change time MERCEDES-BENZ SPRINTER 2016 MY16 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2016, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2016Pages: 290, PDF Size: 6.44 MB

Page 170 of 290

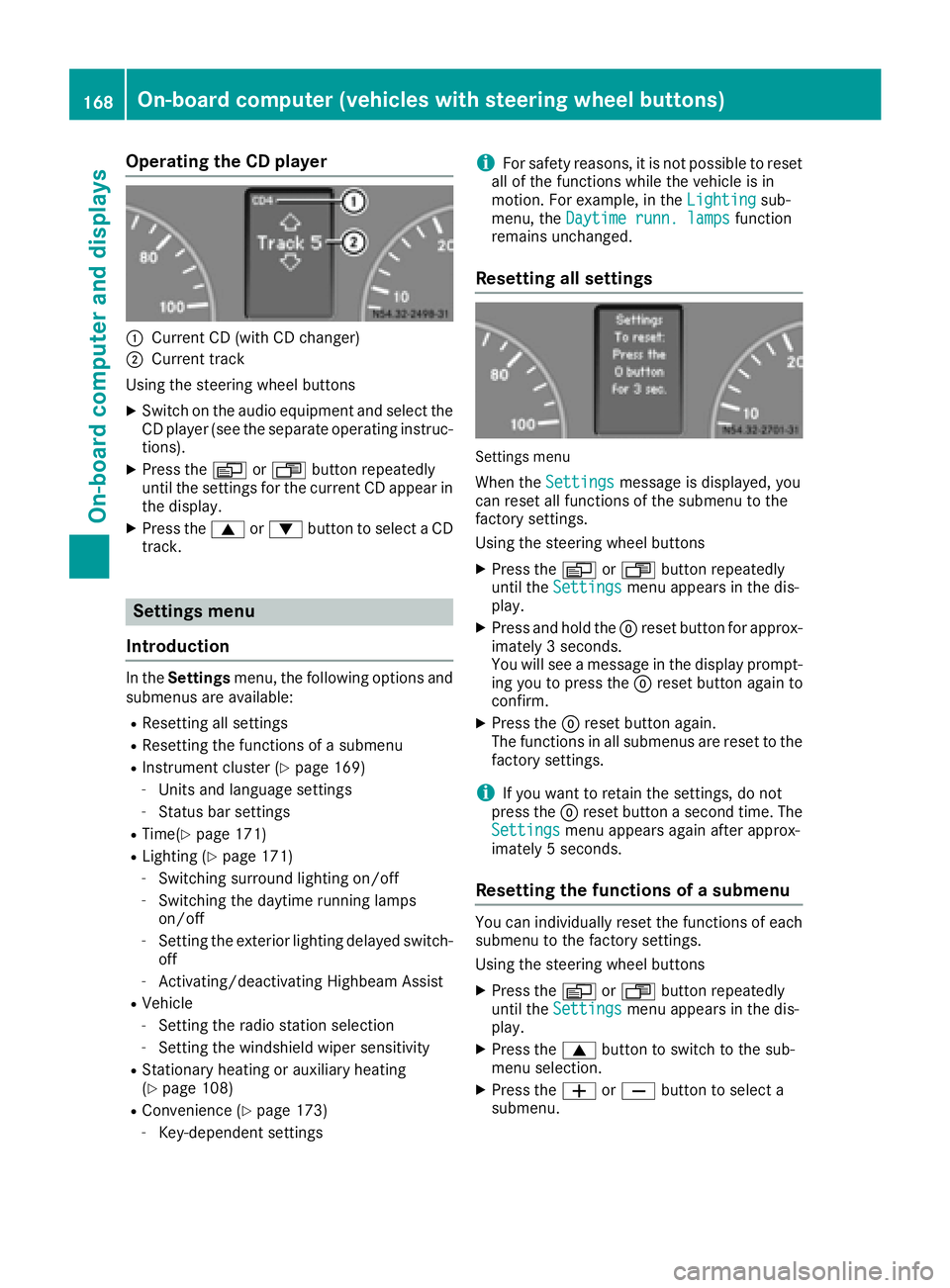

Operating the CD player

:Current CD (with CD changer)

;Current track

Using the steering wheel buttons

XSwitch on the audio equipment and select the

CD player (see the separate operating instruc-

tions).

XPress the VorU button repeatedly

until the settings for the current CD appear in

the display.

XPress the 9or: button to select a CD

track.

Settings menu

Introduction

In the Settings menu, the following options and

submenus are available:

RResetting all settings

RResetting the functions of a submenu

RInstrument cluster (Ypage 169)

-Units and language settings

-Status bar settings

RTime(Ypage 171)

RLighting (Ypage 171)

-Switching surround lighting on/off

-Switching the daytime running lamps

on/off

-Setting the exterior lighting delayed switch-

off

-Activating/deactivating Highbeam Assist

RVehicle

-Setting the radio station selection

-Setting the windshield wiper sensitivity

RStationary heating or auxiliary heating

(Ypage 108)

RConvenience (Ypage 173)

-Key-dependent settings

iFor safety reasons, it is not possible to reset

all of the functions while the vehicle is in

motion. For example, in the Lighting

sub-

menu, the Daytime runn. lampsfunction

remains unchanged.

