Mercury Villager 2000 Owner's Manuals

Manufacturer: MERCURY, Model Year: 2000, Model line: Villager, Model: Mercury Villager 2000Pages: 256, PDF Size: 2.21 MB

Page 181 of 256

Do not push start your vehicle. You could damage the catalytic

converter.

Batteries contain sulfuric acid which can burn skin, eyes, and

clothing, if contacted.

Do not attempt to push start your vehicle. Automatic

transmissions do not have push-start capability.

Preparing your vehicle

1.Use only a 12±volt supply to start your vehicle.

2. Do not disconnect the battery of the disabled vehicle as this could

damage the vehicle's electrical system.

3. Park the booster vehicle close to the hood of the disabled vehicle

making sure the two vehiclesdo nottouch. Set the parking brake on

both vehicles and stay clear of the engine cooling fan and other moving

parts.

4. Check all battery terminals and remove any excessive corrosion before

you attach the battery cables. Ensure that vent caps are tight and level.

5. Turn the heater fan on in both vehicles to protect any electrical

surges. Turn all other accessories off.

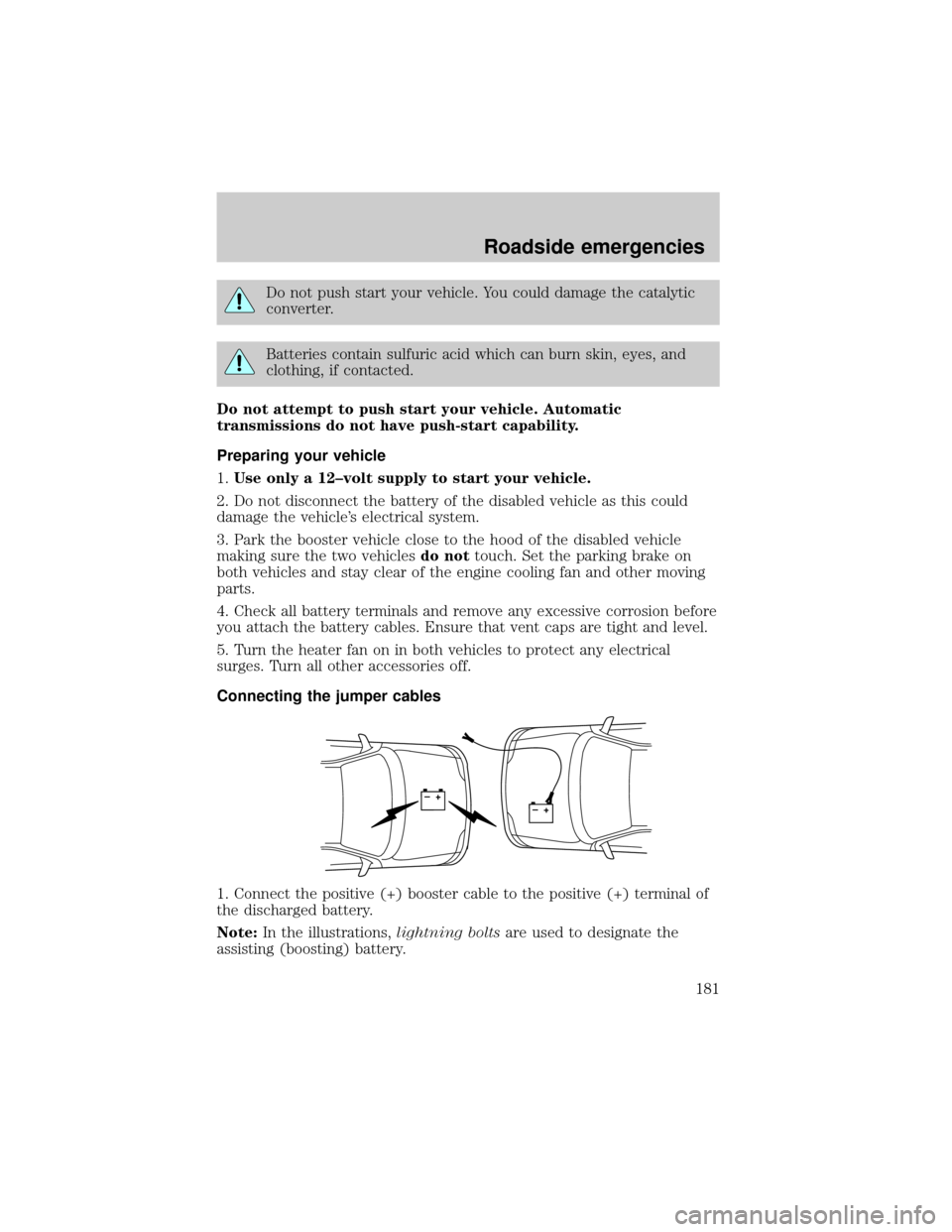

Connecting the jumper cables

1. Connect the positive (+) booster cable to the positive (+) terminal of

the discharged battery.

Note:In the illustrations,lightning boltsare used to designate the

assisting (boosting) battery.

