clock Mercury Sable 1998 Owner's Manuals

[x] Cancel search | Manufacturer: MERCURY, Model Year: 1998, Model line: Sable, Model: Mercury Sable 1998Pages: 190, PDF Size: 1.29 MB

Page 118 of 190

Removing the anti-theft lug nut

1. Insert the key over the locking lug nut. Make sure

you hold the key square to the lug nut. If you hold

the key at an angle, you could damage the key and

the lug nut.

2. Place the lug nut wrench over the lug nut key and

apply pressure on the key with the wrench.

3. Turn the wrench in a counterclockwise direction

to remove the lug nut.

Reinstalling the anti-theft lug nut

1. Insert the key over the locking lug nut.

2. Place the lug nut wrench over the lug nut key and

apply pressure on the key with the wrench.

3. Install the lug nut.

Tire change procedure

1. Park on a level surface, activate hazard flashers

and set parking brake.

When one of the front wheels is off the

ground, the transaxle alone will not prevent

the vehicle from moving or slipping off the jack,

even if the vehicle is in P (Park).

To prevent the vehicle from moving when

you change a tire, be sure the parking brake

is set, then block (in both directions) the wheel

that is diagonally opposite (other side and end of

the vehicle) to the tire being changed.

Roadside emergencies

118

Page 119 of 190

If the vehicle slips off the jack, you or

someone else could be seriously injured.

