warning MERCEDES-BENZ SPRINTER 2018 MY18 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2018, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2018Pages: 294, PDF Size: 4.36 MB

Page 258 of 294

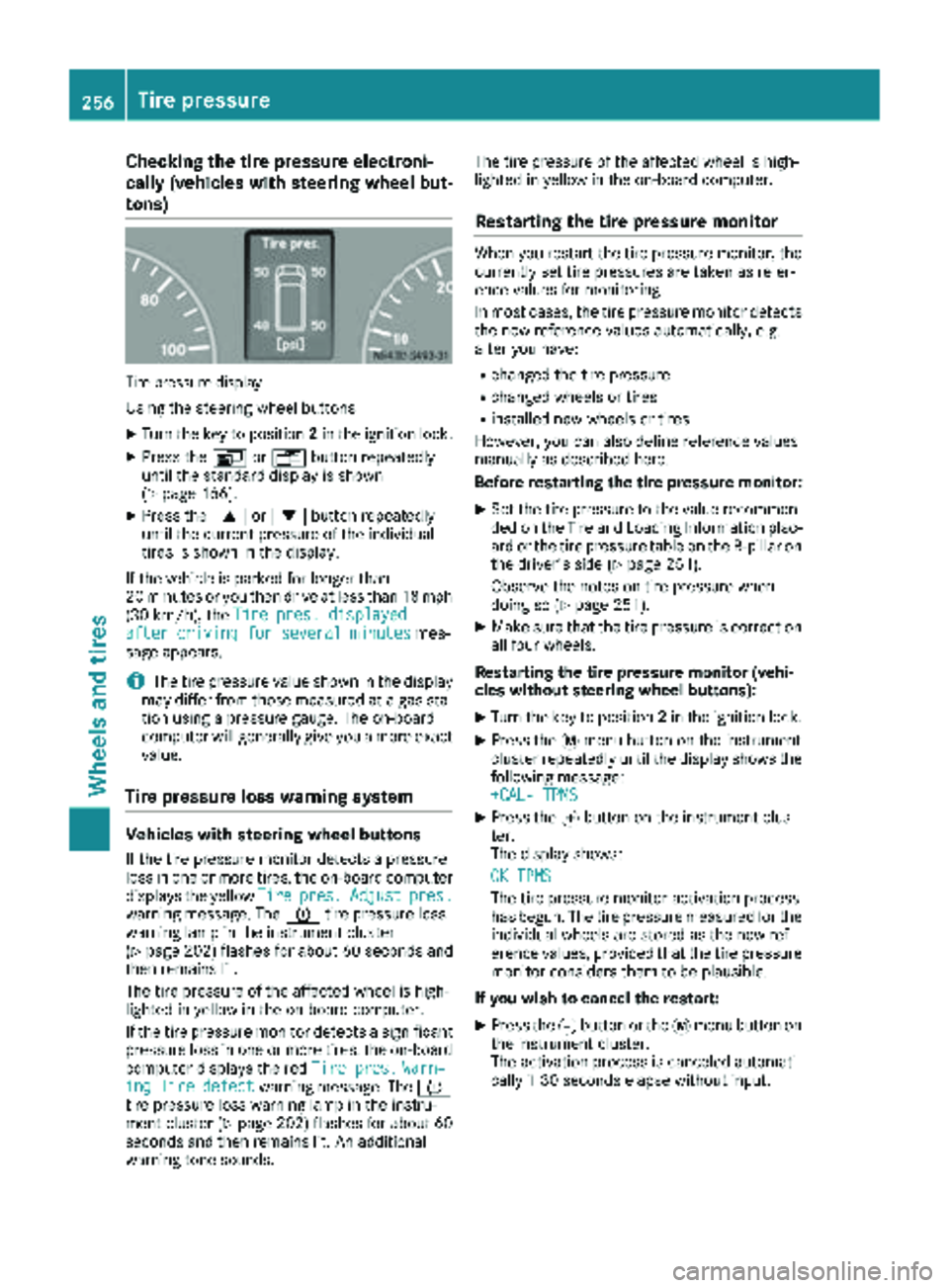

Checking the tire pressure electroni-

cally (vehicles with steering wheel but-

tons)

Tire pressuredisplay

Using the steering wheel buttons

XTurn the key to position 2in the ignition lock.

XPress the VorU button repeatedly

until the standard display is shown

(

Ypage 166).

XPress the 9or: button repeatedly

until the current pressure of the individual

tires is shown in the display.

If the vehicle is parked for longer than

20 minutes or you then drive at less than 18 mph

(30 km/h), the Tire pres. displayed

after driving for several minutesmes-

sage appears.

iThe tire pressure value shown in the display

may differ from those measured at a gas sta-

tion using a pressure gauge. The on-board

computer will generally give you a more exact

value.

Tire pressure loss warning system

Vehicles with steering wheel buttons

If the tire pressure monitor detects a pressure

loss in one or more tires, the on-board computer

displays the yellow Tire

pres.Adjustpres.warning message. The htire pressure loss

warning lamp in the instrument cluster

(

Ypage 202) flashes for about 60 seconds and

then remains lit.

The tire pressure of the affected wheel is high-

lighted in yellow in the on-board computer.

If the tire pressure monitor detects a significant

pressure loss in one or more tires, the on-board

computer displays the red Tire pres.

Warn‐ingTiredefectwarning message. Theh

tire pressure loss warning lamp in the instru-

ment cluster (

Ypage 202) flashes for about 60

seconds and then remains lit. An additional

warning tone sounds. The tire pressure of the affected wheel is high-

lighted in yellow in the on-board computer.

Restarting the tire pressure monitor

When you restart the tire pressure monitor, the

currently set tire pressures are taken as refer-

ence values for monitoring.

In most cases, the tire pressure monitor detects

the new reference values automatically, e.g.

after you have:

Rchanged the tire pressure

Rchanged wheels or tires

Rinstalled new wheels or tires

However, you can also define reference values

manually as described here.

Before restarting the tire pressure monitor:

XSet the tire pressure to the value recommen- ded on the Tire and Loading Information plac-

ard or the tire pressure table on the B-pillar on

the driver's side (

Ypage 251).

Observe the notes on tire pressure when

doing so (

Ypage 251).

XMake sure that the tire pressure is correct on

all four wheels.

Restarting the tire pressure monitor (vehi-

cles without steering wheel buttons):

XTurn the key to position 2in the ignition lock.

XPress the 4menu button on the instrument

cluster repeatedly until the display shows the

following message:

+CAL- TPMS

XPress the fbutton on the instrument clus-

ter.

The display shows:

OK TPMS

The tire pressure monitor activation process

has begun. The tire pressure measured for the individual wheels are stored as the new ref-

erence values, provided that the tire pressure

monitor considers them to be plausible.

If you wish to cancel the restart:

XPress the gbutton or the 4menu button on

the instrument cluster.

The activation process is canceled automati-

cally if 30 seconds elapse without input.

256Tire pressure

Wheels and tires

Page 261 of 294

Loading the vehicle

Instruction labels for tires and loads

GWARNING

Overloaded tires can overheat, causing a

blowout. Overloaded tires can also impair the steering and driving characteristics and lead

to brake failure. There is a risk of accident.

