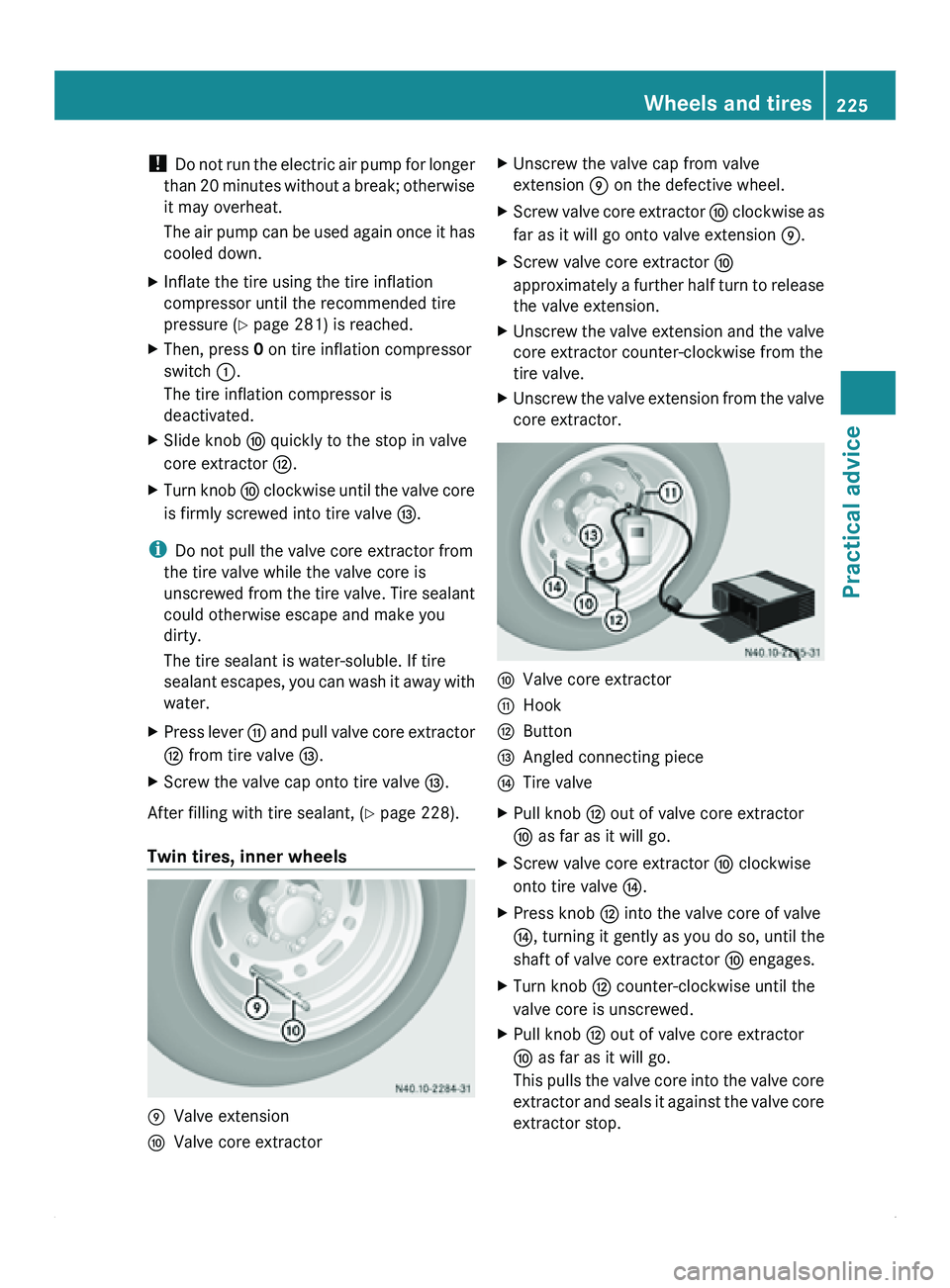

Twin tires, inner wheels 0070

Valve extension

0071 Valve core extractor X

Unscrew the valve cap from valve

extension 0070 on the defective wheel.

X Screw valve core extractor 0071

clockwise as

far as it will go onto valve extension 0070

.

X Screw valve core extractor 0071

approximately a

further

half turn to release

the valve extension.

X Unscrew the valve extension and the valve

core extractor counter-clockwise from the

tire valve.

X Unscrew the valve extension from the valve

core extractor. 0071

Valve core extractor

0072 Hook

0073 Button

0074 Angled connecting piece

0075 Tire valve

X Pull knob 0073 out of valve core extractor

0071 as far as it will go.

X Screw valve core extractor 0071 clockwise

onto tire valve 0075.

X Press knob 0073 into the valve core of valve

0075, turning it gently as you do so, until the

shaft of valve core extractor 0071 engages.

X Turn knob 0073 counter-clockwise until the

valve core is unscrewed.

X Pull knob 0073 out of valve core extractor

0071 as far as it will go.

