lock MERCEDES-BENZ SPRINTER 2016 MY16 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2016, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2016Pages: 290, PDF Size: 6.44 MB

Page 257 of 290

Using the steering wheel buttons

XTurn the SmartKey to position2in the ignition

lock.

XPress the VorU button repeatedly

until the standard display is shown

(

Ypage 167).

XPress the 9or: button repeatedly

until the current pressure of the individual

tires is shown in the display.

If the vehicle is parked for longer than

20 minutes or you then drive at less than 18 mph

(30 km/h), the Tire pres. displayed

after driving for several minutesmes-

sage appears.

iThe tire pressure value shown in the display

may differ from those measured at a gas sta-

tion using a pressure gage. The on-board

computer will generally give you a more exact

value.

Tire pressure loss warning system

Vehicles with steering wheel buttons

If the tire pressure monitor detects a pressure

loss in one or more tires, the on-board computer

displays the yellow Tire

pres.Adjustpres.warning message. The htire pressure loss

warning lamp in the instrument cluster

(

Ypage 202) flashes for about 60 seconds and

then remains lit.

The pressure of the affected tire is highlighted in

yellow in the on-board computer (

Ypage 176).

If the tire pressure monitor detects a significant

pressure loss in one or more tires, the on-board

computer displays the red Tire pres.

Warn‐ingTiredefectwarning message. Theh

tire pressure loss warning lamp in the instru-

ment cluster (

Ypage 202) flashes for about 60

seconds and then remains lit. An additional

warning tone sounds.

The pressure of the affected tire is highlighted in

yellow in the on-board computer (

Ypage 176).

Restarting the tire pressure monitor

When you restart the tire pressure monitor, the

currently set tire pressure are taken as refer-

ence values for monitoring. In most cases, the tire pressure monitor detects

the new reference values automatically, e.g.

after you have:

Rchanged the tire pressure

Rchanged wheels or tires

Rinstalled new wheels or tires

However, you can also define reference values

manually as described here.

Before restarting the tire pressure monitor:

XSet the tire pressure to the value recommen- ded on the Tire and Loading Information plac-

ard or the tire pressure table on the B-pillar on

the driver's side (

Ypage 250).

Observe the notes on tire pressure when

doing so (

Ypage 250).

XMake sure that the tire pressure is correct on

all four wheels.

Restarting the tire pressure monitor (vehi-

cles without steering wheel buttons):

XTurn the SmartKey to position 2in the ignition

lock.

XPress the 4menu button on the instrument

cluster repeatedly until the display shows the

following message:

+CAL- TPMS

XPress the fbutton on the instrument clus-

ter.

The display shows:

OK TPMS

The tire pressure monitor activation process

has begun. The tire pressures measured for

the individual wheels are stored as the new

reference values, provided that the tire pres-

sure monitor considers them to be plausible.

If you wish to cancel the restart:

XPress the gbutton or the 4menu button on

the instrument cluster.

The activation process is canceled automati-

cally if 30 seconds elapse without input.

Restarting the tire pressure monitor (vehi-

cles with steering wheel buttons):

XTurn the key to position 2in the ignition lock.

XPress the VorU button on the steering

wheel until the standard display (Ypage 167)

appears in the display.

XPress the 9or: button on the steering

wheel repeatedly until the current pressure of

Tire pressure255

Wheels and tires

Z

Page 270 of 290

Raising the vehicle

GWARNING

If you do not position the jack correctly at the

appropriate jacking point of the vehicle, the

jack could tip over with the vehicle raised.

There is a risk of injury.

Only position the jack at the appropriate jack-

ing point of the vehicle. The base of the jack

must be positioned vertically, directly under

the jacking point of the vehicle.

GWARNING

On uphill and downhill slopes, the jack could

tip over with the vehicle raised. There is a risk

of injury.

Do not change wheels on uphill or downhill

gradients. Notify a qualified specialist work-

shop.

!Only position the jack on the jacking points

intended for this purpose. You could other-

wise damage the vehicle.

Observe the following when raising the vehicle:

RWhen raising the vehicle, only use the jack

which Mercedes-Benz has specifically

approved for your vehicle.

RThe vehicle's jack is intended only to raise the

vehicle for a short time when changing a

wheel. It is not suited for performing mainte-

nance work under the vehicle.

RAvoid changing the wheel on uphill and down- hill slopes.

