ECU MERCEDES-BENZ SPRINTER 2017 MY17 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2017, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2017Pages: 286, PDF Size: 4.36 MB

Page 213 of 286

You should therefore observe the respective

legal requirements for the relevant country.

Make sure that the load is secure before every

journey and at regular intervals during a long

journey. Correct an incorrectly or inadequately

secured load if necessary.

You can obtain information about securing the

load correctly from the manufacturer of the load

securing aids or tie down for securing the load.

XFill spaces between the load and the cargo

compartment walls or wheel housings (form-

locking). Use rigid load securing aids, such as

wedges, wooden fixings or padding.

XAttach secured and stabilized loads in all

directions. Use the cargo tie-down points or

cargo tie-down rings and the loading rails in

the cargo compartment or on the cargo area.

Only use tie downs, such as lashing rods or

lashing nets and lashing straps, that have

been tested in accordance with current

standards (e.g. DIN EN).

Always use the cargo tie-down rings closest to

the load to secure it and pad sharp edges for

protection.

Loads, and heavy loads in particular, should

preferably be secured using the cargo tie-

down rings.

iTie downs tested in accordance with current

standards (e.g. DIN EN) are available at any

qualified specialist workshop.

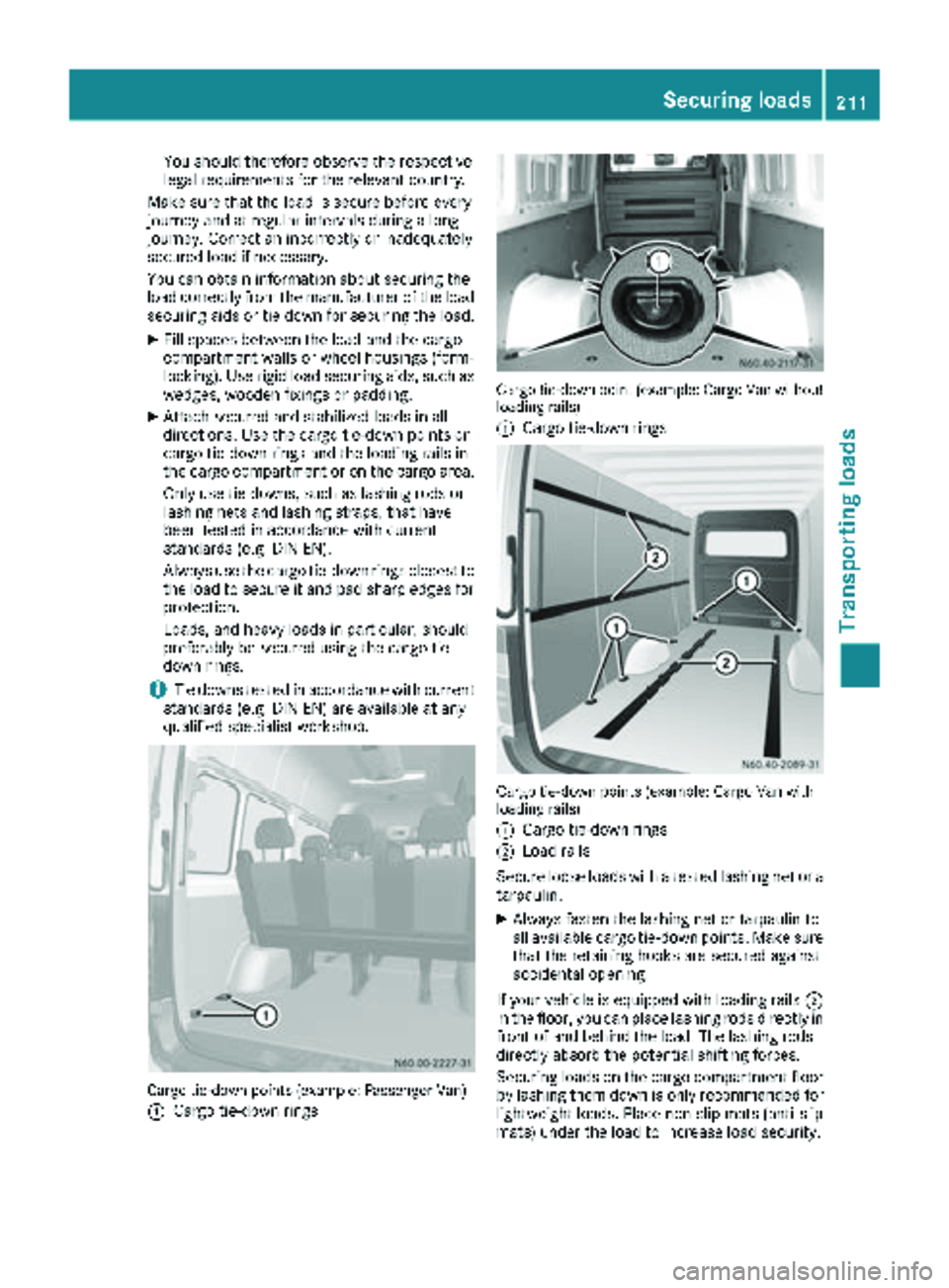

Cargo tie-down points (example: Passenger Van)

:

Cargo tie-down rings

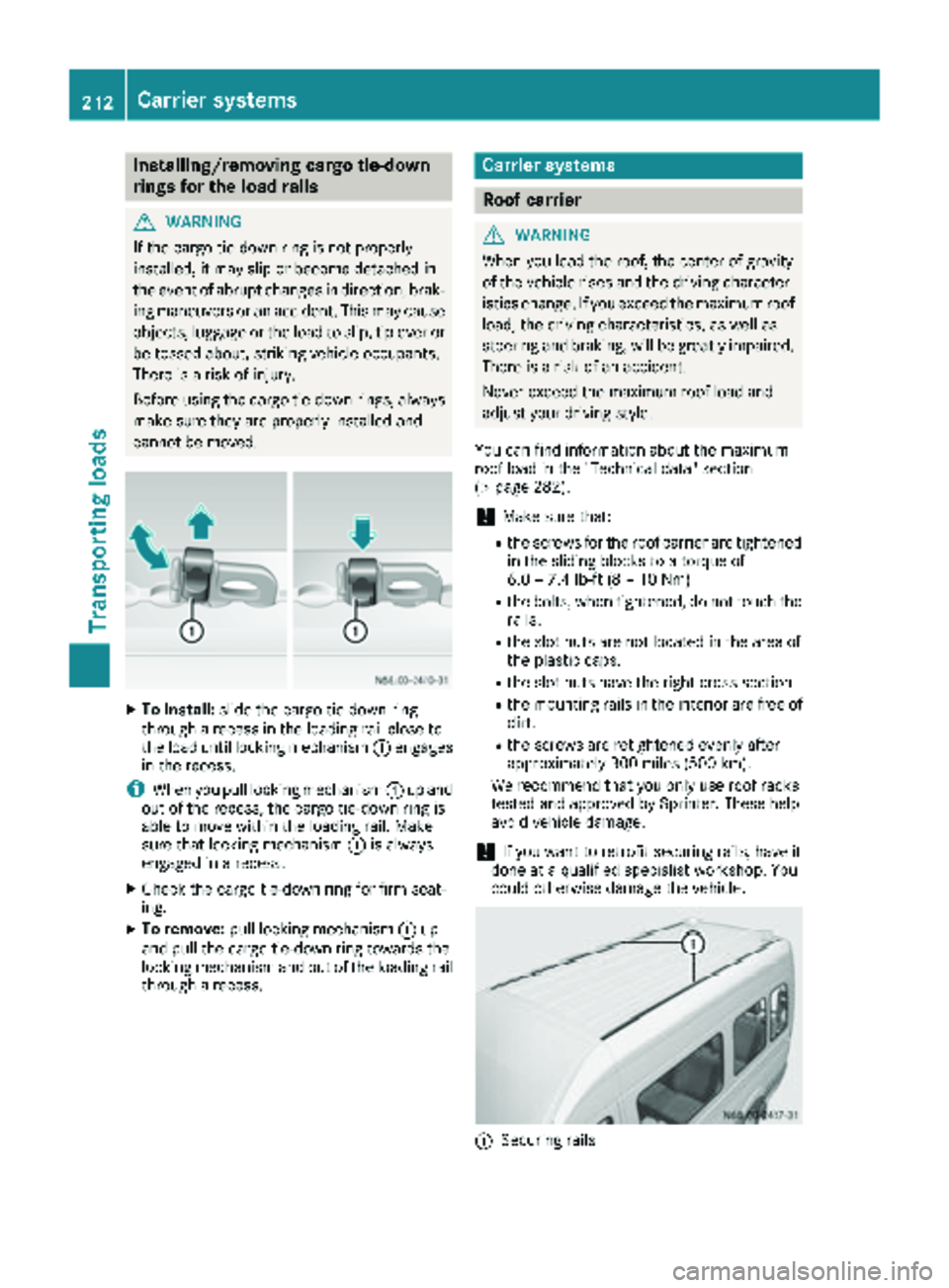

Cargo tie-down point (example: Cargo Van without

loading rails)

:

Cargo tie-down rings

Cargo tie-down points (example: Cargo Van with

loading rails)

:

Cargo tie-down rings

;Load rails

Secure loose loads with a tested lashing net or a

tarpaulin.

XAlways fasten the lashing net or tarpaulin to

all available cargo tie-down points. Make sure

that the retaining hooks are secured against

accidental opening.

If your vehicle is equipped with loading rails ;

in the floor, you can place lashing rods directly in

front of and behind the load. The lashing rods

directly absorb the potential shifting forces.

Securing loads on the cargo compartment floor

by lashing them down is only recommended for

lightweight loads. Place non-slip mats (anti-slip

mats) under the load to increase load security.

Securing loads211

Transporting loads

Z

Page 214 of 286

Installing/removing cargo tie-down

rings for the load rails

GWARNING

If th ecargo tie-down rin gis no tproperly

installed, it may slip or become detached in

th eevent of abrup tchanges in direction ,brak -

ing maneuvers or an accident. This may caus e

objects ,luggag eor th eload to slip, ti pove ror

be tosse dabout ,striking vehicl eoccupants.

Ther eis aris kof injury.

Before usin gth ecargo tie-down rings, always

mak esur ethey are properly installed and

canno tbe moved.

XTo install: slide thecargo tie-down rin g

throug h arecess in th eloadin grail close to

th eload until lockin gmechanism :engage s

in th erecess .

iWhen you pull lockin gmechanism :up and

out of th erecess ,th ecargo tie-down rin gis

able to mov ewithin th eloadin grail. Mak e

sur ethat lockin gmechanism :is always

engage din arecess .

XCheckth ecargo tie-down rin gfor fir mseat -

ing .

XTo remove: pull lockingmechanism :up

and pull th ecargo tie-down rin gtowards th e

lockin gmechanism and out of th eloadin grail

throug h arecess .

Carrier systems

Roof carrier

GWARNIN G

When you load th eroof, th ecenter of gravit y

of th evehicl erises and th edriving character-

istics change. If you exceed th emaximum roo f

load, th edriving characteristics ,as well as

steering and braking ,will be greatl yimpaired.

Ther eis aris kof an accident.

Never exceed th emaximum roo fload and

adjust your driving style.

You can fin dinformation about th emaximum

roo fload in th e"Technical data" section

(

Ypage 282).

!Mak esur ethat:

Rth escrews for th eroo fcarrie rare tightened

in th esliding blocks to atorque of

6. 0 – 7.4lb-ft (8 –10 Nm)

Rth ebolts, when tightened, do no ttouch th e

rails .

Rtheslot nut sare no tlocate din th earea of

th eplastic caps.

Rth eslot nut shav eth eright cross-section .

Rthemounting rails in th einterior are free of

dirt .

Rthescrews are retightened evenly after

approximately 30 0mile s(50 0km).

We recommen dtha tyou only use roo fracks

tested and approve dby Sprinter. These help

avoid vehicl edamage.

!If you wan tto retrofit securin grails, hav eit

don eat aqualified specialist workshop .You

could otherwise damage th evehicle.

:Securin grail s

212Carrier systems

Transporting loads

Page 215 of 286

It is possible to install a roof carrier if your vehi-

cle is equipped with securing rails on the roof.

Special mounting elements (grooved plates) are

available as accessories.

These mounting elements are available at any

authorized Sprinter Dealer.

