tow MINI 3 door 2013 Owner's Guide

[x] Cancel search | Manufacturer: MINI, Model Year: 2013, Model line: 3 door, Model: MINI 3 door 2013Pages: 233, PDF Size: 17.19 MB

Page 174 of 233

100. The relative performance of tires depends

upon the actual conditions of their use, how‐

ever, and may depart significantly from the

norm due to variations in driving habits, service

practices and differences in road characteristics

and climate.

Traction The traction grades, from highest to lowest, are

AA, A, B, and C.

Those grades represent the tire's ability to stop

on wet pavement as measured under control‐

led conditions on specified government test

surfaces of asphalt and concrete. A tire marked

C may have poor traction performance.

The traction grade assigned to this tire is based

on straight-ahead braking traction tests, and

does not include acceleration, cornering, hy‐

droplaning, or peak traction characteristics.

Temperature The temperature grades are A, the highest, B,

and C, representing the tire's resistance to the

generation of heat and its ability to dissipate

heat when tested under controlled conditions

on a specified indoor laboratory test wheel.

Sustained high temperature can cause the ma‐

terial of the tire to degenerate and reduce tire

life, and excessive temperature can lead to

sudden tire failure. The grade C corresponds to

a level of performance which all passenger car

tires must meet under the Federal Motor Vehi‐

cle Safety Standard No. 109. Grades Band A

represent higher levels of performance on the

laboratory test wheel than the minimum re‐

quired by law.

Temperature grade for this tire

The temperature grade for this tire is es‐

tablished for a tire that is properly inflated and

not overloaded. Excessive speed, underinfla‐

tion, or excessive loading, either separately or

in combination, can cause heat buildup and

possible tire failure.

If necessary, have the vehicle towed. ◀RSC – Run-flat tires

Run-flat tires, refer to page 173, are labeled

with a circular symbol containing the letters

RSC marked on the sidewall.

M+S Winter and all-season tires with better cold

weather performance than summer tires.

Tire tread Summer tires

Do not drive with a tire tread depth of less than

0.12 in/3 mm.

There is an increased danger of hydroplaning if

the tread depth is less than 0.12 in/3 mm.

Winter tires Do not drive with a tire tread depth of less than

0.16 in/4 mm.

Below a tread depth of 0.16 in/4 mm, tires are

less suitable for winter operation.

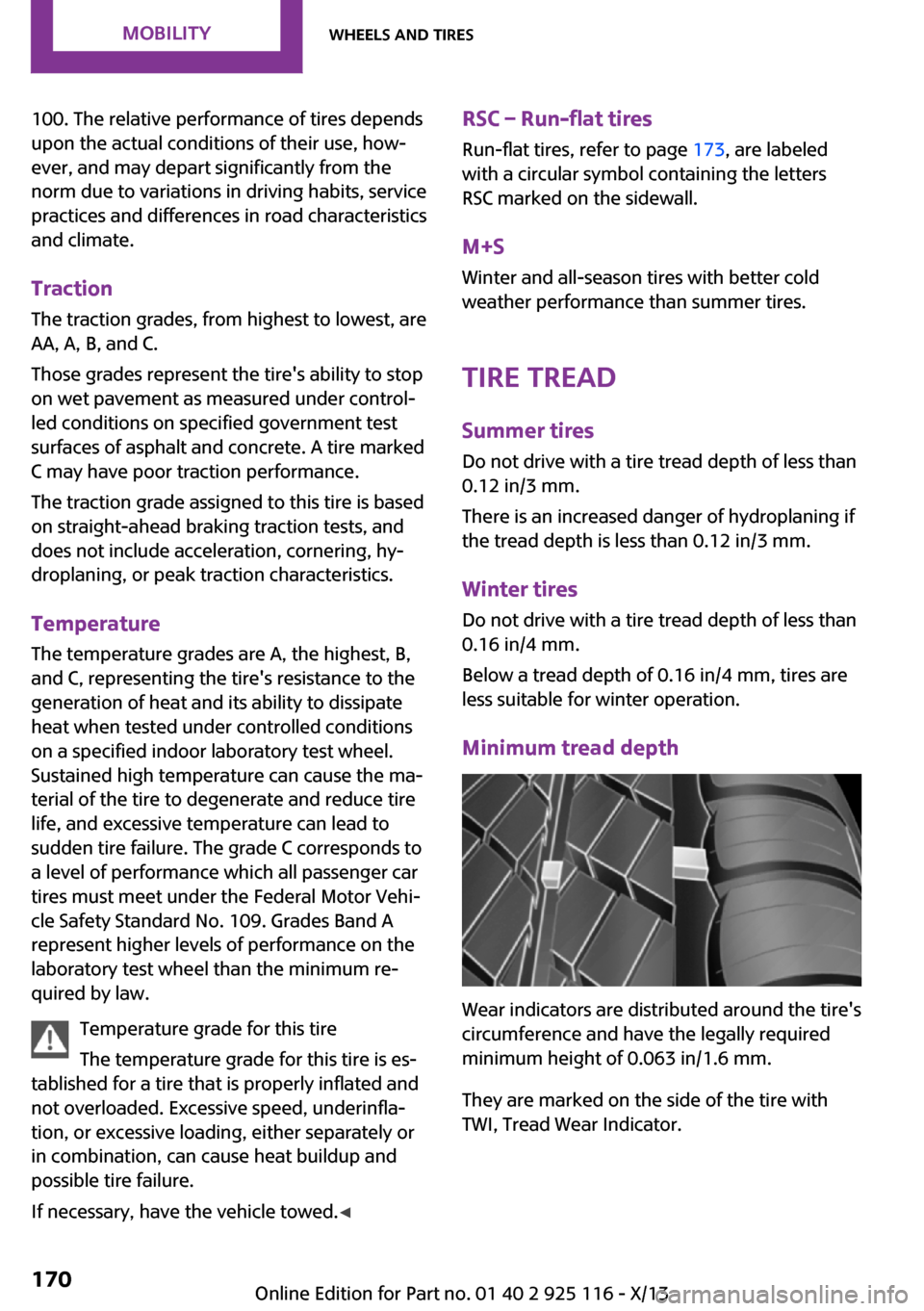

Minimum tread depth

Wear indicators are distributed around the tire's

circumference and have the legally required

minimum height of 0.063 in/1.6 mm.

