change wheel MINI Convertible 2009 Owner's Manual

[x] Cancel search | Manufacturer: MINI, Model Year: 2009, Model line: Convertible, Model: MINI Convertible 2009Pages: 176, PDF Size: 2.82 MB

Page 26 of 176

Opening and closing

24

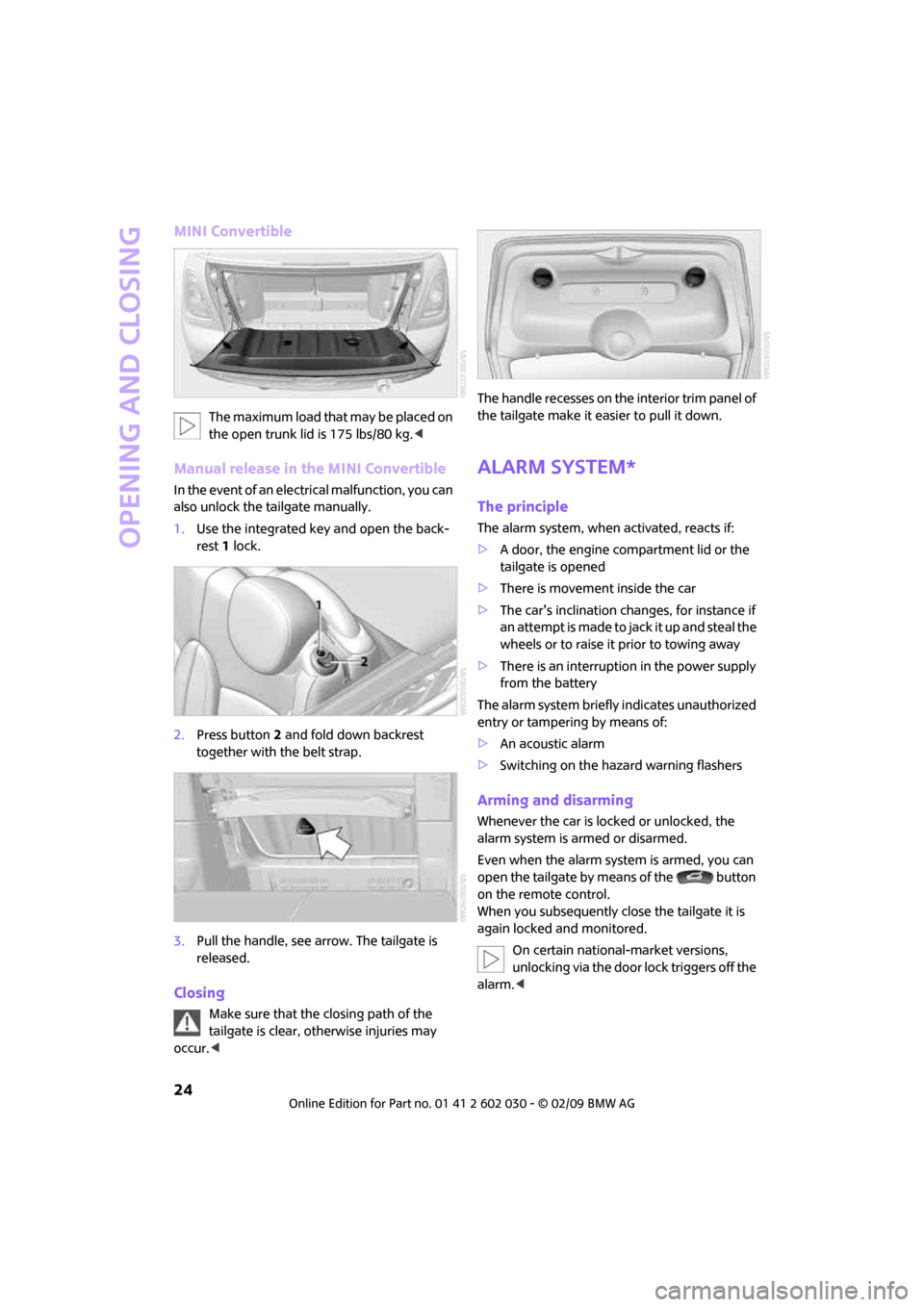

MINI Convertible

The maximum load that may be placed on

the open trunk lid is 175 lbs/80 kg.<

Manual release in the MINI Convertible

In the event of an electrical malfunction, you can

also unlock the tailgate manually.