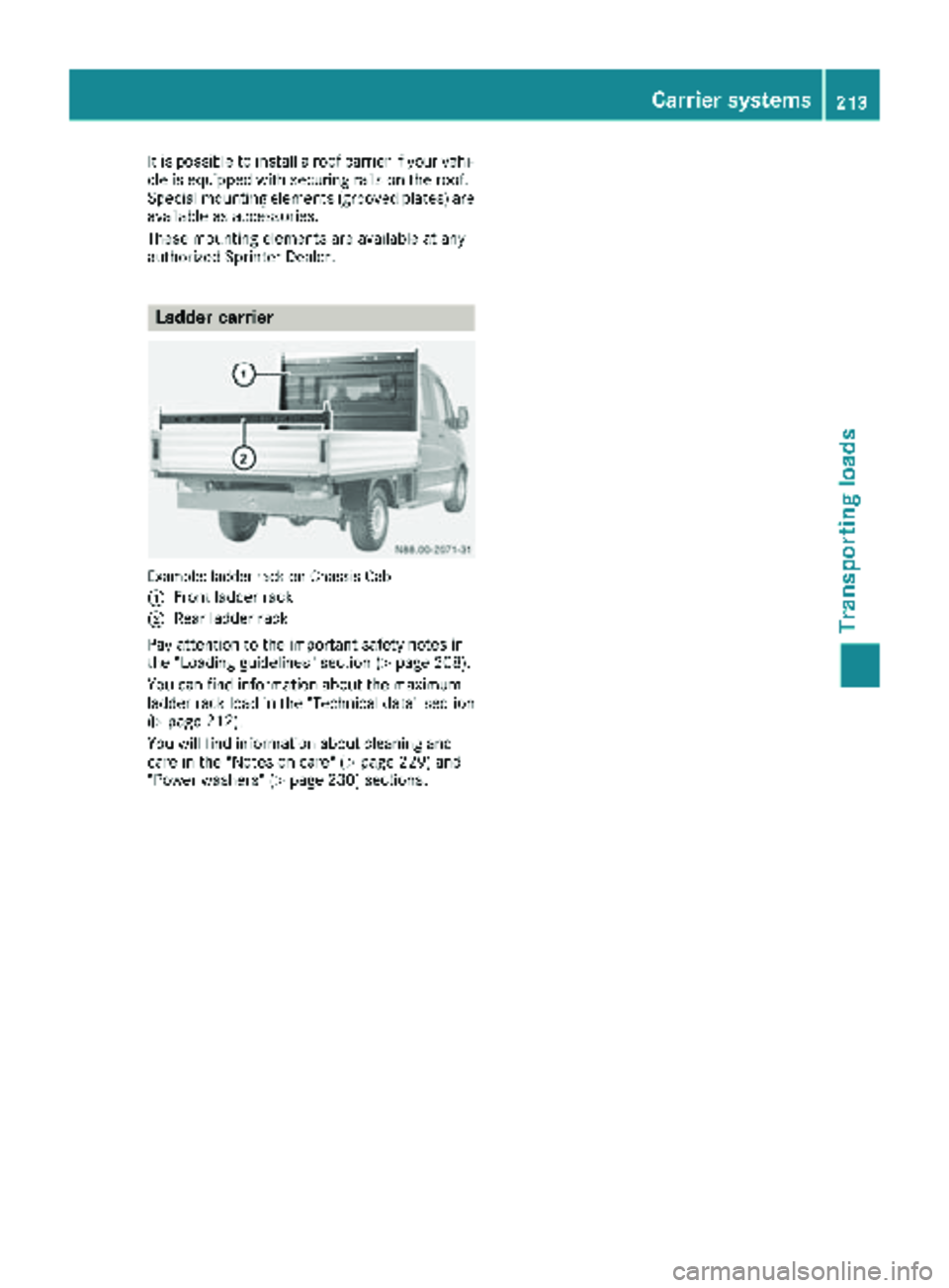

Ladder carrier

Example: ladder rack on Chassis Cab

:

Front ladder rack

;Rear ladder rack

Pay attention to the important safety notes in

the "Loading guidelines" section (

Ypage 208).

You can find information about the maximum

ladder rack load in the "Technical data" section

(

Ypage 212).

You will find information about cleaning and

care in the "Notes on care" (

Ypage 229) and

"Power washers" (Ypage 230) sections.