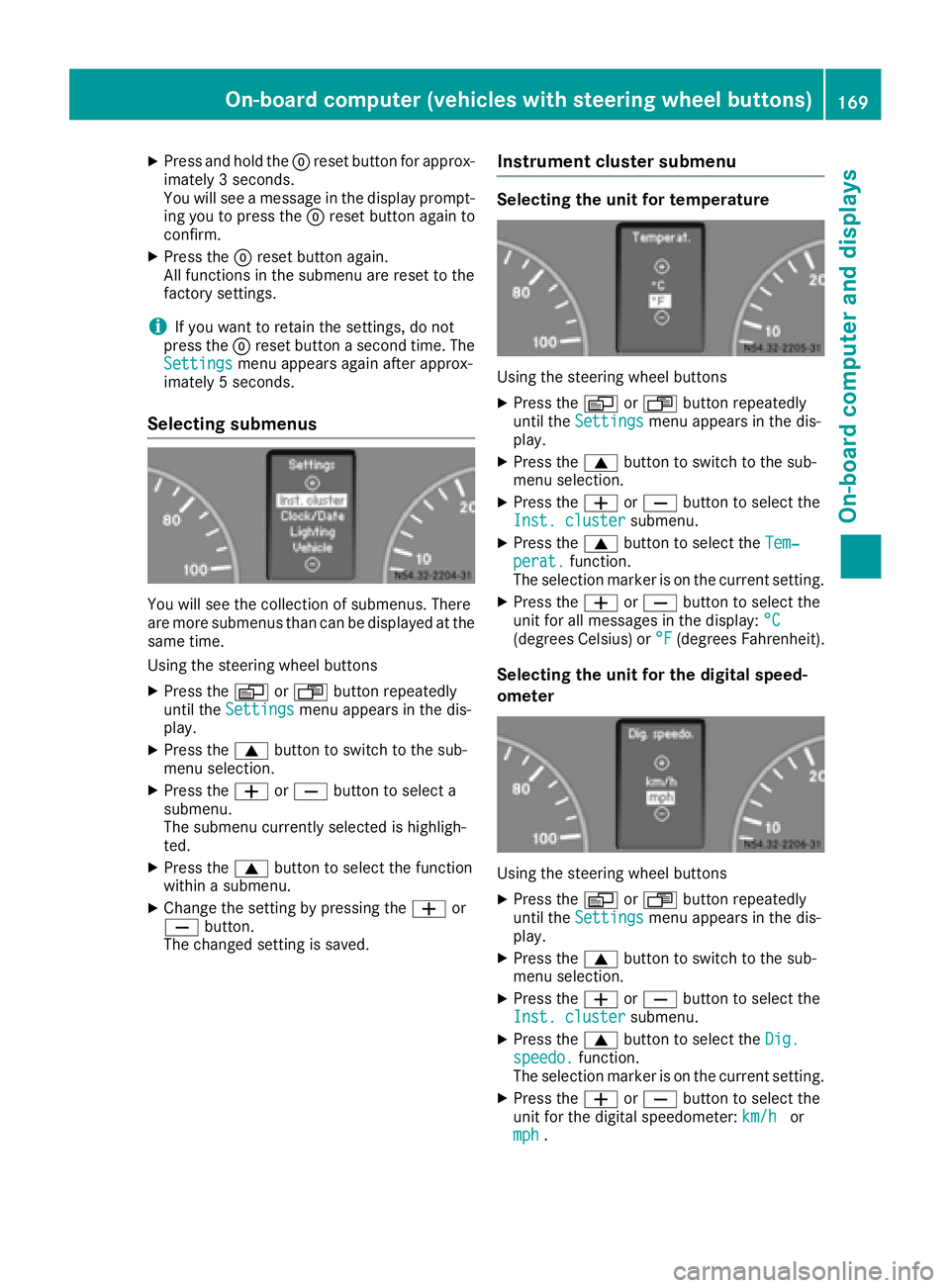

Resetting all settings

Settings menu

When the Settingsmessage is displayed, you

can reset all functions of the submenu to the

factory settings.

Using the steering wheel buttons

XPress the VorU button repeatedly

until the Settingsmenu appears in the dis-

play.

XPress and hold the 9reset button for approx-

imately 3 seconds.

You will see a message in the display prompt-

ing you to press the 9reset button again to

confirm.

XPress the 9reset button again.

The functions in all submenus are reset to the

factory settings.

iIf you want to retain the settings, do not

press the 9reset button a second time. The

Settings

menu appears again after approx-

imately 5 seconds.

Resetting the functions of a submenu

You can individually reset the functions of each

submenu to the factory settings.

Using the steering wheel buttons

XPress the VorU button repeatedly

until the Settingsmenu appears in the dis-

play.

XPress the 9button to switch to the sub-

menu selection.

XPress the WorX button to select a

submenu.

168On-board computer (vehicles with steering wheel buttons)

On-board computer and displays

Page 171 of 290

XPress and hold the9reset button for approx-

imately 3 seconds.

You will see a message in the display prompt-

ing you to press the 9reset button again to

confirm.

XPress the 9reset button again.

All functions in the submenu are reset to the

factory settings.

iIf you want to retain the settings, do not

press the 9reset button a second time. The

Settings

menu appears again after approx-

imately 5 seconds.

