clock Mercury Mountaineer 1998 Owner's Manuals

[x] Cancel search | Manufacturer: MERCURY, Model Year: 1998, Model line: Mountaineer, Model: Mercury Mountaineer 1998Pages: 216, PDF Size: 1.72 MB

Page 16 of 216

HEADLAMP CONTROL

Rotate the headlamp control

clockwise to the first position to

turn on the parking lamps only.

Rotate to the second position to

also turn on the headlamps.

Foglamp control (if equipped)

Turn on the low-beam headlamps

and press the foglamp control to

activate the foglamps. The foglamp

control button will illuminate when

the foglamps are on.

Press the foglamp control a second

time to deactivate the foglamps.

Daytime running lamps (DRL)

(if equipped)

Turns the highbeam headlamps on

with a reduced output. To activate:

²the engine must be running

²the gearshift must not be in P

(Park)

²the headlamp control is in the

OFF or Parking lamps position.

The Daytime Running

Light (DRL) system will

not illuminate the tail lamps and

parking lamps. Turn on your

headlamps at dusk. Failure to do

so may result in a collision.

OFF

Controls and features

16

Page 145 of 216

a tire could result in damage to

driveline components and make

the vehicle difficult to control.

Location of the spare tire and

tools

The spare tire and tools for your

vehicle are stowed in the following

locations:

Tool Location

Spare tire Under the vehicle, just in front of

the rear bumper

Jack, lug nut wrench Left rear quarter panel behind

interior trim

Jack handle Behind rear seats, under carpet

Removing the spare tire

1. Insert the jack handle into the

rear bumper opening.

The handle will stop moving and

forward resistance to turning will

be felt when properly engaged.

2. Turn the handle

counterclockwise until tire is

lowered to the ground, the tire can

be slid rearward and the cable is

slightly slack.

3. Remove the retainer from the

spare tire.

Stowing the spare

1. Lay the tire on the ground with

the valve stem facing up.

