tire pressure MERCEDES-BENZ SPRINTER 2017 MY17 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2017, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2017Pages: 286, PDF Size: 4.36 MB

Page 254 of 286

Restarting the tire pressure monitor (vehi-

cles with steering wheel buttons):

XTurn the key to position2in the ignition lock.

XPress the VorU button on the steering

wheel until the standard display (Ypage 164)

appears in the display.

XPress the 9or: button on the steering

wheel repeatedly until the current pressure of

the individual tires is displayed or the display

shows the following message:

Tire pres. displayed after driving

for several minutes

XPress the 9reset button on the instrument

cluster.

The display shows the following message: Monitor current tire pressure?

XPress the

Wbutton on the steering wheel.

The display shows the following message:

Tire pres. monitor reactivated

The tire pressure monitor activation process

has begun. The tire pressures measured for

the individual wheels are stored as the new

reference values, provided that the tire pres-

sure monitor considers them to be plausible.

If you wish to cancel the restart:

XPress the Xbutton on the steering wheel.

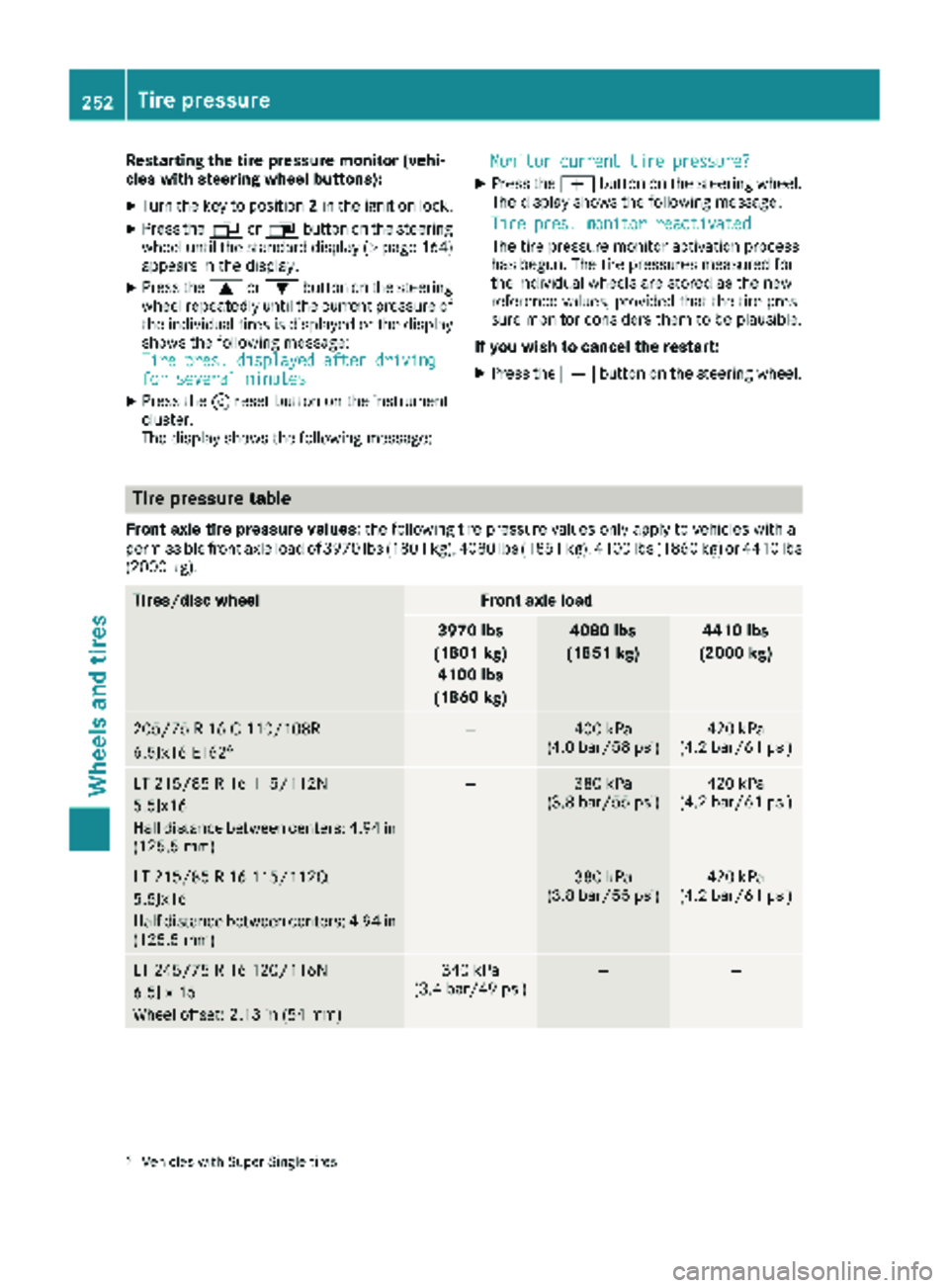

Tire pressure table

Front axle tire pressure values: the following tire pressure values only apply to vehicles with a

permissible front axle load of 3970 lb s(1801 kg), 4080 lbs (1851 kg), 4100 lbs (1860 kg) or 4410 lbs

(2000 kg).

Tires/disc wheelFront axle load

3970 lbs

(1801 kg) 4100 lbs

(1860 kg)4080 lbs

(1851 kg)4410 lbs

(2000 kg)

205/75 R 16 C 110/108R

6.5Jx16 ET626—400 kPa

(4.0 bar/58 psi)420 kPa

(4.2 bar/61 psi)

LT 215/85 R 16 115/112N

5.5Jx16

Half distance between centers: 4.94 in

(125.5 mm)—380 kPa

(3.8 bar/55 psi)420 kPa

(4.2 bar/61 psi)

LT 215/85 R 16 115/112Q

5.5Jx16

Half distance between centers: 4.94 in

(125.5 mm)—380 kPa

(3.8 bar/55 psi)420 kPa

(4.2 bar/61 psi)