RBefore raising the vehicle, secure it from roll-

ing away by applying the parking brake and

inserting wheel chocks. Never disengage the

parking brake while the vehicle is raised.

RThe jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a large,

load-bearing underlay must be used. On a

slippery surface, a non-slip underlay must be

used, e.g. rubber mats.

RMake sure that the distance between the

underside of the tires and the ground does not

exceed 1.2 in(3 cm).

RNever place your hands or feet under the

ra

ised vehicle.

RNever lie under the raised vehicle.

RNever start the engine when the vehicle is

raised.

RNever open or close a door when the vehicle

is raised.

RMake sure that no persons are present in the

vehicle when the vehicle is raised.

!Only use the jack pump lever middle rod and

the rod with the largest diameter as a lug

wrench extension. Only slide the middle rod

as far as it will go onto the lug wrench. The

rods may otherwise bend and be distorted to

such an extent that they can no longer be

used as a pump lever for the jack.

!Do not place the jack on the leaf spring or

the differential case.

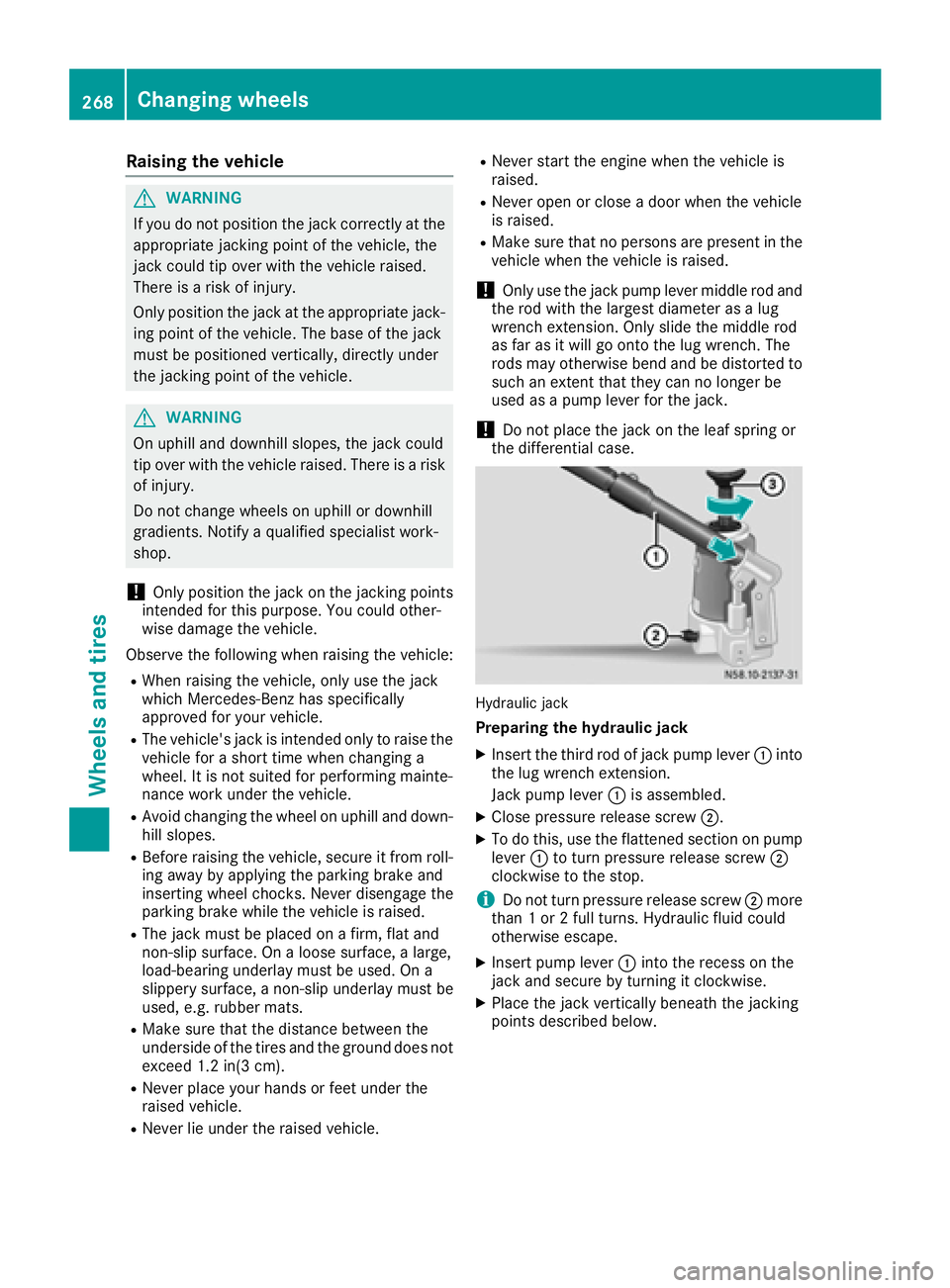

Hydraulic jack

Preparing the hydraulic jack

XInsert the third rod of jack pump lever :into

the lug wrench extension.

Jack pump lever :is assembled.

XClose pressure release screw ;.

XTo do this, use the flattened section on pump

lever:to turn pressure release screw ;

clockwise to the stop.

iDo not turn pressure release screw ;more

than 1 or 2 full turns. Hydraulic fluid could

otherwise escape.

XInsert pump lever :into the recess on the

jack and secure by turning it clockwise.

XPlace the jack vertically beneath the jacking

points described below.