Observe the load rating of the tires. The load

rating must be at least half of the GAWR of

your vehicle. Never overload the tires by

exceeding the maximum load.

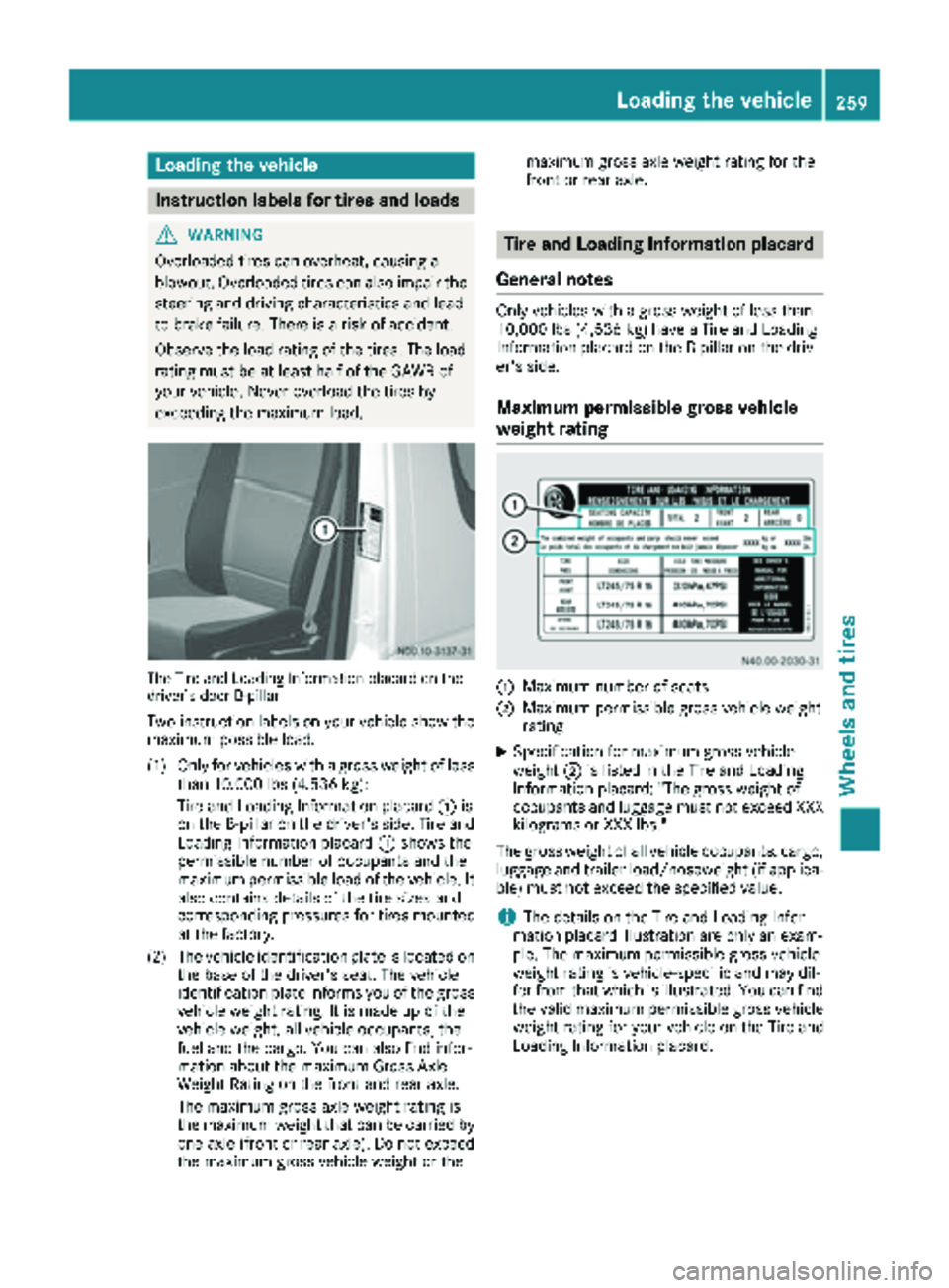

The Tire and Loading Information placard on the

driver’s door B-pillar

Two instruction labels on your vehicle show themaximum possible load.

(1) Only for vehicles with a gross weight of less than 10,000 lbs (4,536 kg):

Tire and Loading Information placard :is

on the B-pillar on the driver's side. Tire and

Loading Information placard :shows the

permissible number of occupants and the

maximum permissible load of the vehicle. It

also contains details of the tire sizes and

corresponding pressures for tires mounted

at the factory.

(2) The vehicle identification plate is located on the base of the driver's seat. The vehicle

identification plate informs you of the gross

vehicle weight rating. It is made up of the

vehicle weight, all vehicle occupants, the

fuel and the cargo. You can also find infor-

mation about the maximum Gross Axle

Weight Rating on the front and rear axle.

The maximum gross axle weight rating is

the maximum weight that can be carried by

one axle (front or rear axle). Do not exceed

the maximum gross vehicle weight or the maximum gross axle weight rating for the

front or rear axle.

Tire and Loading Information placard

General notes

Only vehicles with a gross weight of less than

10,000 lbs (4,536 kg) have a Tire and Loading

Information placard on the B-pillar on the driv-

er's side.

Maximum permissible gross vehicle

weight rating

:Maximum number of seats

;Maximum permissible gross vehicle weight

rating

XSpecification for maximum gross vehicle

weight ;is listed in the Tire and Loading

Information placard: "The gross weight of

occupants and luggage must not exceed XXX

kilograms or XXX lbs."

The gross weight of all vehicle occupants, cargo,

luggage and trailer load/noseweight (if applica-

ble) must not exceed the specified value.

iThe details on the Tire and Loading Infor-

mation placard illustration are only an exam-

ple. The maximum permissible gross vehicle

weight rating is vehicle-specific and may dif-

fer from that which is illustrated. You can find

the valid maximum permissible gross vehicle

weight rating for your vehicle on the Tire and

Loading Information placard.

Loading the vehicle259

Wheels and tires

Z

Page 264 of 294

Trailer load/noseweight

The trailer load/noseweight affects the gross

weight of the vehicle. If a trailer is attached, the

trailer load/noseweight is included in the load

along with occupants and luggage. The trailer

load/noseweight is usually approximately 10%

of the gross weight of the trailer and its load.