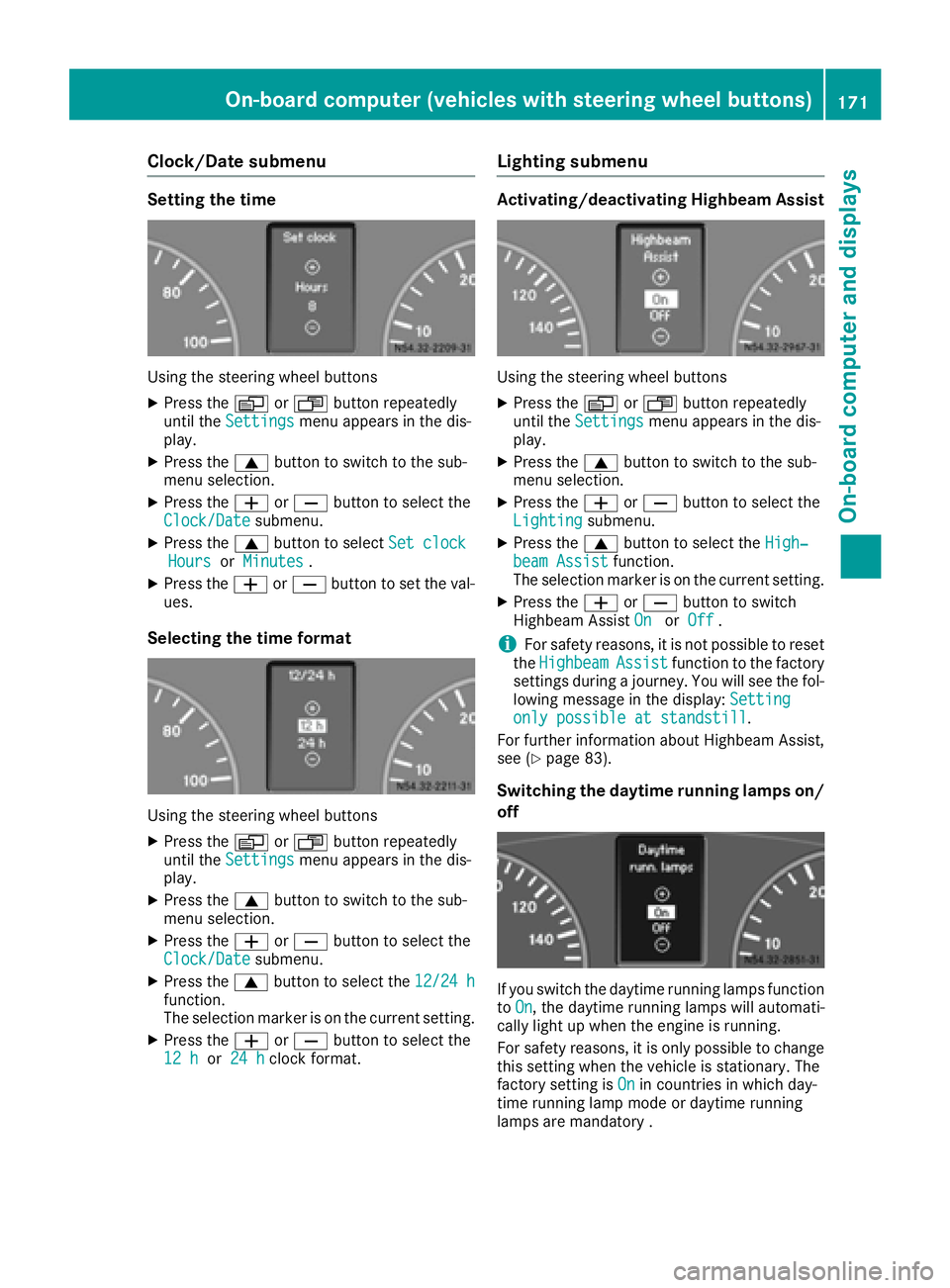

Selecting submenus

You will see the collection of submenus. There

are more submenus than can be displayed at the

same time.

Using the steering wheel buttons

XPress the VorU button repeatedly

until the Settingsmenu appears in the dis-

play.

XPress the 9button to switch to the sub-

menu selection.

XPress the WorX button to select a

submenu.

The submenu currently selected is highligh-

ted.

XPress the 9button to select the function

within a submenu.

XChange the setting by pressing the Wor

X button.

The changed setting is saved.

Instrument cluster submenu

Selecting the unit for temperature

Using the steering wheel buttons

XPress the VorU button repeatedly

until the Settingsmenu appears in the dis-

play.

XPress the 9button to switch to the sub-

menu selection.

XPress the WorX button to select the

Inst. clustersubmenu.

XPress the 9button to select the Tem‐perat.function.

The selection marker is on the current setting.

XPress the WorX button to select the

unit for all messages in the display: °C

(degrees Celsius) or°F(degrees Fahrenheit).

Selecting the unit for the digital speed-

ometer

Using the steering wheel buttons

XPress theVorU button repeatedly

until the Settingsmenu appears in the dis-

play.

XPress the 9button to switch to the sub-

menu selection.

XPress the WorX button to select the

Inst. clustersubmenu.

XPress the 9button to select the Dig.speedo.function.

The selection marker is on the current setting.

XPress the WorX button to select the

unit for the digital speedometer: km/hor

mph.

On-board computer (vehicles with steering wheel buttons)169

On-board computer and displays

Z

Page 173 of 290

Clock/Date submenu

Setting the time

Using the steering wheel buttons

XPress theVorU button repeatedly

until the Settingsmenu appears in the dis-

play.

XPress the 9button to switch to the sub-

menu selection.

XPress the WorX button to select the

Clock/Datesubmenu.

XPress the 9button to select Set clockHoursorMinutes.

XPress the WorX button to set the val-

ues.

Selecting the time format

Using the steering wheel buttons

XPress the VorU button repeatedly

until the Settingsmenu appears in the dis-

play.

XPress the 9button to switch to the sub-

menu selection.

XPress the WorX button to select the

Clock/Datesubmenu.

XPress the 9button to select the 12/24 hfunction.

The selection marker is on the current setting.

XPress theWorX button to select the

12 hor 24 hclock format.

Lighting submenu

Activating/deactivating Highbeam Assist

Using the steering wheel buttons

XPress the VorU button repeatedly

until the Settingsmenu appears in the dis-

play.

XPress the 9button to switch to the sub-

menu selection.

XPress the WorX button to select the

Lightingsubmenu.