268Changing wheels

Wheels and tires

Page 271 of 290

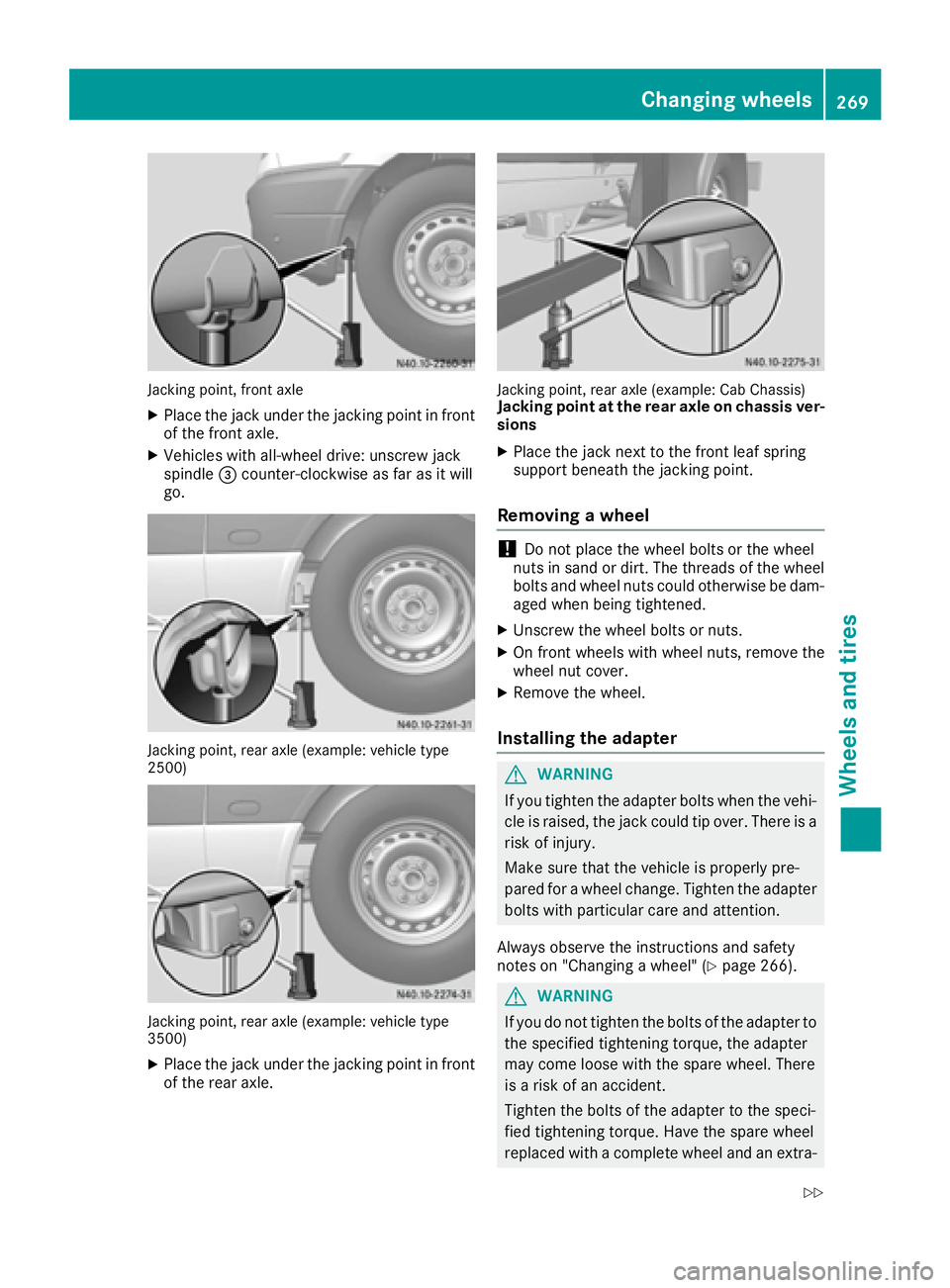

Jacking point, front axle

XPlace the jack under the jacking point in frontof the front axle.

XVehicles with all-wheel drive: unscrew jack

spindle =counter-clockwise as far as it will

go.

Jacking point, rear axle (example: vehicle type

2500)

Jacking point, rear axle (example: vehicle type

3500)

XPlace the jack under the jacking point in front

of the rear axle.

Jacking point, rear axle (example: Cab Chassis)Jacking point at the rear axle on chassis ver-

sions

XPlace the jack next to the front leaf spring

support beneath the jacking point.

Removing a wheel

!Do not place the wheel bolts or the wheel

nuts in sand or dirt. The threads of the wheel

bolts and wheel nuts could otherwise be dam-

aged when being tightened.

XUnscrew the wheel bolts or nuts.

XOn front wheels with wheel nuts, remove the

wheel nut cover.

XRemove the wheel.

Installing the adapter

GWARNING

If you tighten the adapter bolts when the vehi-

cle is raised, the jack could tip over. There is a risk of injury.

Make sure that the vehicle is properly pre-

pared for a wheel change. Tighten the adapter

bolts with particular care and attention.

Always observe the instructions and safety

notes on "Changing a wheel" (

Ypage 266).

GWARNING

If you do not tighten the bolts of the adapter to

the specified tightening torque, the adapter

may come loose with the spare wheel. There

is a risk of an accident.

Tighten the bolts of the adapter to the speci-

fied tightening torque. Have the spare wheel

replaced with a complete wheel and an extra-

Changing wheels269

Wheels and tires

Z

Page 273 of 290

Slide the new wheel onto the wheel hub and

push it on.

Wheels with centering by wheel bolts:

XVehicles with alloy wheels: take the short

wheel bolts that secure the steel spare wheel

out of the vehicle tool kit.

XScrew in the wheel bolts and tighten them

lightly.

For wheels with wheel nuts:

XFront wheels with wheel nut covers: press the

wheel nut covers onto the wheel nuts.

XScrew in the three wheel nuts over the fixing

discs of the wheel nut cover.

XTurn the wheel so that the wheel bolts are in

the middle of the holes.

XScrew on the rest of the wheel nuts.

XSlightly tighten all the wheel nuts.

Lowering the vehicle

GWARNING

The wheels could work loose if the wheel nuts and bolts are not tightened to the specified

tightening torque. There is a risk of accident.

Have the tightening torque immediately

checked at a qualified specialist workshop

after a wheel is changed.

!Only use the jack pump lever middle rod and

the rod with the largest diameter as a lug

wrench extension. Only slide the middle rod

as far as it will go onto the lug wrench. The

rods may otherwise bend and be distorted to

such an extent that they can no longer be

used as a pump lever for the jack.

!Vehicles with Super Single tires: if you

install the spare wheel, do not exceed the

maximum speed of 40 mph (60 km/h) and do

not drive further than 65 miles(100 km).

The transmission could otherwise be dam-

aged by the difference in wheel rotation

speeds.