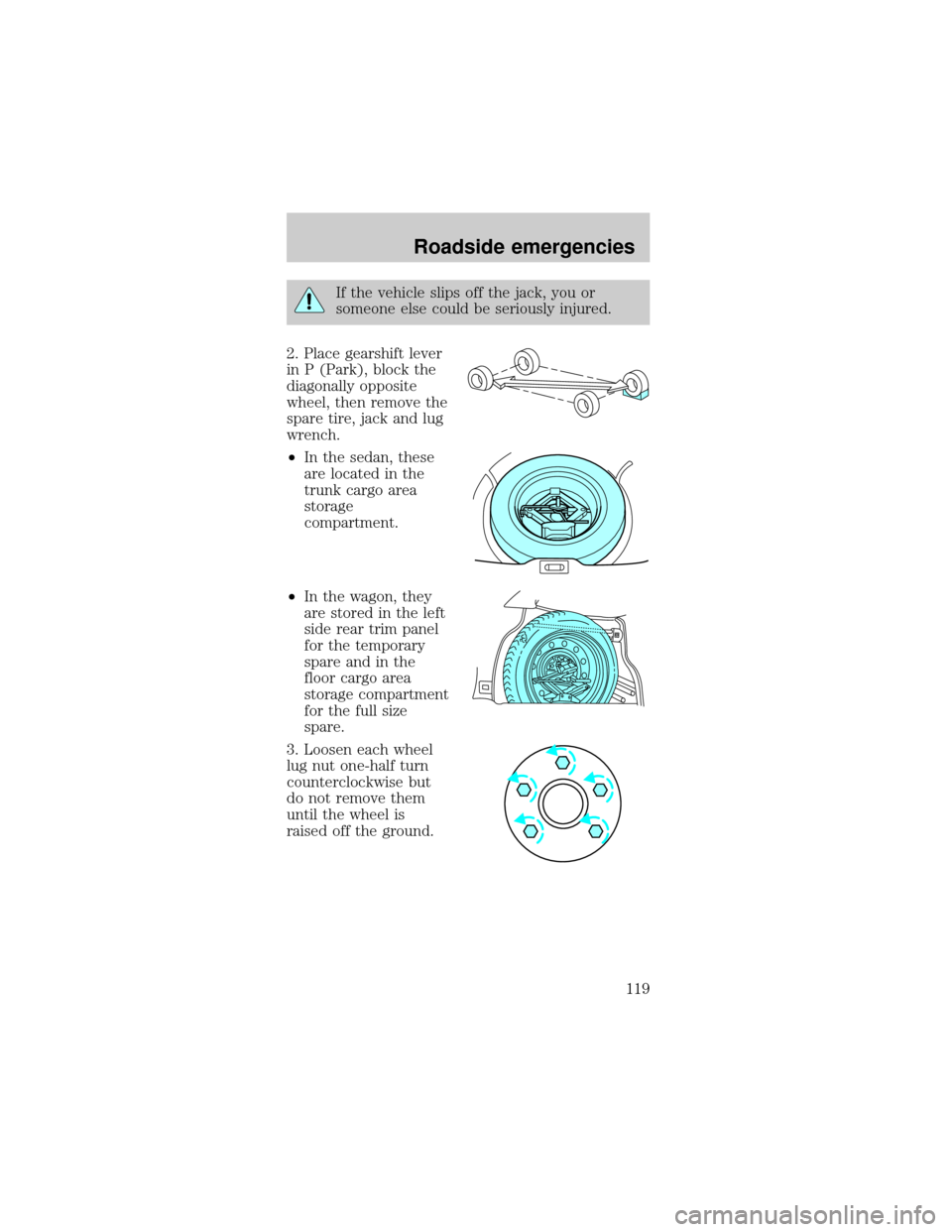

2. Place gearshift lever

in P (Park), block the

diagonally opposite

wheel, then remove the

spare tire, jack and lug

wrench.

²In the sedan, these

are located in the

trunk cargo area

storage

compartment.

²In the wagon, they

are stored in the left

side rear trim panel

for the temporary

spare and in the

floor cargo area

storage compartment

for the full size

spare.

3. Loosen each wheel

lug nut one-half turn

counterclockwise but

do not remove them

until the wheel is

raised off the ground.

Roadside emergencies

119

Page 120 of 190

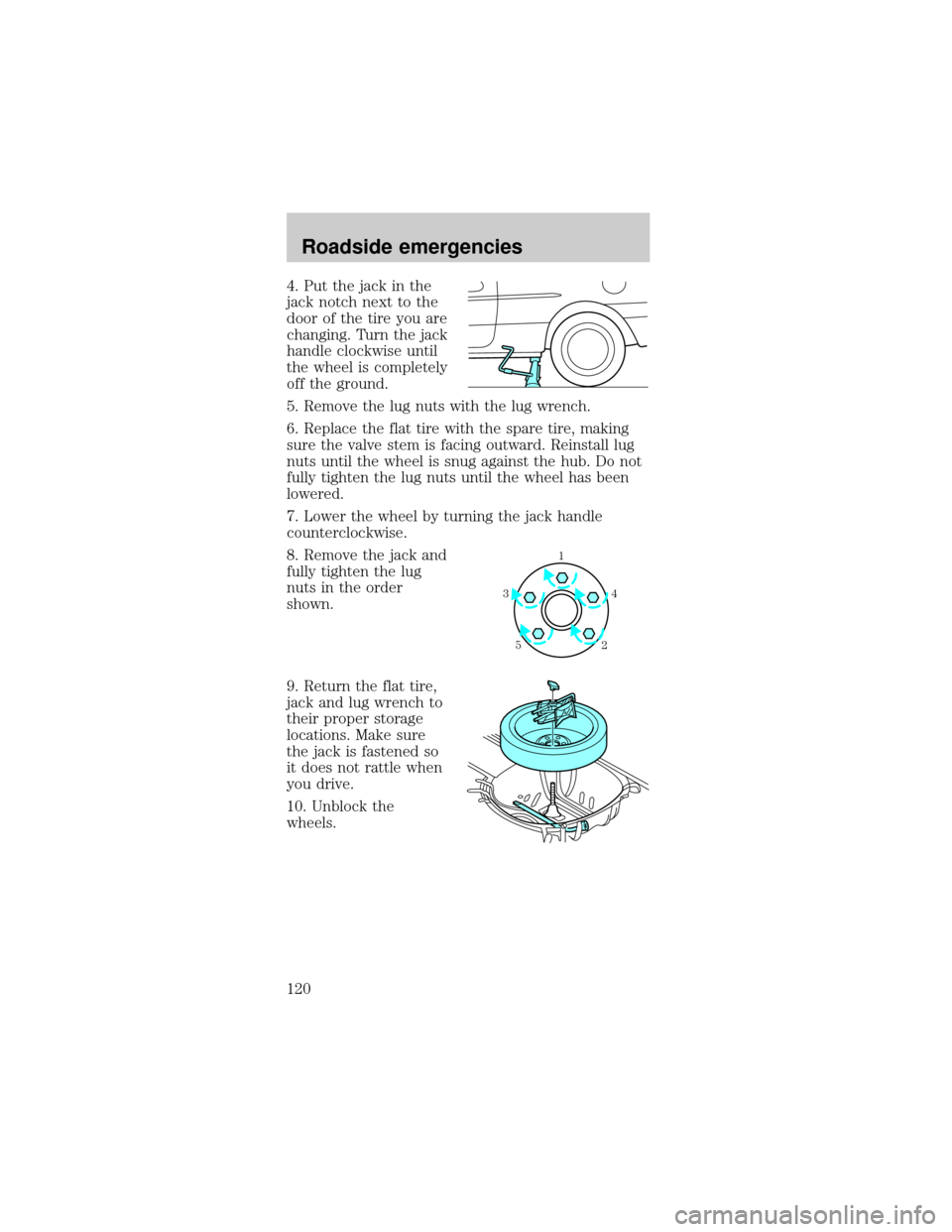

4. Put the jack in the

jack notch next to the

door of the tire you are

changing. Turn the jack

handle clockwise until

the wheel is completely

off the ground.