XPress the 9button to select the High‐beam Assistfunction.

The selection marker is on the current setting.

XPress the WorX button to switch

Highbeam Assist OnorOff.

iFor safety reasons, it is not possible to reset

the HighbeamAssistfunction to the factory

settings during a journey. You will see the fol-

lowing message in the display: Setting

only possible at standstill.

For further information about Highbeam Assist,

see (

Ypage 83).

Switching the daytime running lamps on/

off

If you switch the daytime running lamps function

to On, the daytime running lamps will automati-

cally light up when the engine is running.

For safety reasons, it is only possible to change

this setting when the vehicle is stationary. The

factory setting is On

in countries in which day-

time running lamp mode or daytime running

lamps are mandatory .

On-board computer (vehicles with steering wheel buttons)171

On-board computer and displays

Z

Page 214 of 290

Useful information

This Operator's Manual describes all models as

well as standard and optional equipment of your

vehicle that were available at the time of going

to print. Country-specific variations are possi-

ble. Note that your vehicle may not be equipped

with all of the described functions. This also

applies to systems and functions relevant to

safety.

Read the information on qualified specialist

workshops (

Ypage 26).

Loading guidelines

Important safety notes

GWARNING

As a result of improperly placed or unevenly

distributed loads, the center of gravity of the

load being transported may be too high or too

far back. This can significantly impair handling

as well as steering and braking characteris-

tics. There is a risk of an accident.

Always make sure that the center of gravity of

the load is:

Rbetween the axles

and

Ras low as possible, near the rear axle.

GWARNING

When objects are unsecured or inadequately

secured, they can slip, turn over or be thrown

about, striking vehicle occupants. This also

applies to:

Rluggage or loads

Ra rear bench seat which has been removed

and is being transported in the vehicle in an

exceptional case.

There is a risk of injury, particularly in the

event of braking maneuvers or abrupt

changes in direction.

Always stow objects in such a way that they

cannot be tossed about. Before traveling,

secure objects, luggage or loads to prevent

them slipping or tipping over. If you remove a

rear bench seat, it is advisable to store it out- side the vehicle.

GWARNING

When the permissible wheel loads, axle loads

and/or the maximum permissible gross vehi-

cle weight are exceeded, driving safety is

compromised. The handling as well as steer-

ing and braking characteristics may be signif-

icantly impaired. Overloaded tires may over-

heat, causing them to burst. There is a risk of

an accident.

When transporting a load, always observe the

permissible wheel loads, axle loads and the

maximum permissible gross vehicle weight

for the vehicle (including occupants).

GWARNING

When you load the roof, the center of gravity

of the vehicle rises and the driving character-

istics change. If you exceed the maximum roof

load, the driving characteristics, as well as

steering and braking, will be greatly impaired.

There is a risk of an accident.

Never exceed the maximum roof load and

adjust your driving style.

!If you are using a roof carrier, observe the

maximum roof load and maximum roof carrier

load.

You will find information about the maximum

roof load in the "Technical data" section

(

Ypage 286) and information about roof carri-

ers in the "Carrier systems" section

(

Ypage 216).

RDo not stack luggage or loads higher than the

backrests.

RStow objects preferably in the cargo com-

partment.

RWhen transporting luggage, always use the

cargo tie-down rings and a parcel net, if pres-

ent.

RUse cargo tie-down rings and fasteners which

are suitable for the weight and size of the

load.

Always observe the operating instructions of the respective manufacturer when using suitable

load securing aids or tie downs. In particular, the

information on service life.

212Loading guidelines

Transporting loads

Page 216 of 290

Load distribution

General notes

!

Excessive loads on individual points of the

cargo floor or on the load surface impair vehi-

cle handling characteristics and could cause

damage to the floor covering.

The overall center of gravity of the load should

always be as low as possible, centered and

between the axles near the rear axle.

On Cargo Vans and Passenger Vans:

XAlways transport loads in the cargo compart-

ment.

XAlways place the load against the backrests of the rear bench seat.

XMove large and heavy loads as far towards the

front of the vehicle as possible against the

rear bench seat. Stow the load flush with the

rear bench seat.

XAlways additionally secure the load with suit-

able load-securing aids or tie downs.

Observe the following notes:

RDo not stack loads higher than the upper edge

of the backrests.

RTransport loads behind seats that are not

occupied.

RIf the rear bench seat is not occupied, insert

the seat belts crosswise into the buckle of the

opposite seat belt.

Securing loads

Important safety notes

GWARNING

If you attach the tie-down incorrectly when

securing the load, the following may occur in

the event of abrupt changes in direction, brak- ing maneuvers or an accident:

Rthe cargo tie-down rings may become

detached or the tie-down may tear if the

permissible load is exceeded

Rthe load may not be restrained.

This may cause the load to slip, tip over or be

tossed about, striking vehicle occupants.

There is a risk of an accident and injury.

Always tension the tie-downs in the proper

manner and only between the described

cargo tie-down rings. Always use tie-downs

designed specifically for the loads.

GWARNING

You may not transport anyone in the cargo

compartment or on the load surface. Never let more people ride in the vehicle than there are

seat belts available. Make sure everyone rid-

ing in the vehicle is correctly restrained with a

separate seat belt. Never use a seat belt for

more than one person at a time.

!Observe the information on the maximum

loading capacity of the individual cargo tie-

down points.

If you use several cargo tie-down points to

secure a load, you must always take the max-

imum loading capacity of the weakest cargo

tie-down point into account.

If you brake hard, for example, the forces act-

ing could be up to several times the weight

force of the load. Always use multiple cargo

tie-down points in order to distribute the force

absorption. Load the anchorages evenly.

Spread the load evenly between the cargo tie-

down points or tie-down rings.