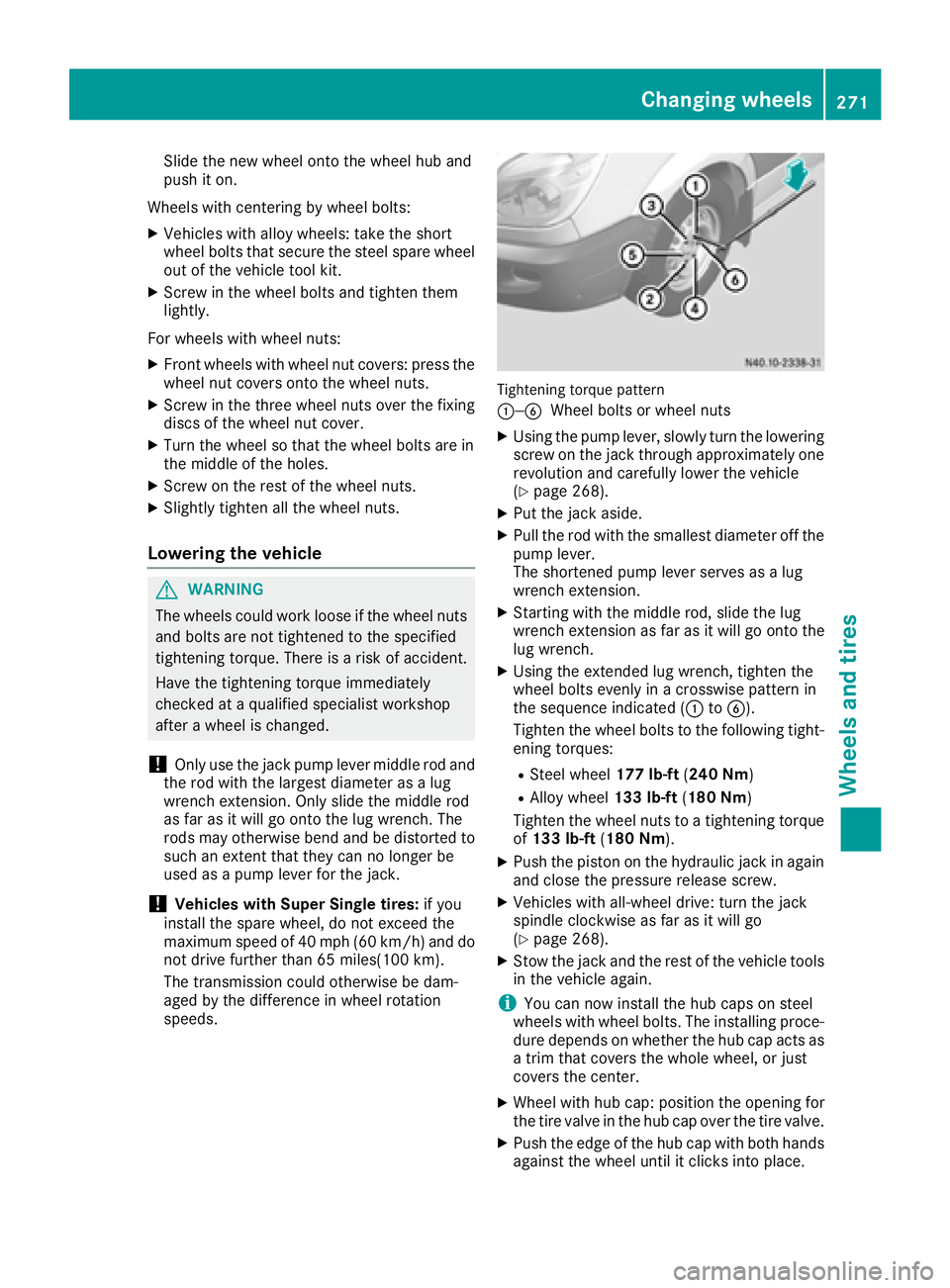

Tightening torque pattern

:—B

Wheel bolts or wheel nuts

XUsing the pump lever, slowly turn the lowering

screw on the jack through approximately one revolution and carefully lower the vehicle

(

Ypage 268).

XPut the jack aside.

XPull the rod with the smallest diameter off the

pump lever.

The shortened pump lever serves as a lug

wrench extension.

XStarting with the middle rod, slide the lug

wrench extension as far as it will go onto the

lug wrench.

XUsing the extended lug wrench, tighten the

wheel bolts evenly in a crosswise pattern in

the sequence indicated ( :toB).

Tighten the wheel bolts to the following tight-

ening torques:

RSteel wheel 177 lb-ft(240 Nm)

RAlloy wheel 133 lb-ft(180 Nm)

Tighten the wheel nuts to a tightening torque

of 133 lb-ft (180 Nm).