LT 245/75 R 16 120/116N

6.5J x 16

Wheel offset: 2.13 in (54 mm)340 kPa

(3.4 bar/49 psi)——

6Vehicles with Super Single tires

252Tire pressure

Wheels and tires

Page 255 of 286

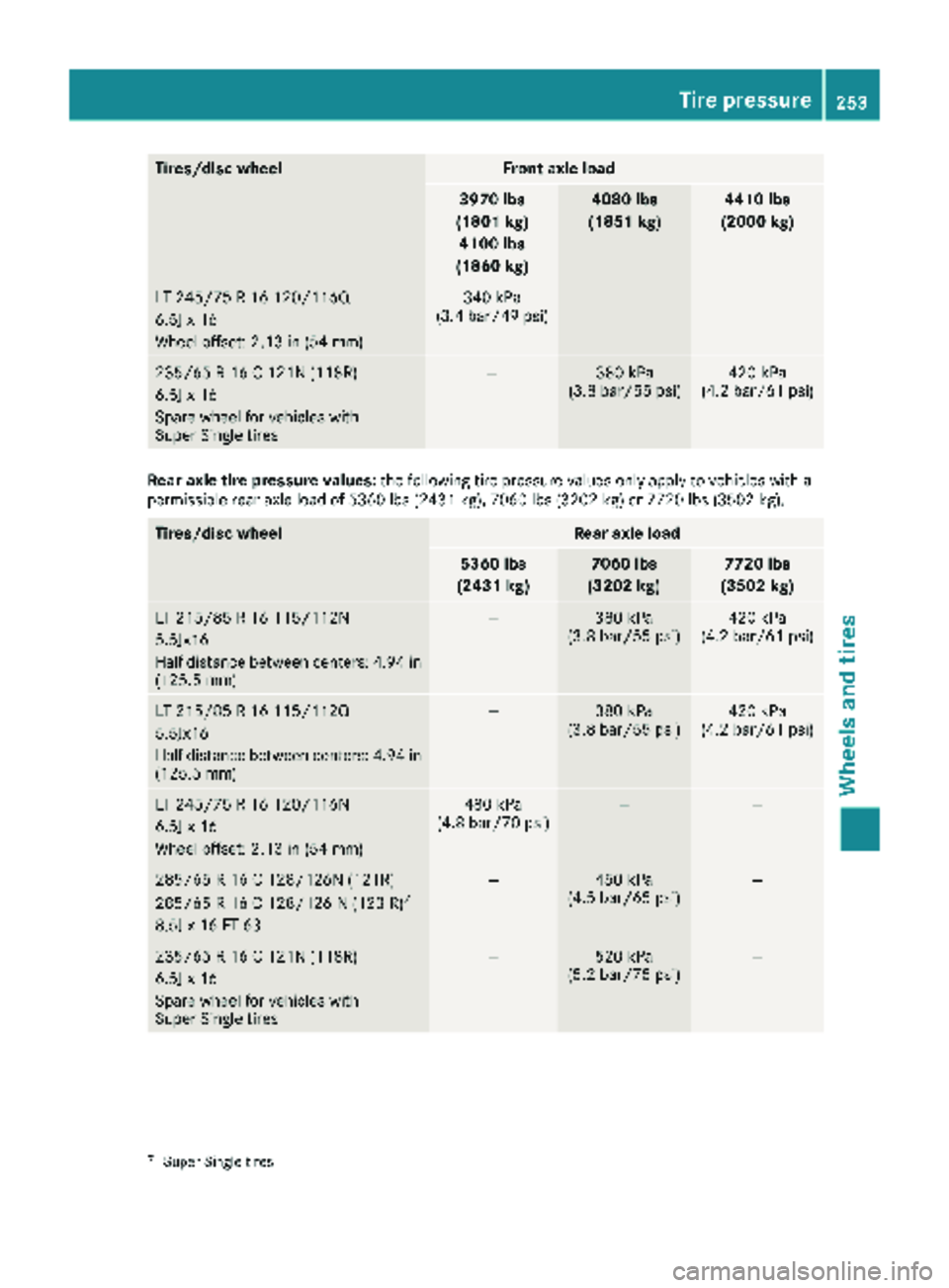

Tires/disc wheelFront axle load

3970 lbs

(1801 kg) 4100 lbs

(1860 kg)4080 lbs

(1851 kg)4410 lbs

(2000 kg)

LT 245/75 R 16 120/116Q

6.5J x 16

Wheel offset: 2.13 in (54 mm)340 kPa

(3.4 bar/49 psi)——

235/65 R 16 C 121N (118R)

6.5J x 16

Spare wheel for vehicles with

Super Single tires—380 kPa

(3.8 bar/55 psi)420 kPa

(4.2 bar/61 psi)

Rear axle tire pressure values: the following tire pressure values only apply to vehicles with a

permissible rear axle load of 5360 lbs (2431 kg), 7060 lbs (3202 kg) or 7720 lbs (3502 kg).

Tires/disc wheelRear axle load

5360 lbs

(2431 kg)7060 lbs

(3202 kg)7720 lbs

(3502 kg)

LT 215/85 R 16 115/112N

5.5Jx16

Half distance between centers: 4.94 in

(125.5 mm)—380 kPa

(3.8 bar/55 psi)420 kPa

(4.2 bar/61 psi)

LT 215/85 R 16 115/112Q

5.5Jx16

Half distance between centers: 4.94 in

(125.5 mm)—380 kPa

(3.8 bar/55 psi)420 kPa

(4.2 bar/61 psi)

LT 245/75 R 16 120/116N

6.5J x 16

Wheel offset: 2.13 in (54 mm)480 kPa

(4.8 ba r/70 psi)——

285/65 R16 C128/126N (121R)

285/65 R16 C128/12 6 N(123 R)7

8.5J x 16 ET 63

—450 kPa

(4.5 bar/65 psi)—

235/65 R 16 C 121N (118R)

6.5J x 16

Spare wheel for vehicles with

Super Single tires—520 kPa

(5.2 bar/75 psi)—

7Super Single tires

Tire pressure253

Wheels and tires

Z

Page 256 of 286

Loading the vehicle

Instruction labels for tires and loads

GWARNING

Overloaded tires can overheat, causing a

blowout. Overloaded tires can also impair the steering and driving characteristics and lead

to brake failure. There is a risk of accident.

Observe the load rating of the tires. The load

rating must be at least half of the GAWR of

your vehicle. Never overload the tires by

exceeding the maximum load.