1.Use the integrated key and open the back-

rest 1 lock.

2.Press button2 and fold down backrest

together with the belt strap.

3.Pull the handle, see arrow. The tailgate is

released.

Closing

Make sure that the closing path of the

tailgate is clear, otherwise injuries may

occur.

Alarm system*

The principle

The alarm system, when activated, reacts if:

>A door, the engine compartment lid or the

tailgate is opened

>There is movement inside the car

>The car's inclination changes, for instance if

an attempt is made to jack it up and steal the

wheels or to raise it prior to towing away

>There is an interruption in the power supply

from the battery

The alarm system briefly indicates unauthorized

entry or tampering by means of:

>An acoustic alarm

>Switching on the hazard warning flashers

Arming and disarming

Whenever the car is locked or unlocked, the

alarm system is armed or disarmed.

Even when the alarm system is armed, you can

open the tailgate by means of the button

on the remote control.

When you subsequently close the tailgate it is

again locked and monitored.

On certain national-market versions,

unlocking via the door lock triggers off the

alarm.<

Page 66 of 176

Technology for driving comfort and safety

64

in hazardous driving thereby running the risk of

an accident.<

Antilock Brake System ABS

ABS prevents locking of the wheels during brak-

ing. Safe steering response is maintained even

during full braking. Active safety is thus

increased.

Braking safely, refer to page93.

Among others, ABS includes the following

functions:

>Cornering Brake Control CBC

>Electronic brake-force distribution EBV

>Brake Assist

Cornering Brake Control CBC

Driving stability and steering characteristics are

further enhanced while braking in turns or dur-

ing a lane change.

Electronic brake-force distribution EBV

The system controls the brake pressure in the

rear wheels to ensure stable braking behavior.

Brake Assist

Rapidly depressing the brake causes this system

to automatically develop maximum braking

force. Thus, the system helps keep braking dis-

tance to a minimum. At the same time, all the

benefits provided by ABS are exploited.

Do not reduce the pressure on the brake for the

duration of the full braking application.

Dynamic Stability Control DSC

DSC prevents the driving wheels from losing

traction when you pull away from rest or accel-

erate. The system also recognizes unstable driv-

ing conditions, for example if the rear of the car

is about to swerve or if momentum is acting at

an angle past the front wheels. In these cases,

DSC helps the vehicle maintain a safe course

within physical limits by reducing engine output

and through braking actions at the individual

wheels.

DSC also encompasses the following functions:>Antilock Brake System ABS

>Electronic brake-force distribution EBV

>Brake Assist

>Cornering Brake Control CBC

>Hill Start Assist

Deactivating DSC

Press the button repeatedly until the DSC indica-

tor lamps come on. DSC is deactivated. Stabiliz-

ing and propulsion promoting actions are no

longer executed.

When driving with snow chains or to 'rock free'

in snow, it can be helpful to switch off DSC for a

brief period.

To increase vehicle stability, activate DSC again

as soon as possible.

Activating DSC

Press the button again: the DSC indicator lamps

go out.

For better control

If the indicator lamp flashes:

The DSC controls the driving and break-

ing forces.

If the indicator lamps are on:

DSC is deactivated.

Dynamic Traction Control DTC*

DTC is a type of DSC that is propulsion optimized

for special road conditions such as uncleared

snowy roads. The system ensures maximum

propulsion though with restricted driving stabil-

Page 68 of 176

Technology for driving comfort and safety

66

>Engine responds more spontaneously to

movements of the accelerator.

>Steering response is more direct.

With automatic transmission:

>More rapid gear shifting in Sport program.