XPush the piston on the hydraulic jack in again

and close the pressure release screw.

XVehicles with all-wheel drive: turn the jack

spindle clockwise as far as it will go

(

Ypage 268).

XStow the jack and the rest of the vehicle tools

in the vehicle again.

iYou can now install the hub caps on steel

wheels with wheel bolts. The installing proce-

dure depends on whether the hub cap acts as

a trim that covers the whole wheel, or just

covers the center.

XWheel with hub cap: position the opening for

the tire valve in the hub cap over the tire valve.

XPush the edge of the hub cap with both hands against the wheel until it clicks into place.

Changing wheels271

Wheels and tires

Z

Page 275 of 290

You must observe the correct wheel and

tire dimensions as well as the wheel type.

When using a spare wheel of a different size, do

not exceed the maximum speed of 80 km/h.

General notes

!

Check the spare wheel regularly to see that

it is secure and has the prescribed tire pres-

sure.

The procedure for mounting the spare wheel is

described in "Mounting a wheel" (

Ypage 267).

The following should be checked regularly, par-

ticularly prior to long journeys:

Rthe tire pressure of the spare wheel, which

should then be corrected if necessary

(

Ypage 250).

Rthe fastenings of the spare wheel bracket.

The spare wheel is located in a spare wheel

bracket under the rear of the vehicle.

Replace the tires after 6 years at the latest,

regardless of wear. This also applies to the spare

wheel.

iIf you have mounted a spare wheel, the tire

pressure monitor (Ypage 253) will not func-

tion for this wheel. The spare wheel is not

equipped with a sensor for monitoring tire

pressure.