+–+–

Roadside emergencies

181

Page 182 of 256

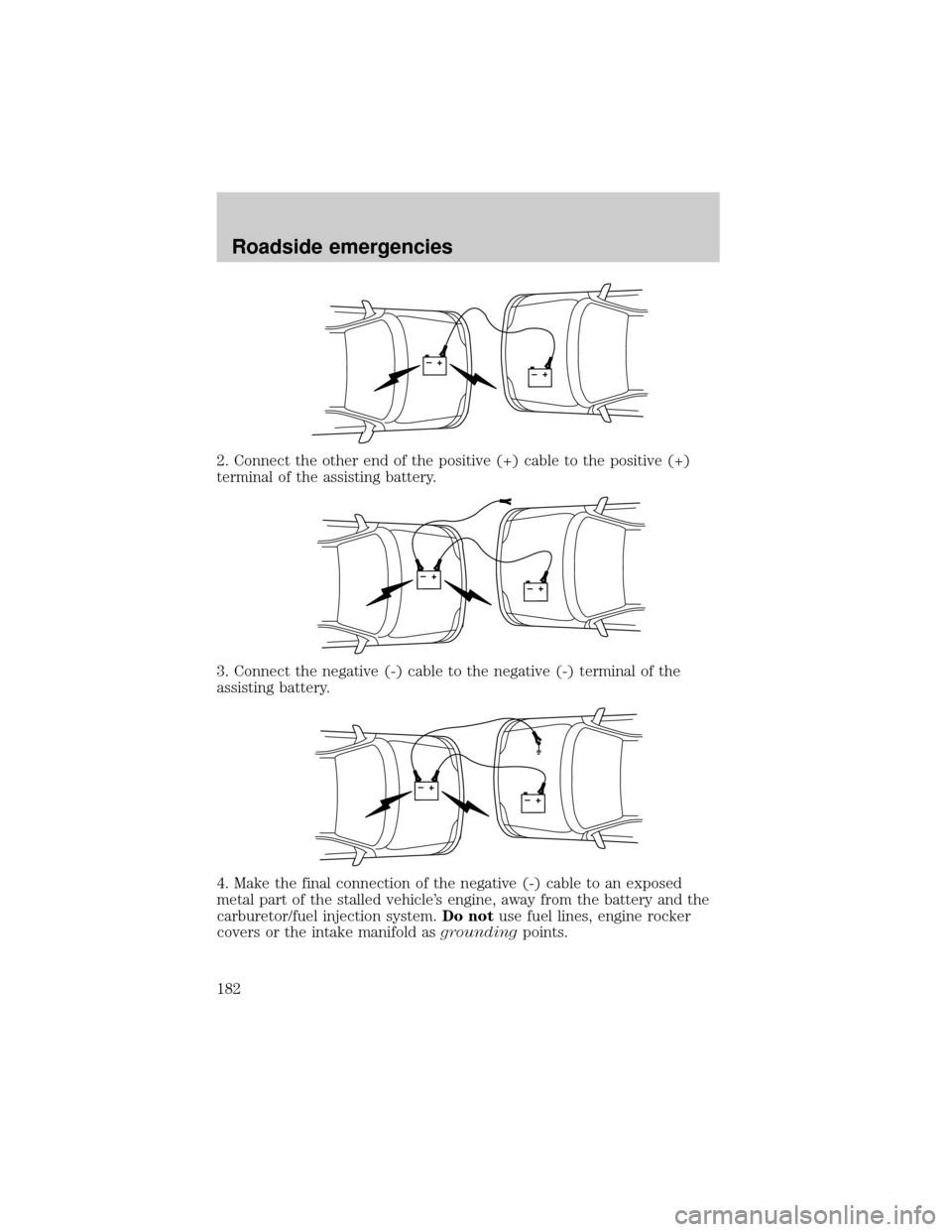

2. Connect the other end of the positive (+) cable to the positive (+)

terminal of the assisting battery.

3. Connect the negative (-) cable to the negative (-) terminal of the

assisting battery.

4. Make the final connection of the negative (-) cable to an exposed

metal part of the stalled vehicle's engine, away from the battery and the

carburetor/fuel injection system.Do notuse fuel lines, engine rocker

covers or the intake manifold asgroundingpoints.

+–+–

+–+–

+–+–

Roadside emergencies

182

Page 183 of 256

Do not connect the end of the second cable to the negative (-)

terminal of the battery to be jumped. A spark may cause an

explosion of the gases that surround the battery.

5. Ensure that the cables are clear of fan blades, belts, moving parts of

both engines, or any fuel delivery system parts.

Jump starting

1. Start the engine of the booster vehicle and run the engine at

moderately increased speed.

2. Start the engine of the disabled vehicle.

3. Once the disabled vehicle has been started, run both engines for an

additional three minutes before disconnecting the jumper cables.