They are marked on the side of the tire with

TWI, Tread Wear Indicator.

Seite 170MobilityWheels and tires170

Online Edition for Part no. 01 40 2 925 116 - X/13

Page 175 of 233

Tire damage

General information Inspect your tires often for damage, foreign ob‐

jects lodged in the tread, and tread wear.

Hints

Driving over rough or damaged road surfaces,

as well as debris, curbs and other obstacles can

cause serious damage to wheels, tires and sus‐

pension parts. This is more likely to occur with

low-profile tires, which provide less cushioning

between the wheel and the road. Be careful to

avoid road hazards and reduce your speed, es‐

pecially if your vehicle is equipped with low-

profile tires.

Indications of tire damage or other vehicle de‐

fects:▷Unusual vibrations during driving.▷Unusual handling such as a strong ten‐

dency to pull to the left or right.

Damage can, e. g., be caused by driving over

curbs, road damage, or similar things.

In case of tire damage

If there are indications of tire damage, re‐

duce your speed immediately and have the

wheels and tires checked right away; other‐

wise, there is the increased risk of an accident.

Drive carefully to the nearest service center.

Have the vehicle towed or transported there.

Otherwise, tire damage can become life threat‐

ening for vehicle occupants and also other road

users. ◀

Repair of tire damage

For safety reasons, the manufacturer of

your vehicle recommends that you do not have

damaged tires repaired; they should be re‐

placed. Otherwise, damage can occur as a re‐

sult. ◀

Changing wheels and

tires

Mounting Information on mounting tires

Have mounting and balancing performed

only by a service center.

If this work is not carried out properly, there is

the danger of subsequent damage and related

safety hazards. ◀

Wheel and tire combination Information on the correct wheel-tire combina‐

tion and rim versions for your vehicle can be

obtained from your service center.

Incorrect wheel and tire combinations impair

the function of a variety of systems such as ABS

or DSC.

To maintain good handling and vehicle re‐

sponse, use only tires with a single tread con‐

figuration from a single manufacturer.

Following tire damage, have the original wheel

and tire combination remounted on the vehicle

as soon as possible.

Approved wheels and tires

The manufacturer of your vehicle recom‐

mends that you use only wheels and tires that

have been approved for your particular vehicle

model.

For example, despite having the same official

size ratings, variations can lead to body contact

and with it, the risk of severe accidents.

The manufacturer of your vehicle cannot evalu‐

ate non-approved wheels and tires to deter‐

mine if they are suited for use, and therefore

cannot ensure the operating safety of the vehi‐

cle if they are mounted. ◀Seite 171Wheels and tiresMobility171

Online Edition for Part no. 01 40 2 925 116 - X/13

Page 178 of 233

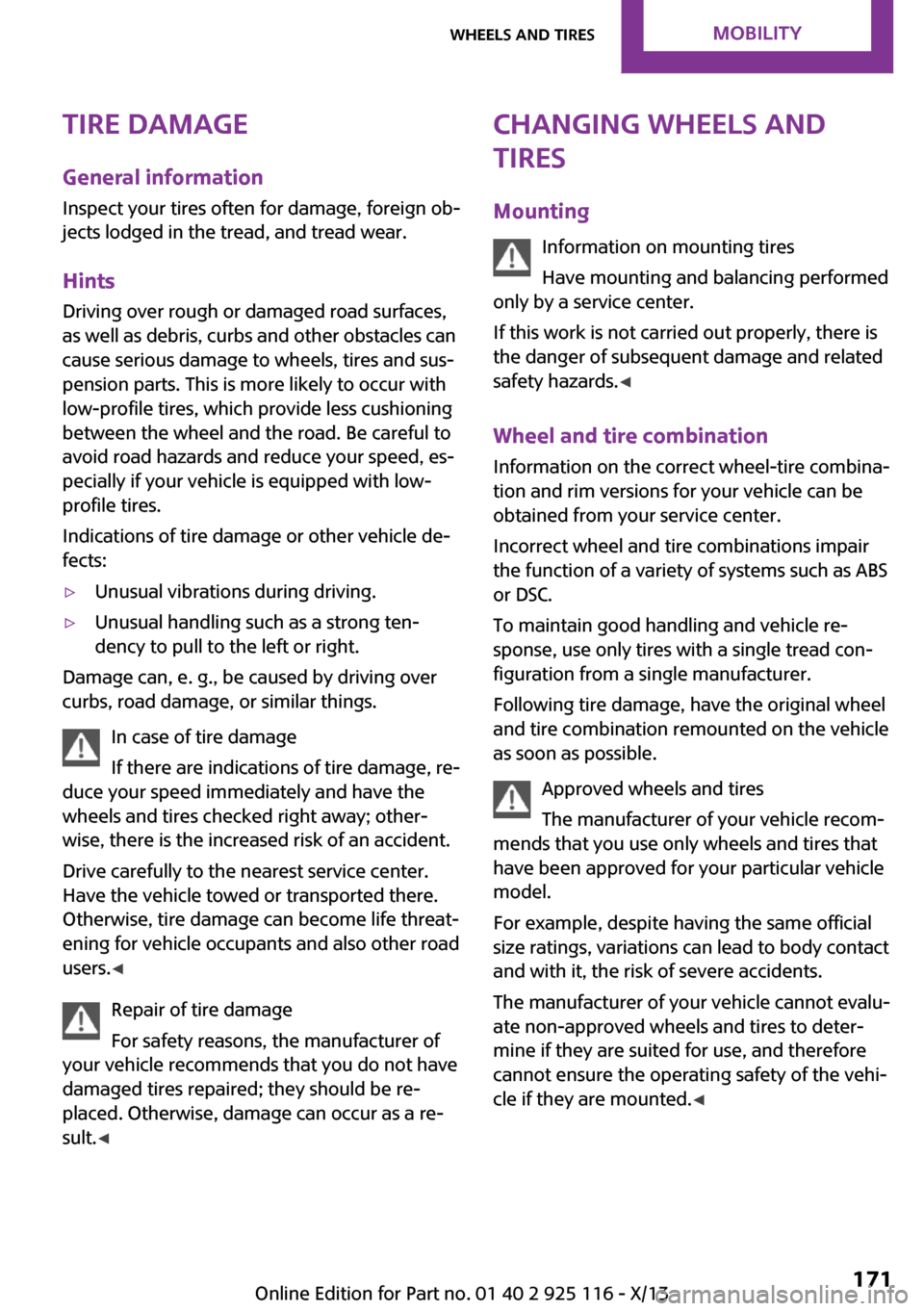

Sealant bottle▷Sealant bottle, arrow 1.▷Filling hose, arrow 2.

