Product and specifications Mercury Milan 2008 s User Guide

[x] Cancel search | Manufacturer: MERCURY, Model Year: 2008, Model line: Milan, Model: Mercury Milan 2008Pages: 304, PDF Size: 2.83 MB

Page 278 of 304

1. Start the engine and let it run until it reaches normal operating

temperature (the engine coolant temperature gauge indicator will be

near the center of the normal area between H and C).

2. While the engine idles, turn the steering wheel left and right several

times.

3. Turn the engine off.

4. Check the fluid level in the reservoir. It should be between the

MIN/MAX or upper and lower lines. Do not add fluid if the level is in this

range.

5. If the fluid is low, add fluid in small amounts, continuously checking

the level until it reaches the range between the MIN/MAX or upper and

lower lines. Be sure to put the cap back on the reservoir. Refer to

Maintenance product specifications and capacitiesin this chapter for

the proper fluid type.

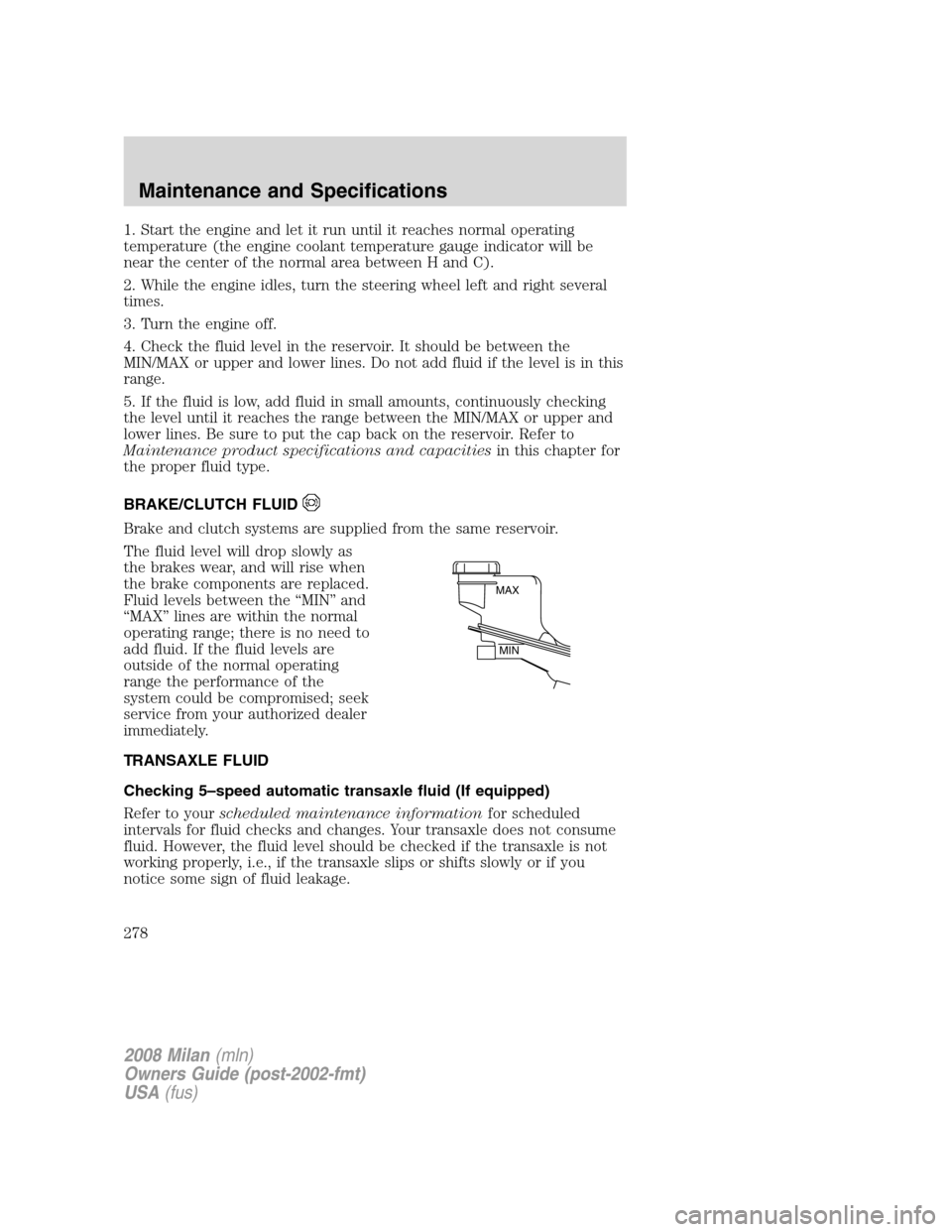

BRAKE/CLUTCH FLUID

Brake and clutch systems are supplied from the same reservoir.

The fluid level will drop slowly as

the brakes wear, and will rise when

the brake components are replaced.

Fluid levels between the “MIN” and

“MAX” lines are within the normal

operating range; there is no need to

add fluid. If the fluid levels are

outside of the normal operating

range the performance of the

system could be compromised; seek

service from your authorized dealer

immediately.

TRANSAXLE FLUID

Checking 5–speed automatic transaxle fluid (If equipped)

Refer to yourscheduled maintenance informationfor scheduled

intervals for fluid checks and changes. Your transaxle does not consume

fluid. However, the fluid level should be checked if the transaxle is not

working properly, i.e., if the transaxle slips or shifts slowly or if you

notice some sign of fluid leakage.

MAX

MIN

2008 Milan(mln)

Owners Guide (post-2002-fmt)

USA(fus)