Please also refer to the notes about qualified

specialist workshops (

Ypage 26).

Always observe the operating instructions or the

notes of the lashing strap manufacturer for the

operation of the lashing strap.

Information about the maximum loading capa-

city of the cargo tie-down points can be found in

the "Technical data" section (

Ypage 285).

As the driver, you are responsible for ensuring

that:

RThe load is secured against slipping, tipping,

rolling or falling off. This applies both in nor-

mal traffic conditions and if the vehicle must

swerve to avoid an obstacle, in the event of

full brake application and on poor road surfa-

ces.

RThe applicable requirements and guidelines

relating to load-securing practices must be

met.

If this is not the case, this may constitute a

punishable offense, depending on local legis-

lation and any ensuing consequences.

214Securing loads

Transporting loads

Page 251 of 290

RDo not drive with tires which have too little

tread depth, as this significantly reduces the

traction on wet roads (hydroplaning).

RReplace the tires after 6 years at the latest,

regardless of wear. This also applies to the

spare wheel.

Operation in winter

General notes

Have your vehicle winterproofed at a qualified

specialist workshop at the onset of winter.

Prior to the onset of winter, ensure that snow

chains are stowed in the vehicle (

Ypage 249).

Also observe the notes in the "Changing a

wheel" section (

Ypage 266).

Driving with summer tires

At temperatures below 45 ‡ (+7 †), summer

tires lose elasticity and therefore traction and

braking power. Change the tires on your vehicle

to M+S tire. Using summer tires at very cold

temperatures could cause tears to form,

thereby damaging the tires permanently. We

cannot accept responsibility for this type of

damage.

M+S tires

GWARNING

Wheel and tire dimensions as well as the type of tire can vary between the spare wheel and

the wheel to be replaced. When the spare

wheel is mounted, driving characteristics may be severely affected. There is a risk of an acci-

dent.

In order to reduce risks:

Ryou should therefore adapt your driving

style and drive carefully.

Rnever mount more than one spare wheel

that differs from the wheel to be replaced.

Ronly use a spare wheel that differs from the

wheel to be replaced for a short time.

Rdo not deactivate ESP®.

Rhave a spare wheel that differs from the

wheel that has been changed replaced at

the nearest qualified specialist workshop.

You must observe the correct wheel and

tire dimensions as well as the wheel type.

GWARNING

M+S tires with a tire tread depth of less than

ã in (4 mm) are not suitable for use in winter

and do not provide sufficient traction. There is

a risk of an accident.

M+S tires with a tread depth of less than ãin

(4 mm) must be replaced immediately.

Use winter tires or all-season tires at tempera-

tures below 45 ‡ (+7 †). Both types of tire are

identified by the M+S marking.

Only winter tires bearing the isnowflake

symbol in addition to the M+S marking provide

the best possible grip in wintry road conditions.

Only these tires will allow driving safety systems

such as ABS and ESP

®to function optimally in

winter. These tires have been developed specif-

ically for driving in snow.

For safe driving, use M+S tire sof the same make

and tread pattern on all wheels.

Always observe the maximum permissible

speed specified for the M+S tires you have

mounted.

If you mount M+S tires that have a lower maxi-

mum permissible speed than that of the vehicle,

affix a corresponding warning label in the driv-

er's field of vision. You can obtain this at a quali-

fied specialist workshop.

Once you have mounted the winter tires:

XCheck the tire pressure (Ypage 250).

XReactivate the tire pressure moni-

tor* (

Ypage 255).

Snow chains

GWARNING

If you drive too fast with snow chains moun-

ted, they may snap. As a result, you could

injure others and damage the vehicle. There is

a risk of an accident.

Operation in winter249

Wheels and tires

* optionalZ

Page 268 of 290

Load bearing index

The load bearing index (also load index) is a code

that contains the maximum load bearing capa-

city of a tire.

Traction

Traction is the result of friction between the tires

and the road surface.

TWR (permissible trailer drawbar load)

The TWR is the maximum permissible weight

that may act on the ball coupling of the trailer

tow hitch.

Wear indicator

Narrow bars (tread wear bars) that are distrib-

uted over the tire tread. If the tire tread is level

with the bars, the wear limit ofáin(1.6 mm )

ha sbeen re ached.

Distribution of the vehicle occupants

The distribution of vehicle occupants over des-

ignated seat positions in a vehicle.

Maximum permissible payload weight

Nominal load and goods/luggage load plus

68 kg (150 lbs) multiplied by the number of

seats in the vehicle.

Flat tire

General notes

If your vehicle is equipped with a spare wheel,

the spare wheel is under the rear of the vehicle

(

Ypage 272).

Information about installing a wheel can be

found in the "Wheel change" section

(

Ypage 267).

Changing wheels

Rotating the wheels

GWARNING

Interchanging the front and rear wheels may

severely impair the driving characteristics if

the wheels or tires have different dimensions. The wheel brakes or suspension components

may also be damaged. There is a risk of acci-

dent.

Rotate front and rear wheels only if the wheels and tires are of the same dimensions.

!On vehicles equipped with a tire pressure

monitor, electronic components are located

in the wheel.

Tire-mounting tools should not be used near

the valve. This could damage the electronic

components.

Only have tires changed at a qualified spe-

cialist workshop.

Always observe the instructions and safety

notes in the "Mounting a wheel" section

(

Ypage 267).

The wear patterns on the front and rear tires

differ, depending on the operating conditions.

Rotate the wheels before a clear wear pattern

has formed on the tires. Front tires typically

wear more on the shoulders and the rear tires in

the center.