Note the use-by date on the sealant bottle.

Compressor

1On/off switch2Holder for bottle3Reduce inflation pressure4Inflation pressure dial5Compressor6Connector/cable for socket7Connection hose — stowed in the bottom

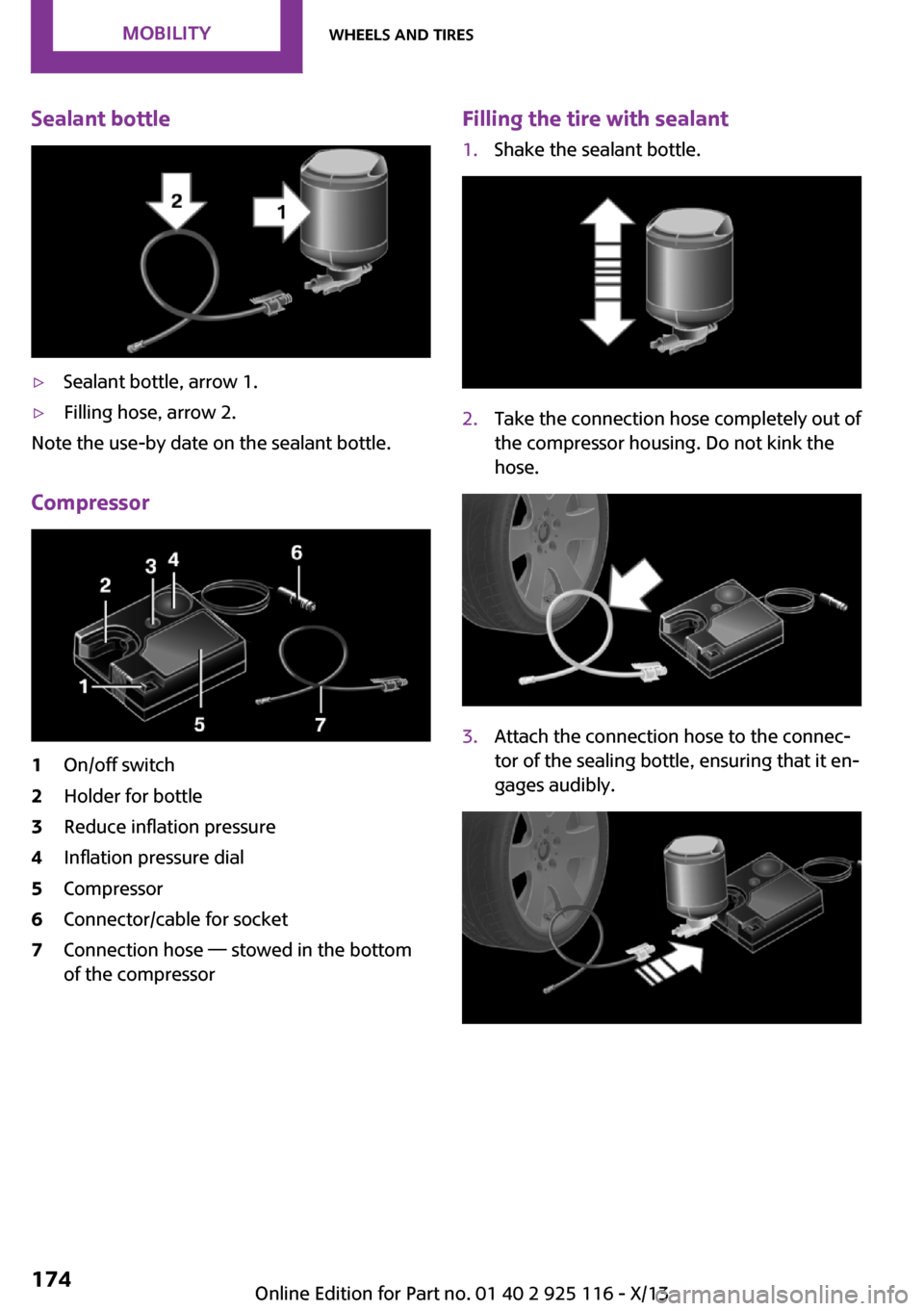

of the compressorFilling the tire with sealant1.Shake the sealant bottle.2.Take the connection hose completely out of

the compressor housing. Do not kink the

hose.3.Attach the connection hose to the connec‐

tor of the sealing bottle, ensuring that it en‐

gages audibly.Seite 174MobilityWheels and tires174

Online Edition for Part no. 01 40 2 925 116 - X/13

Page 180 of 233

Stowing the Mobility System1.Disconnect the connection hose of the seal‐

ant bottle from the wheel.2.Disconnect the connection hose from the

sealant bottle.3.Wrap the empty sealant bottle and connec‐

tion hose in suitable material to avoid dirty‐

ing the cargo area.4.Stow the Mobility System back in the vehi‐

cle.

Distributing the sealant

Immediately drive to ensure that the sealant is

evenly distributed in the tire.

Do not exceed a speed of .

Do not drop below if possible.