Roadside emergencies

145

Page 146 of 216

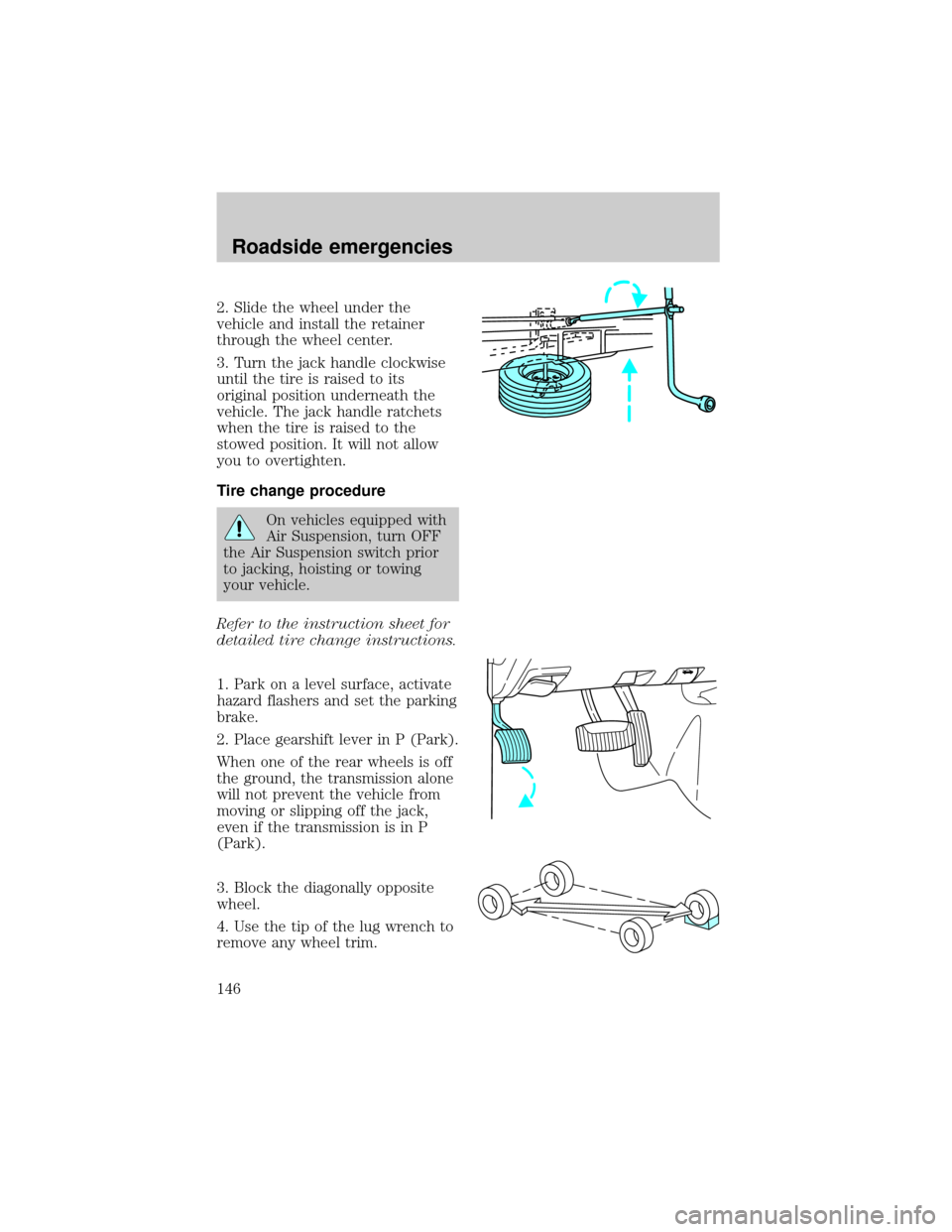

2. Slide the wheel under the

vehicle and install the retainer

through the wheel center.

3. Turn the jack handle clockwise

until the tire is raised to its

original position underneath the

vehicle. The jack handle ratchets

when the tire is raised to the

stowed position. It will not allow

you to overtighten.

Tire change procedure

On vehicles equipped with

Air Suspension, turn OFF

the Air Suspension switch prior

to jacking, hoisting or towing

your vehicle.

Refer to the instruction sheet for

detailed tire change instructions.

1. Park on a level surface, activate

hazard flashers and set the parking

brake.

2. Place gearshift lever in P (Park).

When one of the rear wheels is off

the ground, the transmission alone

will not prevent the vehicle from

moving or slipping off the jack,

even if the transmission is in P

(Park).

3. Block the diagonally opposite

wheel.

4. Use the tip of the lug wrench to

remove any wheel trim.