Maintenance and Specifications

278

Page 280 of 304

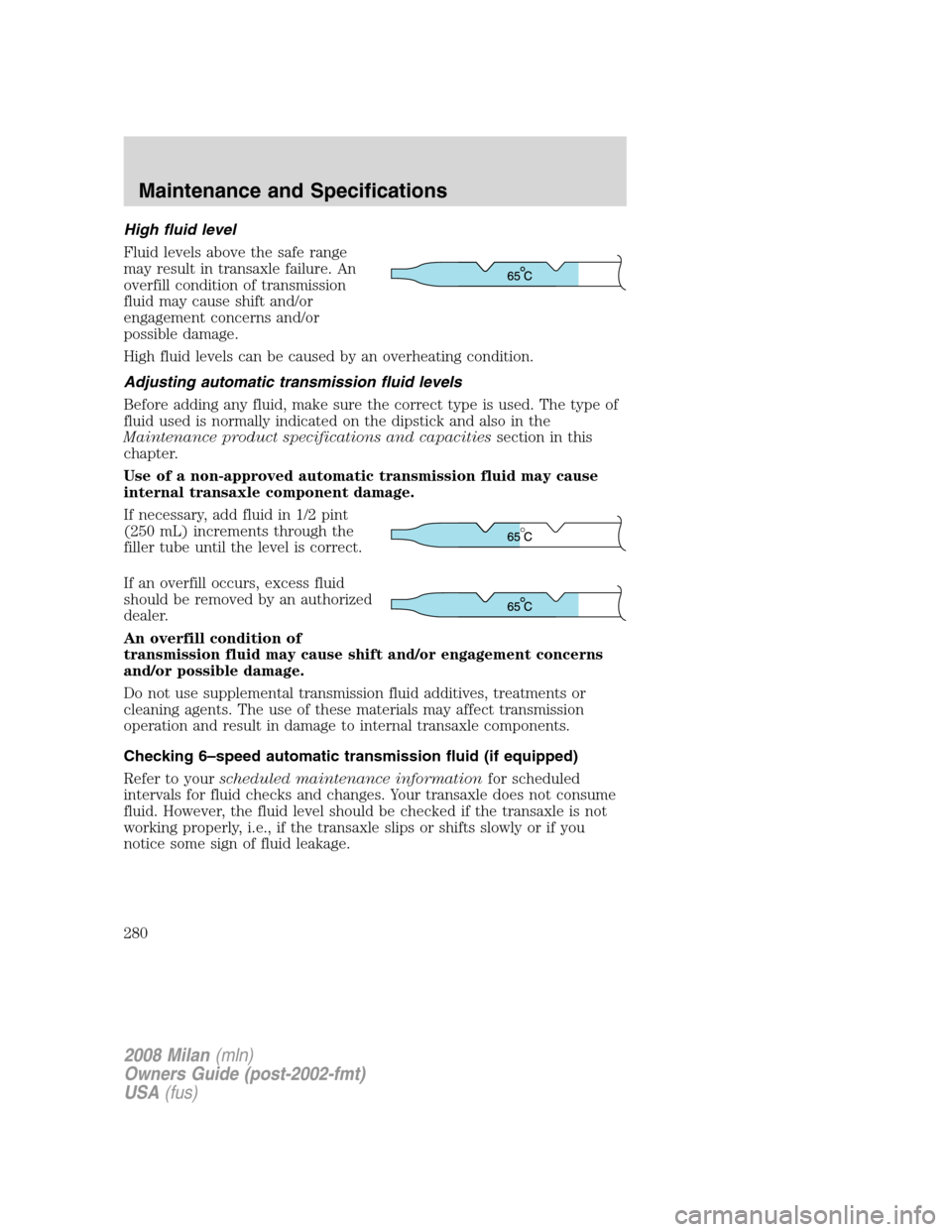

High fluid level

Fluid levels above the safe range

may result in transaxle failure. An

overfill condition of transmission

fluid may cause shift and/or

engagement concerns and/or

possible damage.

High fluid levels can be caused by an overheating condition.

Adjusting automatic transmission fluid levels

Before adding any fluid, make sure the correct type is used. The type of

fluid used is normally indicated on the dipstick and also in the

Maintenance product specifications and capacitiessection in this

chapter.

Use of a non-approved automatic transmission fluid may cause

internal transaxle component damage.

If necessary, add fluid in 1/2 pint

(250 mL) increments through the

filler tube until the level is correct.

If an overfill occurs, excess fluid

should be removed by an authorized

dealer.

An overfill condition of

transmission fluid may cause shift and/or engagement concerns

and/or possible damage.

Do not use supplemental transmission fluid additives, treatments or

cleaning agents. The use of these materials may affect transmission

operation and result in damage to internal transaxle components.

Checking 6–speed automatic transmission fluid (if equipped)

Refer to yourscheduled maintenance informationfor scheduled

intervals for fluid checks and changes. Your transaxle does not consume

fluid. However, the fluid level should be checked if the transaxle is not

working properly, i.e., if the transaxle slips or shifts slowly or if you

notice some sign of fluid leakage.

2008 Milan(mln)

Owners Guide (post-2002-fmt)

USA(fus)

Maintenance and Specifications

280

Page 282 of 304

Low fluid level

Do not drive the vehicle if the fluid

level does not show at all on the

dipstick.

Driving the vehicle with less than

the recommended fluid level may result in transaxle failure. An under fill

condition of transmission fluid may cause shift and/or engagement

concerns and /or possible damage to the transaxle.

High fluid level

Fluid levels above the normal

operating range may result in

transaxle failure. An overfill

condition of transmission fluid may

cause shift and/or engagement

concerns and/or possible damage to

the transaxle.

High fluid levels can be caused by an overheating condition.

Adjusting automatic transmission fluid levels

Before adding any fluid, make sure the correct type is used. The type of

fluid used is normally indicated on the dipstick and also in the

Maintenance product specifications and capacitiessection in this

chapter.

Note:Only one ATF fluid specification has been tested and approved for

use with the automatic 6-speed: Premium Automatic Transmission fluid.