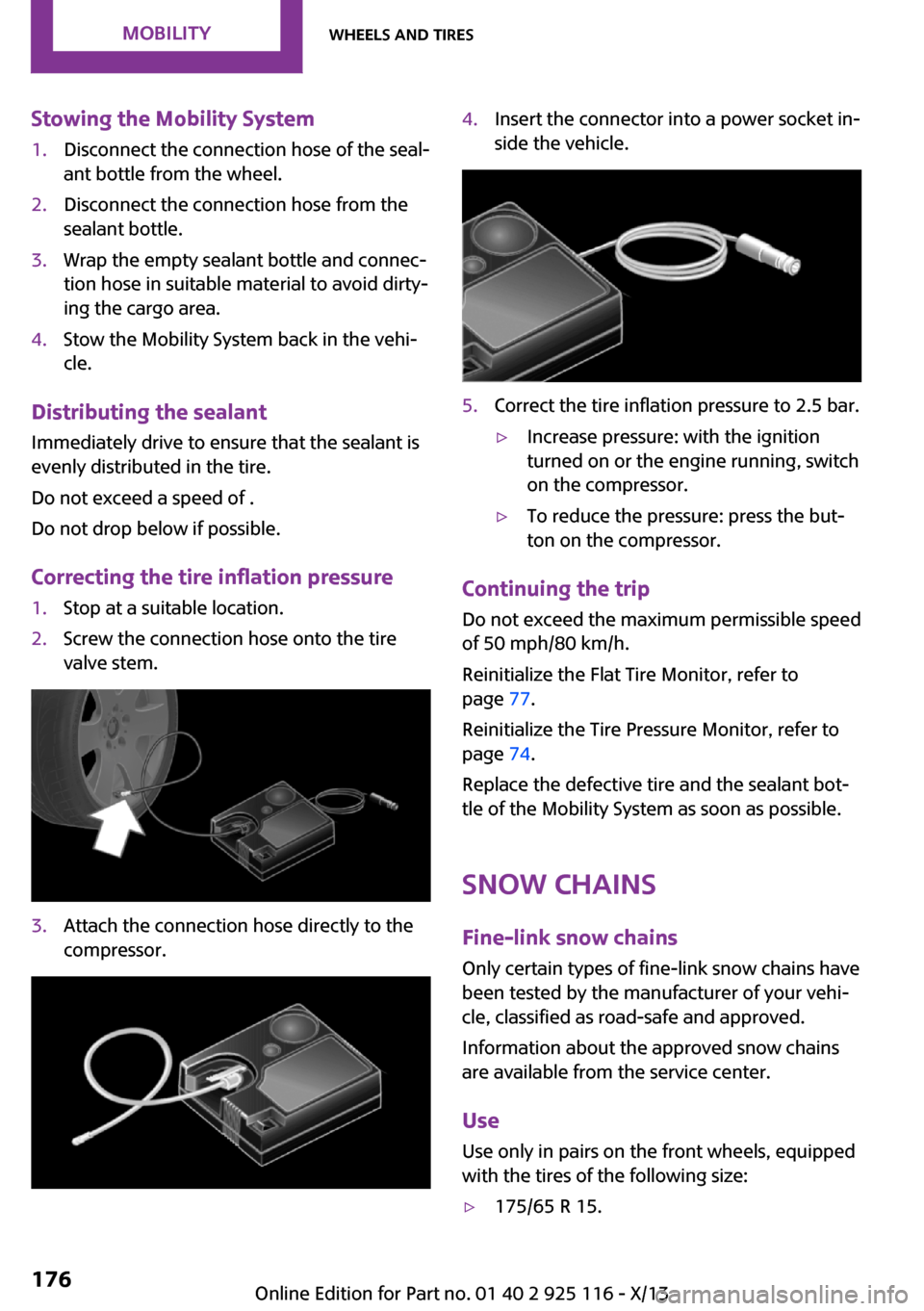

Correcting the tire inflation pressure

1.Stop at a suitable location.2.Screw the connection hose onto the tire

valve stem.3.Attach the connection hose directly to the

compressor.4.Insert the connector into a power socket in‐

side the vehicle.5.Correct the tire inflation pressure to 2.5 bar.▷Increase pressure: with the ignition

turned on or the engine running, switch

on the compressor.▷To reduce the pressure: press the but‐

ton on the compressor.

Continuing the trip

Do not exceed the maximum permissible speed

of 50 mph/80 km/h.

Reinitialize the Flat Tire Monitor, refer to

page 77.

Reinitialize the Tire Pressure Monitor, refer to

page 74.

Replace the defective tire and the sealant bot‐

tle of the Mobility System as soon as possible.

Snow chains

Fine-link snow chains Only certain types of fine-link snow chains have

been tested by the manufacturer of your vehi‐

cle, classified as road-safe and approved.

Information about the approved snow chains

are available from the service center.

Use

Use only in pairs on the front wheels, equipped

with the tires of the following size:

▷175/65 R 15.Seite 176MobilityWheels and tires176

Online Edition for Part no. 01 40 2 925 116 - X/13

Page 199 of 233

5.Unscrewing the wheel wrench6.Pull out the well with compact wheel under

the vehicle toward the rear.7.Remove the spacer and compact wheel of

the well.8.Stow the well and spacer in the vehicle.

Prepare wheel change

1.Follow the Safety instructions, refer to

page 194.2.With the wheel chock from the wheel

change set, also secure the vehicle against

rolling away at the front wheel of the oppo‐

site side.3.Loosen the wheel lug bolts a half turn.