If your vehicle's tire configuration allows, you

can rotate the wheels according to the intervals

in the tire manufacturer's warranty book in your

vehicle documents. If no warranty book is avail-

able, the tires should be rotated every 3,000 to

6,000 miles (5,000 to 10,000 km), or earlier if

tire wear requires. Do not change the direction

of rotation.

Clean the contact surfaces of the wheel and the brake disc thoroughly every time a wheel is rota-

ted.

Check the tire pressure and reactivate the tire

pressure monitor if necessary.

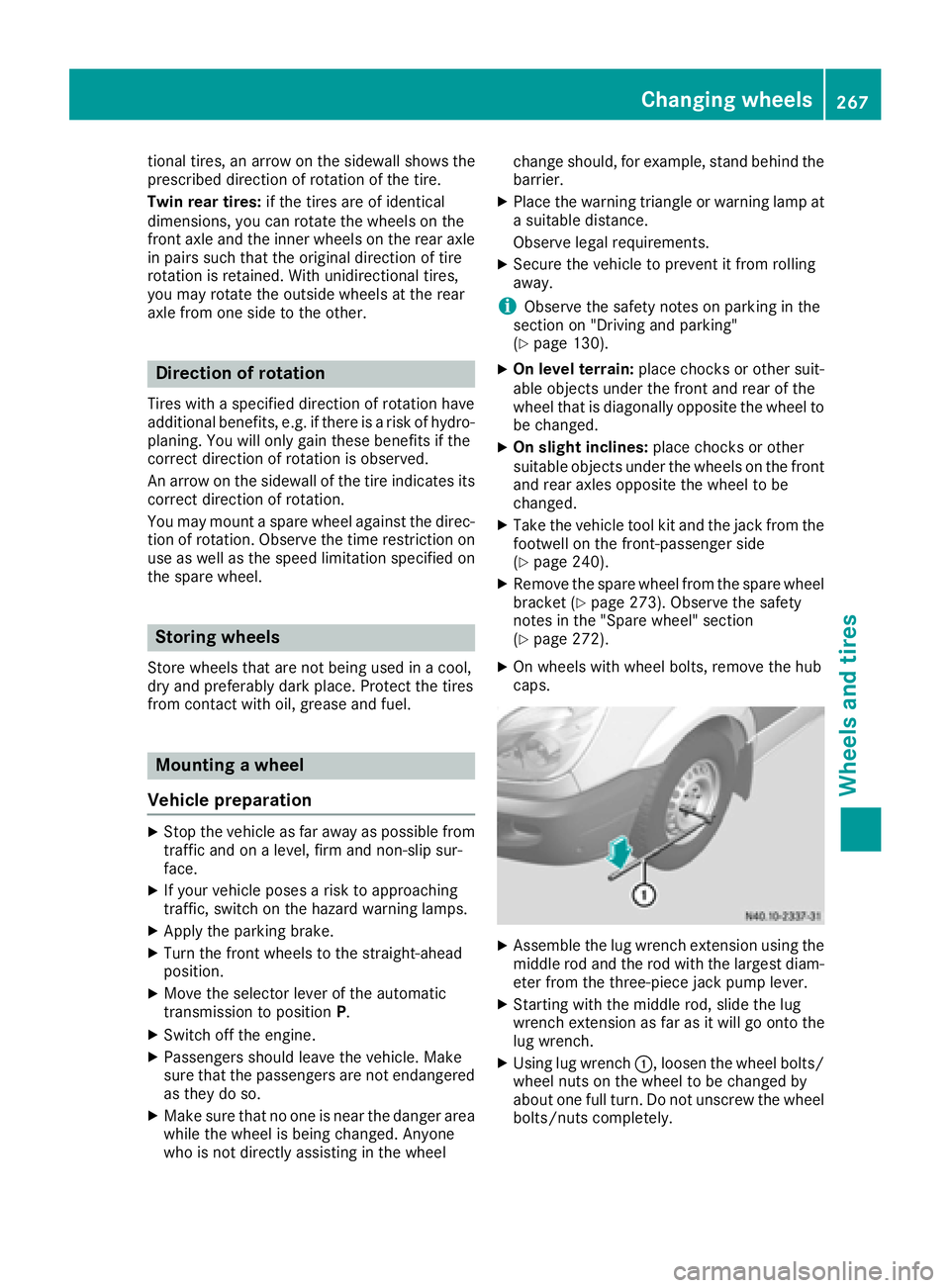

Diagram showing tire rotation for single and dual

tires

Single tires: if the tires are of identical dimen-

sions, you can rotate both wheels on both the

front and rear axles so that the tires' original

direction of rotation is maintained. On unidirec-

266Changing wheels

Wheels and tires

Page 269 of 290

tional tires, an arrow on the sidewall shows the

prescribed direction of rotation of the tire.

Twin rear tires:if the tires are of identical

dimensions, you can rotate the wheels on the

front axle and the inner wheels on the rear axle

in pairs such that the original direction of tire

rotation is retained. With unidirectional tires,

you may rotate the outside wheels at the rear

axle from one side to the other.

Direction of rotation

Tires with a specified direction of rotation have

additional benefits, e.g. if there is a risk of hydro-

planing. You will only gain these benefits if the

correct direction of rotation is observed.

An arrow on the sidewall of the tire indicates its

correct direction of rotation.

You may mount a spare wheel against the direc-

tion of rotation. Observe the time restriction on

use as well as the speed limitation specified on

the spare wheel.

Storing wheels

Store wheels that are not being used in a cool,

dry and preferably dark place. Protect the tires

from contact with oil, grease and fuel.

Mounting a wheel

Vehicle preparation

XStop the vehicle as far away as possible from

traffic and on a level, firm and non-slip sur-

face.

XIf your vehicle poses a risk to approaching

traffic, switch on the hazard warning lamps.