What you should know about wheels

and tires

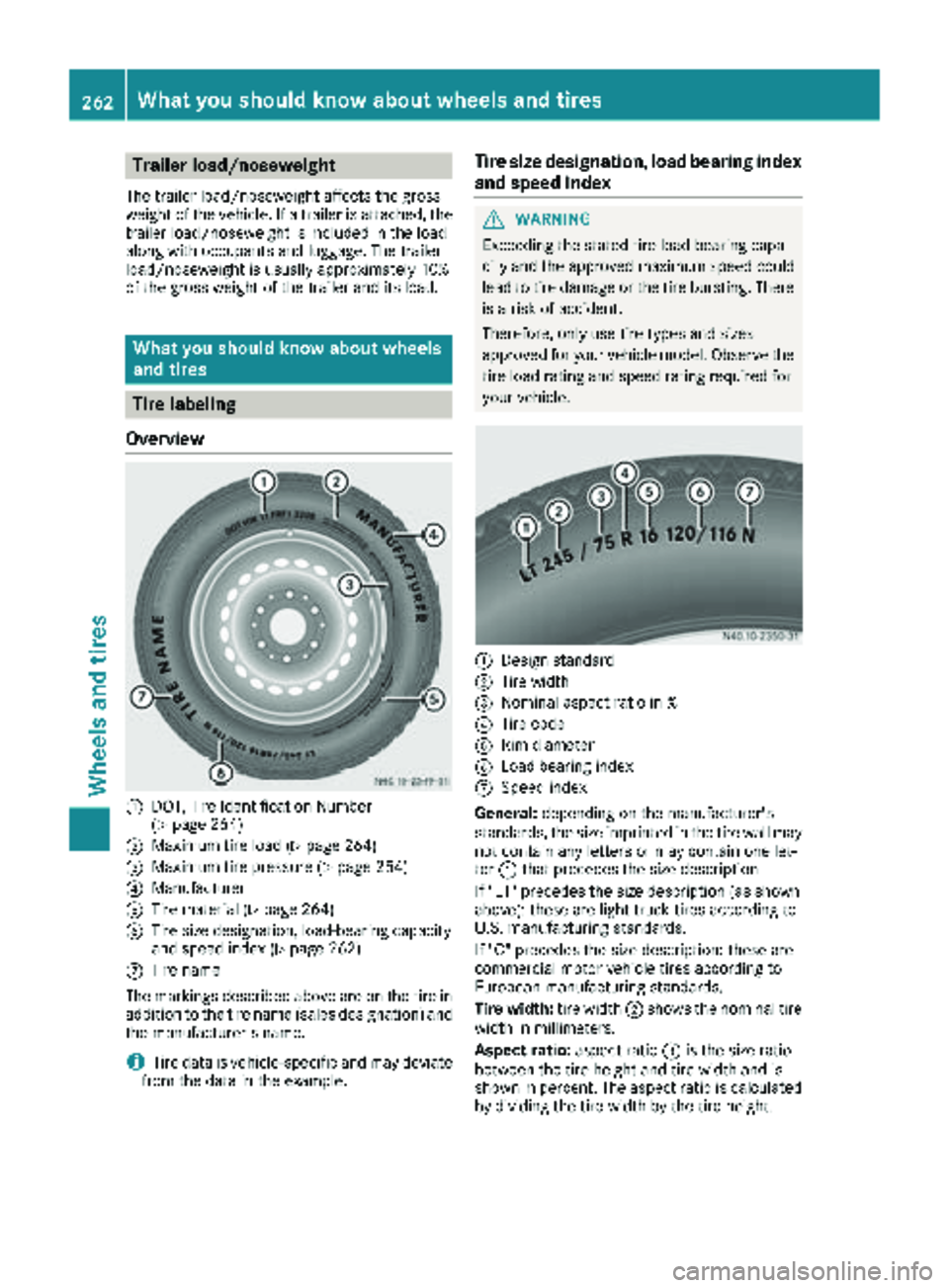

Tire labeling

Overview

:DOT, Tire Identification Number

(Ypage 264)

;Maximum tire load (Ypage 264)

=Maximum tire pressure (Ypage 254)

?Manufacturer

ATire material (Ypage 264)

BTire size designation, load-bearing capacity

and speed index (Ypage 262)

CTire name

The markings described above are on the tire in addition to the tire name (sales designation) and

the manufacturer's name.

iTire data is vehicle-specific and may deviate

from the data in the example.

Tire size designation, load bearing index

and speed index

GWARNING

Exceeding the stated tire load-bearing capa-

city and the approved maximum speed could

lead to tire damage or the tire bursting. There is a risk of accident.

Therefore, only use tire types and sizes

approved for your vehicle model. Observe the

tire load rating and speed rating required for

your vehicle.

:Design standard

;Tire width

=Nominal aspect ratio in %

?Tire code

ARim diameter

BLoad bearing index

CSpeed index

General: depending on the manufacturer's

standards, the size imprinted in the tire wall may

not contain any letters or may contain one let-

ter :that precedes the size description

If "LT" precedes the size description (as shown

above): these are light truck tires according to

U.S. manufacturing standards.

If "C" precedes the size description: these are

commercial motor vehicle tires according to

European manufacturing standards.

Tire width: tire width;shows the nominal tire

width in millimeters.

Aspect ratio: aspect ratio=is the size ratio

between the tire height and tire width and is

shown in percent. The aspect ratio is calculated

by dividing the tire width by the tire height.