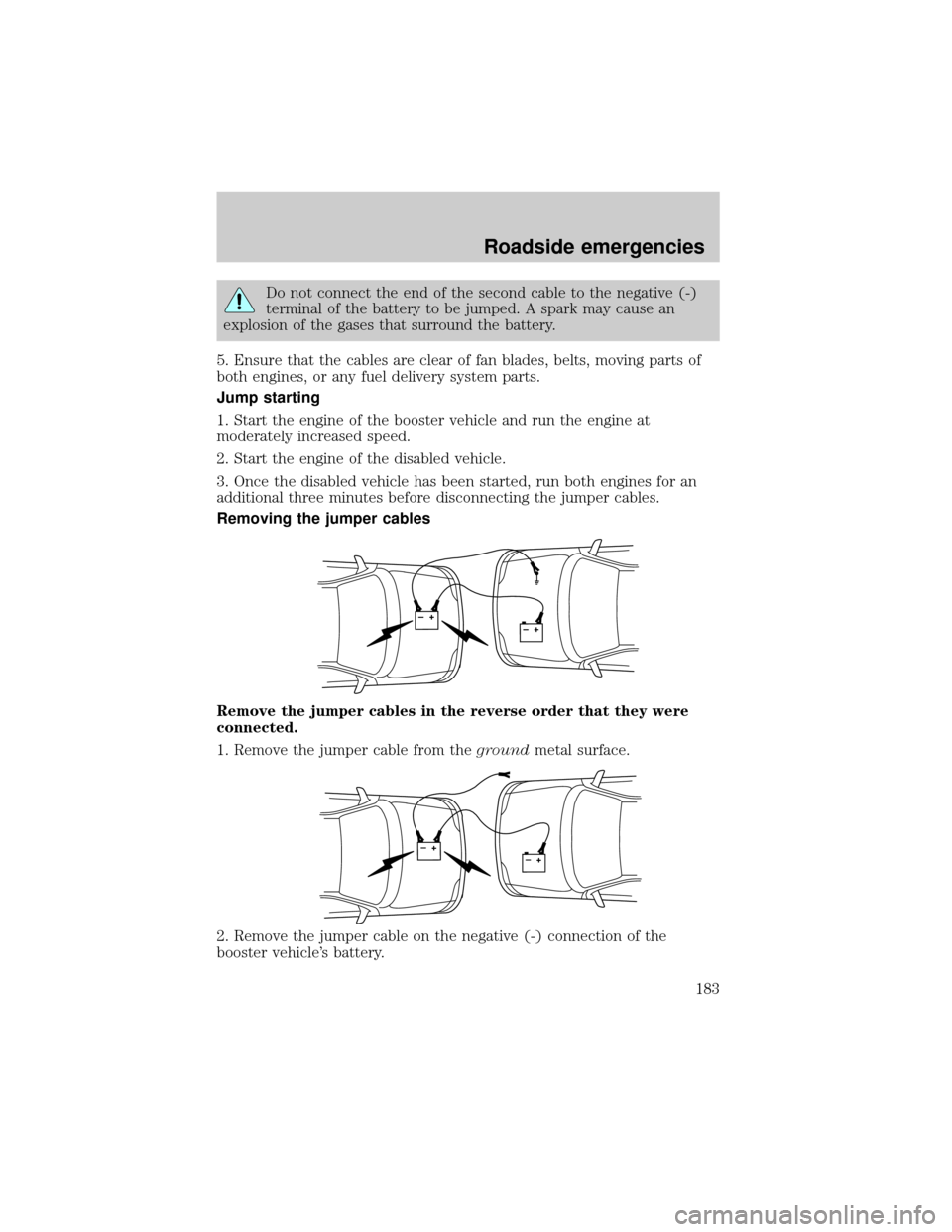

Removing the jumper cables

Remove the jumper cables in the reverse order that they were

connected.

1. Remove the jumper cable from thegroundmetal surface.

2. Remove the jumper cable on the negative (-) connection of the

booster vehicle's battery.