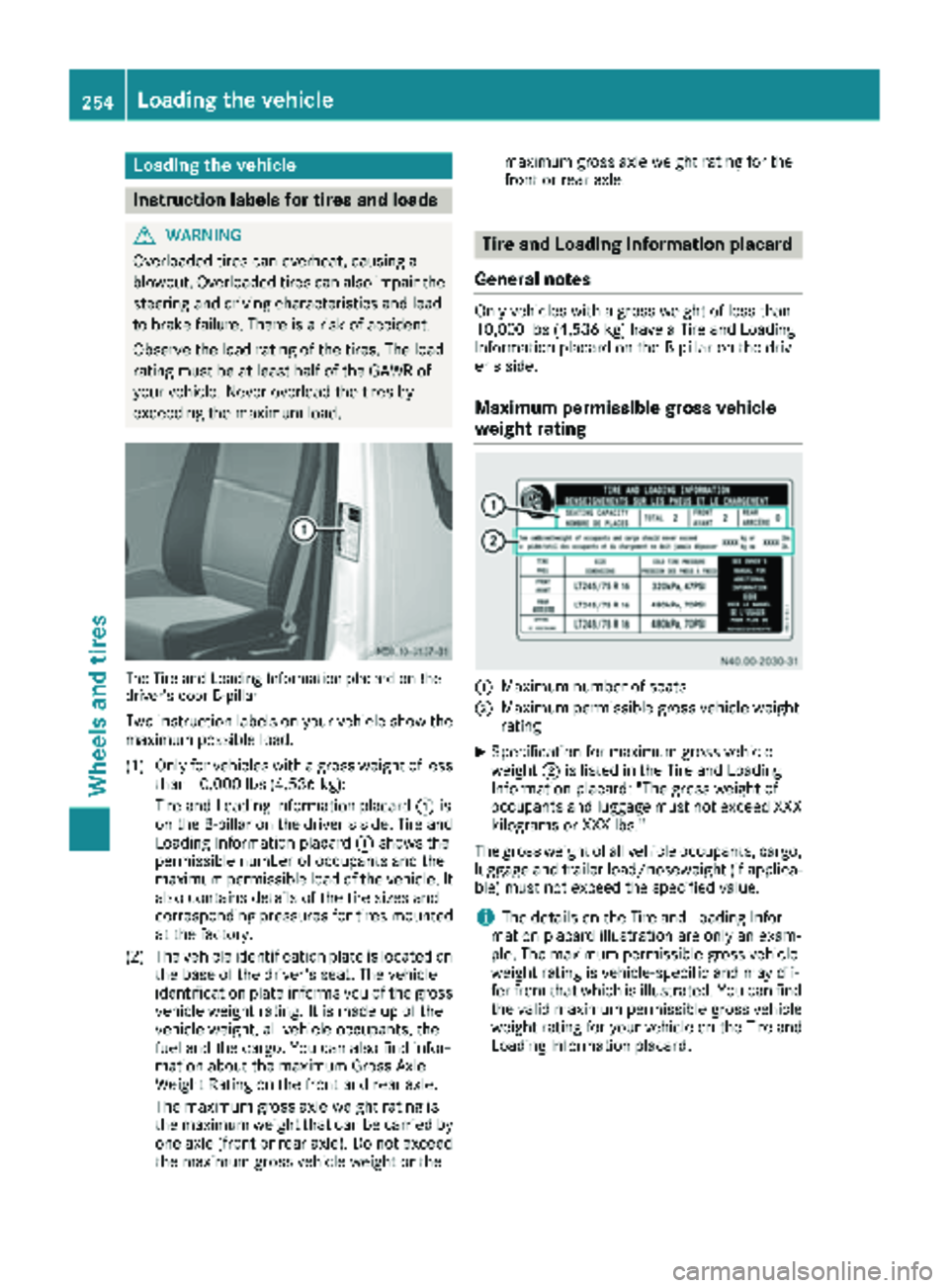

The Tire and Loading Information placard on the

driver’s door B-pillar

Two instruction labels on your vehicle show themaximum possible load.

(1) Only for vehicles with a gross weight of less than 10,000 lbs (4,536 kg):

Tire and Loading Information placard :is

on the B-pillar on the driver's side. Tire and

Loading Information placard :shows the

permissible number of occupants and the

maximum permissible load of the vehicle. It

also contains details of the tire sizes and

corresponding pressures for tires mounted

at the factory.

(2) The vehicle identification plate is located on the base of the driver's seat. The vehicle

identification plate informs you of the gross

vehicle weight rating. It is made up of the

vehicle weight, all vehicle occupants, the

fuel and the cargo. You can also find infor-

mation about the maximum Gross Axle

Weight Rating on the front and rear axle.

The maximum gross axle weight rating is

the maximum weight that can be carried by

one axle (front or rear axle). Do not exceed

the maximum gross vehicle weight or the maximum gross axle weight rating for the

front or rear axle.

Tire and Loading Information placard

General notes

Only vehicles with a gross weight of less than

10,000 lbs (4,536 kg) have a Tire and Loading

Information placard on the B-pillar on the driv-

er's side.

Maximum permissible gross vehicle

weight rating

:Maximum number of seats

;Maximum permissible gross vehicle weight

rating

XSpecification for maximum gross vehicle

weight ;is listed in the Tire and Loading

Information placard: "The gross weight of

occupants and luggage must not exceed XXX

kilograms or XXX lbs."

The gross weight of all vehicle occupants, cargo,

luggage and trailer load/noseweight (if applica-

ble) must not exceed the specified value.

iThe details on the Tire and Loading Infor-

mation placard illustration are only an exam-

ple. The maximum permissible gross vehicle

weight rating is vehicle-specific and may dif-

fer from that which is illustrated. You can find

the valid maximum permissible gross vehicle

weight rating for your vehicle on the Tire and

Loading Information placard.

254Loading the vehicle

Wheels and tires

Page 259 of 286

Trailer load/noseweight

The trailer load/noseweight affects the gross

weight of the vehicle. If a trailer is attached, the

trailer load/noseweight is included in the load

along with occupants and luggage. The trailer

load/noseweight is usually approximately 10%

of the gross weight of the trailer and its load.