262What you should know about wheels and tires

Wheels and tires

Page 270 of 294

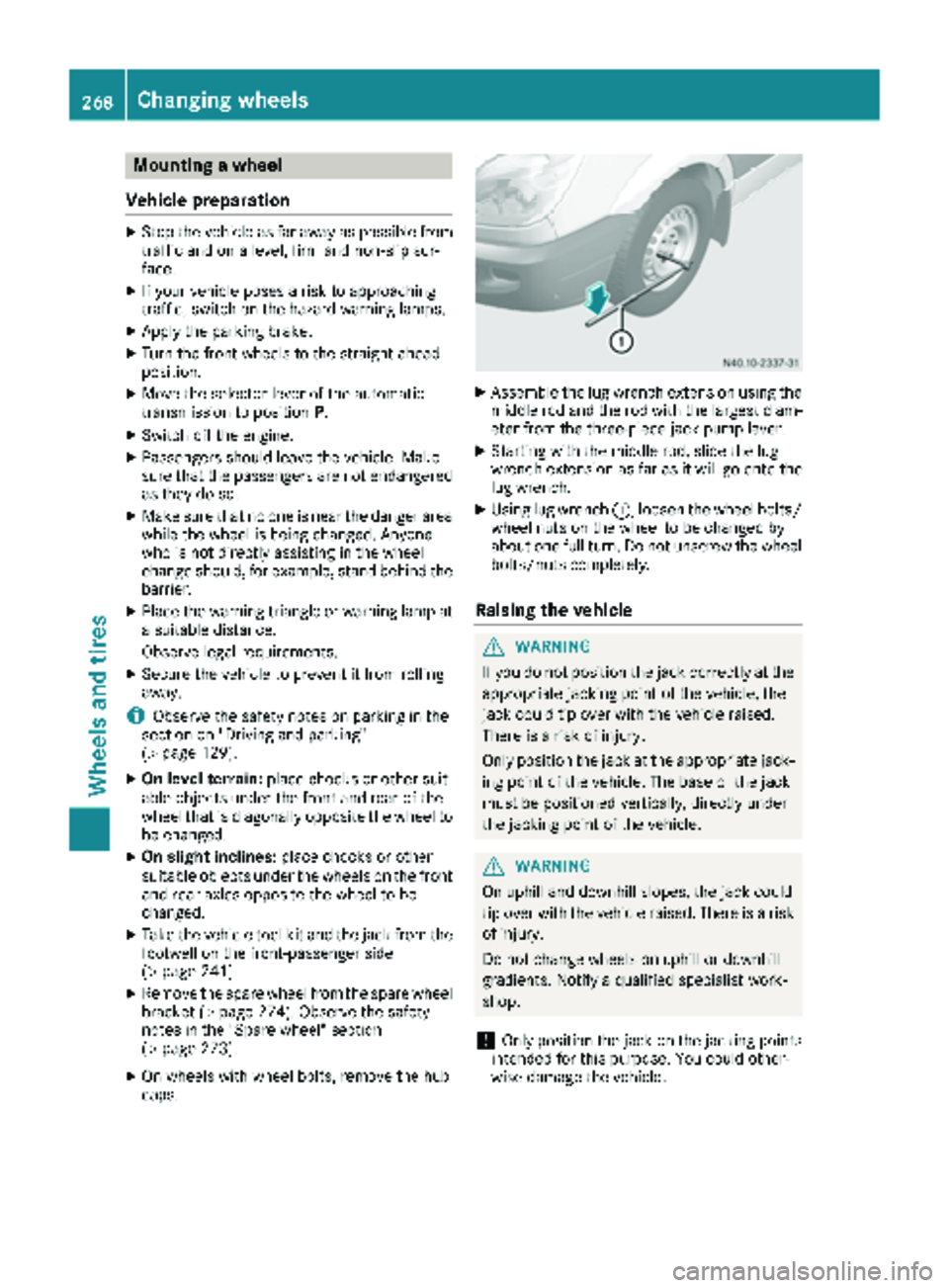

Mounting a wheel

Vehicle preparation

XStop the vehicle as far away as possible from

traffic and on a level, firm and non-slip sur-

face.

XIf your vehicle poses a risk to approaching

traffic, switch on the hazard warning lamps.

XApply the parking brake.

XTurn the front wheels to the straight-ahead

position.

XMove the selector lever of the automatic

transmission to position P.

XSwitch off the engine.

XPassengers should leave the vehicle. Make

sure that the passengers are not endangered

as they do so.

XMake sure that no one is near the danger area

while the wheel is being changed. Anyone

who is not directly assisting in the wheel

change should, for example, stand behind the

barrier.

XPlace the warning triangle or warning lamp at

a suitable distance.

Observe legal requirements.

XSecure the vehicle to prevent it from rolling

away.

iObserve the safety notes on parking in the

section on "Driving and parking"

(

Ypage 129).

XOn level terrain: place chocks or other suit-

able objects under the front and rear of the

wheel that is diagonally opposite the wheel to

be changed.

XOn slight inclines: place chocks or other

suitable objects under the wheels on the front and rear axles opposite the wheel to be

changed.

XTake the vehicle tool kit and the jack from the

footwell on the front-passenger side

(

Ypage 241).

XRemove the spare wheel from the spare wheel

bracket (Ypage 274). Observe the safety

notes in the "Spare wheel" section

(

Ypage 273).

XOn wheels with wheel bolts, remove the hub

caps.

XAssemble the lug wrench extension using the

middle rod and the rod with the largest diam-

eter from the three-piece jack pump lever.

XStarting with the middle rod, slide the lug

wrench extension as far as it will go onto the

lug wrench.

XUsing lug wrench :, loosen the wheel bolts/

wheel nuts on the wheel to be changed by

about one full turn. Do not unscrew the wheel bolts/nuts completely.

Raising the vehicle

GWARNING

If you do not position the jack correctly at the

appropriate jacking point of the vehicle, the

jack could tip over with the vehicle raised.

There is a risk of injury.

Only position the jack at the appropriate jack-

ing point of the vehicle. The base of the jack

must be positioned vertically, directly under

the jacking point of the vehicle.

GWARNING

On uphill and downhill slopes, the jack could

tip over with the vehicle raised. There is a risk

of injury.

Do not change wheels on uphill or downhill

gradients. Notify a qualified specialist work-

shop.

!Only position the jack on the jacking points

intended for this purpose. You could other-

wise damage the vehicle.

268Changing wheels

Wheels and tires

Page 272 of 294

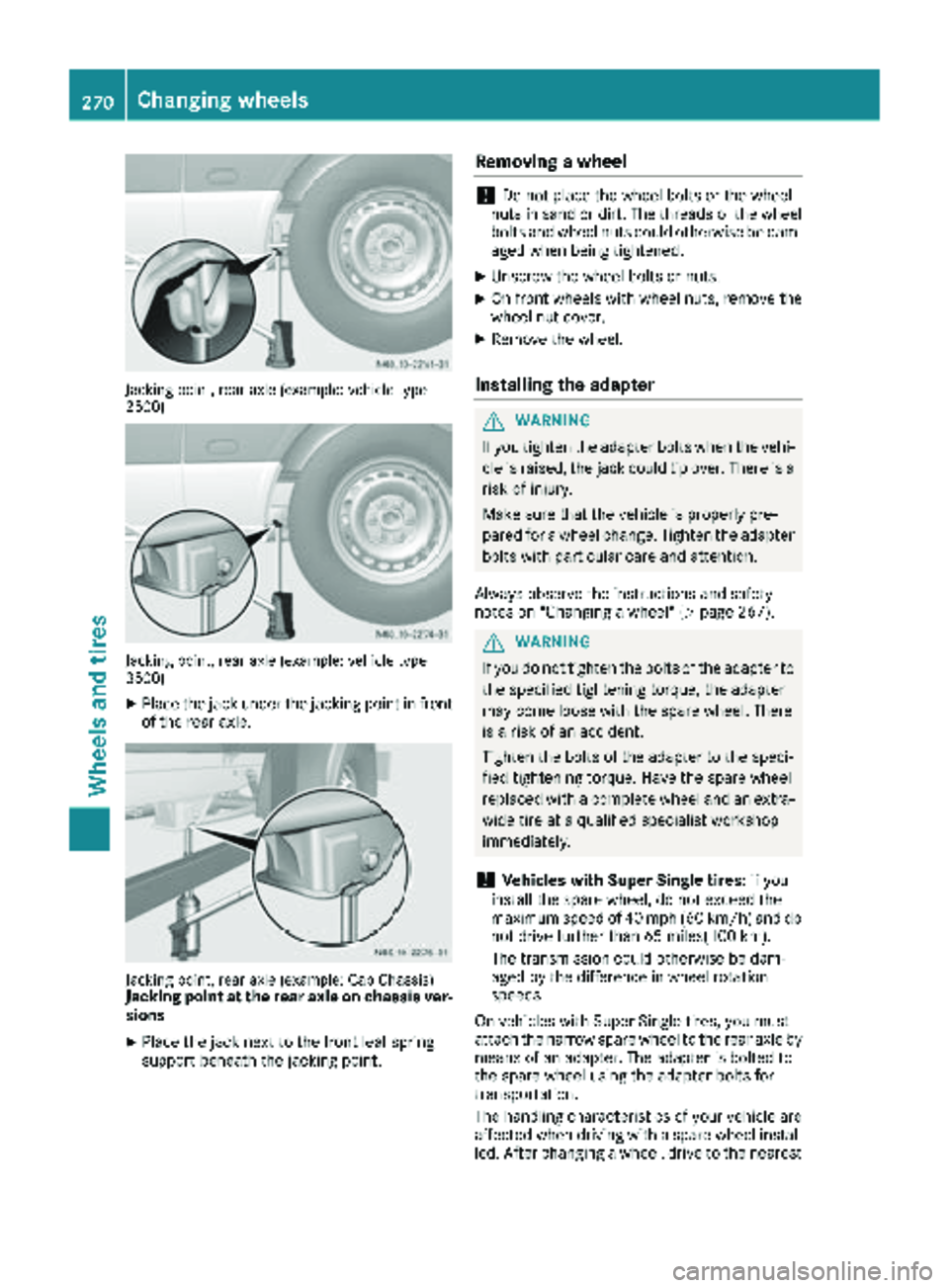

Jacking point, rear axle (example: vehicle type

2500)

Jacking point, rear axle (example: vehicle type

3500)

XPlace the jack under the jacking point in front

of the rear axle.