+–+–

+–+–

Roadside emergencies

183

Page 184 of 256

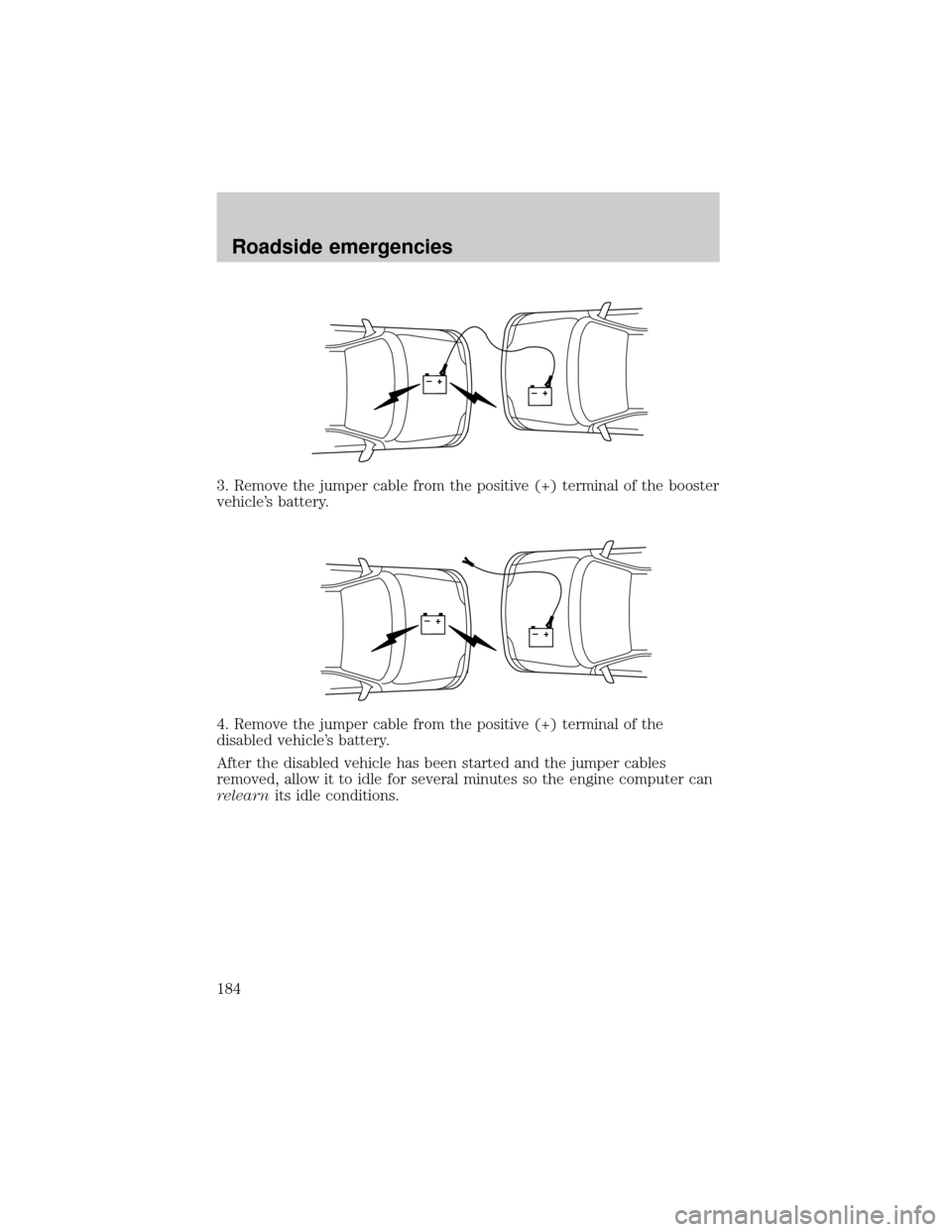

3. Remove the jumper cable from the positive (+) terminal of the booster

vehicle's battery.

4. Remove the jumper cable from the positive (+) terminal of the

disabled vehicle's battery.

After the disabled vehicle has been started and the jumper cables

removed, allow it to idle for several minutes so the engine computer can

relearnits idle conditions.