5. Remove the lug nuts with the lug wrench.

6. Replace the flat tire with the spare tire, making

sure the valve stem is facing outward. Reinstall lug

nuts until the wheel is snug against the hub. Do not

fully tighten the lug nuts until the wheel has been

lowered.

7. Lower the wheel by turning the jack handle

counterclockwise.

8. Remove the jack and

fully tighten the lug

nuts in the order

shown.

9. Return the flat tire,

jack and lug wrench to

their proper storage

locations. Make sure

the jack is fastened so

it does not rattle when

you drive.

10. Unblock the

wheels.

1

4 3

52

Roadside emergencies

120

Page 136 of 190

Never remove the coolant reservoir cap

while the engine is running or hot.

If you must remove the coolant reservoir cap, follow

these steps to avoid personal injury:

1. Before you remove the cap, turn the engine off

and let it cool.

2. When the engine is cool, wrap a thick cloth

around the cap. Slowly turn cap counterclockwise

until pressure begins to release.

3. Step back while the pressure releases.

4. When you are sure that all the pressure has been

released, use the cloth to turn it counterclockwise

and remove the cap.

Change your engine coolant according to the

appropriate schedule listed in the ªService Guideº.

Before adding engine coolant, check the color of the

coolant in your vehicle.

For vehicles with green coolant,use Ford

Premium Cooling System Fluid E2FZ-19549±AA (in

Canada, Motorcraft CXC-8±B) or an equivalent

premium engine coolant that meets Ford

specification ESE-M97B44±A.

Do not add orange coolant or recycled coolant

to your vehicle originally equipped with

conventional green coolant .

For vehicles with orange coolant,use Ford

Extended Life Engine Coolant F6AZ-19544±AA or a

DEX-COOLtequivalent that meets Ford

specification WSS-M97B44±D.

Do not add conventional green coolant or

recycled coolant to your vehicle originally

equipped with orange coolant.

Do not use alcohol or methanol antifreeze or any

engine coolants mixed with alcohol or methanol

antifreeze. Do not use supplemental coolant

Maintenance and care

136

Page 144 of 190

Because your vehicle's engine is electronically

controlled by a computer, some control conditions

are maintained by power from the battery. When the

battery is disconnected or a new battery is installed,

the engine must relearn its idle conditions before

your vehicle will drive properly. To begin this

process:

1. Set your parking brake.

2. Put the gearshift in P (Park), turn off all

accessories and start the engine.

3. Let the engine idle for at least one minute.

4. The relearning process will automatically

complete as you drive the vehicle.

²If you do not allow the engine to relearn its idle,

the idle quality of your vehicle may be adversely

affected until the idle is eventually relearned.

²If the battery has been disconnected or a new

battery has been installed, the clock and the

preset radio stations must be reset once the

battery is reconnected.

²Always dispose of

automotive batteries

in a responsible

manner. Follow your

local authorized

standards for

disposal. Call your

local authorized

authorized recycling center to find out more

about recycling automotive batteries.

LEAD

RETURN

RECYCLE

Maintenance and care

144

Page 155 of 190

Fuel Filler Cap

Your fuel tank filler cap has an indexed design with

a one-eighth turn on/off feature.

When fueling your vehicle:

1. Turn the engine off.

2. Carefully turn the filler cap counterclockwise 1/8

of a turn until it stops.

3. Pull to remove the cap from the fuel filler pipe.

4. To install the cap, align the tabs on the cap with

the notches on the filler pipe.

5. Turn the filler cap clockwise 1/8 of a turn until it

stops.

If the ªService Engine Soon/Check Engine ª indicator

comes on and stays on when you start the engine,

the fuel filler cap may not be properly installed.

Turn off the engine, remove the fuel filler cap and

reinstall it being careful to align the cap properly.

If you must replace the fuel filler cap, replace

it with an authorized Motorcraft part. The

customer warranty may be void for any damage

to the fuel tank or fuel system if an authorized

Motorcraft fuel filler cap is not used.