Mercon fluids cannot be used with the automatic 6-speed without

damage or voiding warranty.

Use of a non-approved automatic transmission fluid may cause

internal transaxle component damage.

If necessary, add fluid in 1/2 pint (250 mL) increments through the filler

tube until the level is correct.

If an overfill occurs, excess fluid should be removed by an authorized

dealer.

An overfill condition of transmission fluid may cause shift and/or

engagement concerns and/or possible damage.

Do not use supplemental transmission fluid additives, treatments or

cleaning agents. The use of these materials may affect transmission

operation and result in damage to internal transaxle components.

2008 Milan(mln)

Owners Guide (post-2002-fmt)

USA(fus)

Maintenance and Specifications

282

Page 283 of 304

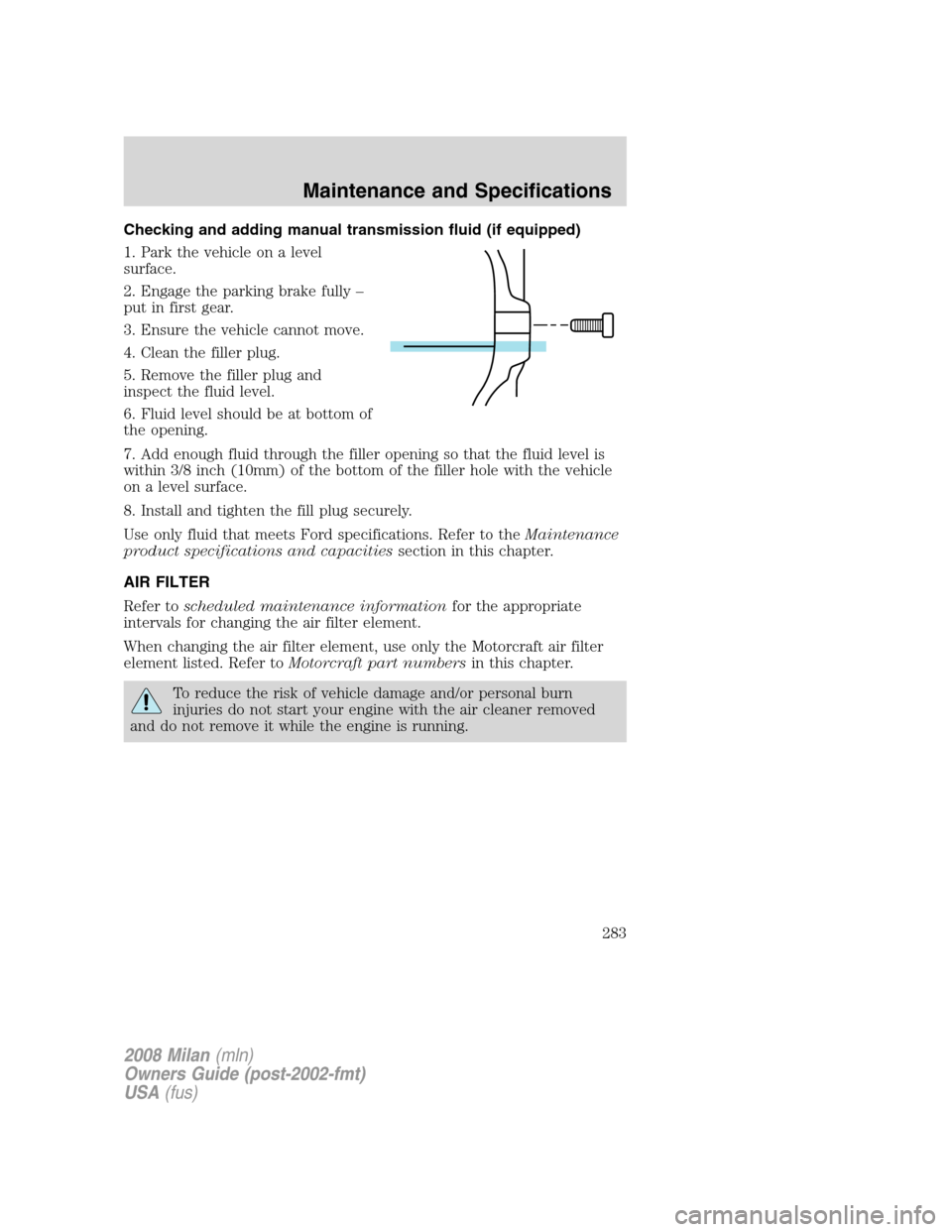

Checking and adding manual transmission fluid (if equipped)

1. Park the vehicle on a level

surface.

2. Engage the parking brake fully –

put in first gear.

3. Ensure the vehicle cannot move.

4. Clean the filler plug.

5. Remove the filler plug and

inspect the fluid level.

6. Fluid level should be at bottom of

the opening.

7. Add enough fluid through the filler opening so that the fluid level is

within 3/8 inch (10mm) of the bottom of the filler hole with the vehicle

on a level surface.

8. Install and tighten the fill plug securely.

Use only fluid that meets Ford specifications. Refer to theMaintenance

product specifications and capacitiessection in this chapter.

AIR FILTER

Refer toscheduled maintenance informationfor the appropriate

intervals for changing the air filter element.

When changing the air filter element, use only the Motorcraft air filter

element listed. Refer toMotorcraft part numbersin this chapter.

To reduce the risk of vehicle damage and/or personal burn

injuries do not start your engine with the air cleaner removed

and do not remove it while the engine is running.

2008 Milan(mln)

Owners Guide (post-2002-fmt)

USA(fus)