+–+–

+–+–

Roadside emergencies

184

Page 185 of 256

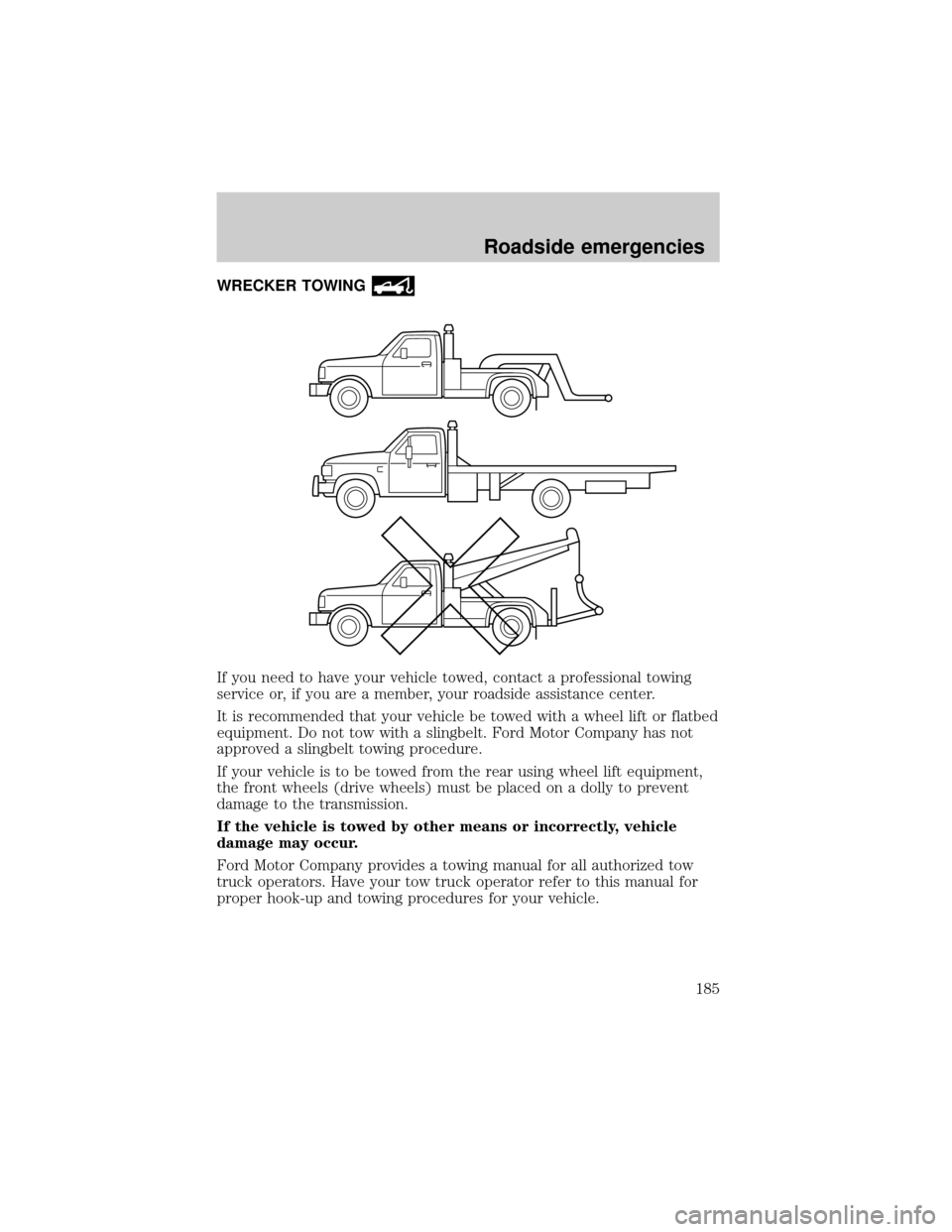

WRECKER TOWING

If you need to have your vehicle towed, contact a professional towing

service or, if you are a member, your roadside assistance center.

It is recommended that your vehicle be towed with a wheel lift or flatbed

equipment. Do not tow with a slingbelt. Ford Motor Company has not

approved a slingbelt towing procedure.

If your vehicle is to be towed from the rear using wheel lift equipment,

the front wheels (drive wheels) must be placed on a dolly to prevent

damage to the transmission.

If the vehicle is towed by other means or incorrectly, vehicle

damage may occur.

Ford Motor Company provides a towing manual for all authorized tow

truck operators. Have your tow truck operator refer to this manual for

proper hook-up and towing procedures for your vehicle.

Roadside emergencies

185

Page 186 of 256

SERVICE RECOMMENDATIONS

To help you service your vehicle:

²We highlight do-it-yourself items in the engine compartment for easy

location.

²We provide a Scheduled Maintenance Guide which makes tracking

routine service easy.

If your vehicle requires professional service, your dealership can provide

necessary parts and service. Check your ªWarranty Guideº to find out

which parts and services are covered.

Use only recommended fuels, lubricants, fluids and service parts

conforming to specifications. Motorcraft parts are designed and built to

provide the best performance in your vehicle.

PRECAUTIONS WHEN SERVICING YOUR VEHICLE

Be especially careful when inspecting or servicing your vehicle.

²Do not work on a hot engine.

²When the engine is running, make sure that loose clothing, jewelry or

long hair does not get caught up in moving parts.

²Do not work on a vehicle with the engine running in an enclosed

space, unless you are sure you have enough ventilation.

²Keep all lit cigarettes, open flames and other lit material away from

the battery and all fuel related parts.

If you disconnect the battery, the engine must ªrelearnº its idle

conditions before your vehicle will drive properly, as explained inBattery

in this chapter.

Working with the engine off

1. Set the parking brake and ensure the gearshift is securely latched in P

(Park).

2. Turn off the engine and remove the key.

3. Block the wheels to prevent the vehicle from moving unexpectedly.

Working with the engine on

1. Set the parking brake and ensure the gearshift is securely latched in P

(Park).

2. Block the wheels to prevent the vehicle from moving unexpectedly.

Maintenance and care

186

Page 187 of 256

Do not start your engine with the air cleaner removed and do

not remove it while the engine is running.