What you should know about wheels

and tires

Tire labeling

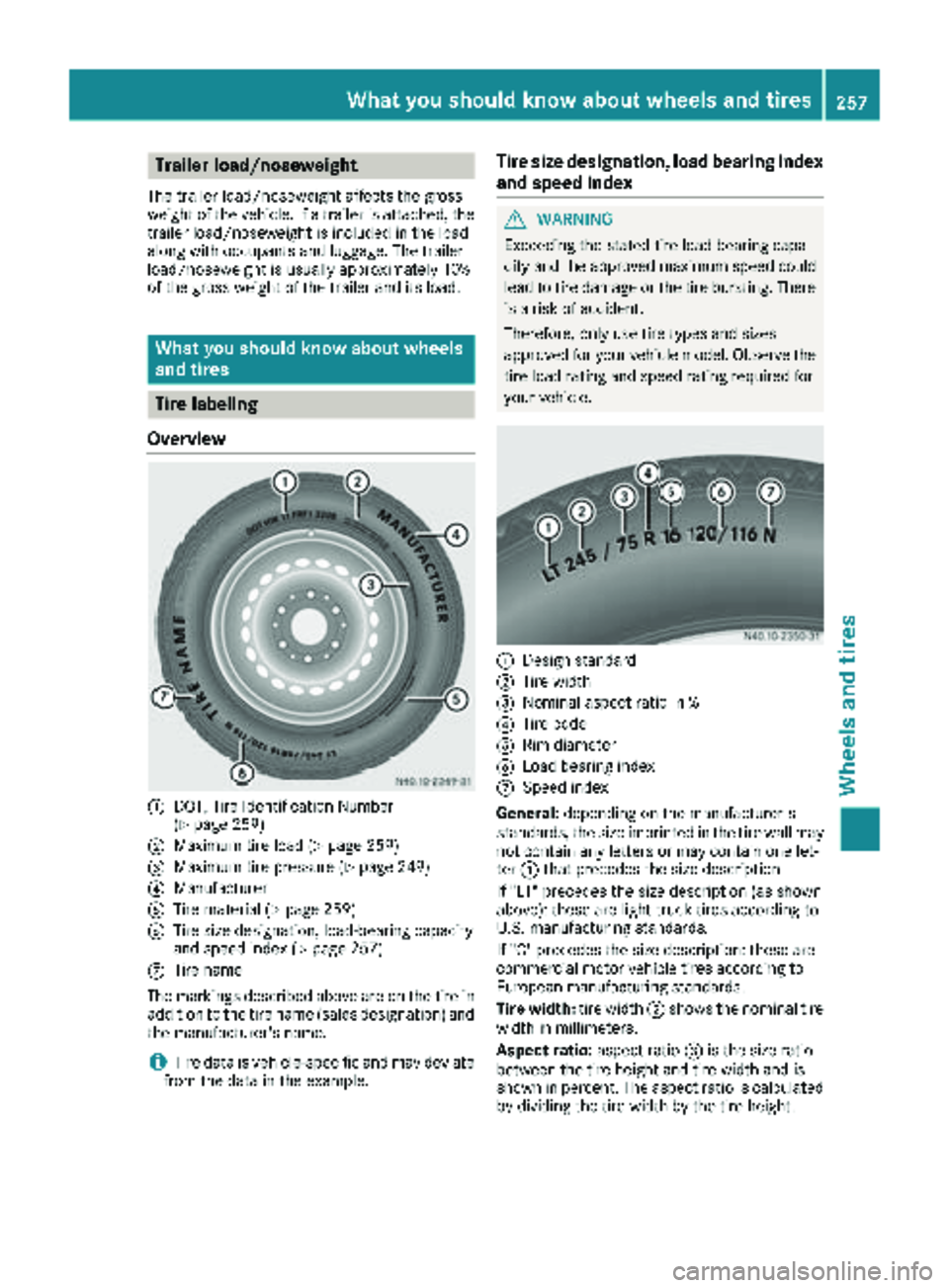

Overview

:DOT, Tire Identification Number

(Ypage 259)

;Maximum tire load (Ypage 259)

=Maximum tire pressure (Ypage 249)

?Manufacturer

ATire material (Ypage 259)

BTire size designation, load-bearing capacity

and speed index (Ypage 257)

CTire name

The markings described above are on the tire in addition to the tire name (sales designation) and

the manufacturer's name.

iTire data is vehicle-specific and may deviate

from the data in the example.

Tire size designation, load bearing index

and speed index

GWARNING

Exceeding the stated tire load-bearing capa-

city and the approved maximum speed could

lead to tire damage or the tire bursting. There is a risk of accident.

Therefore, only use tire types and sizes

approved for your vehicle model. Observe the

tire load rating and speed rating required for

your vehicle.

:Design standard

;Tire width

=Nominal aspect ratio in %

?Tire code

ARim diameter

BLoad bearing index

CSpeed index

General: depending on the manufacturer's

standards, the size imprinted in the tire wall may

not contain any letters or may contain one let-

ter :that precedes the size description

If "LT" precedes the size description (as shown

above): these are light truck tires according to

U.S. manufacturing standards.

If "C" precedes the size description: these are

commercial motor vehicle tires according to

European manufacturing standards.

Tire width: tire width;shows the nominal tire

width in millimeters.

Aspect ratio: aspect ratio=is the size ratio

between the tire height and tire width and is

shown in percent. The aspect ratio is calculated

by dividing the tire width by the tire height.

What you should know about wheels and tires257

Wheels and tires

Z

Page 260 of 286

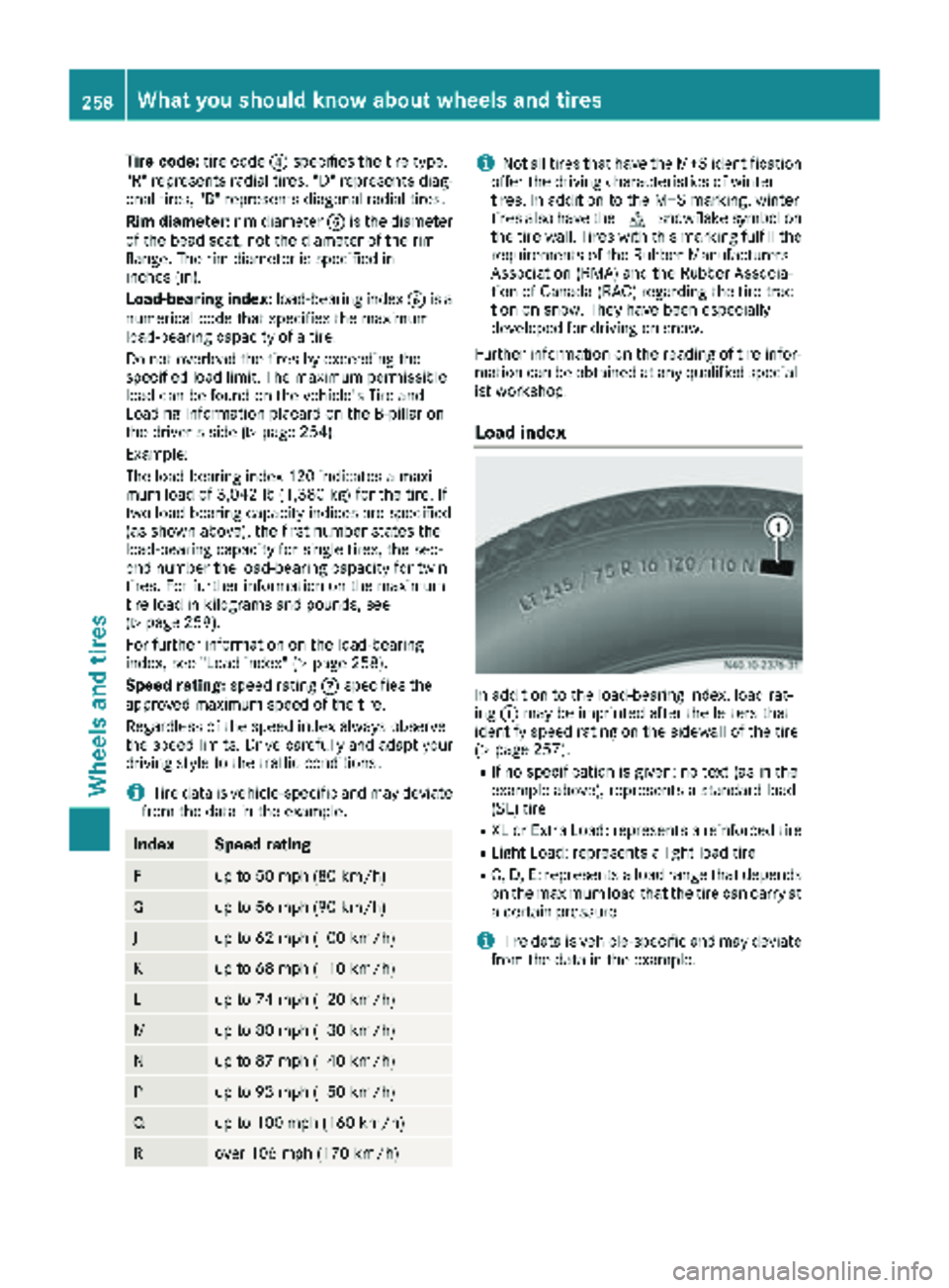

Tire code:tire code?specifies the tire type.

"R" represents radial tires. "D" represents diag-

onal tires, "B" represents diagonal radial tires.

Rim diameter: rim diameterAis the diameter

of the bead seat, not the diameter of the rim

flange. The rim diameter is specified in

inches (in).