XApply the parking brake.

XTurn the front wheels to the straight-ahead

position.

XMove the selector lever of the automatic

transmission to position P.

XSwitch off the engine.

XPassengers should leave the vehicle. Make

sure that the passengers are not endangered

as they do so.

XMake sure that no one is near the danger area

while the wheel is being changed. Anyone

who is not directly assisting in the wheel change should, for example, stand behind the

barrier.

XPlace the warning triangle or warning lamp at

a suitable distance.

Observe legal requirements.

XSecure the vehicle to prevent it from rolling

away.

iObserve the safety notes on parking in the

section on "Driving and parking"

(

Ypage 130).

XOn level terrain: place chocks or other suit-

able objects under the front and rear of the

wheel that is diagonally opposite the wheel to

be changed.

XOn slight inclines: place chocks or other

suitabl e objects under the wheels on the front

and rear axles opposite the wheel to be

changed.

XTake the vehicle tool kit and the jack from the

footwell on the front-passenger side

(

Ypage 240).

XRemove the spare wheel from the spare wheel

bracket (Ypage 273). Observe the safety

notes in the "Spare wheel" section

(

Ypage 272).

XOn wheels with wheel bolts, remove the hub

caps.

XAssemble the lug wrench extension using the

middle rod and the rod with the largest diam-

eter from the three-piece jack pump lever.

XStarting with the middle rod, slide the lug

wrench extension as far as it will go onto the

lug wrench.

XUsing lug wrench :, loosen the wheel bolts/

wheel nuts on the wheel to be changed by

about one full turn. Do not unscrew the wheel bolts/nuts completely.

Changing wheels267

Wheels an d tires

Z

Page 270 of 290

Raising the vehicle

GWARNING

If you do not position the jack correctly at the

appropriate jacking point of the vehicle, the

jack could tip over with the vehicle raised.

There is a risk of injury.

Only position the jack at the appropriate jack-

ing point of the vehicle. The base of the jack

must be positioned vertically, directly under

the jacking point of the vehicle.

GWARNING

On uphill and downhill slopes, the jack could

tip over with the vehicle raised. There is a risk

of injury.

Do not change wheels on uphill or downhill

gradients. Notify a qualified specialist work-

shop.

!Only position the jack on the jacking points

intended for this purpose. You could other-

wise damage the vehicle.

Observe the following when raising the vehicle:

RWhen raising the vehicle, only use the jack

which Mercedes-Benz has specifically

approved for your vehicle.

RThe vehicle's jack is intended only to raise the

vehicle for a short time when changing a

wheel. It is not suited for performing mainte-

nance work under the vehicle.

RAvoid changing the wheel on uphill and down- hill slopes.

RBefore raising the vehicle, secure it from roll-

ing away by applying the parking brake and

inserting wheel chocks. Never disengage the

parking brake while the vehicle is raised.

RThe jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a large,

load-bearing underlay must be used. On a

slippery surface, a non-slip underlay must be

used, e.g. rubber mats.

RMake sure that the distance between the

underside of the tires and the ground does not

exceed 1.2 in(3 cm).

RNever place your hands or feet under the

ra

ised vehicle.

RNever lie under the raised vehicle.

RNever start the engine when the vehicle is

raised.

RNever open or close a door when the vehicle

is raised.

RMake sure that no persons are present in the

vehicle when the vehicle is raised.

!Only use the jack pump lever middle rod and

the rod with the largest diameter as a lug

wrench extension. Only slide the middle rod

as far as it will go onto the lug wrench. The

rods may otherwise bend and be distorted to

such an extent that they can no longer be

used as a pump lever for the jack.

!Do not place the jack on the leaf spring or

the differential case.