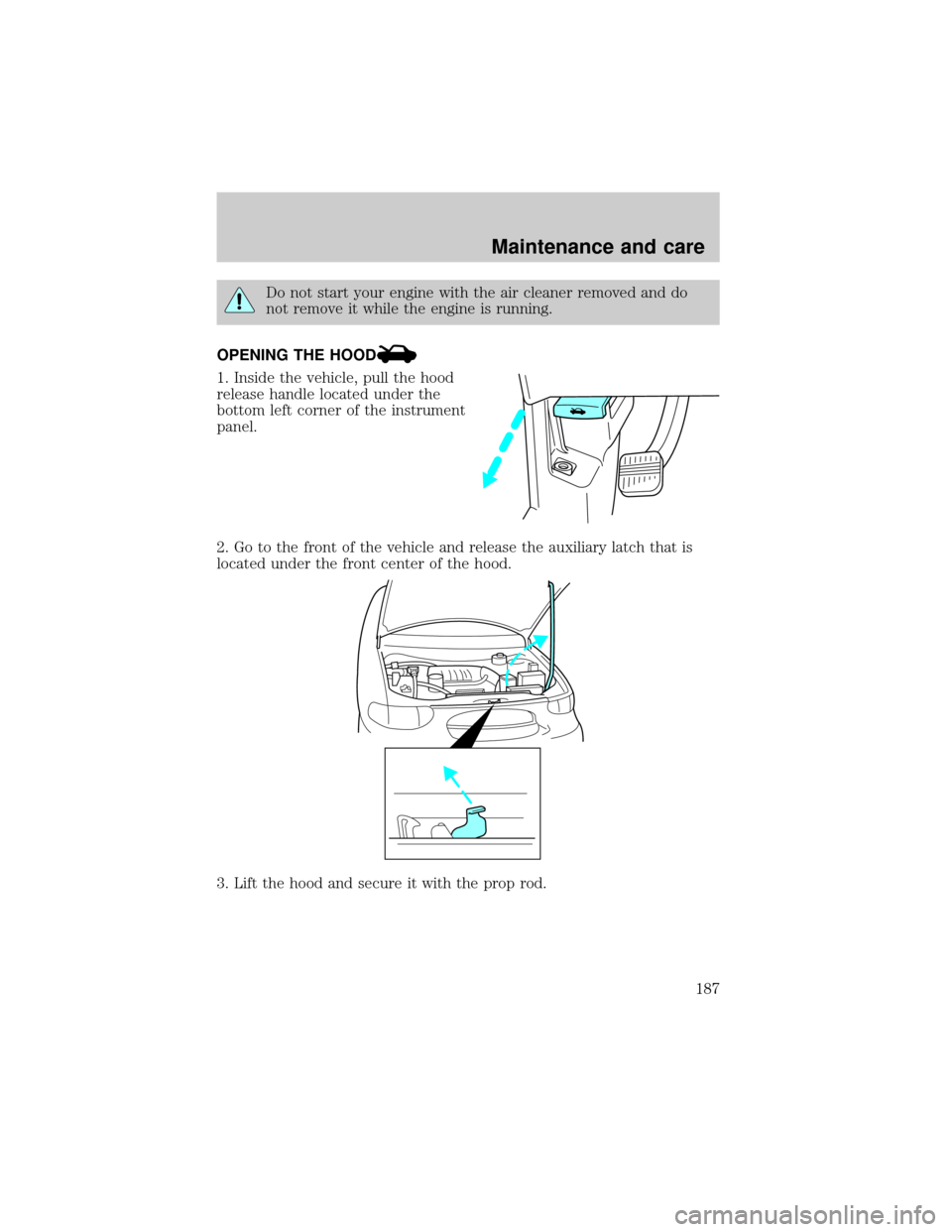

OPENING THE HOOD

1. Inside the vehicle, pull the hood

release handle located under the

bottom left corner of the instrument

panel.

2. Go to the front of the vehicle and release the auxiliary latch that is

located under the front center of the hood.