Lug bolt lock, refer to page 196

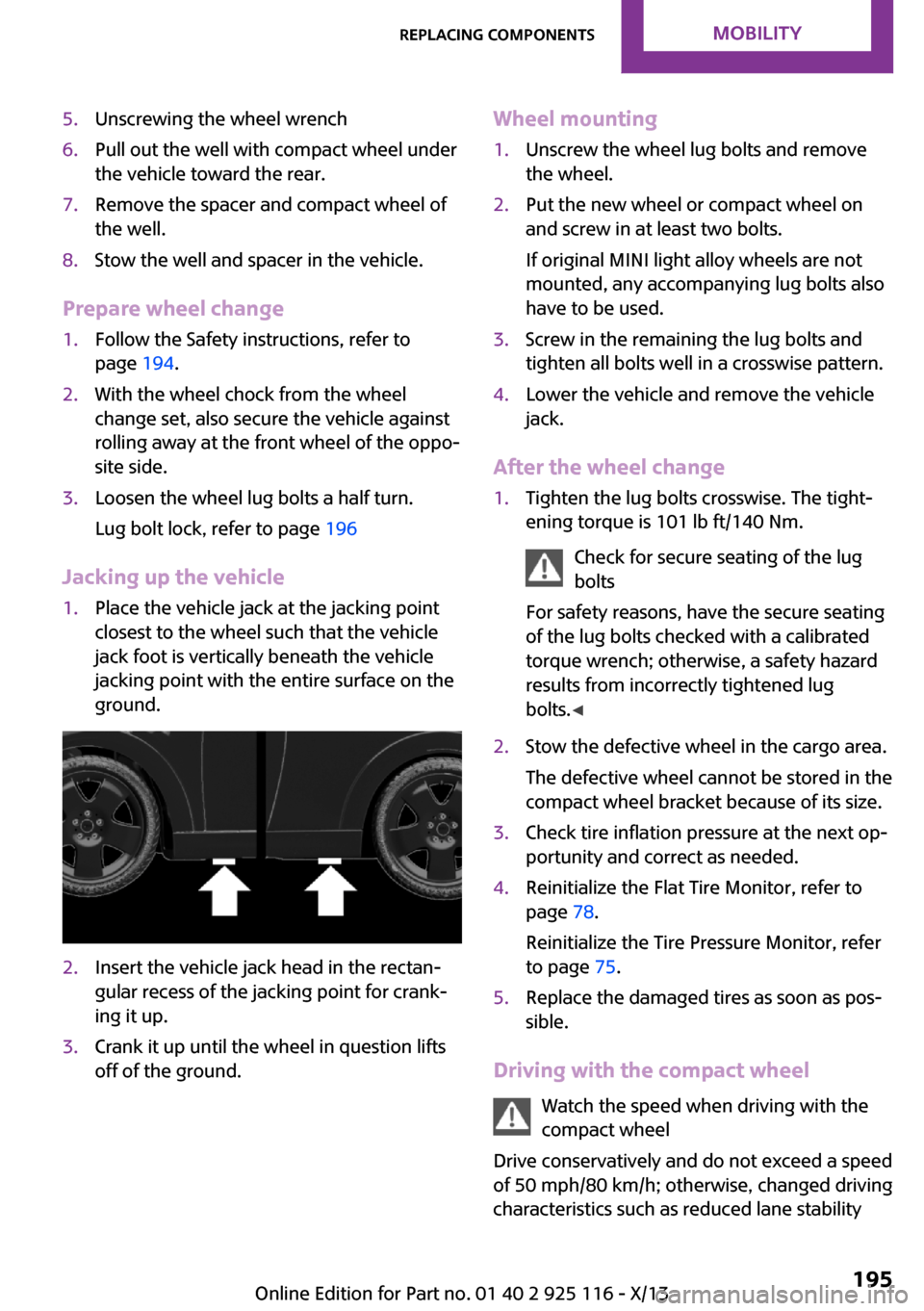

Jacking up the vehicle

1.Place the vehicle jack at the jacking point

closest to the wheel such that the vehicle

jack foot is vertically beneath the vehicle

jacking point with the entire surface on the

ground.2.Insert the vehicle jack head in the rectan‐

gular recess of the jacking point for crank‐

ing it up.3.Crank it up until the wheel in question lifts

off of the ground.Wheel mounting1.Unscrew the wheel lug bolts and remove

the wheel.2.Put the new wheel or compact wheel on

and screw in at least two bolts.

If original MINI light alloy wheels are not

mounted, any accompanying lug bolts also

have to be used.3.Screw in the remaining the lug bolts and

tighten all bolts well in a crosswise pattern.4.Lower the vehicle and remove the vehicle

jack.

After the wheel change

1.Tighten the lug bolts crosswise. The tight‐

ening torque is 101 lb ft/140 Nm.

Check for secure seating of the lug

bolts

For safety reasons, have the secure seating

of the lug bolts checked with a calibrated

torque wrench; otherwise, a safety hazard

results from incorrectly tightened lug

bolts. ◀2.Stow the defective wheel in the cargo area.

The defective wheel cannot be stored in the

compact wheel bracket because of its size.3.Check tire inflation pressure at the next op‐

portunity and correct as needed.4.Reinitialize the Flat Tire Monitor, refer to

page 78.

Reinitialize the Tire Pressure Monitor, refer

to page 75.5.Replace the damaged tires as soon as pos‐

sible.

Driving with the compact wheel

Watch the speed when driving with the

compact wheel

Drive conservatively and do not exceed a speed

of 50 mph/80 km/h; otherwise, changed driving

characteristics such as reduced lane stability

Seite 195Replacing componentsMobility195

Online Edition for Part no. 01 40 2 925 116 - X/13

Page 203 of 233

3.Switch off any electronic systems/power

consumers in both vehicles.