Removing and installing the spare

wheel

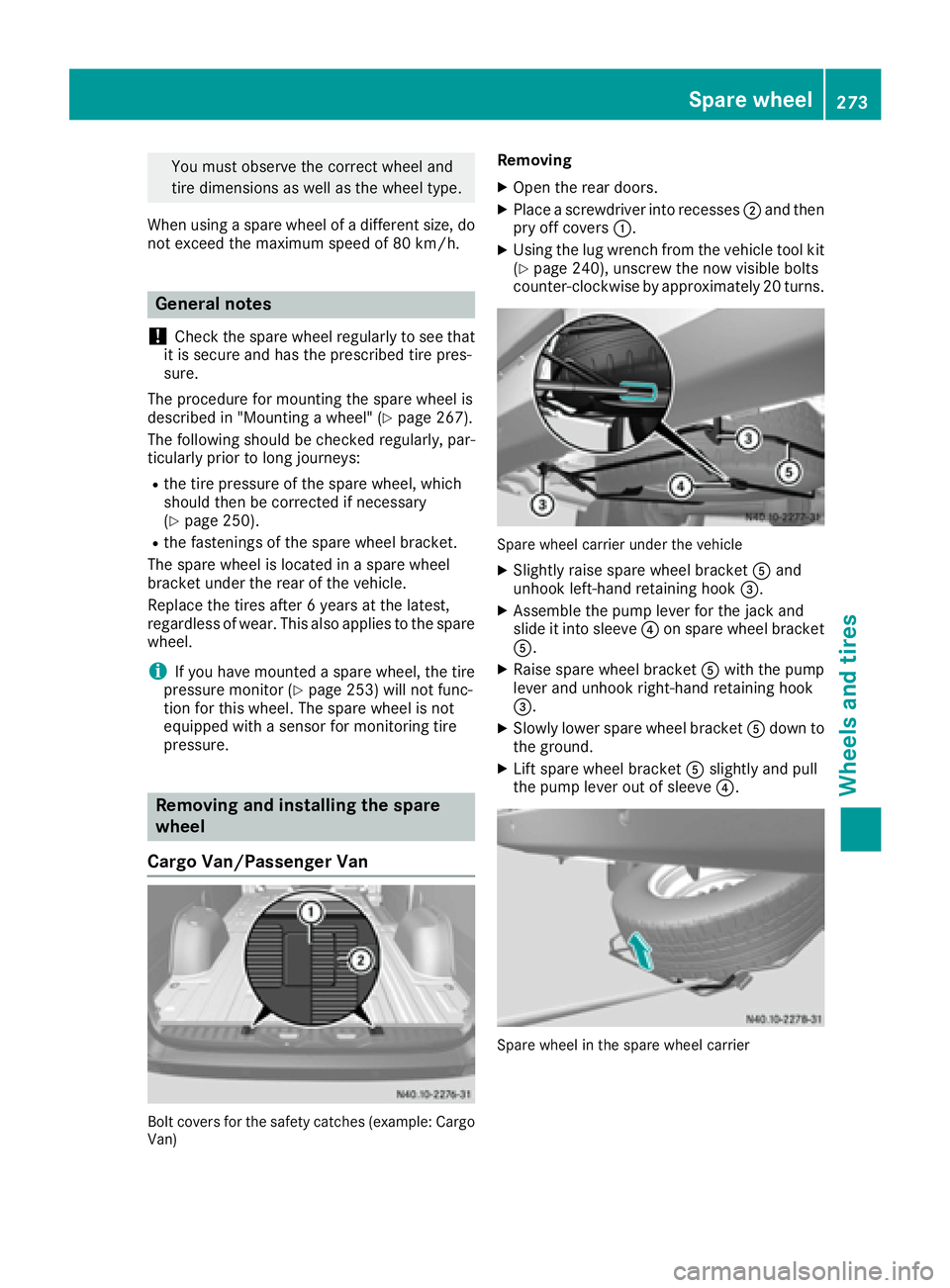

Cargo Van/Passenger Van

Bolt covers for the safety catches (example: Cargo

Van)

Removing

XOpen the rear doors.

XPlace a screwdriver into recesses ;and then

pry off covers :.

XUsing the lug wrench from the vehicle tool kit

(Ypage 240), unscrew the now visible bolts

counter-clockwise by approximately 20 turns.