3. Lift the hood and secure it with the prop rod.

Maintenance and care

187

Page 188 of 256

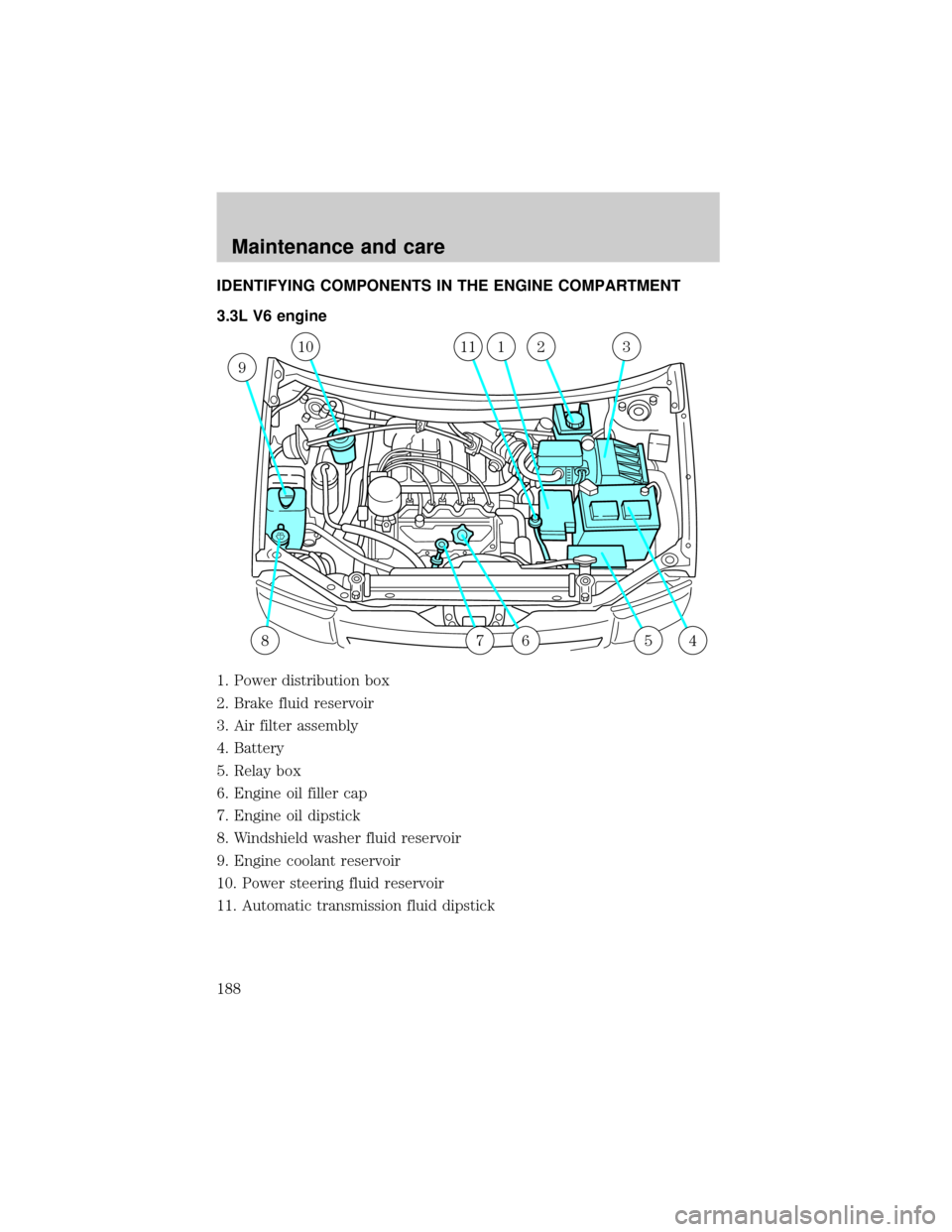

IDENTIFYING COMPONENTS IN THE ENGINE COMPARTMENT

3.3L V6 engine

1. Power distribution box

2. Brake fluid reservoir

3. Air filter assembly

4. Battery

5. Relay box

6. Engine oil filler cap

7. Engine oil dipstick

8. Windshield washer fluid reservoir

9. Engine coolant reservoir

10. Power steering fluid reservoir

11. Automatic transmission fluid dipstick

9

45678

1011123

Maintenance and care

188

Page 189 of 256

ENGINE OIL

Checking the engine oil

Refer to the Scheduled Maintenance Guide for the appropriate intervals

for checking the engine oil.

1. Make sure the vehicle is on level ground.

2. Turn the engine off and wait a few minutes for the oil to drain into the

oil pan.

3. Set the parking brake and ensure the gearshift is securely latched in P.

4. Open the hood. Protect yourself from engine heat.

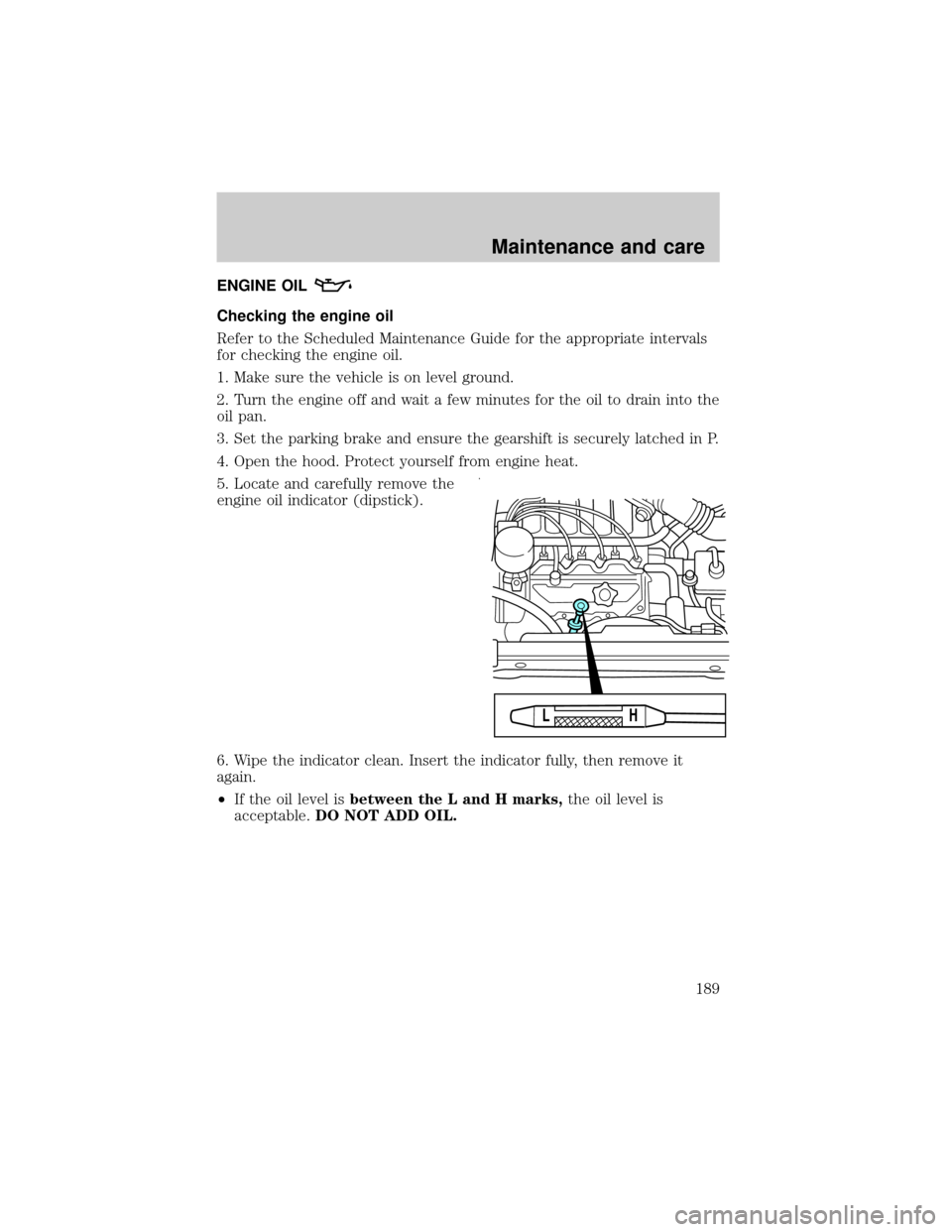

5. Locate and carefully remove the

engine oil indicator (dipstick).