Jacking point, rear axle (example: Cab Chassis)Jacking point at the rear axle on chassis ver-

sions

XPlace the jack next to the front leaf spring

support beneath the jacking point.

Removing a wheel

!Do not place the wheel bolts or the wheel

nuts in sand or dirt. The threads of the wheel

bolts and wheel nuts could otherwise be dam-

aged when being tightened.

XUnscrew the wheel bolts or nuts.

XOn front wheels with wheel nuts, remove the

wheel nut cover.

XRemove the wheel.

Installing the adapter

GWARNING

If you tighten the adapter bolts when the vehi-

cle is raised, the jack could tip over. There is a risk of injury.

Make sure that the vehicle is properly pre-

pared for a wheel change. Tighten the adapter

bolts with particular care and attention.

Always observe the instructions and safety

notes on "Changing a wheel" (

Ypage 267).

GWARNING

If you do not tighten the bolts of the adapter to

the specified tightening torque, the adapter

may come loose with the spare wheel. There

is a risk of an accident.

Tighten the bolts of the adapter to the speci-

fied tightening torque. Have the spare wheel

replaced with a complete wheel and an extra- wide tire at a qualified specialist workshop

immediately.

!Vehicles with Super Single tires: if you

install the spare wheel, do not exceed the

maximum speed of 40 mph (60 km/h)and do

not drive further than 65 miles(100 km).

The transmission could otherwise be dam-

aged by the difference in wheel rotation

speeds.

On vehicles with Super Single tires, you must

attach the narrow spare wheel to the rear axle by means of an adapter. The adapter is bolted to

the spare wheel using the adapter bolts for

transportation.

The handling characteristics of your vehicle are

affected when driving with a spare wheel instal-

led. After changing a wheel, drive to the nearest

270Changing wheels

Wheels and tires

Page 273 of 294

specialist workshop and have the spare wheel

replaced with a wheel and tire assembly that has

a Super Single tire.

XClean the wheel and wheel hub contact sur-

faces.

XUnscrew the six adapter bolts on the spare

wheel and remove the adapter.

XTighten the adapter with the six adapter bolts

evenly in a crosswise pattern through the

outer holes on the wheel hub.

XTighten the six adapter bolts on the wheel hub

to a tightening torque of177 lb-ft(240 Nm).

XPush the wheel onto the adapter and attach it.

Mounting a new wheel

GWARNING

Oiled or greased wheel bolts or damaged

wheel bolts/hub threads can cause the wheel bolts to come loose. As a result, you could

lose a wheel while driving. There is a risk of

accident.

Never oil or grease wheel bolts. In the event of

damage to the threads, contact a qualified

specialist workshop immediately. Have the

damaged wheel bolts or hub threads

replaced/renewed. Do not continue driving.

GWARNING

If you tighten the wheel bolts or wheel nuts

when the vehicle is raised, the jack could tip

over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts

when the vehicle is on the ground.

Always observe the instructions and safety

notes on "Changing a wheel" (

Ypage 267).

Only use wheel bolts or wheel nuts that have

been designed for the wheel and the vehicle. For safety reasons, we recommend that you only

use wheel bolts or wheel nuts which have been

approved for Sprinter vehicles and the respec-

tive wheel.

!For a steel wheel, only use the short wheel

bolts to mount the steel spare wheel. Using

other wheel bolts to mount the steel spare

wheel could damage the brake system.

!On vehicles equipped with a tire pressure

monitor, electronic components are located

in the wheel.

Tire-mounting tools should not be used near

the valve. This could damage the electronic

components.

Only have tires changed at a qualified spe-

cialist workshop.