Carrier systems213

Transporting loads

Z

Page 217 of 286

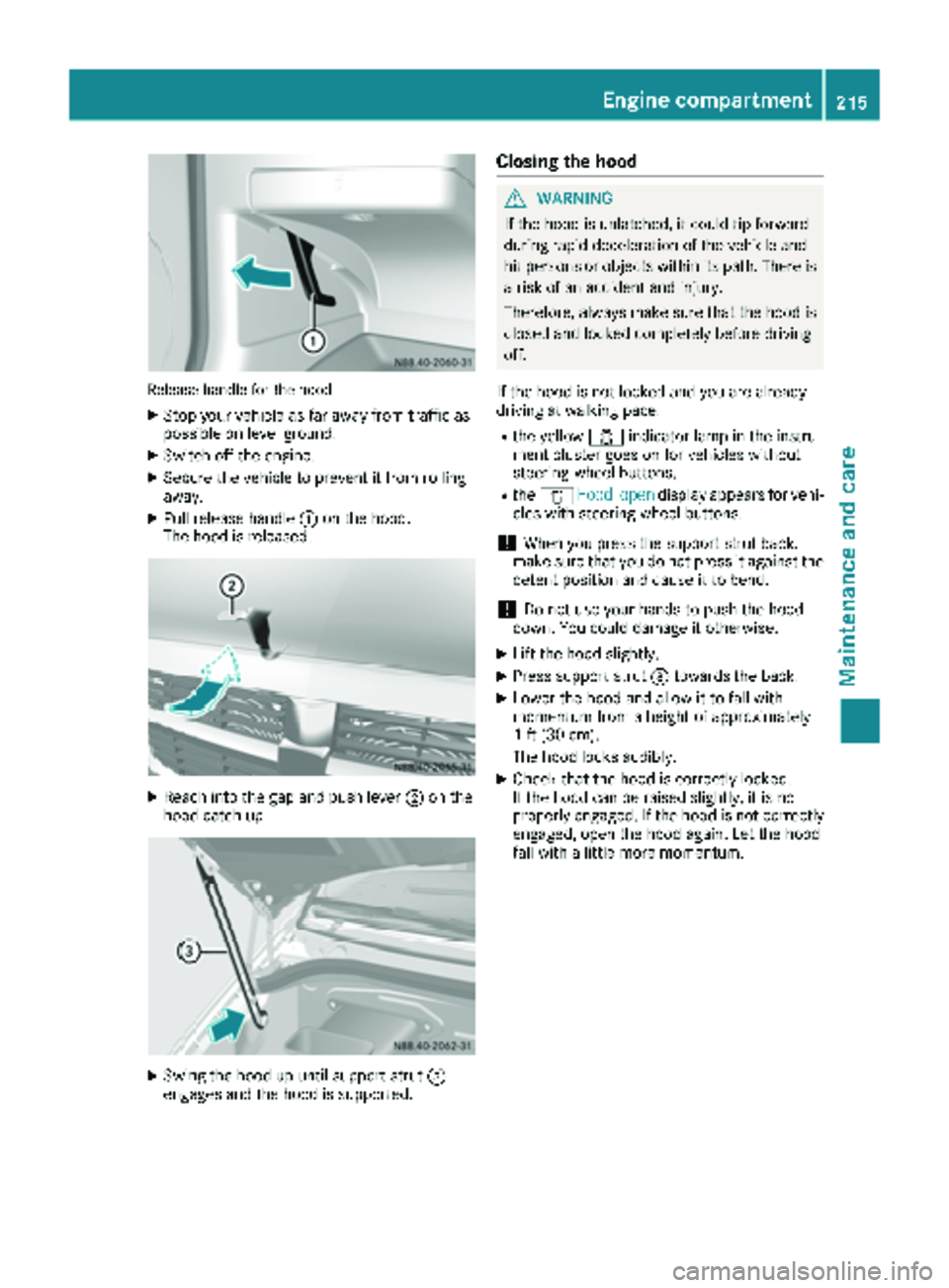

Releasehandle for th ehoo d

XStop your veh icleas far away fr omtraff icas

possible on level ground.

XSwitch off the engine.

XSecure the veh icleto prevent itfrom rolling

away.

XPull release handle :onthe hood.

The hoodis released.

XReach into the gap and push lever ;onthe

hoo d catch up.

XSwin g the hood up unt ilsupport strut =

engages and the hood issupported.

Closing the hood

GWARNIN G

If the hoodis unlatched, it could tip forward

during rapid decelerati on ofthe vehicle and

hit persons or objectswithin its path. There is

a risk ofan accident and injury.

Therefore, always make sure that the hood is

closed and locked co mpletely before driv ing

off.

If the hood is not locked and you are alrea dy

driving at walkingpace:

Rthe yellow 1indicat or lamp in theinstru-

ment cluster goes onfor vehicles without

steering-wheel butto ns.

Rthe 1 Hoodopendisp lay appears for vehi-

cles with steering-wheel butto ns.

!When you press the support strut back,

make sure that you do not press it against the

detent position and cause itto bend.

!Do no t use your hands to push thehood

down .You could damage it otherwise.

XLift the hood slightly.

XPress support strut =towards the back.

XLowe r the hood and allow itto fall with

mom entum fr oma height of approximat ely

1 ft (30 cm).

The hood locks audibly.

XChec k that the hood is correctly locke d.

If the hood can beraised slightly, it is not

properly engaged. If the hood is not correctly

engaged, openthehood again. Let the hood

fall with a little moremom entum.

Engine compartment215

Maintenance and care

Z

Page 219 of 286

EngineoilAdd1.0 quart

XAdd the amount of oil

shown (Ypage 218).

XCheck the engine oil level

again after a few minutes.

EngineoilAdd1.5quarts

EngineoilAdd2.0quarts

EngineoillevelReduceoillevel

The oil level is too high.

XHave excess oil removed.

Eng. oillev. Turnignitionon forlevel

XTurn the key to position2in

the ignition lock.

Observewait.period

XRepeat the engine oil

measurement after about

5 minutes if the engine is at

normal operating tempera-

ture.

XRepeat the engine oil

measurement after about

30 minutes if the engine is

not at normal operating

temperature.

Engineoillevel Notwhen eng.running

XSwitch off the engine when it is at normal operating

temperature and wait

approximately 5 minutes

before measuring the

engine oil level.

Measurement units in the display:

RqtsUSA only

RltrCanada only

Checking the oil level using the oil dip-

stick

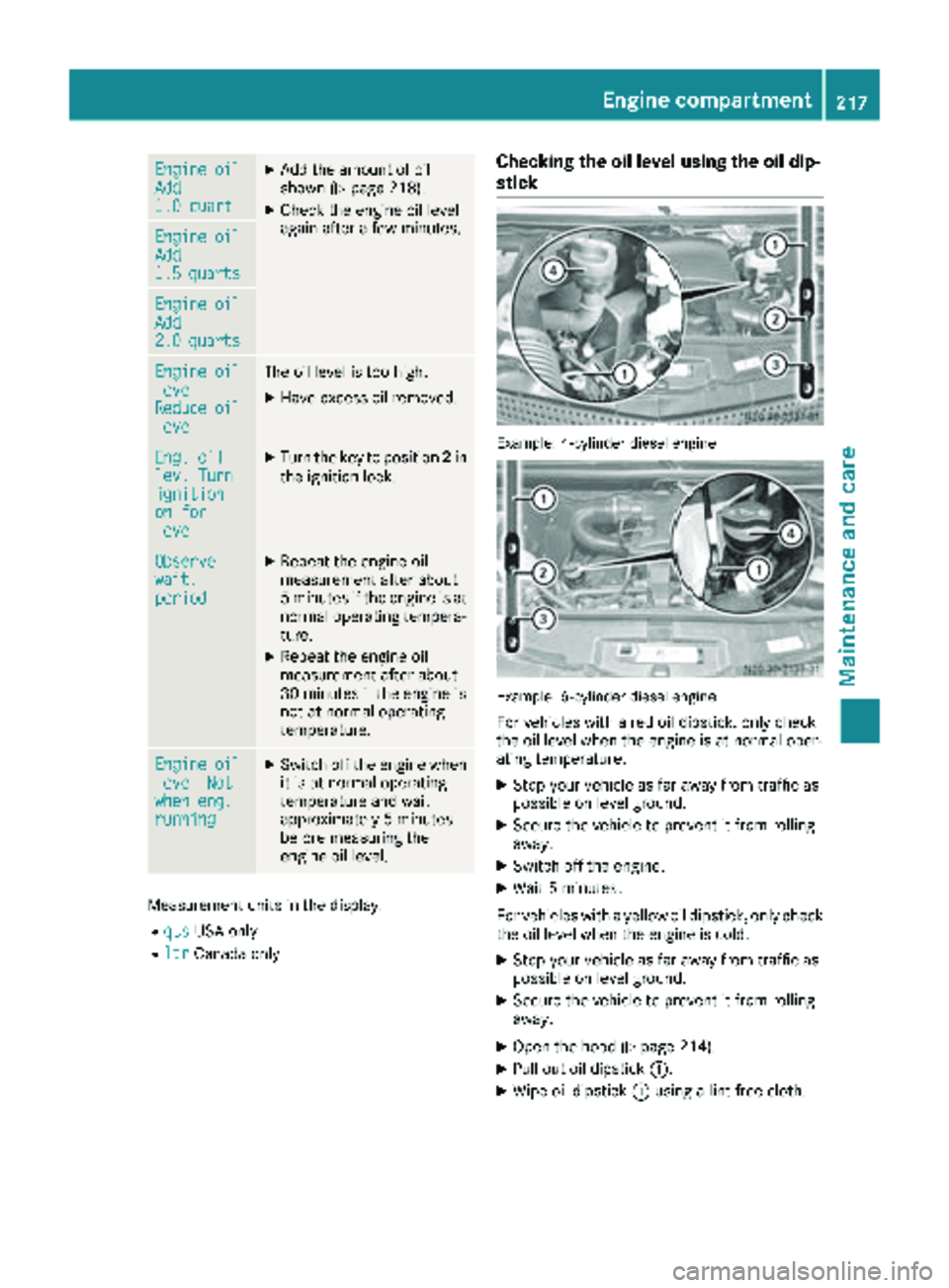

Example: 4-cylinder diesel engine

Example: 6-cylinder diesel engine

For vehicles with a red oil dipstick, only check

the oil level when the engine is at normal oper-

ating temperature:

XStop your vehicle as far away from traffic as

possible on level ground.

XSecure the vehicle to prevent it from rolling

away.

XSwitch off the engine.

XWait 5 minutes.

For vehicles with a yellow oil dipstick, only check

the oil level when the engine is cold.

XStop your vehicle as far away from traffic as

possible on level ground.

XSecure the vehicle to prevent it from rolling

away.

XOpen the hood (Ypage 214).

XPull out oil dipstick :.

XWipe oil dipstick:using a lint-free cloth.

Engine compartment217

Maintenance and care

Z

Page 221 of 286

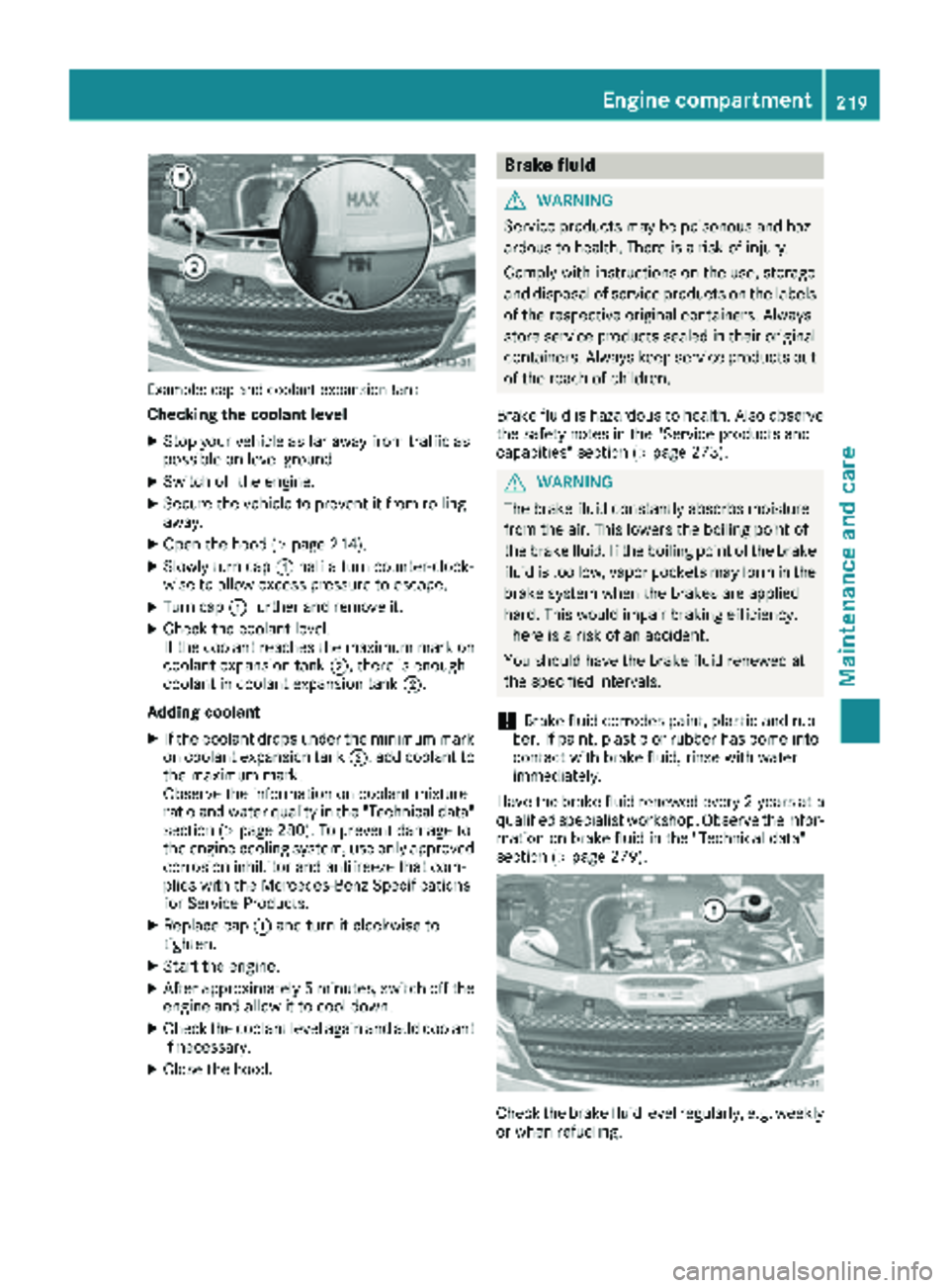

Example: cap and coolant expansion tank

Checking the coolant level

XStop your vehicle as far away from traffic as

possible on level ground.

XSwitch off the engine.

XSecure the vehicle to prevent it from rolling

away.

XOpen the hood (Ypage 214).

XSlowly turn cap:half a turn counter-clock-

wise to allow excess pressure to escape.

XTurn cap :further and remove it.

XCheck the coolant level.

If the coolant reaches the maximum mark on

coolant expansion tank ;, there is enough

coolant in coolant expansion tank ;.

Adding coolant

XIf the coolant drops under the minimum mark

on coolant expansion tank ;, add coolant to

the maximum mark.