6. Wipe the indicator clean. Insert the indicator fully, then remove it

again.

²If the oil level isbetween the L and H marks,the oil level is

acceptable.DO NOT ADD OIL.

LH

Maintenance and care

189

Page 190 of 256

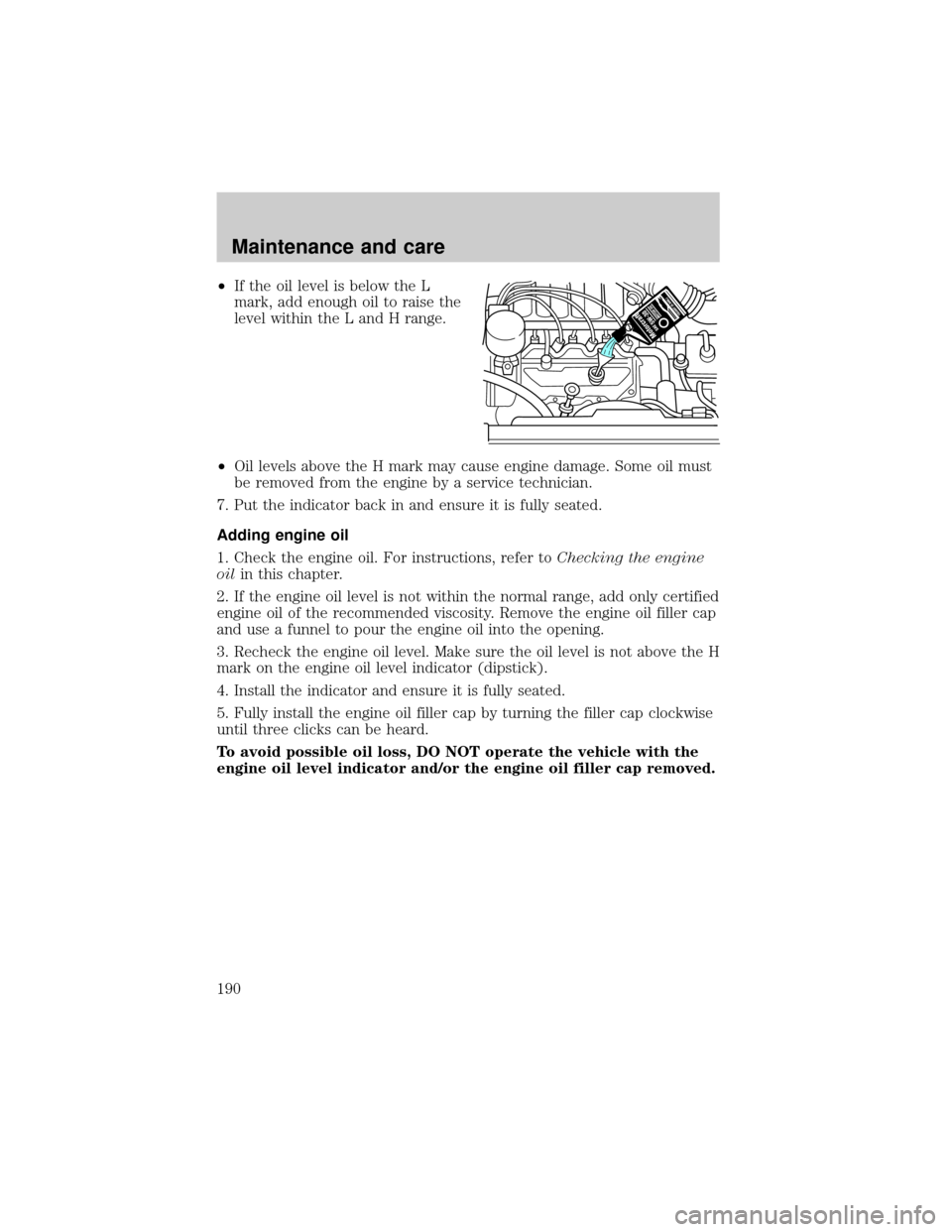

²If the oil level is below the L

mark, add enough oil to raise the

level within the L and H range.

²Oil levels above the H mark may cause engine damage. Some oil must

be removed from the engine by a service technician.

7. Put the indicator back in and ensure it is fully seated.

Adding engine oil

1. Check the engine oil. For instructions, refer toChecking the engine

oilin this chapter.

2. If the engine oil level is not within the normal range, add only certified

engine oil of the recommended viscosity. Remove the engine oil filler cap

and use a funnel to pour the engine oil into the opening.

3. Recheck the engine oil level. Make sure the oil level is not above the H

mark on the engine oil level indicator (dipstick).

4. Install the indicator and ensure it is fully seated.

5. Fully install the engine oil filler cap by turning the filler cap clockwise

until three clicks can be heard.

To avoid possible oil loss, DO NOT operate the vehicle with the

engine oil level indicator and/or the engine oil filler cap removed.

Maintenance and care

190