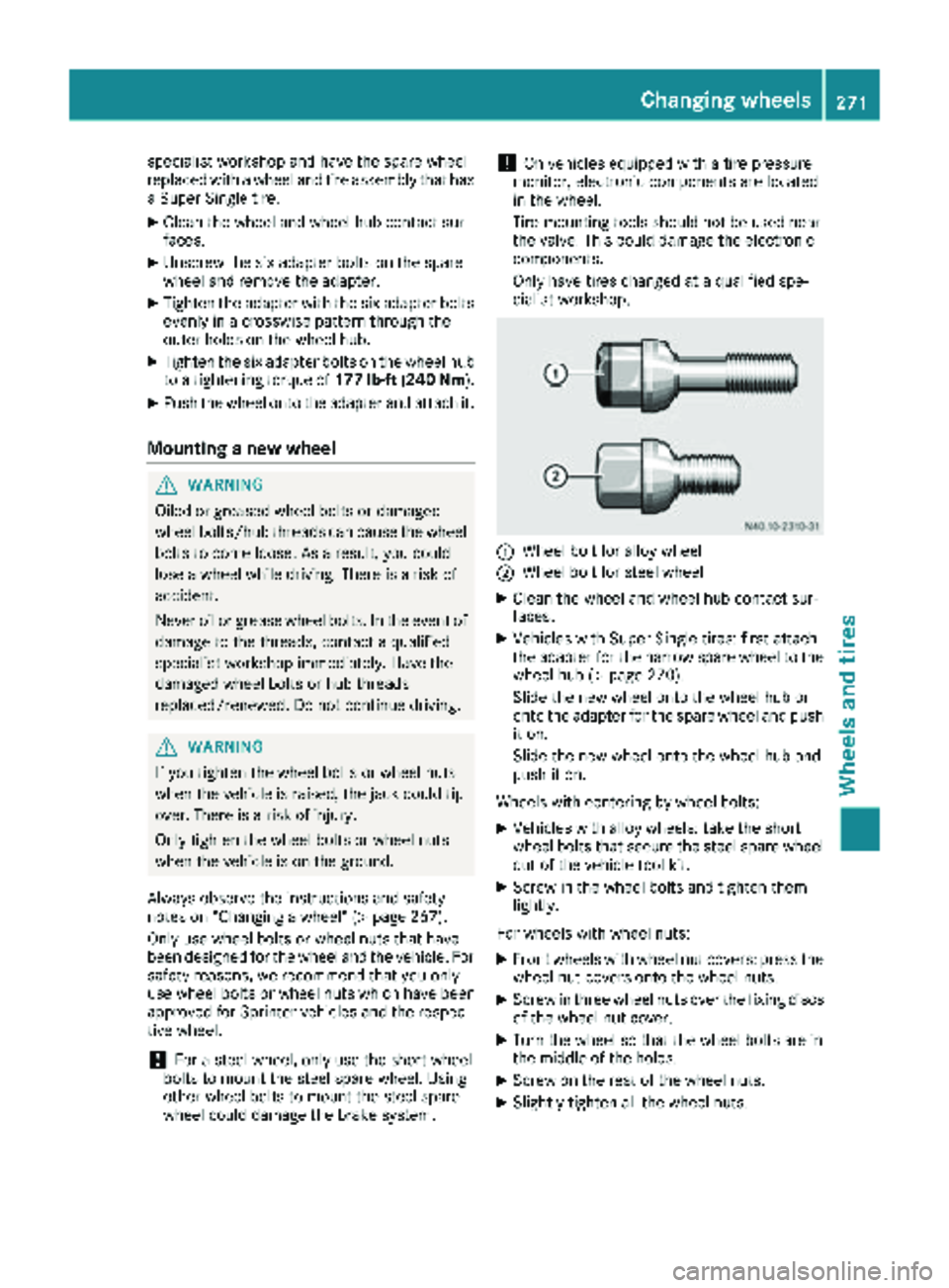

:Wheel bolt for alloy wheel

;Wheel bolt for steel wheel

XClean the wheel and wheel hub contact sur-

faces.

XVehicles with Super Single tires: first attach

the adapter for the narrow spare wheel to the

wheel hub (

Ypage 270).

Slide the new wheel onto the wheel hub or

onto the adapter for the spare wheel and push

it on.

Slide the new wheel onto the wheel hub and

push it on.

Wheels with centering by wheel bolts:

XVehicles with alloy wheels: take the short

wheel bolts that secure the steel spare wheel

out of the vehicle tool kit.

XScrew in the wheel bolts and tighten them

lightly.

For wheels with wheel nuts:

XFront wheels with wheel nut covers: press the wheel nut covers onto the wheel nuts.

XScrew in three wheel nuts over the fixing discs

of the wheel nut cover.

XTurn the wheel so that the wheel bolts are in

the middle of the holes.

XScrew on the rest of the wheel nuts.

XSlightly tighten all the wheel nuts.

Changing wheels271

Wheels and tires

Z

Page 274 of 294

Lowering the vehicle

GWARNING

The wheels could work loose if the wheel nuts and bolts are not tightened to the specified

tightening torque. There is a risk of accident.

Have the tightening torque immediately

checked at a qualified specialist workshop

after a wheel is changed.

!Only use the jack pump lever middle rod and

the rod with the largest diameter as a lug

wrench extension. Only slide the middle rod

as far as it will go onto the lug wrench. The

rods may otherwise bend and be distorted to

such an extent that they can no longer be

used as a pump lever for the jack.

!Vehicles with Super Single tires: if you

install the spare wheel, do not exceed the

maximum speed of 40 mph (60 km/h) and do

not drive further than 65 miles(100 km).

The transmission could otherwise be dam-

aged by the difference in wheel rotation

speeds.

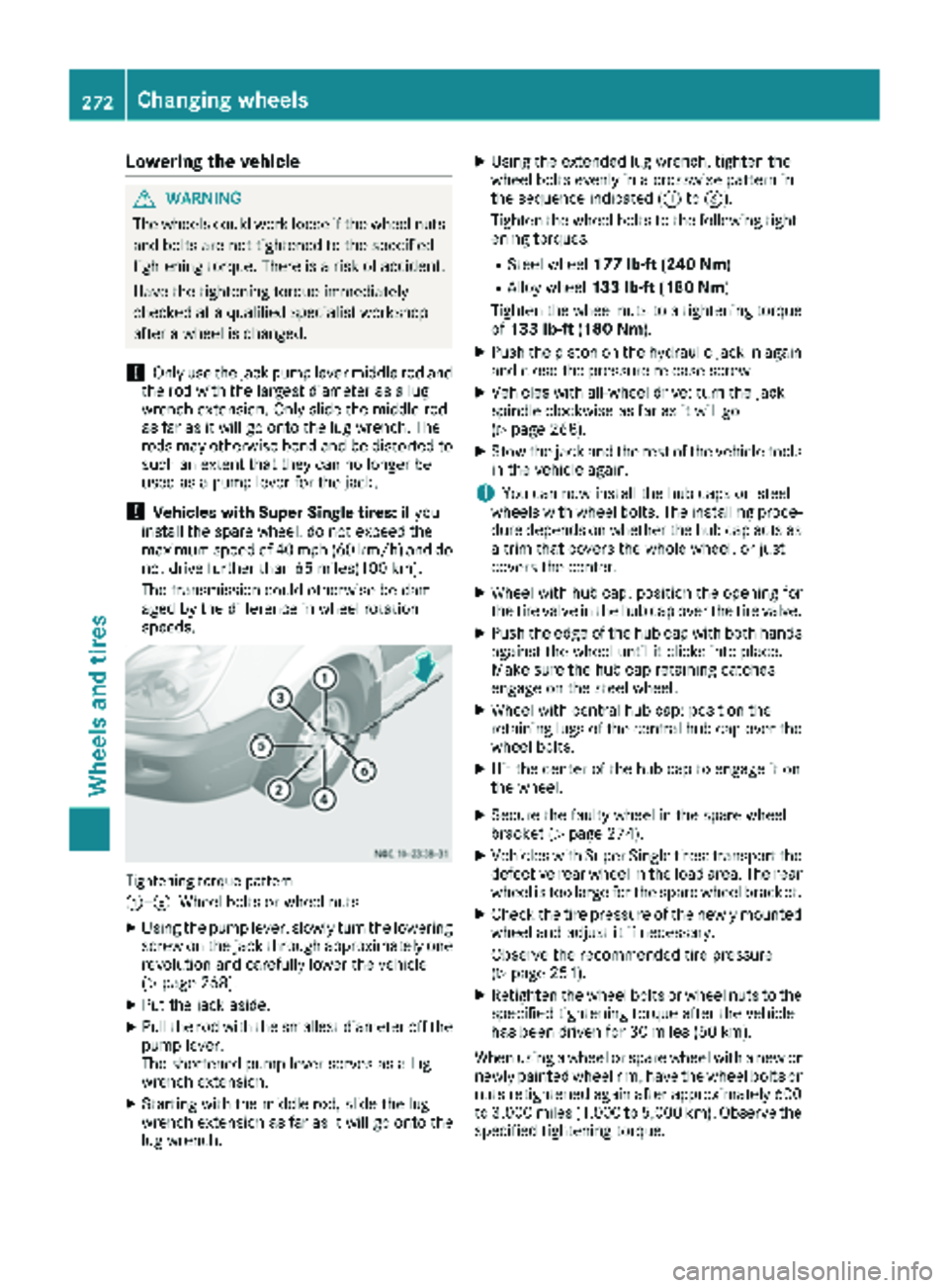

Tightening torque pattern

:— B

Wheel bolts or wheel nuts

XUsing the pump lever, slowly turn the lowering

screw on the jack through approximately one

revolution and carefully lower the vehicle

(

Ypage 268).

XPut the jack aside.