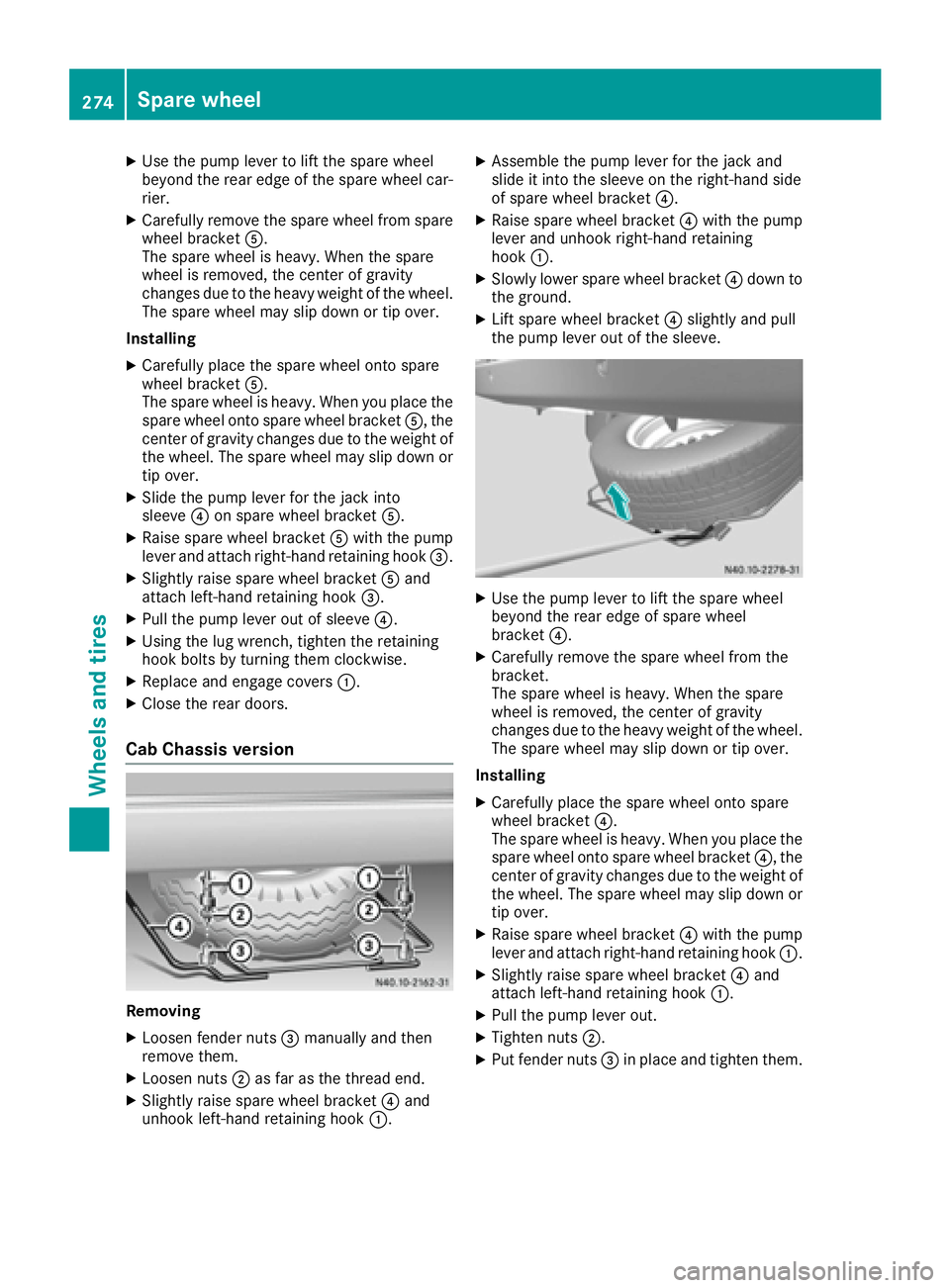

Spare wheel carrier under the vehicle

XSlightly raise spare wheel bracket Aand

unhook left-hand retaining hook =.

XAssemble the pump lever for the jack and

slide it into sleeve?on spare wheel bracket

A.

XRaise spare wheel bracket Awith the pump

lever and unhook right-hand retaining hook

=.

XSlowly lower spare wheel bracket Adown to

the ground.

XLift spare wheel bracket Aslightly and pull

the pump lever out of sleeve ?.

Spare wheel in the spare wheel carrier

Spare wheel273

Wheels and tires

Z

Page 276 of 290

XUse the pump lever to lift the spare wheel

beyond the rear edge of the spare wheel car-

rier.

XCarefully remove the spare wheel from sparewheel bracket A.

The spare wheel is heavy. When the spare

wheel is removed, the center of gravity

changes due to the heavy weight of the wheel.

The spare wheel may slip down or tip over.

Installing

XCarefully place the spare wheel onto spare

wheel bracket A.

The spare wheel is heavy. When you place the

spare wheel onto spare wheel bracket A, the

center of gravity changes due to the weight of

the wheel. The spare wheel may slip down or

tip over.

XSlide the pump lever for the jack into

sleeve ?on spare wheel bracket A.

XRaise spare wheel bracket Awith the pump

lever and attach right-hand retaining hook =.

XSlightly raise spare wheel bracketAand

attach left-hand retaining hook =.

XPull the pump lever out of sleeve ?.

XUsing the lug wrench, tighten the retaining