Bodywork contact between vehicles

Make sure that there is no contact be‐

tween the bodywork of the two vehicles; other‐

wise, there is the danger of short circuits. ◀

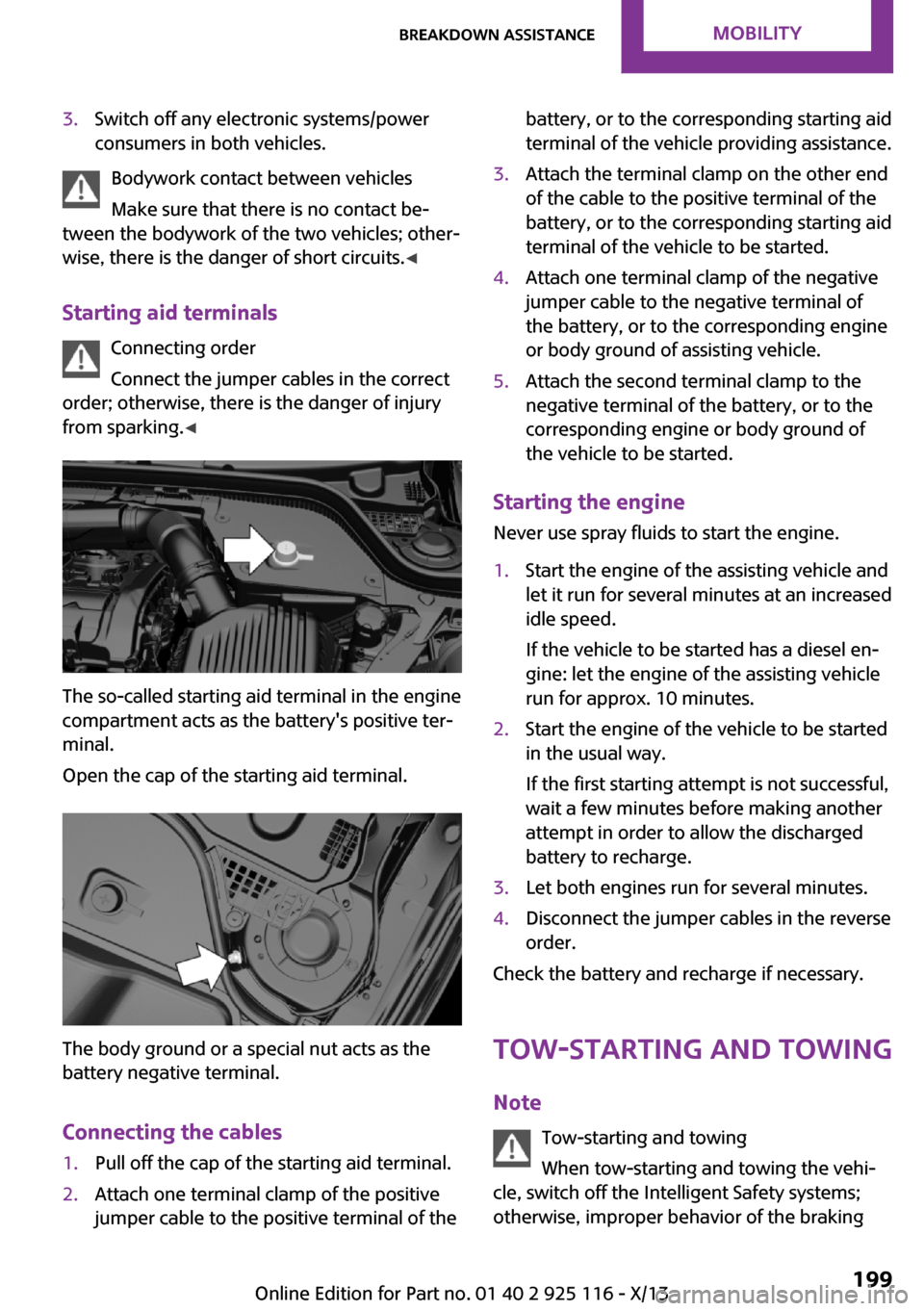

Starting aid terminals Connecting order

Connect the jumper cables in the correct

order; otherwise, there is the danger of injury

from sparking. ◀

The so-called starting aid terminal in the engine

compartment acts as the battery's positive ter‐

minal.

Open the cap of the starting aid terminal.

The body ground or a special nut acts as the

battery negative terminal.

Connecting the cables

1.Pull off the cap of the starting aid terminal.2.Attach one terminal clamp of the positive

jumper cable to the positive terminal of thebattery, or to the corresponding starting aid

terminal of the vehicle providing assistance.3.Attach the terminal clamp on the other end

of the cable to the positive terminal of the

battery, or to the corresponding starting aid

terminal of the vehicle to be started.4.Attach one terminal clamp of the negative

jumper cable to the negative terminal of

the battery, or to the corresponding engine

or body ground of assisting vehicle.5.Attach the second terminal clamp to the

negative terminal of the battery, or to the

corresponding engine or body ground of

the vehicle to be started.

Starting the engine

Never use spray fluids to start the engine.

1.Start the engine of the assisting vehicle and

let it run for several minutes at an increased

idle speed.

If the vehicle to be started has a diesel en‐

gine: let the engine of the assisting vehicle

run for approx. 10 minutes.2.Start the engine of the vehicle to be started

in the usual way.

If the first starting attempt is not successful,

wait a few minutes before making another

attempt in order to allow the discharged

battery to recharge.3.Let both engines run for several minutes.4.Disconnect the jumper cables in the reverse

order.

Check the battery and recharge if necessary.

Tow-starting and towing

Note Tow-starting and towing

When tow-starting and towing the vehi‐

cle, switch off the Intelligent Safety systems;

otherwise, improper behavior of the braking

Seite 199Breakdown assistanceMobility199

Online Edition for Part no. 01 40 2 925 116 - X/13

Page 204 of 233

function of individual systems could result in an

accident. ◀

Switching off Intelligent Safety systems, refer to

page 79.

Automatic transmission: transporting

your vehicle

Note Your vehicle must not be towed if the frontwheels are touching the ground. Therefore,

contact a service center in the event of a break‐ down.