Load-bearing index: load-bearing indexBis a

numerical code that specifies the maximum

load-bearing capacity of a tire.

Do not overload the tires by exceeding the

specified load limit. The maximum permissible

load can be found on the vehicle's Tire and

Loading Information placard on the B-pillar on

the driver's side (

Ypage 254).

Example:

The load-bearing index 120 indicates a maxi-

mum load of 3,042 lb (1,380 kg) for the tire. If

two load-bearing capacity indices are specified

(as shown above), the first number states the

load-bearing capacity for single tires, the sec-

ond number the load-bearing capacity for twin

tires. For further information on the maximum

tire load in kilograms and pounds, see

(

Ypage 259).

For further information on the load-bearing

index, see "Load index" (

Ypage 258).

Speed rating: speed ratingCspecifies the

approved maximum speed of the tire.

Regardless of the speed index alw

ays observe

the speed limits. Drive carefully and adapt your driving style to the traffic conditions.

iTire data is vehicle-specific and may deviate

from the data in the example.

IndexSpeed rating

Fup to 50 mph (80 km/h)

Gup to 56 mph (90 km/h)

Jup to 62 mph (100 km/h)

Kup to 68 mph (110 km/h)

Lup to 74 mph (120 km/h)

Mup to 80 mph (130 km/h)

Nup to 87 mph (140 km/h)

Pup to 93 mph (150 km/h)

Qup to 100 mph (160 km/h)

Rover 106 mph (170 km/h)

iNot all tires that have the M+S identification

offer the driving characteristics of winter

tires. In addition to the M+S marking, winter

tires also have the isnowflake symbol on

the tire wall. Tires with this marking fulfill the

requirements of the Rubber Manufacturers

Association (RMA) and the Rubber Associa-

tion of Canada (RAC) regarding the tire trac-

tion on snow. They have been especially

developed for driving on snow.

Further information on the reading of tire infor-

mation can be obtained at any qualified special-

ist workshop.

Load index

In addition to the load-bearing index, load rat-

ing :may be imprinted after the letters that

identify speed rating on the sidewall of the tire

(

Ypage 257).

RIf no specification is given: no text (as in the

example above), represents a standard load

(SL) tire

RXL or Extra Load: represents a reinforced tire

RLight Load: represents a light load tire

RC, D, E: represents a load range that depends

on the maximum load that the tire can carry at

a certain pressure

iTire data is vehicle-specific and may deviate

from the data in the example.

258What you should know about wheels and tires

Wheels and tires

Page 262 of 286

Bar

Metric unit for tire pressure. 14.5038 pounds

per square inch (psi) and 100 kilopascals (kPa)

are the equivalent of 1 bar.

DOT (Department of Transportation)

DOT marked tires fulfill the requirements of the

United States Department of Transportation.

Average weight of vehicle occupants

The number of occupants for which the vehicle

is designed multiplied by 68 kilograms (150 lbs).

Uniform Tire Quality Grading Standards

A uniform standard to grade the quality of tires

with regard to tread quality, traction and tem-

perature characteristics. The quality grading

assessment is made by the manufacturer fol-

lowing specifications from the U.S government.

The quality grade of a tire is imprinted on the

sidewall of the tire.

Recommended tire pressure

The recommended tire pressures are the pres-

sures specified for the tires mounted on the

vehicle at the factory.

The tire and load information table

8contains the

recommended tire pressures for cold tires, the

maximum permissible load and the maximum

permissible vehicle speed.

The tire pressure table contains the recommen- ded tire pressure for cold tires under various

operating conditions, i.e. loading and/or speed

of the vehicle.

Increased vehicle weight due to optional

equipment

The combined weight of all standard and

optional equipment available for the vehicle,

regardless of whether it is actually installed on

the vehicle or not.

Wheel rim

The part of the wheel on which the tire is moun-

ted.

GAWR (Gross Axle Weight Rating)

GAWR is the maximum gross axle weight rating.

The actual load on an axle must never exceed

the gross axle weight rating. The Gross Axle

Weight Rating can be found on the vehicle iden- tification plate on the driver seat frame

(

Ypage 272).

Speed index

The speed index is part of the tire identification.

It specifies the speed range for which the tire is

approved.

GTW (Gross Trailer Weight)

GTW is the total of weight of a trailer and the

weight of the load, accessories etc. on the

trailer.

GVW (Gross Vehicle Weight)

The gross vehicle weight includes the weight of

the vehicle including fuel, tools, spare wheel,

accessories installed, occupants, luggage and

the drawbar noseweight if applicable. The gross

vehicle weight may never exceed the gross vehi-

cle weight rating (GVWR) specified on the vehi-

cle i

dentification plate at the base of the driver's

seat (Ypage 272).

GVWR (Gross Vehicle Weight Rating)

The GVWR is the maximum permitted gross

weight of the fully laden vehicle (weight of the

vehicle including all accessories, occupants,

fuel, luggage and the drawbar noseweight if

applicable). The Gross Vehicle Weight Rating is

specified on the vehicle identification plate on

the driver seat frame (

Ypage 272).

Maximum weight of the laden vehicle

The maximum weight is the sum of:

Rthe curb weight of the vehicle

Rthe weight of the accessories

Rthe load limit

Rthe weight of the factory installed optional

equipment

Kilopascal (kPa)

Metric unit for tire pressure. 6.9 kPa are the

equivalent of 1 ps i.Another tire pressure unit is

bar. 100 kilopascal s(kPa) are the equivalent of

1 bar.

Load index

In addition to the load bearing index, a load

index can be stamped onto the sidewall of the

tire. It specifies the load-bearing capacity of the

tire more precisely.

8Only for vehicles with a gross weight of less than 10,000 lbs (4536 kg).

260What you should know about wheels and tires

Wheels and tires

Page 263 of 286

Curb weight

The weight of a vehicle with standard equipment

including the maximum filling capacity of fuel,

oil, and coolant. It also includes the air-condi-

tioning system and optional equipment if these

are installed on the vehicle, but does not include

passengers or luggage.

Maximum tire load

The maximum tire load in kilograms or pounds is

the maximum weight for which a tire is

approved.

Maximum permissible tire pressure

Maximum permissible tire pressure for one tire.

Maximum load on one tire

Maximum load on one tire. This is calculated by

dividing the maximum axle load of one axle by

two.

PSI (Pounds per square inch)

Standard unit of measurement for tire pressure.

Aspect ratio

Relationship between tire height and width in

percent.

tire pressure

Pressure inside the tire applying an outward

force to every square inch of the tire's surface.

Tire pressure is specified in pounds per square

inch (psi), in kilopascal (kPa) or in bar. Tire pres-

sure should only be corrected when the tires are

cold.

Cold tire pressure

The tires are cold:

Rif the vehicle has been parked for at least

three hours without direct sunlight on the

tires, and

Rif the vehicle has not been driven further than

1 mile (1.6 km)

Tire tread

The part of the tire that comes into contact with the road.

Tire bead

The tire bead ensures that the tire sits securely

on t

he wheel. There are several steel wires in the

bead to prevent the tire from coming loose from

the wheel rim.