hook bolts by turning them clockwise.

XReplace and engage covers:.

XClose the rear doors.

Cab Chassis version

Removing

XLoosen fender nuts=manually and then

remove them.

XLoosen nuts ;as far as the thread end.

XSlightly raise spare wheel bracket ?and

unhook left-hand retaining hook :.

XAssemble the pump lever for the jack and

slide it into the sleeve on the right-hand side

of spare wheel bracket?.

XRaise spare wheel bracket ?with the pump

lever and unhook right-hand retaining

hook :.

XSlowly lower spare wheel bracket ?down to

the ground.

XLift spare wheel bracket ?slightly and pull

the pump lever out of the sleeve.

XUse the pump lever to lift the spare wheel

beyond the rear edge of spare wheel

bracket ?.

XCarefully remove the spare wheel from the

bracket.

The spare wheel is heavy. When the spare

wheel is removed, the center of gravity

changes due to the heavy weight of the wheel.

The spare wheel may slip down or tip over.

Installing

XCarefully place the spare wheel onto spare

wheel bracket ?.

The spare wheel is heavy. When you place the

spare wheel onto spare wheel bracket ?, the

center of gravity changes due to the weight of

the wheel. The spare wheel may slip down or

tip over.

XRaise spare wheel bracket ?with the pump

lever and attach right-hand retaining hook :.

XSlightly raise spare wheel bracket?and

attach left-hand retaining hook :.

XPull the pump lever out.

XTighten nuts;.

XPut fender nuts =in place and tighten them.

274Spare wheel

Wheels and tires