cooling MERCEDES-BENZ SPRINTER 2017 MY17 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2017, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2017Pages: 286, PDF Size: 4.36 MB

Page 221 of 286

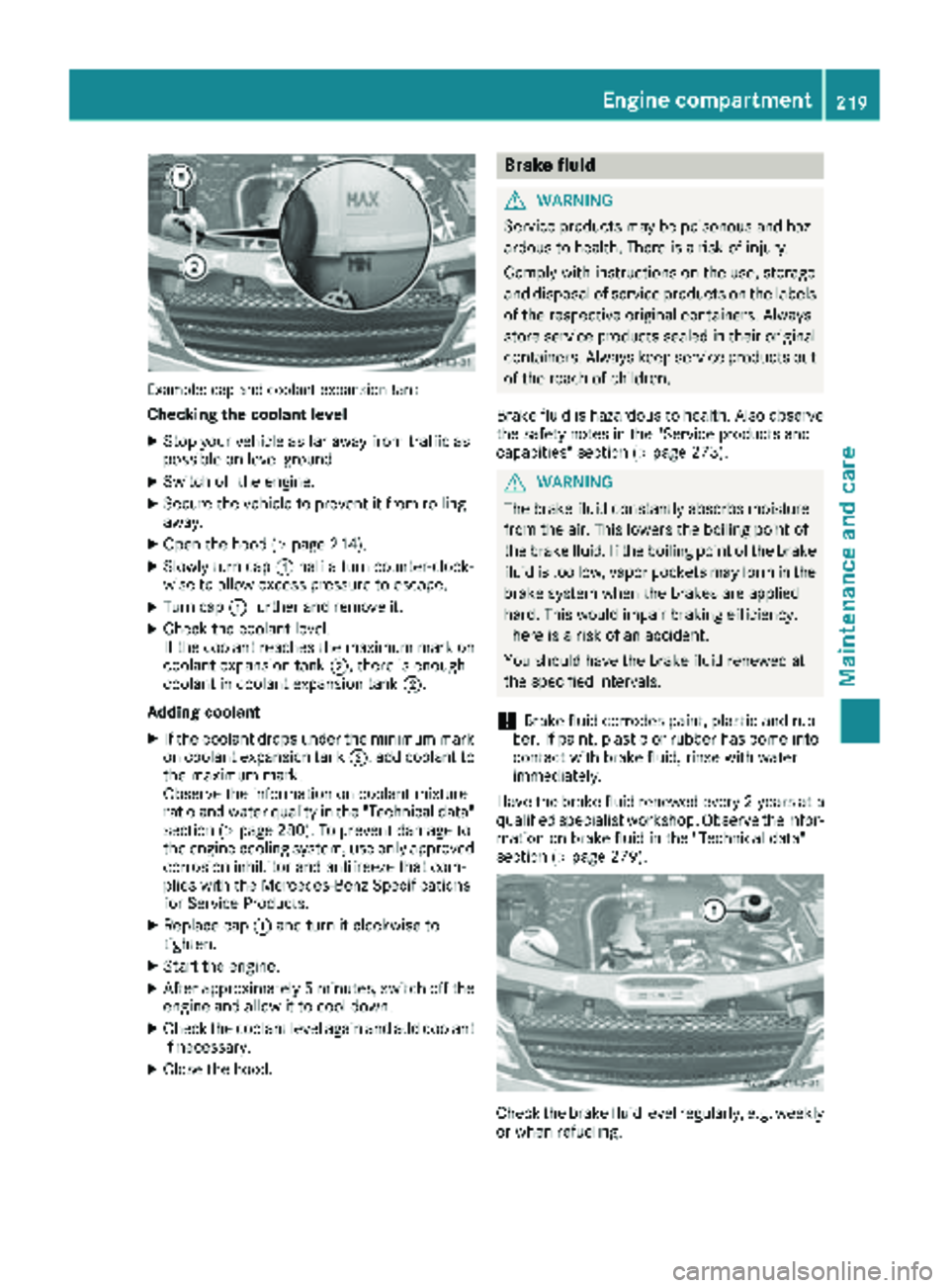

Example: cap and coolant expansion tank

Checking the coolant level

XStop your vehicle as far away from traffic as

possible on level ground.

XSwitch off the engine.

XSecure the vehicle to prevent it from rolling

away.

XOpen the hood (Ypage 214).

XSlowly turn cap:half a turn counter-clock-

wise to allow excess pressure to escape.

XTurn cap :further and remove it.

XCheck the coolant level.

If the coolant reaches the maximum mark on

coolant expansion tank ;, there is enough

coolant in coolant expansion tank ;.

