Mercury Milan 2006 Owner's Manuals

Manufacturer: MERCURY, Model Year: 2006, Model line: Milan, Model: Mercury Milan 2006Pages: 256, PDF Size: 2.45 MB

Page 181 of 256

When driving with the full-size dissimilar spare tire/wheel additional

caution should be given to:

•Towing a trailer

•Driving vehicles equipped with a camper body

•Driving vehicles with a load on the cargo rack

Drive cautiously when using a full-size dissimilar spare tire/wheel and

seek service as soon as possible.

How to change a flat tire

To help prevent the vehicle from moving when you change a tire,

be sure the parking brake is set, then block (in both directions)

the wheel that is diagonally opposite (other side and end of the

vehicle) to the tire being changed.

If the vehicle slips off the jack, you or someone else could be

seriously injured.

Do not attempt to change a tire on the side of the vehicle close

to moving traffic. Pull far enough off the road to avoid the

danger of being hit when operating the jack or changing the wheel.

Before changing the tire:

1. Park on a level surface.

2. Activate the hazard flashers.

3. Place the gearshift lever in P (Park) (automatic transmission) or R

(Reverse) (manual transmission).

4. Set the parking brake.

5. Turn off the ignition.

2006 Milan(mln)

Owners Guide (post-2002-fmt)

USA(fus)

Roadside Emergencies

181

Page 182 of 256

Removing the spare tire and jack

1. Remove the carpeted load floor

panel located in the rear of the

vehicle and remove the lug wrench

and long bolt from the tool bag.

2. Remove the bolt securing the

spare tire using the lug wrench,

then lift and remove the spare tire

from the trunk.

3. Remove the jack retention bolt by

turning it counterclockwise and

remove the jack from the vehicle.

Tire change procedure

Note:Passengers should not remain in the vehicle when the vehicle is

being jacked.

1. Block both the front and rear of

the wheel diagonally opposite the

flat tire. For example, if the left

front tire is flat, block the right rear

wheel.

2006 Milan(mln)

Owners Guide (post-2002-fmt)

USA(fus)

Roadside Emergencies

182

Page 183 of 256

2. Remove the center ornament (if

equipped) from the wheel. Loosen

each wheel lug nut one-half turn

counterclockwise but do not remove

them until the wheel is raised off

the ground.

3. Put the jack in the jack locator

next to the tire you are changing.

Turn the jack handle clockwise until

the wheel is completely off the

ground.

To lessen the risk of

personal injury, do not put

any part of your body under the

vehicle while changing a tire. Do

not start the engine when your

vehicle is on the jack. The jack is

only meant for changing the tire.

4. Remove the lug nuts with the lug

wrench.

5. Replace the flat tire with the

spare tire, making sure the valve

stem is facing outward. Reinstall lug

nuts until the wheel is snug against

the hub. Do not fully tighten the lug nuts until the wheel has been

lowered.

If you are using the temporary tire, the lug nut washers will not appear

to be flush with the rim. This is normal only when using the temporary

spare tire.

6. Lower the wheel by turning the jack handle counterclockwise.

2006 Milan(mln)

Owners Guide (post-2002-fmt)

USA(fus)