Maintenance and Specifications

283

Page 287 of 304

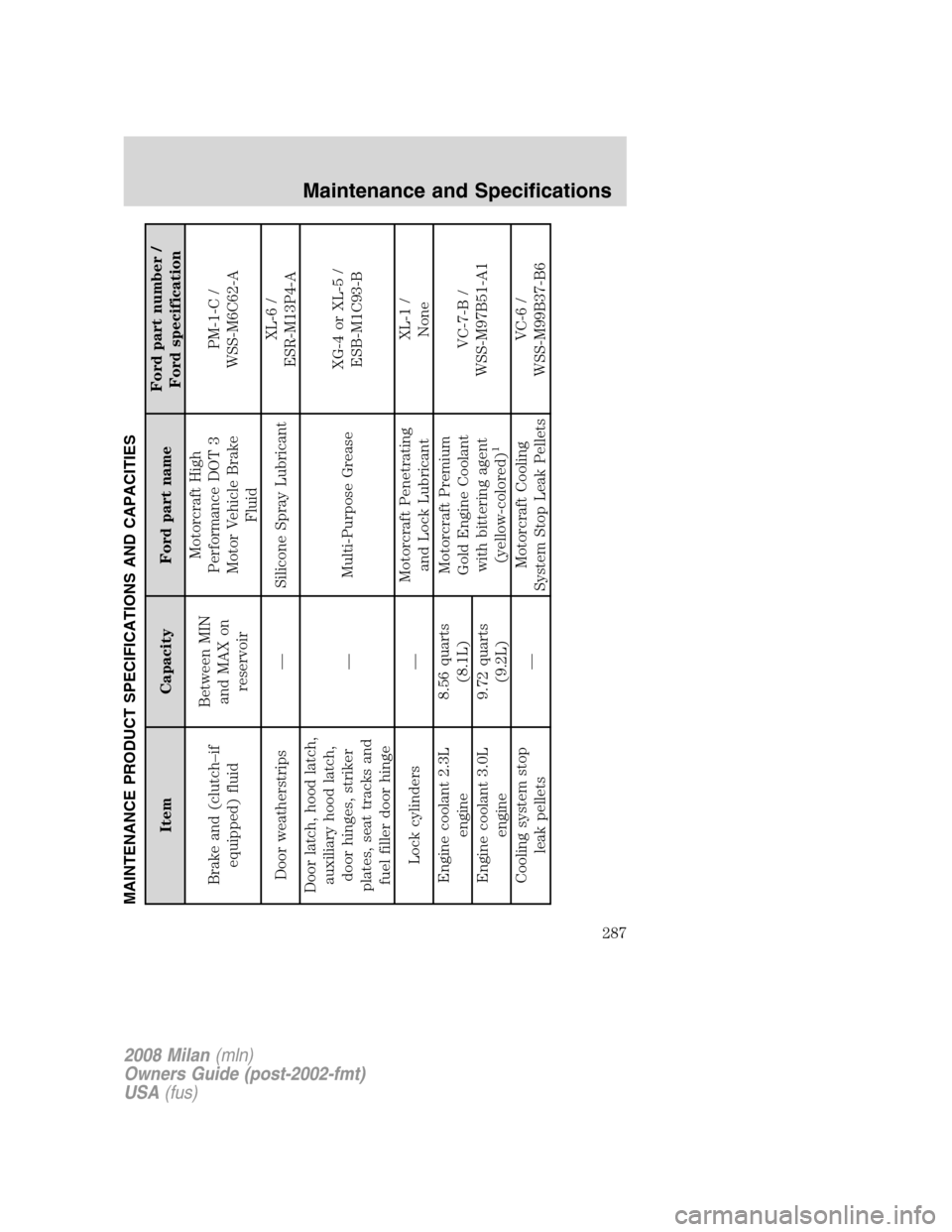

MAINTENANCE PRODUCT SPECIFICATIONS AND CAPACITIES

Item Capacity Ford part nameFord part number /

Ford specification

Brake and (clutch–if

equipped) fluidBetween MIN

and MAX on

reservoirMotorcraft High

Performance DOT 3

Motor Vehicle Brake

FluidPM-1-C /

WSS-M6C62-A

Door weatherstrips — Silicone Spray LubricantXL-6 /

ESR-M13P4-A

Door latch, hood latch,

auxiliary hood latch,

door hinges, striker

plates, seat tracks and

fuel filler door hinge— Multi-Purpose GreaseXG-4 or XL-5 /

ESB-M1C93-B

Lock cylinders —Motorcraft Penetrating

and Lock LubricantXL-1 /

None

Engine coolant 2.3L

engine8.56 quarts

(8.1L)Motorcraft Premium

Gold Engine Coolant

with bittering agent

(yellow-colored)

1

VC-7-B /

WSS-M97B51-A1

Engine coolant 3.0L

engine9.72 quarts

(9.2L)

Cooling system stop

leak pellets—Motorcraft Cooling

System Stop Leak PelletsVC-6 /

WSS-M99B37-B6

2008 Milan(mln)

Owners Guide (post-2002-fmt)

USA(fus)

Maintenance and Specifications

287

Page 292 of 304

The Vehicle Identification Number (VIN) contains the following

information:

1. World manufacturer identifier

2. Brake system / Gross Vehicle

Weight Rating (GVWR) / Restraint

System

3. Vehicle line, series, body type

4. Engine type

5. Check digit

6. Model year

7. Assembly plant

8. Production sequence number

TRANSMISSION/TRANSAXLE CODE DESIGNATIONS

You can find a

transmission/transaxle code on the

Safety Compliance Certification

Label. The following table tells you

which transmission or transaxle

each code represents.

Description Code

5–Speed Manual Transaxle A Mazda G5M 5

5–Speed Automatic Transaxle Mazda FNR5 C

6–Speed Automatic Transaxle Aisin F21 B

2008 Milan(mln)

Owners Guide (post-2002-fmt)

USA(fus)

Maintenance and Specifications

292