XPull the rod with the smallest diameter off the

pump lever.

The shortened pump lever serves as a lug

wrench extension.

XStarting with the middle rod, slide the lug

wrench extension as far as it will go onto the

lug wrench.

XUsing the extended lug wrench, tighten the

wheel bolts evenly in a crosswise pattern in

the sequence indicated ( :toB).

Tighten the wheel bolts to the following tight-

ening torques:

RSteel wheel 177 lb-ft(240 Nm )

RAlloy wheel 133 lb-ft(180 Nm )

Tighten the wheel nuts to a tightening torque

of 133 lb-ft (180 Nm).

XPush the piston on the hydraulic jack in again

and close the pressure release screw.

XVehicles with all-wheel drive: turn the jack

spindle clockwise as far as it will go

(

Ypage 268).

XStow the jack and the rest of the vehicle tools

in the vehicle again.

iYou can now install the hub caps on steel

wheels with wheel bolts. The installing proce-

dure depends on whether the hub cap acts as

a trim that covers the whole wheel, or just

covers the center.

XWheel with hub cap: position the opening for

the tire valve in the hub cap over the tire valve.

XPush the edge of the hub cap with both hands

against the wheel until it clicks into place.

Make sure the hub cap retaining catches

engage on the steel wheel.

XWheel with central hub cap: position the

retaining lugs of the central hub cap over the

wheel bolts.

XHit the center of the hub cap to engage it on

the wheel.

XSecure the faulty wheel in the spare wheel

bracket (Ypage 274).

XVehicles with Super Single tires: transport the

defective rear wheel in the load area. The rear wheel is too large for the spare wheel bracket.

XCheck the tire pressure of the newly mounted

wheel and adjust it if necessary.

Observe the recommended tire pressure

(

Ypage 251).

XRetighten the wheel bolts or wheel nuts to the

specified tightening torque after the vehicle

has been driven for 30 miles (50 km).

When using a wheel or spare wheel with a new or newly painted wheel rim, have the wheel bolts or

nuts retightened again after approximately 600

to 3,000 miles (1,000 to 5,000 km). Observe the

specified tightening torque.

272Changing wheels

Wheels and tires

Page 275 of 294

iVehicles with the tire pressure monitor sys-

tem: all mounted wheels must be equipped

with functioning sensors.

Wheel and tire combination

General notes

!

Retreaded tires are neither tested nor rec-

ommended for Sprinter vehicles, since previ-

ous damage cannot always be detected on

retreaded tires. We can therefore not guar-

antee driving safety. Do not mount used tires

if you have no information about their previ-

ous usage.

The recommended tire pressures can be found:

Ron the Tire and Loading Information placard9

on the B-pillar on the driver's side

Ron the tire pressure table on the B-pillar on the driver's side

The recommended tire pressure can also be

found in the "Tire pressure table" section in this

Operator's Manual (

Ypage 257). The wheel/tire

combination for your vehicle can be found on

the tire pressure table. Further information on

wheel/tire combination can be obtained at any

qualified specialist workshop.

Check tire pressures regularly and only when

the tires are cold. Observe the notes on the rec-

ommended tire pressure (

Ypage 251).

Follow the maintenance recommendations in

the tire manufacturer's warranty book in your

vehicle documents.

Notes on the vehicle equipment – always equip the vehicle:

Rwith tires of the same size across an axle (left

and right)

Rwith the same type of tires on all wheels at a

given time (summer tires, winter tires)

Tires that have been specially designed and

approved for your vehicle are marked with MO

(Mercedes-Benz Original). You can find this

identification on the tires themselves and in the following table.

iNot all wheel/tire combinations can be

installed at the factory in all countries.

Spare wheel

Important safety notes

GWARNING

Wheel and tire dimensions as well as the type of tire can vary between the spare wheel and

the wheel to be replaced. When the spare

wheel is mounted, driving characteristics may be severely affected. There is a risk of an acci-

dent.

In order to reduce risks:

Ryou should therefore adapt your driving

style and drive carefully.

Rnever mount more than one spare wheel

that differs from the wheel to be replaced.

Ronly use a spare wheel that differs from the

wheel to be replaced for a short time.

Rdo not deactivate ESP®.

Rhave a spare wheel that differs from the

wheel that has been changed replaced at

the nearest qualified specialist workshop.

You must observe the correct wheel and

tire dimensions as well as the wheel type.

When using a spare wheel of a different size, do

not exceed the maximum speed of 80 km/h.

General notes

!

Check the spare wheel regularly to see that

it is secure and has the prescribed tire pres-

sure.

The procedure for mounting the spare wheel is

described in "Mounting a wheel" (

Ypage 268).

The following should be checked regularly, par-

ticularly prior to long journeys:

Rthe tire pressure of the spare wheel, which

should then be corrected if necessary

(

Ypage 251).

Rthe fastenings of the spare wheel bracket.

The spare wheel is located in a spare wheel

bracket under the rear of the vehicle.

Replace the tires after 6 years at the latest,

regardless of wear. This also applies to the spare

wheel.

9Only for vehicles with a gross weight of less than 10,000 lbs (4,536 kg).

Spare wheel273

Wheels and tires

Z

Page 280 of 294

iSuch data is vehicle-specific and may differ

from that shown. Always observe the specifi-

cations on your vehicle's identification plate.

Engine number

The engine number is stamped on the crank-

case. More information may be obtained at any

qualified specialist workshop.

Service products and capacities

Important safety notes

GWARNING

Service products may be poisonous and haz-

ardous to health. There is a risk of injury.

Comply with instructions on the use, storage

and disposal of service products on the labels

of the respective original containers. Always

store service products sealed in their original

containers. Always keep service products out

of the reach of children.

HEnvironmental note

Dispose of service products in an environ-

mentally responsible manner.

Service products include the following:

RFuels, e.g. diesel

RAdditives for the exhaust gas aftertreatment,

e.g. Diesel Exhaust Fluid (DEF)

RLubricants, e.g. engine oil, transmission oil

RCoolant

RBrake fluid

RWasher fluid

RClimate control system refrigerants

Approved service products comply with the

highest quality standards and are listed in the

MB Specifications for Service Products. Only

use service products approved for the vehicle.

This is an important condition for the warranty.

You will recognize the approved service prod-

ucts by the inscription on the container: MB

Approval (e.g. MB Approval 228.5)

Other identifications and recommendations

refer to quality level or a specification according to an MB Sheet Number (e.g. MB 228.5). They

are therefore not necessarily approved.

More information can be obtained at any quali-

fied specialist workshop.

Additives for approved service products are nei-

ther required nor permitted. Approved fuel addi- tives are the exception. Additives can cause

engine damage and must therefore not be

added to the service products.

The use of additives is always the responsibility

of the vehicle operator. The use of additives may

result in the restriction or loss of you

r Limited

Warranty entitlements.

Fuel

Important safety notes

GWARNING

Fuel is highly flammable. Improper handling of

fuel creates a risk of fire and explosion.

Avoid fire, open flames, smoking and creating

sparks under all circumstances. Switch off the

engine and, if applicable, the auxiliary heating

before refueling.

GWARNING

Fuel is poisonous and hazardous to health.