Observe the information on coolant mixture

ratio and water quality in the "Technical data"

section (

Ypage 280). To prevent damage to

the engine cooling system, use only approved

corrosion inhibitor and antifreeze that com-

plies with the Mercedes-Benz Specifications

for Service Products.

XReplace cap :and turn it clockwise to

tighten.

XStart the engine.

XAfter approximately 5 minutes, switch off the

engine and allow it to cool down.

XCheck the coolant level again and add coolant

if necessary.

XClose the hood.

Brake fluid

GWARNING

Service products may be poisonous and haz-

ardous to health. There is a risk of injury.

Comply with instructions on the use, storage

and disposal of service products on the labels

of the respective original containers. Always

store service products sealed in their original

containers. Always keep service products out

of the reach of children.

Brake fluid is hazardous to health. Also observe

the safety notes in the "Service products and

capacities" section (

Ypage 273).

GWARNING

The brake fluid constantly absorbs moisture

from the air. This lowers the boiling point of

the brake fluid. If the boiling point of the brake

fluid is too low, vapor pockets may form in the

brake system when the brakes are applied

hard. This would impair braking efficiency.

There is a risk of an accident.

You should have the brake fluid renewed at

the specified intervals.

!Brake fluid corrodes paint, plastic and rub-

ber. If paint, plastic or rubber has come into

contact with brake fluid, rinse with water

immediately.

Have the brake fluid renewed every 2 year sat a

qualified specialist workshop. Observe the infor- mation on brake fluid in the "Technical data"

section (

Ypage 279).

Check the brake fluid level regularly, e.g. weekly

or when refueling.

Engine compartment219

Maintenance and care

Z

Page 222 of 286

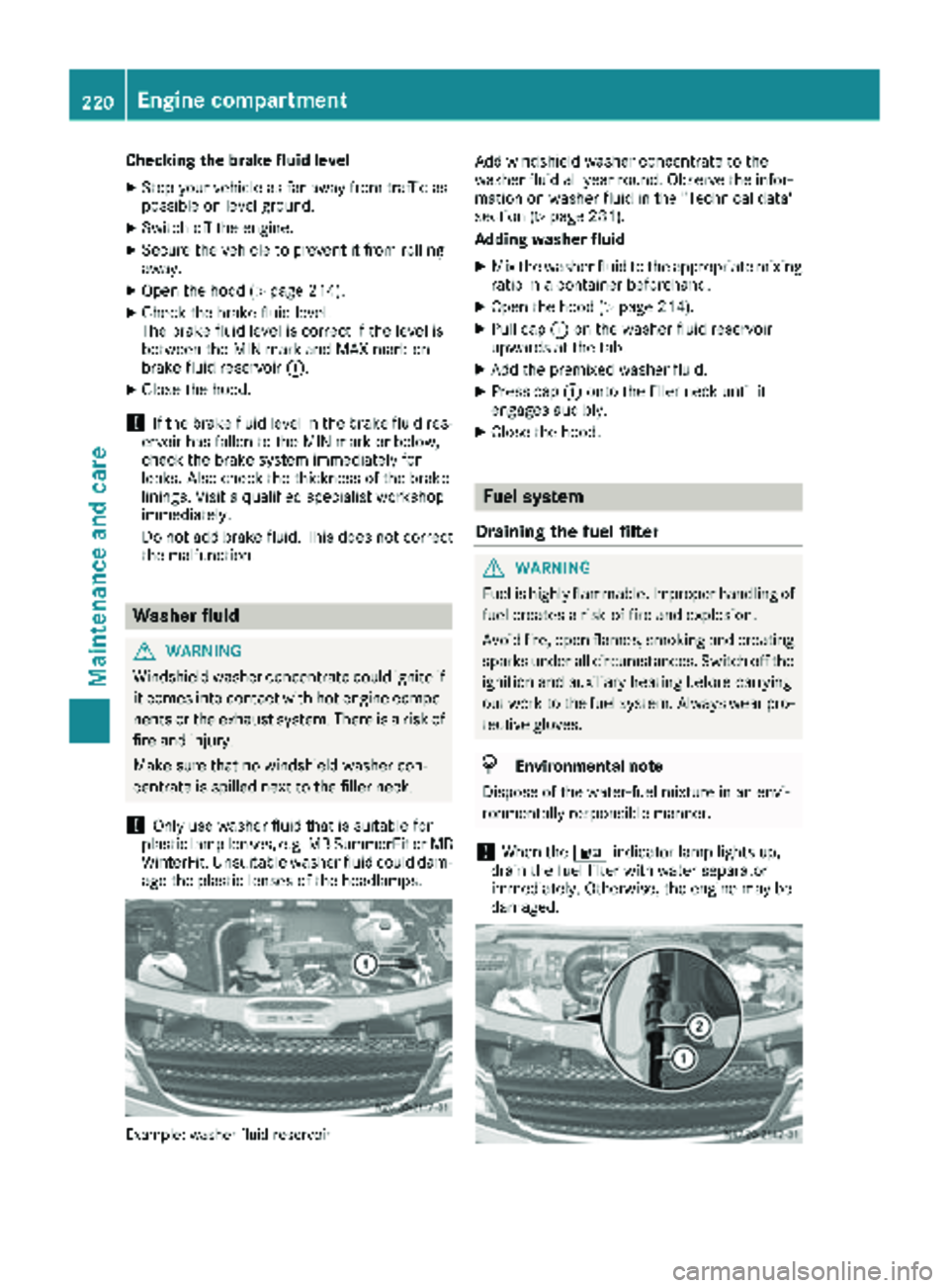

Checking the brake fluid level

XStop your vehicle as far away from traffic as

possible on level ground.

XSwitch off the engine.

XSecure the vehicle to prevent it from rolling

away.

XOpen the hood (Ypage 214).

XCheck the brake fluid level.

The brake fluid level is correct if the level is

between the MIN mark and MAX mark on

brake fluid reservoir:.

XClose the hood.

!If the brake fluid level in the brake fluid res-

ervoir has fallen to the MIN mark or below,

check the brake system immediately for

leaks. Also check the thickness of the brake

linings. Visit a qualified specialist workshop

immediately.

Do not add brake fluid. This does not correct

the malfunction.

Washer fluid

GWARNING

Windshield washer concentrate could ignite if it comes into contact with hot engine compo-

nents or the exhaust system. There is a risk of

fire and injury.

Make sure that no windshield washer con-

centrate is spilled next to the filler neck.

!Only use washer fluid that is suitable for

plastic lamp lenses, e.g. MB SummerFit or MB WinterFit. Unsuitable washer fluid could dam-

age the plastic lenses of the headlamps.