Roadside emergencies

146

Page 147 of 216

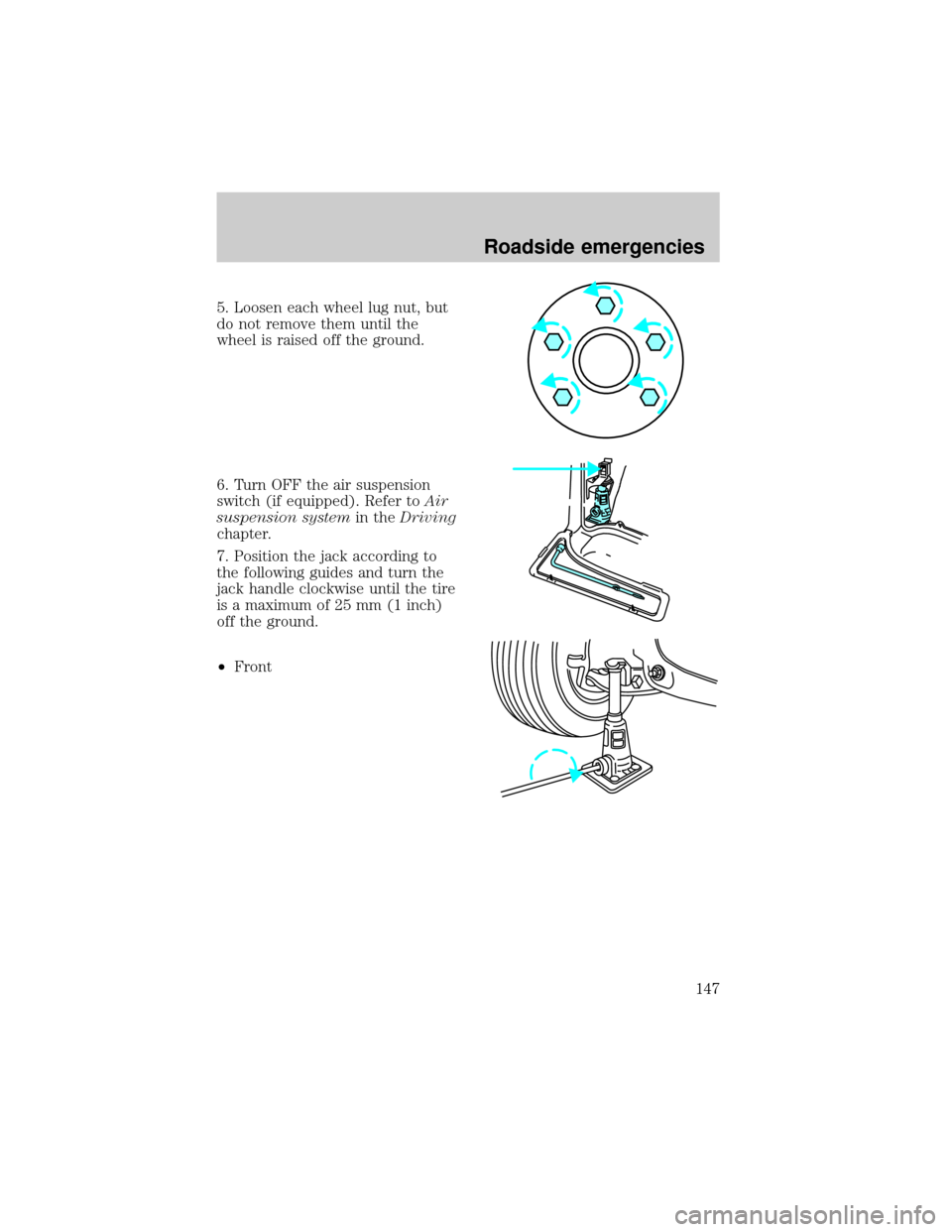

5. Loosen each wheel lug nut, but

do not remove them until the

wheel is raised off the ground.

6. Turn OFF the air suspension

switch (if equipped). Refer toAir

suspension systemin theDriving

chapter.

7. Position the jack according to

the following guides and turn the

jack handle clockwise until the tire

is a maximum of 25 mm (1 inch)

off the ground.

²Front

Roadside emergencies

147

Page 148 of 216

²Rear

²Never use the front or rear

differential as a jacking

point.

8. Remove the lug nuts with the

lug wrench.

9. Replace the flat tire with the

spare tire, making sure the valve

stem is facing outward. Reinstall

the lug nuts, cone side in, until the

wheel is snug against the hub. Do

not fully tighten the lug nuts until

the wheel has been lowered.

10. Lower the wheel by turning the

jack handle counterclockwise.

11. Remove the jack and fully

tighten the lug nuts in the order

shown.

1

4 3

52

Roadside emergencies

148

Page 165 of 216

If sprayed on the windshield,

engine coolant could make it

difficult to see through the

windshield.

When the engine is cool, add a

50/50 mixture of engine coolant

and water to the engine coolant

recovery reservoir-DO NOT ADD

DIRECTLY TO THE RADIATOR.

Add straight water only in an

emergency, but you should replace

it with a 50/50 mixture of coolant

and distilled water as soon as

possible.

Check the coolant level in the

coolant recovery reservoir the next

few times you drive the vehicle. If

necessary, add enough of a 50/50

mixture of coolant and water to

bring the liquid level to the fill line

on the reservoir.

Never remove the coolant

recovery cap while the

engine is running or hot.

If you must remove the coolant

recovery cap, follow these steps to

avoid personal injury:

1. Before you remove the cap, turn

the engine off and let it cool.

2. When the engine is cool, wrap a

thick cloth around the cap. Slowly

turn cap counterclockwise to the

first stop.

3. Step back while the pressure

releases.