There is a risk of injury.

You must make sure that fuel does not come into contact with your skin, eyes or clothing

and that it is not swallowed. Do not inhale fuel

vapors. Keep fuel away from children.

If you or others come into contact with fuel,

observe the following:

RWash away fuel from skin immediately

using soap and water.

RIf fuel comes into contact with your eyes,

immediately rinse them thoroughly with

clean water. Seek medical assistance with-

out delay.

RIf fuel is swallowed, seek medical assis-

tance without delay. Do not induce vomit-

ing.

RImmediately change out of clothing which

has come into contact with fuel.

278Service products and capacities

Technical data

Page 281 of 294

When handling, storing and disposing of fuels,

please observe the relevant regulations.

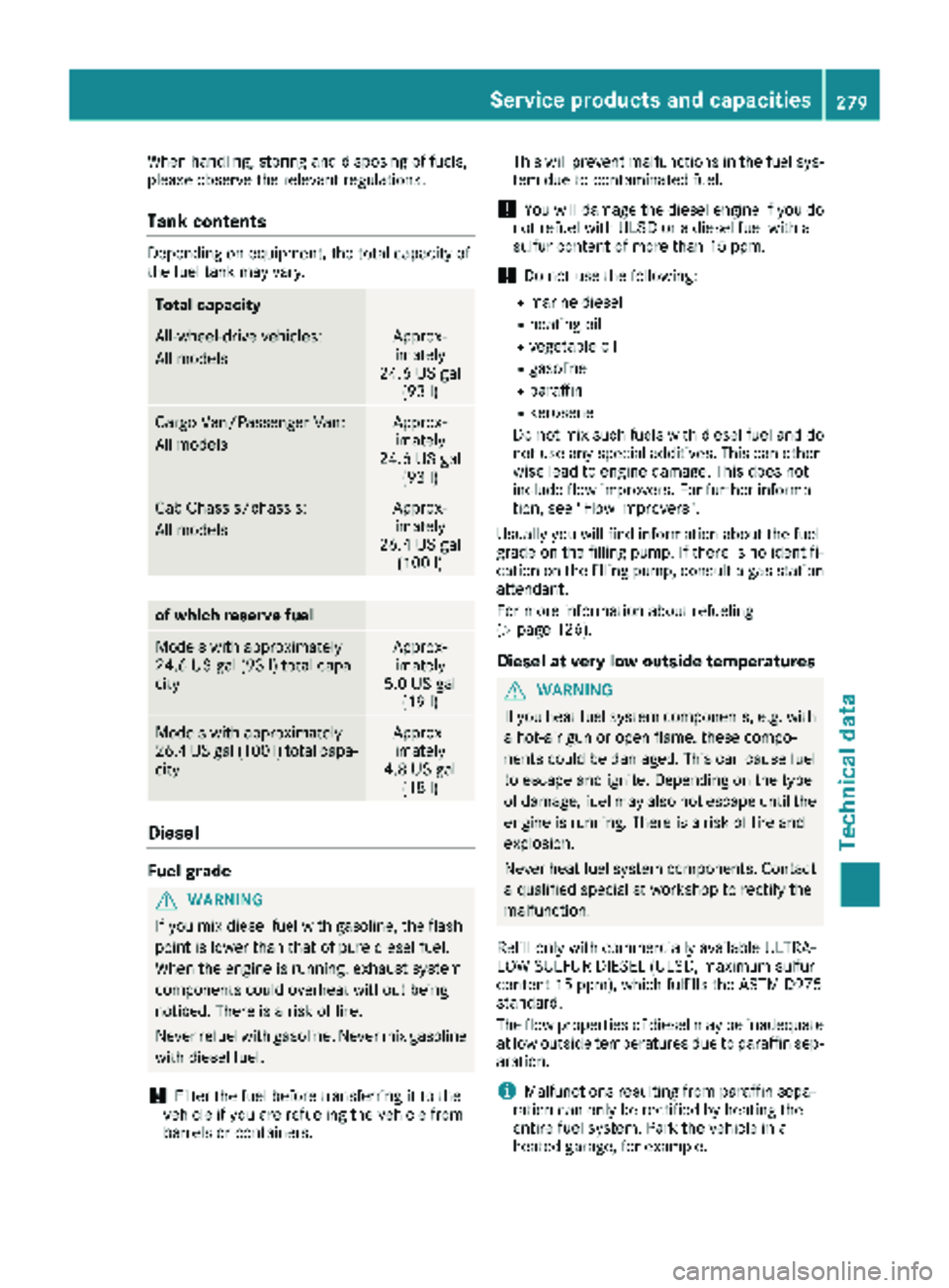

Tank contents

Depending on equipment, the total capacity of

the fuel tank may vary.

Total capacity

All-wheel-drive vehicles:

All modelsApprox-imately

24.6 US gal (93 l)

Cargo Van/Passenger Van:

All modelsApprox-imately

24.6 US gal (93 l)

Cab Chassis/chassis:

All modelsApprox-imately

26.4 US gal (100 l)

of which reserve fuel

Models with approximately

24.6 US gal (93 l) total capa-

cityApprox-imately

5.0 US gal (19 l)

Models with approximately

26.4 US gal (100 l)total capa-

cityApprox- imately

4.8 US gal (18 l)

Diesel

Fuel grade

GWARNING

If you mix diesel fuel with gasoline, the flash

point is lower than that of pure diesel fuel.

When the engine is running, exhaust system

components could overheat without being

noticed. There is a risk of fire.

Never refuel with gasoline. Never mix gasoline with diesel fuel.

!Filter the fuel before transferring it to the

vehicle if you are refueling the vehicle from

barrels or containers. This will prevent malfunctions in the fuel sys-

tem due to contaminated fuel.

!You will damage the diesel engine if you do

not refuel with ULSD or a diesel fuel with a

sulfur content of more than 15 ppm.

!Do not use the following:

Rmarine diesel

Rheating oil

Rvegetable oil

Rgasoline

Rparaffin

Rkerosene

Do not mix such fuels with diesel fuel and do

not use any special additives. This can other-

wise lead to engine damage. This does not

include flow improvers. For further informa-

tion, see "Flow improvers".

Usually you will find information about the fuel

grade on the filling pump. If there is no identifi-

cation on the filling pump, consult a gas station

attendant.

For mo

re information about refueling

(Ypage 126).

Diesel at very low outside temperatures

GWARNING

If you heat fuel system components, e.g. with

a hot-air gun or open flame, these compo-

nents could be damaged. This can cause fuel

to escape and ignite. Depending on the type

of damage, fuel may also not escape until the

engine is running. There is a risk of fire and

explosion.

Never heat fuel system components. Contact

a qualified specialist workshop to rectify the

malfunction.

Refill only with commercially available ULTRA-

LOW SULFUR DIESEL (ULSD, maximum sulfur

content 15 ppm), which fulfills the ASTM D975

standard.

The flow properties of diesel may be inadequate

at low outside temperatures due to paraffin sep-

aration.

iMalfunctions resulting from paraffin sepa-

ration can only be rectified by heating the

entire fuel system. Park the vehicle in a

heated garage, for example.

Service products and capacities279

Technical data

Z