The fuel system may be under pressure. If

the fuel filler cap is venting vapor or if you

hear a hissing sound, wait until it stops before

completely removing the fuel filler cap. Otherwise,

fuel may spray out and injure you or others.

If you do not use the proper fuel filler cap,

the pressure in the fuel tank can damage

the fuel system or cause it to work improperly in a

collision.

Maintenance and care

155

Page 161 of 190

Replacing headlamp bulbs

Handle a halogen headlamp bulb carefully

and keep out of children's reach. Grasp the

bulb only by its plastic base and do not touch the

glass. The oil from your hand could cause the bulb

to break the next time the headlamps are

operated.

If the bulb is accidentally touched, it should be

cleaned with rubbing alcohol before being used.

To remove the headlamp bulb:

1. Make sure headlamp switch is in OFF position,

then open the hood. If you are replacing the driver

side headlamp, unclip the electronic module on the

right side of the battery and move it out of the way.

2. Locate the headlamp bulb through the hole in the

upper radiator support assembly.

3. Release clip and

disconnect the

electrical connector

from the bulb.

4. Remove the bulb

retaining ring by

rotating it

counterclockwise

(when viewed from the

rear) about 1/8 turn to

free it from the bulb socket, and slide the ring off

the plastic base. Keep the ring to retain the new

bulb.

5. With out turning, remove the old bulb from the

lamp assembly by gently pulling it straight out of the

lamp assembly.

Maintenance and care

161

Page 162 of 190

To install the new bulb:

1. With the flat side of

the bulb's plastic base

facing upward, insert

the glass end of the

bulb into the lamp

assembly. You may

need to turn the bulb left or right to align the

grooves in the plastic base with the tabs in the lamp

assembly. When the grooves are aligned, push the

bulb into the lamp assembly until the plastic base

contacts the rear of the lamp assembly.

2. Install the bulb retaining ring over the plastic base

until it contacts the rear of the socket by rotating

clockwise until you feel a ªstop.º

3. Install the electrical connector into the rear of the

plastic base until it snaps, locking it into position.

4. Turn the headlamps on and make sure they work

properly. If the headlamp was correctly aligned

before you changed the bulb, you should not need to

align it again.

High-mount brakelamp bulbs

The following

procedure is for sedans

only. For wagon, refer

to a qualified

technician.

1. Open trunk.

2. Inside trunk, locate

access hole under the

rear window

3. Remove the bulb

socket by rotating it 45 degrees and pulling it out of

the lamp assembly.

4. Carefully pull bulb straight out of socket and push

in new bulb.

5. To complete installation, follow the removal

procedure in reverse order.

Maintenance and care

162

Page 163 of 190

License plate lamp bulbs

To change the license plate bulbs:

Sedan

1. Remove two screws

and the license plate

lamp assembly from

the rear bumper.

2. Remove bulb socket

by turning

counterclockwise .

3. Carefully pull the

bulb out from the

socket and push in the

new bulb.

4. Install the lamp assembly on rear bumper with

two screws.

Wagon

1. Remove screw and

the license plate lamp

assembly from liftgate.

2. Remove bulb socket

by turning

counterclockwise .

3. Carefully pull the

bulb out from the

socket and push in the

new bulb.

4. Install the lamp assembly on liftgate with screw.

Replacing front parking lamp/turn signal bulbs

For bulb replacement, see a dealer or qualified

technician.

Replacing tail lamp/backup bulbs

For bulb replacement, see a dealer or qualified

technician.

Maintenance and care

163

Page 166 of 190

3. Turn the horizontal

adjusting screw in the

direction of the arrow

to change the

horizontal aim as

shown.

4.Usea7mmwrench

or socket to turn the

horizontal adjusting screw until the ª0º reference

mark on the view dial is aligned with the rearward

facing tab (as shown) on the plastic housing.

Vertical aim adjustment

1. Park the vehicle on a level surface.

2. With the hood open,

locate the bubble level

vertical aim indicator.

It is visible when

viewed from above

center rear of the

headlamp. Locate the

vertical adjusting

screw, located on the

outboard side of the headlamp adjacent to the

headlamp upper outboard attachment.

3. The ªUPº and ªDNº on the bubble label indicate

the directional change (up or down) of the vertical

aim.

4.Usea7mmwrench or socket to turn the vertical

adjusting screw clockwise or counterclockwise until

the bubble aligns with the ª0º reference mark on the

vertical indicator when viewed directly from above.

Repeat the above procedures to the other headlamp,

if necessary.

Maintenance and care

166