Sidewall

The part of the tire between the tread and the

tire bead.

Weight of optional extras

The combined weight of those optional extras

that weigh more than the replaced standard

parts and more than 2.3 kg (5 lbs). These

optional extras, such as high-performance

brakes, a roof rack or a high-performance bat-

tery, are not included in the curb weight and the

weight of the accessories.

TIN (Tire Identification Number)

A unique identification number which can be

used by a tire manufacturer to identify tires, for

example for a product recall, and thus identify

the purchasers. The TIN is composed of the

manufacturer identification code, tire size, tire

model code and manufacturing date.

Load bearing index

The load bearing index (also load index) is a code

that contains the maximum load bearing capa-

city of a tire.

Traction

Traction is the result of friction between the tires

and the road surface.

TWR (permissible trailer drawbar load)

The TWR is the maximum permissible weight

that may act on the ball coupling of the trailer

tow hitch.

Wear indicator

Narrow bars (tread wear bars) that are distrib-

uted over the tire tread. If the tir e tread is level

with the bars, the wear limit of áin (1.6 mm)

has been reached.

Distribution of the vehicle occupants

The distribution of vehicle occupants over des-

ignated seat positions in a vehicle.

Maximum permissible payload weight

Nominal load and goods/luggage load plus

68 kg (150lbs) multiplied by the number of

seats in the vehicle.

What you should know about wheels and tires261

Wheels and tires

Z

Page 266 of 286

Observe the following when raising the vehicle:

RWhen raising the vehicle, only use the jack

which Mercedes-Benz has specifically

approved for your vehicle.

RThe vehicle's jack is intended only to raise the

vehicle for a short time when changing a

wheel. It is not suited for performing mainte-

nance work under the vehicle.

RAvoid changing the wheel on uphill and down-

hill slopes.

RBefore raising the vehicle, secure it from roll-

ing away by applying the parking brake and

inserting wheel chocks. Never disengage the

parking brake while the vehicle is raised.

RThe jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a large,

load-bearing underlay must be used. On a

slippery surface, a non-slip underlay must be

used, e.g. rubber mats.

RMake sure that the distance between the

underside of the tires and the ground does not

exceed 1.2 in(3 cm).

RNever place your hands or feet under the

raised vehicle.

RNever lie under the raised vehicle.

RNever start the engine when the vehicle is

raised.

RNever open or close a door when the vehicle

is raised.

RMake sure that no persons are present in the

vehicle when the vehicle is raised.

!Only use the jack pump lever middle rod and

the rod with the largest diameter as a lug

wrench extension. Only slide the middle rod

as far as it will go onto the lug wrench. The

rods may otherwise bend and be distorted to

such an extent that they can no longer be

used as a pump lever for the jack.

!Do not place the jack on the leaf spring or

the differential case.

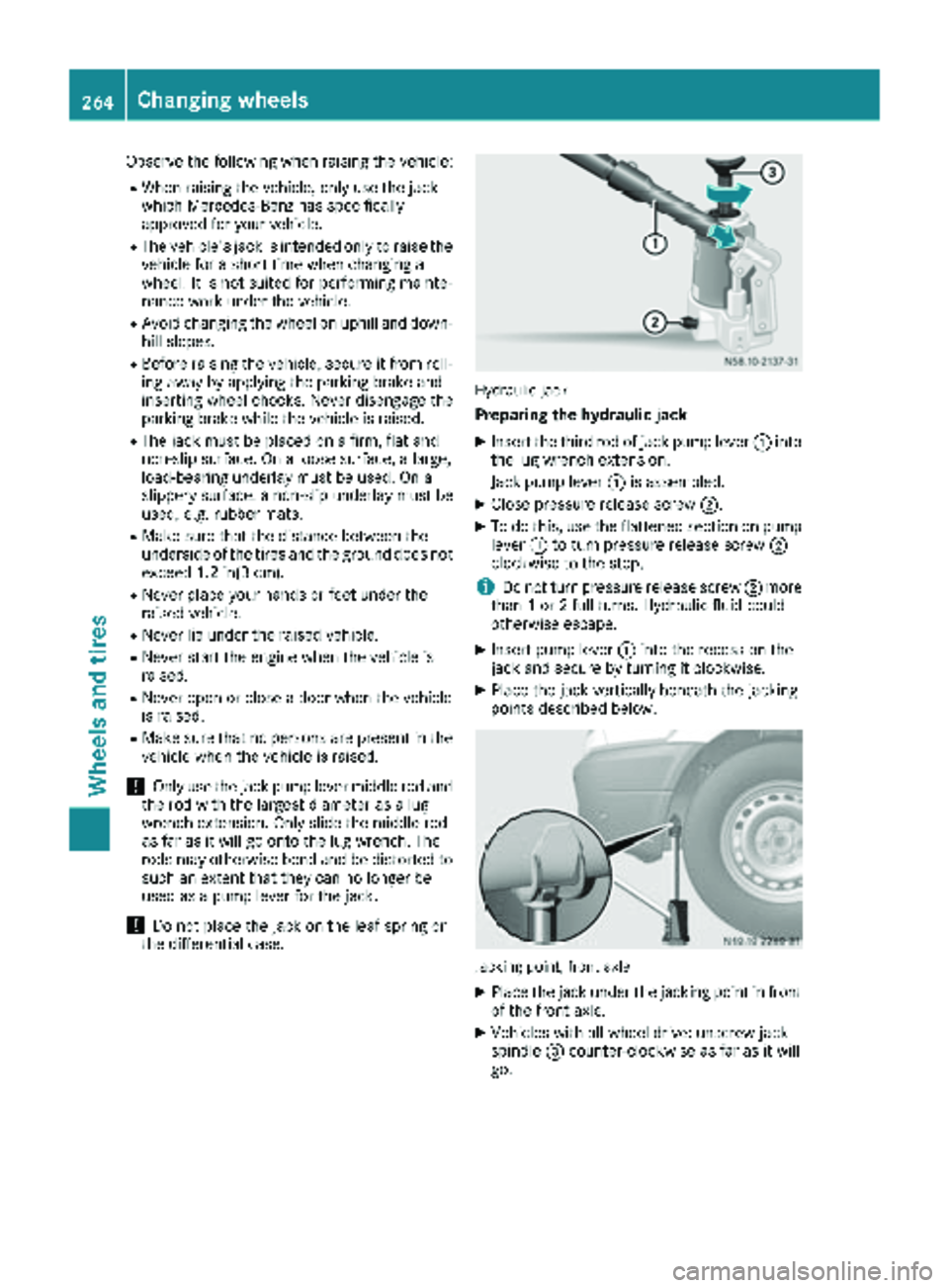

Hydraulic jack

Preparing the hydraulic jack

XInsert the third rod of jack pump lever :into

the lug wrench extension.

Jack pump lever :is assembled.

XClose pressure release screw ;.

XTo do this, use the flattened section on pump

lever:to turn pressure release screw ;

clockwise to the stop.

iDo not turn pressure release screw ;more

than 1 or 2 full turns. Hydraulic fluid could

otherwise escape.