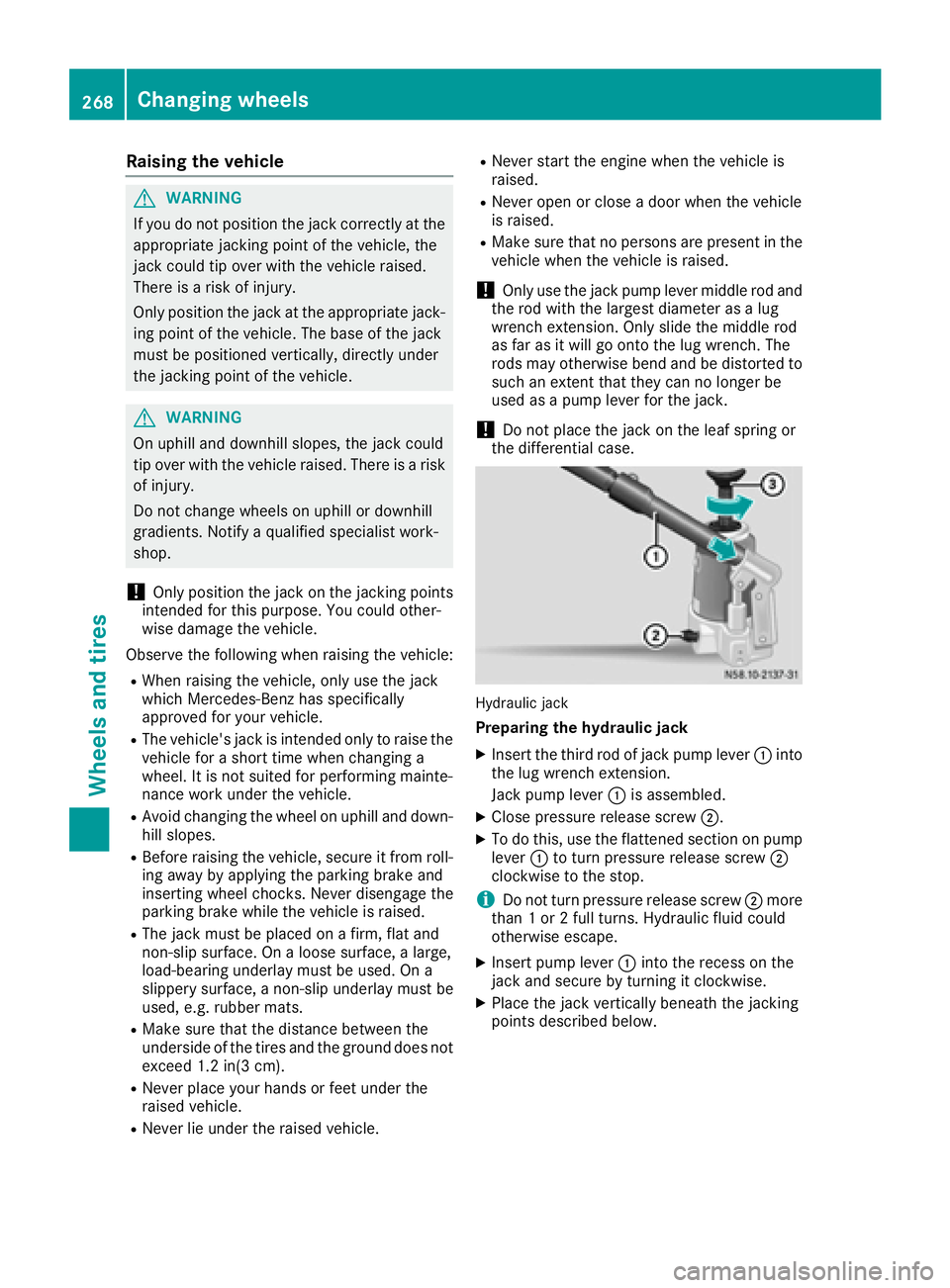

Hydraulic jack

Preparing the hydraulic jack

XInsert the third rod of jack pump lever :into

the lug wrench extension.

Jack pump lever :is assembled.

XClose pressure release screw ;.

XTo do this, use the flattened section on pump

lever:to turn pressure release screw ;

clockwise to the stop.

iDo not turn pressure release screw ;more

than 1 or 2 full turns. Hydraulic fluid could

otherwise escape.

XInsert pump lever :into the recess on the

jack and secure by turning it clockwise.

XPlace the jack vertically beneath the jacking

points described below.

268Changing wheels

Wheels and tires

Page 274 of 290

Make sure the hub cap retaining catches

engage on the steel wheel.

XWheel with central hub cap: position the

retaining lugs of the central hub cap over the

wheel bolts.

XHit the middle of the hub cap to engage it on

the wheel.

XSecure the faulty wheel in the spare wheel

bracket (Ypage 273).

XVehicles with Super Single tires: transport the

defective rear wheel in the load area. The rear

wheel is too large for the spare wheel bracket.

XCheck the tire pressure of the newly mounted

wheel and adjust it if necessary.

Observe the recommended tire pressure

(

Ypage 250).

XRetighten the wheel bolts or wheel nuts to the

specified tightening torque after the vehicle

has been driven for 30 miles (50 km).

When using a wheel or spare wheel with a new or

newly painted wheel rim, have the wheel bolts or

nuts retightened again after approximately 600

to 3,000 miles (1,000 to 5,000 km). Observe the

specified tightening torque.

iVehicles with the tire pressure monitor sys-

tem: all mounted wheels must be equipped

with functioning sensors.

Wheel and tire combination

General notes

!

Retreaded tires are neither tested nor rec-

ommended for Sprinter vehicles, since previ-

ous damage cannot always be detected on

retreaded tires. We can therefore not guar-

antee driving safety. Do not mount used tires if you have no information about their previ-

ous usage.

The recommended tire pressures can be found:

Ron the Tire and Loading Information placard9

on the B-pillar on the driver's side

Ron the tire pressure table on the B-pillar on the driver's side

The recommended tire pressure can also be

found in the "Tire pressure table" section in this

Operator's Manual (

Ypage 257). The wheel/tire

combination for your vehicle can be found on the tire pressure table. Further information on

wheel/tire combination can be obtained at any

qualified specialist workshop.

Check tire pressures regularly and only when

the tires are cold. Observe the notes on the rec-

ommended tire pressure (

Ypage 250).

Follow the maintenance recommendations in

the tire manufacturer's warranty book in your

vehicle documents.

Notes on the vehicle equipment – always equip

the vehicle:

Rwith tires of the same size across an axle (left

and right)

Rwith the same type of tires on all wheels at a

given time (summer tires, winter tires)

Tires that have been specially designed and

approved for your vehicle are marked with MO

(Mercedes-Benz Original). You can find this

identification on the tires themselves and in the

following table.

iNot all wheel/tire combinations can be

installed at the factory in all countries.

Spare wheel

Important safety notes

GWARNING

Wheel and tire dimensions as well as the type of tire can vary between the spare wheel and

the wheel to be replaced. When the spare

wheel is mounted, driving characteristics may be severely affected. There is a risk of an acci-

dent.

In order to reduce risks:

Ryou should therefore adapt your driving

style and drive carefully.

Rnever mount more than one spare wheel

that differs from the wheel to be replaced.

Ronly use a spare wheel that differs from the

wheel to be replaced for a short time.

Rdo not deactivate ESP®.

Rhave a spare wheel that differs from the

wheel that has been changed replaced at

the nearest qualified specialist workshop.

9Only for vehicles with a gross weight of less than 10,000 lbs (4,536 kg).

272Spare wheel

Wheels and tires