Roadside Emergencies

183

Page 184 of 256

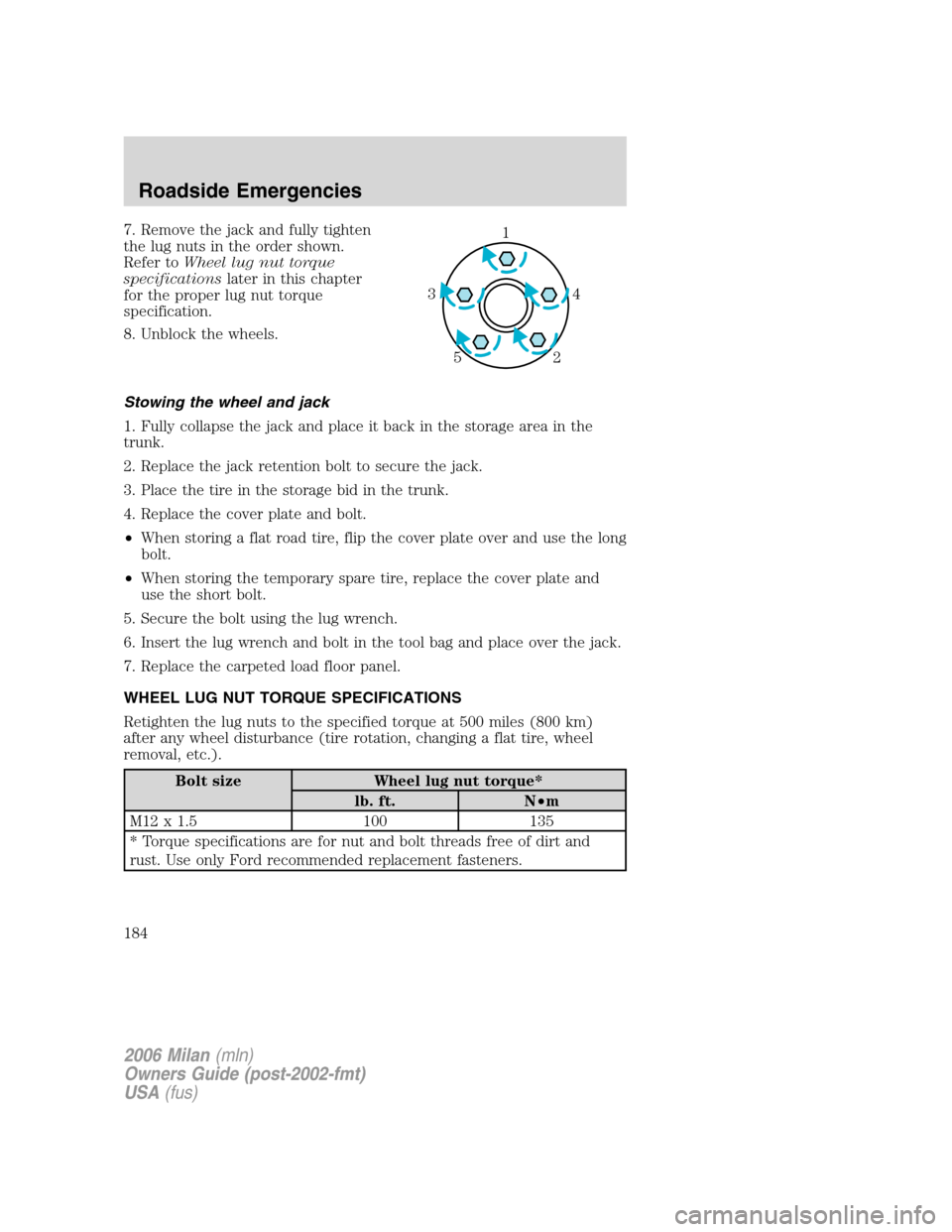

7. Remove the jack and fully tighten

the lug nuts in the order shown.

Refer toWheel lug nut torque

specificationslater in this chapter

for the proper lug nut torque

specification.

8. Unblock the wheels.

Stowing the wheel and jack

1. Fully collapse the jack and place it back in the storage area in the

trunk.

2. Replace the jack retention bolt to secure the jack.

3. Place the tire in the storage bid in the trunk.

4. Replace the cover plate and bolt.

•When storing a flat road tire, flip the cover plate over and use the long

bolt.

•When storing the temporary spare tire, replace the cover plate and

use the short bolt.

5. Secure the bolt using the lug wrench.

6. Insert the lug wrench and bolt in the tool bag and place over the jack.

7. Replace the carpeted load floor panel.

WHEEL LUG NUT TORQUE SPECIFICATIONS

Retighten the lug nuts to the specified torque at 500 miles (800 km)

after any wheel disturbance (tire rotation, changing a flat tire, wheel

removal, etc.).

Bolt size Wheel lug nut torque*

lb. ft. N•m

M12 x 1.5 100 135

* Torque specifications are for nut and bolt threads free of dirt and

rust. Use only Ford recommended replacement fasteners.

1

4 3

2 5

2006 Milan(mln)

Owners Guide (post-2002-fmt)

USA(fus)

Roadside Emergencies

184

Page 185 of 256

When a wheel is installed, always remove any corrosion, dirt or

foreign materials present on the mounting surfaces of the wheel

or the surface of the wheel hub, brake drum or brake disc that

contacts the wheel. Ensure that any fasteners that attach the rotor to

the hub are secured so they do not interfere with the mounting

surfaces of the wheel. Installing wheels without correct metal-to-metal

contact at the wheel mounting surfaces can cause the wheel nuts to

loosen and the wheel to come off while the vehicle is in motion,

resulting in loss of control.

JUMP STARTING

The gases around the battery can explode if exposed to flames,

sparks, or lit cigarettes. An explosion could result in injury or

vehicle damage.