XInsert pump lever :into the recess on the

jack and secure by turning it clockwise.

XPlace the jack vertically beneath the jacking

points described below.

Jacking point, front axle

XPlace the jack under the jacking point in front of the front axle.

XVehicles with all-wheel drive: unscrew jack

spindle =counter-clockwise as far as it will

go.

264Changing wheels

Wheels and tires

Page 268 of 286

specialist workshop and have the spare wheel

replaced with a wheel and tire assembly that has

a Super Single tire.

XClean the wheel and wheel hub contact sur-

faces.

XUnscrew the six adapter bolts on the spare

wheel and remove the adapter.

XTighten the adapter with the six adapter bolts

evenly in a crosswise pattern through the

outer holes on the wheel hub.

XTighten the six adapter bolts on the wheel hub

to a tightening torque of177 lb-ft(240 Nm).

XPush the wheel onto the adapter and attach it.

Mounting a new wheel

GWARNING

Oiled or greased wheel bolts or damaged

wheel bolts/hub threads can cause the wheel bolts to come loose. As a result, you could

lose a wheel while driving. There is a risk of

accident.

Never oil or grease wheel bolts. In the event of

damage to the threads, contact a qualified

specialist workshop immediately. Have the

damaged wheel bolts or hub threads

replaced/renewed. Do not continue driving.

GWARNING

If you tighten the wheel bolts or wheel nuts

when the vehicle is raised, the jack could tip

over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts

when the vehicle is on the ground.

Always observe the instructions and safety

notes on "Changing a wheel" (

Ypage 262).

Only use wheel bolts or wheel nuts that have

been designed for the wheel and the vehicle. For safety reasons, we recommend that you only

use wheel bolts or wheel nuts which have been

approved for Sprinter vehicles and the respec-

tive wheel.

!For a steel wheel, only use the short wheel

bolts to mount the steel spare wheel. Using

other wheel bolts to mount the steel spare

wheel could damage the brake system.

!On vehicles equipped with a tire pressure

monitor, electronic components are located

in the wheel.

Tire-mounting tools should not be used near

the valve. This could damage the electronic

components.

Only have tires changed at a qualified spe-

cialist workshop.

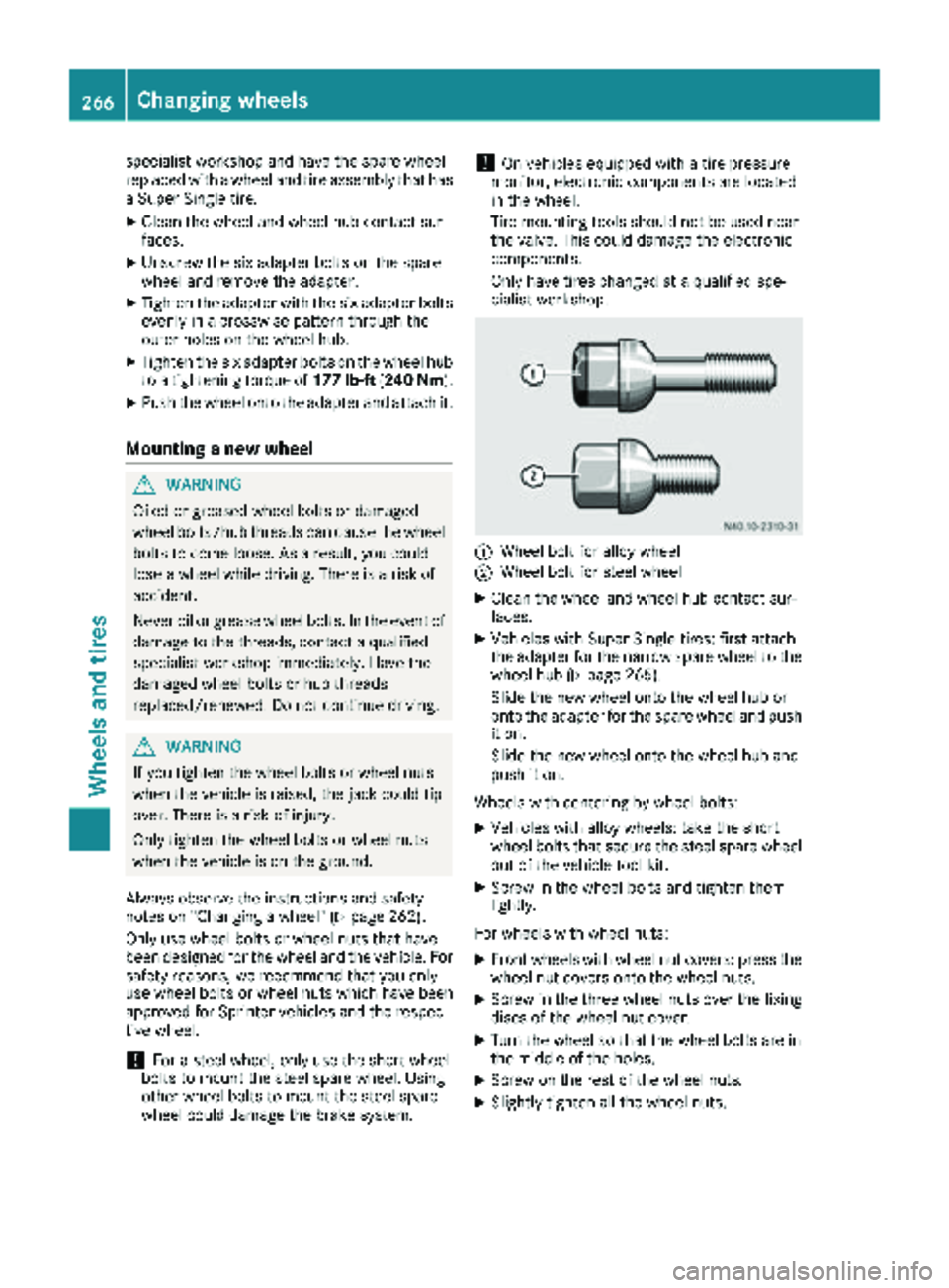

:Wheel bolt for alloy wheel

;Wheel bolt for steel wheel

XClean the wheel and wheel hub contact sur-

faces.

XVehicles with Super Single tires: first attach

the adapter for the narrow spare wheel to the

wheel hub (

Ypage 265).

Slide the new wheel onto the wheel hub or

onto the adapter for the spare wheel and push

it on.

Slide the new wheel onto the wheel hub and

push it on.

Wheels with centering by wheel bolts:

XVehicles with alloy wheels: take the short

wheel bolts that secure the steel spare wheel

out of the vehicle tool kit.

XScrew in the wheel bolts and tighten them

lightly.

For wheels with wheel nuts:

XFront wheels with wheel nut covers: press the wheel nut covers onto the wheel nuts.

XScrew in the three wheel nuts over the fixing

discs of the wheel nut cover.

XTurn the wheel so that the wheel bolts are in

the middle of the holes.

XScrew on the rest of the wheel nuts.

XSlightly tighten all the wheel nuts.