Tow the vehicle only with the front axle

raised

Have the vehicle towed only with the front axle

raised or transported on a loading platform; otherwise, damage may occur. ◀

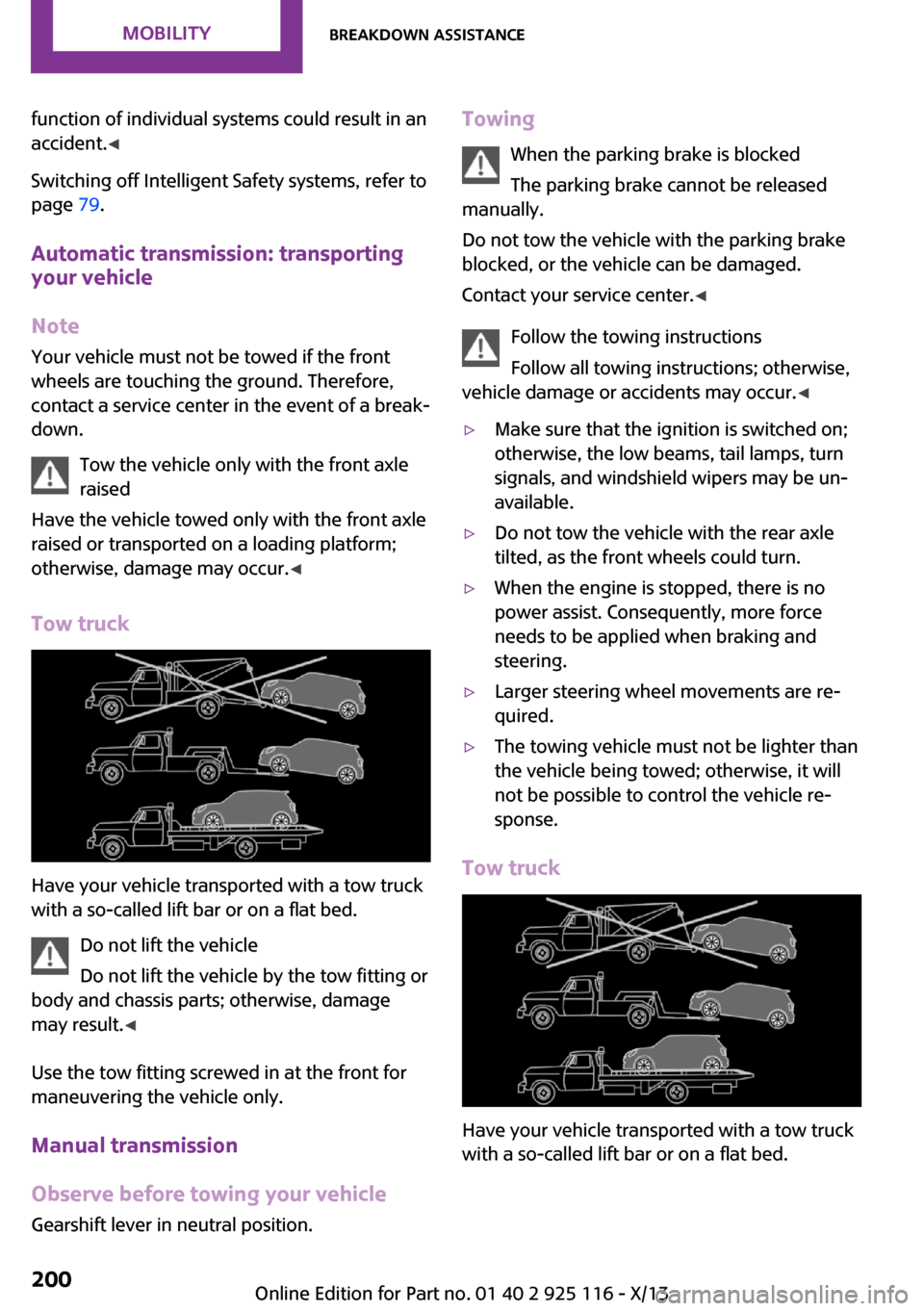

Tow truck

Have your vehicle transported with a tow truck

with a so-called lift bar or on a flat bed.

Do not lift the vehicle

Do not lift the vehicle by the tow fitting or

body and chassis parts; otherwise, damage

may result. ◀

Use the tow fitting screwed in at the front for

maneuvering the vehicle only.

Manual transmission

Observe before towing your vehicle Gearshift lever in neutral position.

Towing

When the parking brake is blocked

The parking brake cannot be released

manually.

Do not tow the vehicle with the parking brake

blocked, or the vehicle can be damaged.

Contact your service center. ◀

Follow the towing instructions

Follow all towing instructions; otherwise,

vehicle damage or accidents may occur. ◀▷Make sure that the ignition is switched on;

otherwise, the low beams, tail lamps, turn

signals, and windshield wipers may be un‐

available.▷Do not tow the vehicle with the rear axle

tilted, as the front wheels could turn.▷When the engine is stopped, there is no

power assist. Consequently, more force

needs to be applied when braking and

steering.▷Larger steering wheel movements are re‐

quired.▷The towing vehicle must not be lighter than

the vehicle being towed; otherwise, it will

not be possible to control the vehicle re‐

sponse.

Tow truck

Have your vehicle transported with a tow truck

with a so-called lift bar or on a flat bed.

Seite 200MobilityBreakdown assistance200

Online Edition for Part no. 01 40 2 925 116 - X/13

Page 205 of 233

Do not lift the vehicle

Do not lift the vehicle by the tow fitting or

body and chassis parts; otherwise, damage

may result. ◀

Towing other vehicles

General information Light towing vehicle

The towing vehicle must not be lighter

than the vehicle being towed; otherwise, it will

not be possible to control the vehicle re‐

sponse. ◀

Attaching the tow bar/tow rope correctly

Attach the tow bar or tow rope to the tow

fitting; connecting it to other vehicle parts may

cause damage. ◀▷Switch on the hazard warning system, de‐

pending on local regulations.▷If the electrical system has failed, clearly

identify the vehicle being towed by placing

a sign or a warning triangle in the rear win‐

dow.

Tow bar

The tow fittings used should be on the same

side on both vehicles.

Should it prove impossible to avoid mounting

the tow bar at an offset angle, please observe

the following:

▷Maneuvering capability is limited during

cornering.▷The tow bar will generate lateral forces if it

is secured with an offset.

Tow rope

When starting to tow the vehicle, make sure

that the tow rope is taut.

To avoid jerking and the associated stresses on

the vehicle components when towing, always

use nylon ropes or nylon straps.