Example: washer fluid reservoir

Add windshield washer concentrate to the

washer fluid all year round. Observe the infor-

mation on washer fluid in the "Technical data"

section (

Ypage 281).

Adding washer fluid

XMix the washer fluid to the appropriate mixing ratio in a container beforehand.

XOpen the hood (Ypage 214).

XPull cap :on the washer fluid reservoir

upwards at the tab.

XAdd the premixed washer fluid.

XPress cap :onto the filler neck until it

engages audibly.

XClose the hood.

Fuel system

Draining the fuel filter

GWARNING

Fuel is highly flammable. Improper handling of

fuel creates a risk of fire and explosion.

Avoid fire, open flames, smoking and creating

sparks under all circumstances. Switch off the

ignition and auxiliary heating before carrying

out work to the fuel system. Always wear pro-

tective gloves.

HEnvironmental note

Dispose of the water-fuel mixture in an envi-

ronmentally responsible manner.

!When the :indicator lamp lights up,

drain the fuel filter with water separator

immediately. Otherwise, the engine may be

damaged.

220Engine compartment

Maintenance and care

Page 223 of 286

If the: indicator lamp in the instrument

cluster goes on, drain the fuel filter with the

water separator immediately.

iWe recommend that you have this mainte-

nance work carried out at a qualified special-

ist workshop.

XPark the vehicle safely and secure it from roll-

ing away.

XSwitch off the auxiliary heating system .

XSwitch off the engine.

XOpen the hood (Ypage 214).

XPlace a suitable receptacle under drain

hose :.

XTurn the SmartKey to position 2in the ignition

lock.

XOpen drain plug ;immediately until the

water/fuel mixture flows out of drain hose :.

XScrew in drain plug;as soon as approx-

imately 0.2 qt (0.2 l)of the water/fuel mixture

has been collected.

The electrical fuel pump automatically halts

the flow of the water/fuel mixture after

30 seconds.

XAfter draining, turn the SmartKey back to

position 0in the ignition lock.

XDispose of the collected water/fuel mixture

in an environmentally responsible manner,

e.g. at a qualified specialist workshop.

XCheck drain plug ;. The drain plug must be

closed.

When the engine is running and drain hose ;

is open, fuel is lost through drain hose :.

XClose the hood (Ypage 215).

If the : indicator lamp does not go out after

draining:

XDrain the fuel filter again.

XIf the : indicator lamp does not go out

after draining for the second time, have the

cause checked immediately at a qualified spe-

cialist workshop.

Vehicle interior

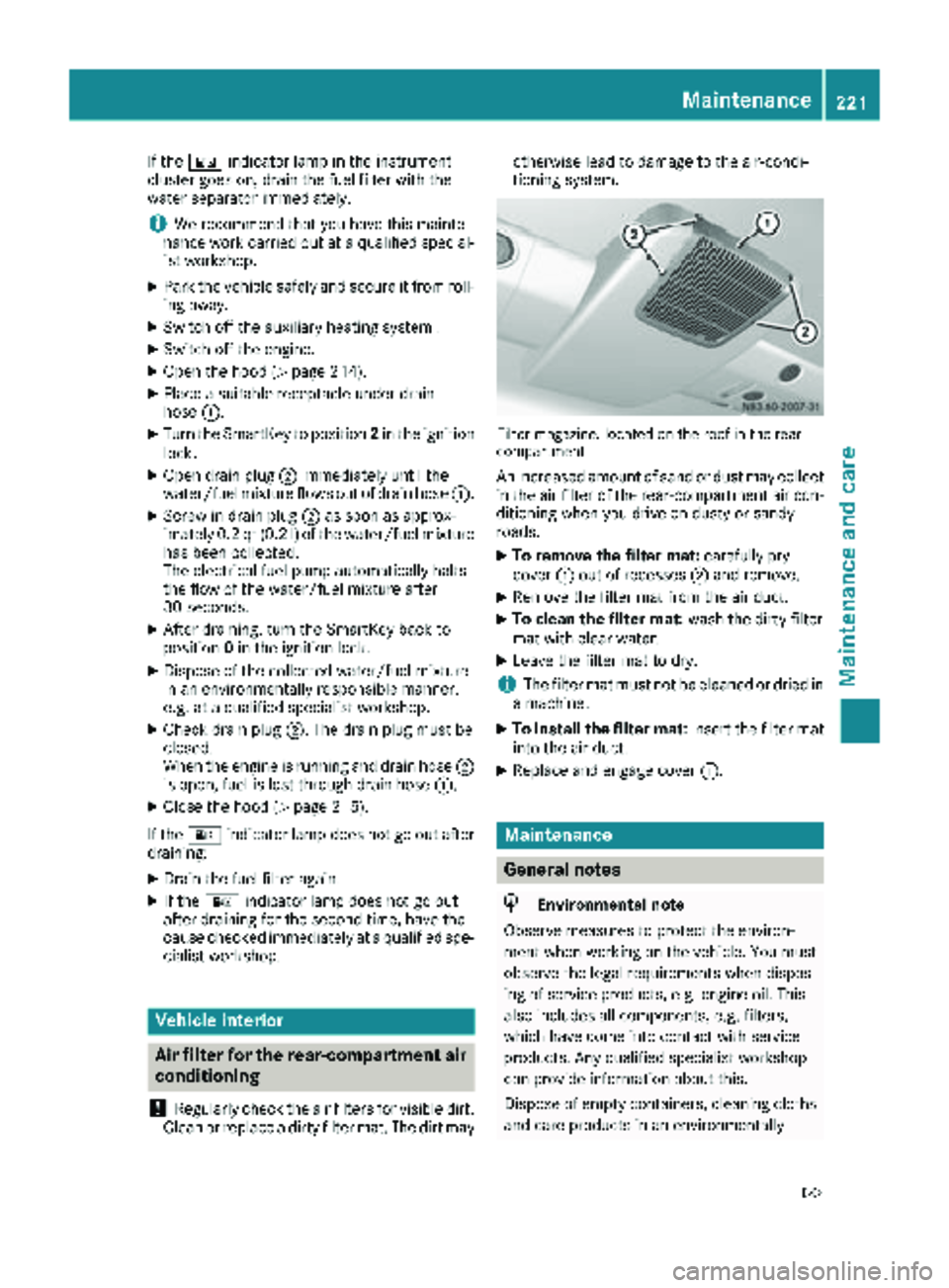

Air filter for the rear-compartment air

conditioning

!