4. When you are sure that all the

pressure has been released, use

Maintenance and care

165

Page 166 of 216

the cloth to press the cap down,

turn it counterclockwise and

remove it.

Use Ford Premium Cooling System

Fluid E2FZ-19549±AA (in Canada,

Motorcraft CXC-8±B) or an

equivalent premium engine coolant

that meets Ford specification

ESE-M97B44±A. Ford Premium

Engine Coolant is an optimized

formula that will protect all metals

and rubber elastomers used in

Ford cooling systems for four years

or 80,000 km (50,000 miles).

Do not use alcohol or methanol

antifreeze or any engine coolants

mixed with alcohol or methanol

antifreeze. Do not use

supplemental coolant additives in

your vehicle. These additives may

harm your engine cooling system.

The use of an improper coolant

may void your warranty of your

vehicle's engine cooling system.

Recycled engine coolant

Ford Motor Company recommends

that Ford and Lincoln-Mercury

dealers use recycled engine

coolant produced by

Ford-approved processes. Not all

coolant recycling processes

produce coolant which meets Ford

specification ESE-M97B44±A, and

use of such coolant may harm

engine and cooling system

components.

Always dispose of used

automotive fluids in a responsible

manner. Follow your community's

Maintenance and care

166

Page 175 of 216

²If the battery has been

disconnected or a new battery

has been installed, the clock and

the preset radio stations must

be reset once the battery is

reconnected.

²Always dispose of automotive

batteries in a responsible

manner. Follow your

communities standards for

disposal. Call your local

recycling center to find out

more about recycling automotive

batteries.

WINDSHIELD WIPER BLADES

Check the wiper blades at least

twice a year or when they seem

less effective. Substances such as

tree sap and some hot wax

treatments used by commercial car

washes reduce the effectiveness of

wiper blades.

Checking the wiper blades

If the wiper blades do not wipe

properly, clean both the windshield

and wiper blades using undiluted

windshield wiper solution or a mild

detergent. Rinse thoroughly with

clean water. To avoid damaging the

blades, do not use fuel, kerosene,

paint thinner or other solvents.

Changing the wiper blades

When replacing wiper blade

assemblies, always use a

Motorcraft part or equivalent. To

make replacing the wipers easy,

Maintenance and care

175

Page 192 of 216

3. Disconnect the electrical

connector from the bulb by pulling

the connector rearward.

4. Remove the bulb retaining ring

by rotating it counterclockwise

(when viewed from the rear) about

an eighth of a turn to free it from

the bulb socket, and by sliding the

ring off the plastic base. Keep the

ring because it will be used again

to retain the new bulb.

5. Remove the old bulb from its

socket by gently pulling it straight

back out of the socket. Do not turn

the bulb while removing it.

To install the new bulb:

1. With the flat side of the bulb's

plastic base facing upward, insert

the glass end of the bulb into the

socket. You may need to turn the

bulb left or right to line up the

grooves in the plastic base with

the tabs in the socket. When the

grooves are aligned, push the bulb

into the socket until the plastic

base contacts the rear of the

socket.

2. Slip the bulb retaining ring over

the plastic base until it contacts

the rear of the socket by rotating it

clockwise until you feel a ªstop.º

Maintenance and care

192

Page 195 of 216

Horizontal aim adjustment

1. With the hood open, locate the

horizontal indicator and adjusting

screw. They are located below the

viewing hole at the rear of the

headlamp assembly.

2. Use a 4mm wrench or socket to

turn the horizontal adjusting screw

until the ª0º mark on the yellow

dial lines up with the reference

mark on the marker (as shown)

when viewed directly from above.

Vertical aim adjustment

1. Park the vehicle on a level

surface.

2. With the hood open, locate the

bubble level and vertical

adjustment screw. The adjustment

screw is located on the outboard

side of the headlamp.

3. The ªUPº and ªDNº on the

bubble indicate the directional

change (up or down) of the

vertical aim.

4.Usea4mmwrench or socket to

turn the vertical adjusting screw

clockwise or counterclockwise until

the bubble is centered over the ª0º

mark.

U

D

U

D

Maintenance and care

195