Attaching the tow rope correctly

Only secure the tow rope on the tow fit‐

ting; otherwise, damage can occur when it is

secured on other parts of the vehicle. ◀

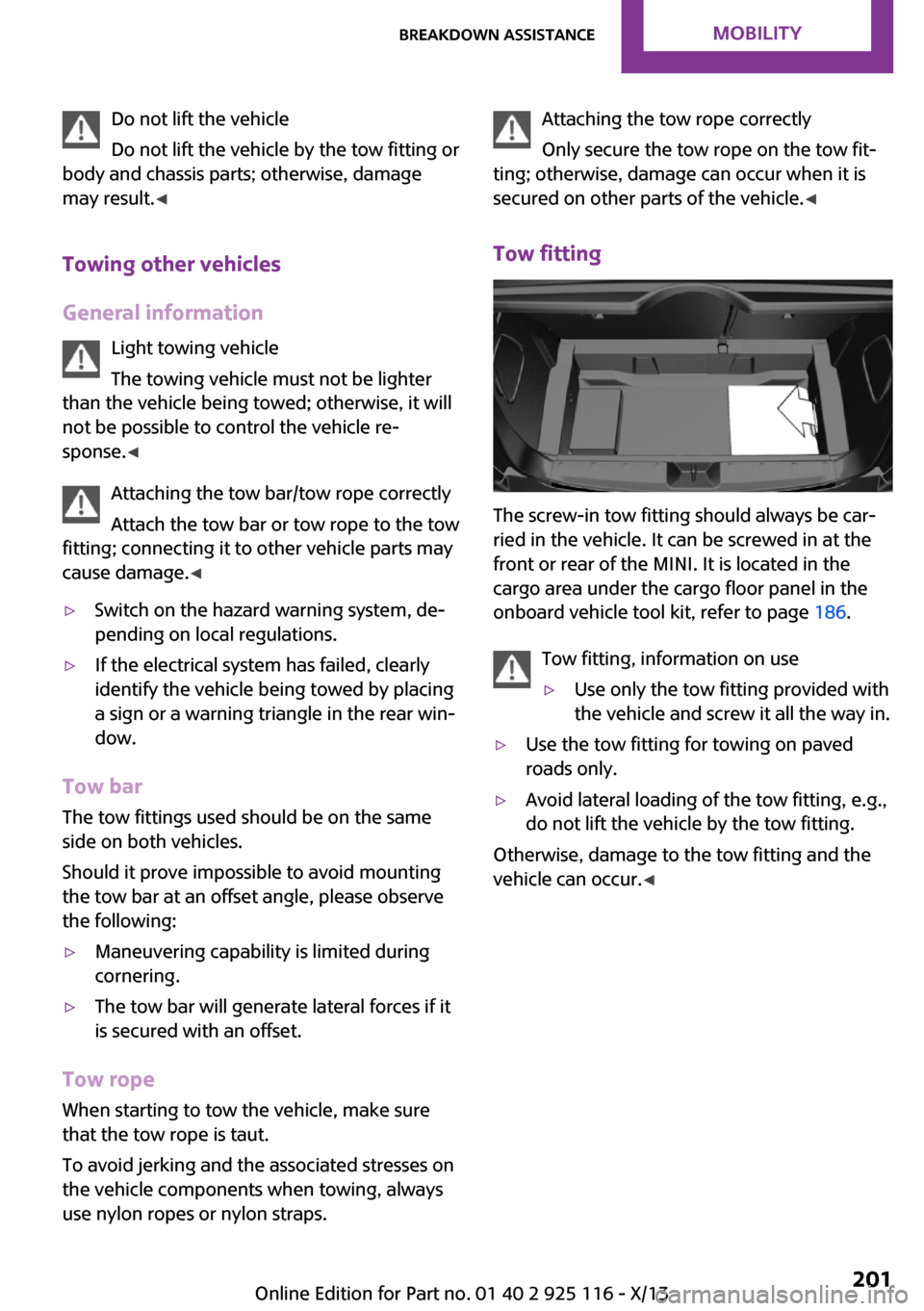

Tow fitting

The screw-in tow fitting should always be car‐

ried in the vehicle. It can be screwed in at the

front or rear of the MINI. It is located in the

cargo area under the cargo floor panel in the

onboard vehicle tool kit, refer to page 186.

Tow fitting, information on use

▷Use only the tow fitting provided with

the vehicle and screw it all the way in.▷Use the tow fitting for towing on paved

roads only.▷Avoid lateral loading of the tow fitting, e.g.,

do not lift the vehicle by the tow fitting.

Otherwise, damage to the tow fitting and the

vehicle can occur. ◀

Seite 201Breakdown assistanceMobility201

Online Edition for Part no. 01 40 2 925 116 - X/13

Page 206 of 233

Screw thread

Threaded holes for the tow fitting are located in

the front and rear of the vehicle on the right

side with respect to the direction of travel.

Push out the cover by pressing on the top edge.

Tow-starting

Automatic transmission Do not tow-start the vehicle.

Due to the automatic transmission, the engine

cannot be started by tow-starting.

Have the cause of the starting difficulties rem‐ edied.

Manual transmission

If possible, do not tow-start the vehicle but

start the engine by jump-starting, refer to

page 198. If the vehicle is equipped with a cat‐

alytic converter, only tow-start while the engine

is cold.

1.Switch on the hazard warning system and

comply with local regulations.2.Ignition, refer to page 44, on.3.Engage third gear.4.Have the vehicle tow-started with the

clutch pedal pressed and slowly release the

pedal. After the engine starts, immediately

press on the clutch pedal again.5.Stop at a suitable location, remove the tow

bar or rope, and switch off the hazard

warning system.6.Have the vehicle checked.Seite 202MobilityBreakdown assistance202

Online Edition for Part no. 01 40 2 925 116 - X/13

Page 224 of 233

Everything from A to Z

Index

A

ABS, Antilock Brake Sys‐

tem 86

ACC, Active Cruise Control 90

Acceleration Assistant, refer to

Launch Control 55

Activated-charcoal filter 109

Active cruise control, ACC 90

Additives, oil 181

Adjusting the headlamps 69

Adjustments, seats/head re‐

straints 32

Adjustments, steering

wheel 39

After washing vehicle 204

Airbags 71

Airbags, indicator/warning

light 72

Air circulation, refer to Recir‐

culated-air mode 105, 108

Air conditioner 104

Air, dehumidifying, refer to

Cooling function 105, 108

Air distribution,

manual 105, 107

Air flow, air conditioner 105

Air flow, automatic climate

control 107

Air pressure, tires 166

Air vents, refer to Ventila‐

tion 109

Alarm system 27

Alarm triggering 27

Alarm, unintentional 28

All around the center con‐

sole 14

All around the headliner 15

All around the steering

wheel 12

All-season tires, refer to Win‐

ter tires 172

Alternating-code hand-held

transmitter 111

Alternative oil types 182

Antifreeze, washer fluid 51

Antilock Brake System,

ABS 86

Anti-slip control, refer to

DSC 86

Appendix

Approved axle load 210

Approved engine oils 182

Ash tray 115

Assistance, Roadside Assis‐

tance 198

Assistance when driving

off 89

Assist system, refer to Intelli‐

gent Safety 79

AUTO intensity 107

Automatic car wash 203

Automatic climate con‐

trol 106

Automatic cruise control with

Stop & Go 90

Automatic Curb Monitor 37

Automatic deactivation, front

passenger airbags 73

Automatic headlamp con‐

trol 67

Automatic locking 27

Automatic recirculated-air

control 108

Automatic transmission with

Steptronic 52

AUTO program, automatic cli‐

mate control 107

AUTO program, intensity 107

Auto Start/Stop function 46

Average fuel consumption 64

Average speed 64

Axle loads, weights 210

B

Backrest curvature, refer to

Lumbar support 33

Balance 138

Band-aids, refer to First aid

kit 198

Bar for tow-starting/

towing 201

Bass 138

Battery replacement, vehicle

battery 196

Battery, vehicle 196

Belts, safety belts 34

Beverage holder, cu‐

pholder 119

Bluetooth, refer to Hands-free

system 152

Bonus range, GREEN

mode 132

Bottle holder, refer to Cu‐

pholder 119

Brake assistant 86

Brake discs, breaking in 124

Brake pads, breaking in 124

Braking, hints 125

Breakdown assistance 198

Breaking in 124

Bug light 188

Bulb replacement 187

Bulb replacement, front 188

Bulb replacement, rear 190

Bulb replacement, side 193

Bulbs and lamps 187

Button, RES 92

Button, Start/Stop 44

Bypassing, refer to Jump-

starting 198

Seite 220ReferenceEverything from A to Z220

Online Edition for Part no. 01 40 2 925 116 - X/13

212