Regularly check the air filters for visible dirt.

Clean or replace a dirty filter mat. The dirt may otherwise lead to damage to the air-condi-

tioning system.

Filter magazine, located on the roof in the rear

compartment

An increased amount of sand or dust may collect

in the air filter of the rear-compartment air con-

ditioning when you drive on dusty or sandy

roads.

XTo remove the filter mat: carefully pry

cover :out of recesses ;and remove.

XRemove the filter mat from the air duct.

XTo clean the filter mat: wash the dirty filter

mat with clear water.

XLeave the filter mat to dry.

iThe filter mat must not be cleaned or dried in

a machine.

XTo install the filter mat: insert the filter mat

into the air duct.

XReplace and engage cover :.

Maintenance

General notes

HEnvironmental note

Observe measures to protect the environ-

ment when working on the vehicle. You must

observe the legal requirements when dispos-

ing of service products, e.g. engine oil. This

also includes all components, e.g. filters,

which have come into contact with service

products. Any qualified specialist workshop

can provide information about this.

Dispose of empty containers, cleaning cloths

and care products in an environmentally

Maintenance221

Maintenance and care

Z

Page 224 of 286

responsible manner. Comply with the instruc-

tions for use of the care products.

Do not run the engine for longer than neces-

sary when the vehicle is stationary.

Before having maintenance and repairs per-

formed, it is essential to read the materials rela-

ted to the maintenance and repairs:

Rthe applicable sections of the technical doc-

umentation, e.g. the Operator's Manual and

workshop information.

Rregulations such as industrial safety regula-

tions and accident prevention regulations.

While working under the vehicle, you must

secure the vehicle on jack stands with sufficient load capacity.

Never use the jack as a substitute. The vehicle's

jack is intended only to raise the vehicle for a

short time when changing a wheel. It is not

suited for performing maintenance work under

the vehicle.

Please also refer to the notes about qualified

specialist workshops (

Ypage 27).

The scope and regularity of the inspection and

maintenance work primarily depend on the

often diverse operating conditions. Specialist

knowledge beyond the scope of this Operator's

Manual is required when carrying out testing

and maintenance work. This work should only be

carried out by trained staff.

The vehicle Maintenance Booklet describes the scope and frequency of maintenance work and

contains additional notes on the New Vehicle

Limited Warranty and on service products.

Maintenance services must be carried out in

accordance with the provisions and recommen-

dations in the Maintenance Booklet. Not doing

so could void the warranty claim and lead to

refusal of goodwill gestures after the manufac-

turer has submitted a damage report.

iObserve the notes on genuine Sprinter parts

(Ypage 29).

Service interval display

General notes

A service that is due is displayed in the service

interval display about 1 month in advance. A

message is then displayed while the vehicle is in motion or when the ignition is switched on.

iThe service interval display does not provide

information about the engine oil level. The

service interval display should therefore not

be confused with the 5engine oil level

display.

The service due date is displayed in days or

miles (kilometers), depending on the total dis-

tance driven.

The symbols or letters on the service display

show the type of service that is due.

¯ orA

for a minor service

° orB

for a major service

Service due date display

Vehicles with steering wheel buttons: the

following messages may be displayed.

R¯ Service A due in ... days

R¯Service A due in ... mi(km)

R¯Service A Carry out now

Vehicles without steering wheel buttons:

the following messages may be displayed.

R¯for service A

R°for Service B

Additionally, you will see the remaining distance

in miles (mi

) or kilometers (km) or the remaining

time in days (d).

Service due date has been exceeded

Vehicles with steering wheel buttons: if you

have missed the service due date, one of the

following messages appears in the display and

warning tone also sounds.

R¯ Service A overdue by ... days

R¯Service A overdue by ... km(km)

Vehicles without steering wheel buttons: if

you have missed the service due date, the ¯

or ° symbol for the service flashes for

10 seconds after the ignition is switched on. A

minus sign also appears in front of the service

due date.

Calling up the service due date

XTurn the key to position 2in the ignition lock.

The display is activated.

222Maintenance

Maintenance and care

Page 226 of 286

water and contact a doctor immedi-

ately.

Keep children at a safe distance.

Children are not able to assess the

dangers posed by batteries and

acid.

When handling batteries, observe

the safety precautions and special

protective measures contained in

this Operator's Manual.

HEnvironmental note

Batteries contain dangerous

substances. It is against the

law to dispose of them with

the household rubbish. They

must be collected separatelyand recycled to protect the

environment.

Dispose of batteries in an

environmentally friendly

manner. Take discharged

batteries to a qualified spe-

cialist workshop or a special

collection point for used bat-

teries.

Observe the following notes:

RRecharge the battery more frequently, if you:

-predominantly drive short distances

-predominantly drive at low outside temper-

atures

-park the vehicle longer than 3 weeks

In order for the batteries to achieve their max- imum possible service life, they must always

be sufficiently charged.

RWhen you park the vehicle, remove the Smart-Key if you do not require any electrical con-

sumers. The vehicle will then use very little

energy, thus conserving battery power.

RWhen replacing a battery, only use batteries

that are recommended for use in Sprinter

vehicles.

RHave the battery removed at a qualified spe-

cialist workshop.

RIf you leave your vehicle parked longer than

3 weeks:

-consult a qualified specialist workshop or

-switch off the power supply using the bat-

tery main switch (Ypage 116) or

-disconnect the batteries (Ypage 225).

Otherwise, you need to check the battery's

condition of charge every 3 weeks, since

standby power consumption can drain the

battery. If the battery voltage is lower than

12.2 V, the battery must be charged. Other-

wise, the battery may be damaged by exhaus-

tive discharging.

Be sure to observe the notes on charging the batteries (

Ypage 228).

Installation locations

Your vehicle may be equipped with three bat-

teries, depending on the equipment version:

RStarter battery in the battery case in the left

footwell

RAdditional battery in the engine compartment

RAuxiliary battery under the left-hand front

seat

Have the auxiliary battery removed at a qualified

specialist workshop.

Installing/removing the floor cover-

ing (starter battery)

GWARNING

Objects in the driver's footwell can restrict the pedal travel or obstruct a depressed pedal.

The operating and road safety of the vehicle is

jeopardized. There is a risk of an accident.

Make sure that all objects in the vehicle are

stowed correctly, and that they cannot enter

the driver's footwell. Install the floormats

securely and as specified in order to ensure

sufficient clearance for the pedals. Do not use

loose floormats and do not place floormats on

top of one another.

224Battery

Maintenance and care