266Changing wheels

Wheels and tires

Page 269 of 286

Lowering the vehicle

GWARNING

The wheels could work loose if the wheel nuts and bolts are not tightened to the specified

tightening torque. There is a risk of accident.

Have the tightening torque immediately

checked at a qualified specialist workshop

after a wheel is changed.

!Only use the jack pump lever middle rod and

the rod with the largest diameter as a lug

wrench extension. Only slide the middle rod

as far as it will go onto the lug wrench. The

rods may otherwise bend and be distorted to

such an extent that they can no longer be

used as a pump lever for the jack.

!Vehicles with Super Single tires: if you

install the spare wheel, do not exceed the

maximum speed of 40 mph (60 km/h) and do

not drive further than 65 miles(100 km).

The transmission could otherwise be dam-

aged by the difference in wheel rotation

speeds.

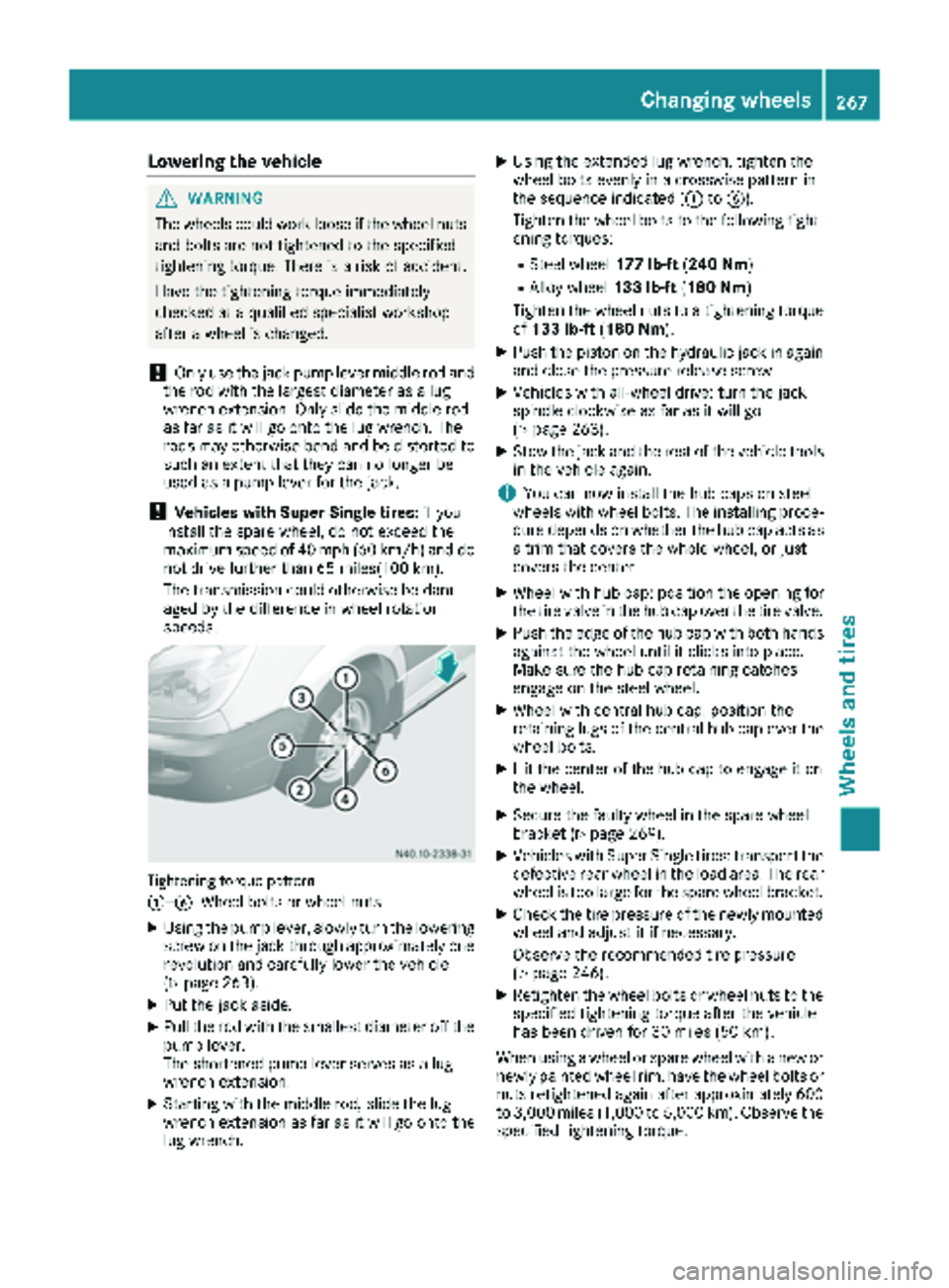

Tightening torque pattern

:— B

Wheel bolts or wheel nuts

XUsing the pump lever, slowly turn the lowering

screw on the jack through approximately one

revolution and carefully lower the vehicle

(

Ypage 263).

XPut the jack aside.

XPull the rod with the smallest diameter off the

pump lever.

The shortened pump lever serves as a lug

wrench extension.

XStarting with the middle rod, slide the lug

wrench extension as far as it will go onto the

lug wrench.

XUsing the extended lug wrench, tighten the

wheel bolts evenly in a crosswise pattern in

the sequence indicated ( :toB).

Tighten the wheel bolts to the following tight-

ening torques:

RSteel wheel 177 lb-ft(240 Nm )

RAlloy wheel 133 lb-ft(180 Nm )

Tighten the wheel nuts to a tightening torque

of 133 lb-ft (180 Nm).

XPush the piston on the hydraulic jack in again

and close the pressure release screw.

XVehicles with all-wheel drive: turn the jack

spindle clockwise as far as it will go

(

Ypage 263).

XStow the jack and the rest of the vehicle tools

in the vehicle again.

iYou can now install the hub caps on steel

wheels with wheel bolts. The installing proce-

dure depends on whether the hub cap acts as

a trim that covers the whole wheel, or just

covers the center.

XWheel with hub cap: position the opening for

the tire valve in the hub cap over the tire valve.

XPush the edge of the hub cap with both hands

against the wheel until it clicks into place.

Make sure the hub cap retaining catches

engage on the steel wheel.

XWheel with central hub cap: position the

retaining lugs of the central hub cap over the

wheel bolts.

XHit the center of the hub cap to engage it on

the wheel.

XSecure the faulty wheel in the spare wheel

bracket (Ypage 269).

XVehicles with Super Single tires: transport the

defective rear wheel in the load area. The rear wheel is too large for the spare wheel bracket.

XCheck the tire pressure of the newly mounted

wheel and adjust it if necessary.

Observe the recommended tire pressure

(

Ypage 246).

XRetighten the wheel bolts or wheel nuts to the

specified tightening torque after the vehicle

has been driven for 30 miles (50 km).

When using a wheel or spare wheel with a new or newly painted wheel rim, have the wheel bolts or

nuts retightened again after approximately 600

to 3,000 miles (1,000 to 5,000 km). Observe the

specified tightening torque.

Changing wheels267

Wheels and tires

Z