Batteries contain sulfuric acid which can burn skin, eyes and

clothing, if contacted.

Do not attempt to push-start your vehicle. Automatic

transmissions do not have push-start capability; doing so may

damage the catalytic converter.

Preparing your vehicle

When the battery is disconnected or a new battery is installed, the

transmission must relearn its shift strategy. As a result, the transmission

may have firm and/or soft shifts. This operation is considered normal and

will not affect function or durability of the transmission. Over time, the

adaptive learning process will fully update transmission operation.

1.Use only a 12–volt supply to start your vehicle.

2. Do not disconnect the battery of the disabled vehicle as this could

damage the vehicle’s electrical system.

3. Park the booster vehicle close to the hood of the disabled vehicle making

sure the two vehiclesdo nottouch. Set the parking brake on both vehicles

and stay clear of the engine cooling fan and other moving parts.

4. Check all battery terminals and remove any excessive corrosion before

you attach the battery cables. Ensure that vent caps are tight and level.

5. Turn the heater fan on in both vehicles to protect any electrical

surges. Turn all other accessories off.

2006 Milan(mln)

Owners Guide (post-2002-fmt)

USA(fus)

Roadside Emergencies

185

Page 186 of 256

Connecting the jumper cables

1. Connect the positive (+) jumper cable to the positive (+) terminal of

the discharged battery.

Note:In the illustrations,lightning boltsare used to designate the

assisting (boosting) battery.

2. Connect the other end of the positive (+) cable to the positive (+)

terminal of the assisting battery.

+–+–

+–+–

2006 Milan(mln)

Owners Guide (post-2002-fmt)

USA(fus)

Roadside Emergencies

186

Page 187 of 256

3. Connect the negative (-) cable to the negative (-) terminal of the

assisting battery.

4. Make the final connection of the negative (-) cable to an exposed

metal part of the stalled vehicle’s engine, away from the battery and the

carburetor/fuel injection system.Do notuse fuel lines, engine rocker

covers or the intake manifold asgroundingpoints.

Do not connect the end of the second cable to the negative (-)

terminal of the battery to be jumped. A spark may cause an

explosion of the gases that surround the battery.

5. Ensure that the cables are clear of fan blades, belts, moving parts of

both engines, or any fuel delivery system parts.

+–+–

+–+–

2006 Milan(mln)

Owners Guide (post-2002-fmt)

USA(fus)

Roadside Emergencies

187

Page 188 of 256

Jump starting

1. Start the engine of the booster vehicle and run the engine at

moderately increased speed.

2. Start the engine of the disabled vehicle.

3. Once the disabled vehicle has been started, run both engines for an

additional three minutes before disconnecting the jumper cables.

Removing the jumper cables

Remove the jumper cables in the reverse order that they were

connected.

1. Remove the jumper cable from thegroundmetal surface.

Note:In the illustrations,lightning boltsare used to designate the

assisting (boosting) battery.

2. Remove the jumper cable on the negative (-) connection of the

booster vehicle’s battery.

+–+–

+–+–

2006 Milan(mln)

Owners Guide (post-2002-fmt)

USA(fus)

Roadside Emergencies

188

Page 189 of 256

3. Remove the jumper cable from the positive (+) terminal of the booster

vehicle’s battery.

4. Remove the jumper cable from the positive (+) terminal of the

disabled vehicle’s battery.

After the disabled vehicle has been started and the jumper cables

removed, allow it to idle for several minutes so the engine computer can

relearnits idle conditions.

+–+–

+–+–

2006 Milan(mln)

Owners Guide (post-2002-fmt)

USA(fus)

Roadside Emergencies

189

Page 190 of 256

WRECKER TOWING

If you need to have your vehicle towed, contact a professional towing

service or, if you are a member of a roadside assistance program, your

roadside assistance service provider.

It is recommended that your vehicle be towed with a wheel lift or flatbed

equipment. Do not tow with a slingbelt. Ford Motor Company has not

approved a slingbelt towing procedure.

If the vehicle is towed by other means or incorrectly, vehicle

damage may occur.

If your vehicle is to be towed using wheel lift equipment, the non-lifted

wheels must be place on a dolly to prevent damage to the vehicle.

Ford Motor Company produces a towing manual for all authorized tow

truck operators. Have your tow truck operator refer to this manual for

proper hook-up and towing procedures for your vehicle.

2006 Milan(mln)

Owners Guide (post-2002-fmt)

USA(fus)

Roadside Emergencies

190