Adding coolant

XIf the coolant drops under the minimum mark

on coolant expansion tank ;, add coolant to

the maximum mark.

Observe the information on coolant mixture

ratio and water quality in the "Technical data"

section (

Ypage 280). To prevent damage to

the engine cooling system, use only approved

corrosion inhibitor and antifreeze that com-

plies with the Mercedes-Benz Specifications

for Service Products.

XReplace cap :and turn it clockwise to

tighten.

XStart the engine.

XAfter approximately 5 minutes, switch off the

engine and allow it to cool down.

XCheck the coolant level again and add coolant

if necessary.

XClose the hood.

Brake fluid

GWARNING

Service products may be poisonous and haz-

ardous to health. There is a risk of injury.

Comply with instructions on the use, storage

and disposal of service products on the labels

of the respective original containers. Always

store service products sealed in their original

containers. Always keep service products out

of the reach of children.

Brake fluid is hazardous to health. Also observe

the safety notes in the "Service products and

capacities" section (

Ypage 273).

GWARNING

The brake fluid constantly absorbs moisture

from the air. This lowers the boiling point of

the brake fluid. If the boiling point of the brake

fluid is too low, vapor pockets may form in the

brake system when the brakes are applied

hard. This would impair braking efficiency.

There is a risk of an accident.

You should have the brake fluid renewed at

the specified intervals.

!Brake fluid corrodes paint, plastic and rub-

ber. If paint, plastic or rubber has come into

contact with brake fluid, rinse with water

immediately.

Have the brake fluid renewed every 2 year sat a

qualified specialist workshop. Observe the infor- mation on brake fluid in the "Technical data"

section (

Ypage 279).

Check the brake fluid level regularly, e.g. weekly

or when refueling.

Engine compartment219

Maintenance and care

Z

Page 282 of 286

Coolant

Important safety notes

GWARNING

If antifreeze comes into contact with hot com- ponents in the engine compartment, it may

ignite. There is a risk of fire and injury.

Let the engine cool down before you add anti-

freeze. Make sure that antifreeze is not spilled

next to the filler neck. Thoroughly clean the

antifreeze from components before starting

the engine.

!Take care not to spill any coolant on painted

surfaces. You could otherwise damage the

paintwork.

When handling coolant, observe the important

safety notes for service products (

Ypage 273).

Coolant additive with antifreeze

requirements

!Use only approved antifreeze/corrosion

inhibitor that complies with MB Specification for Service Products, Sheet Number 325.

Using other, non-approved antifreeze/corro-

sion inhibitors may cause damage to the cool-

ant system and reduce the engine's service

life.

Coolant is a mixture of water and antifreeze/

corrosion inhibitor. It performs the following

tasks:

RAnti-corrosion protection

RAntifreeze protection

RRaises the boiling point

When the vehicle is first delivered, it is filled with

a coolant mixture that ensures adequate anti-

freeze/corrosion protection. Coolant must be

used in the system all year round to ensure anti-

corrosion protection and a raised boiling point –

even in countries with high outside tempera-

tures.

To prevent damage to the engine cooling sys-

tem, use only approved corrosion inhibitor/anti-

freeze that comply with the Mercedes-Benz

Specifications for Service Products.

We recommend corrosion inhibitor/antifreeze

that meets the requirements in MB Specifica-

tions for Service Products Sheet Number 325. Check the antifreeze/corrosion inhibitor con-

centration in the coolant every six months.

The percentage of corrosion inhibitor/anti-

freeze additive in the engine coo

ling system

should:

Rbe at least 50%. This way, the engine cooling

system is protected against freezing down to

approximately -35 ‡ (-37 †).

Rnot exceed 55% (antifreeze protection down

to -49 ‡ [-45 †]). Otherwise, heat will not be

dissipated as effectively.

If there has been coolant loss, do not refill only

with water. If the vehicle has lost coolant, add

equal parts water and corrosion inhibitor/anti-

freeze additive. The water used as part of the

coolant mixture must fulfill certain require-

ments; these are usually fulfilled by drinking

water. If the water quality is not sufficient, you

must treat the water.

Operating fluid: coolant

Product name/number

EURO Peak Coolant/Antifreeze,

OLD WORLD INDUSTRIES

MB Sheet No. 325.0

Zerex G05, The Valvoline Company

MB Sheet No. 325.0

Zerex G48, The Valvoline Company

MB Sheet No. 325.0

Glysantin G05, BASF AG

MB Sheet No. 325.0

Capacities

Engine cooling system

CoolantApprox. 10.75 qt (10.0 l)

280Service products and capacities

Technical data