This pulls

the

valve core into the valve core

extractor and seals it against the valve core

extractor stop. Wheels and tires

225

Practical advice Z

Page 228 of 292

X

Hook tire sealant bottle 006F into the upper

vent hole in the wheel using hook 0072.

X Push angled connecting piece 0074 located

on the hose of tire sealant filler bottle 006F

as far

as

it will go on to valve core extractor

0071 and fix it in place.

X Make sure that the pressure release screw

on pressure gauge 0086 is closed.

X Connect connector 0087 to the 12 V socket

(12 V, 25 A, 300 W) on the center console

(Y page 133).

! Only use the 12 V socket on the center

console to connect the electric air pump.

You could otherwise damage the vehicle's

electrics.

X Start the engine.

X Press I on tire inflation compressor

switch 0046.

The tire inflation compressor is activated.

The tire

sealant

is then pumped into the tire

and the tire pressure is increased. Let the

tire inflation compressor run for at least 10

minutes until tire sealant bottle 006F is

completely empty and the tire pressure is

at least 43.5 psi (3.0 bar).

! Do not

run

the electric air pump for longer

than 20 minutes without a break; otherwise

it may overheat.

The air pump can be used again once it has

cooled down.

X Inflate the tire using the tire inflation

compressor until the recommended tire

pressure ( Y page 281) is reached.

X Then, press 0 on tire inflation compressor

switch 0046.

The tire inflation compressor is

deactivated.

X Slide knob 0073 quickly to the stop in valve

core extractor 0071.

X Turn knob 0073 clockwise

until

the valve core

is firmly screwed into tire valve 0075.i

Do not pull the valve core extractor from

the tire valve while the valve core is

unscrewed from the

tire valve. Tire sealant

could otherwise escape and make you

dirty.

The tire sealant is water-soluble. If tire

sealant escapes, you can wash it away with

water.

X Pull knob 0073 out of valve core extractor

0071 as far as it will go.

X Unscrew valve core extractor 0071 counter-

clockwise from tire valve 0075.

X Screw valve extension 0070 onto tire valve

0075 and tighten it.

X Screw the valve cap onto valve extension

0070.

After filling with tire sealant, ( Y page 228).

Twin tires, outer wheel The tire valve is located on the inside of the

outer wheel and should be positioned

horizontally on the left side of the wheel for

the repair process.

Valve tool with handle and turning piece226

Wheels and tires

Practical advice

Page 230 of 292

i

If the valve

insert is damaged or lost when

it is unscrewed, you can use the valve insert

of the tire sealant bottle after you have

used the tire sealant.

X Unscrew the valve insert from the valve of

the tire sealant bottle using the valve

extractor.

! Do not run

the electric air pump for longer

than 20 minutes without a break; otherwise

it may overheat.

The air pump can be used again once it has

cooled down.

X Push angled connecting piece 0047 located

on tire inflation

compressor hose 008A as far

as it will go onto valve 0072 and fix it in place.

X Push I on tire inflation compressor

switch 0046 and inflate the tire to the

recommended tire pressure ( Y page 281).

X Then, press 0 on tire inflation compressor

switch 0046.

The tire inflation compressor is

deactivated.

i The tire sealant is water-soluble. If tire

sealant escapes,

you

can wash it away with

water.

X Screw the valve cap onto tire valve 0072.

After filling with tire sealant, ( Y page 228).

After filling with tire sealant X

Turn the pressure release screw on

pressure gauge 0086 counter-clockwise and

bleed the system.

X Turn the key to position 0 in the ignition

lock.

X Pull the tire inflation compressor connector

out of the 12 V socket.

X Stow the tire inflation compressor, tire

sealant bottle 006F with the valve core

extractor and/or valve tool, the warning triangle and hazard warning lights inside

the vehicle.

X Remove angled connecting piece 0047 from

valve 006E of tire sealant filler bottle 006F and

screw the valve cap onto the valve. G

Warning

You must not exceed a maximum speed of

50 mph (80 km/h) .

The "max.

50 mph" (80 km/h) sticker must be

affixed within the driver's field of vision.

The vehicle's handling characteristics may be

affected.

X Pull away immediately.

This enables the tire sealant to distribute

inside the tire and create a more effective

seal.

X Stop after driving for about three minutes

and check the tire pressure using the tire

inflation compressor, for example.

i You must connect the angled connecting

piece on hose 008A of the tire inflation

compressor directly to

the tire valve on the

tire.

X Correct the tire pressure accordingly if it

does not correspond to the recommended

tire pressure ( Y page 281).

X To increase the tire pressure: switch on

the tire inflation compressor.

X To reduce the tire pressure: open the

pressure release screw on pressure

gauge 0086.

X Drive to the nearest workshop and have the

tire repaired or replaced.

X Clean the valve core extractor with clean

water.

X Have tire sealant bottle 006F replaced as

soon as possible at a qualified specialist

workshop, e.g. an authorized Sprinter

Dealer.228

Wheels and tires

Practical advice