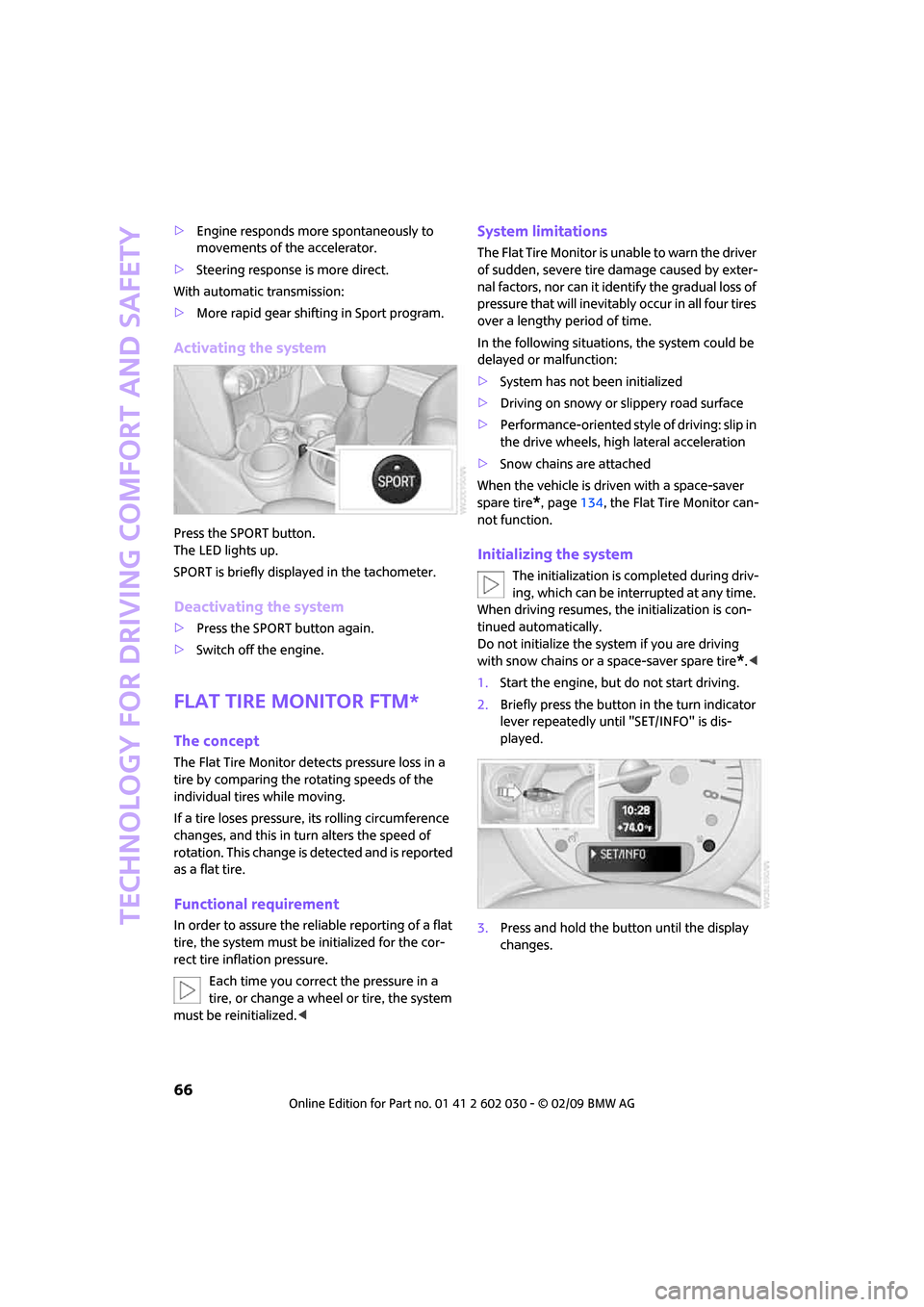

Activating the system

Press the SPORT button.

The LED lights up.

SPORT is briefly displayed in the tachometer.

Deactivating the system

>Press the SPORT button again.

>Switch off the engine.

Flat Tire Monitor FTM*

The concept

The Flat Tire Monitor detects pressure loss in a

tire by comparing the rotating speeds of the

individual tires while moving.

If a tire loses pressure, its rolling circumference

changes, and this in turn alters the speed of

rotation. This change is detected and is reported

as a flat tire.

Functional requirement

In order to assure the reliable reporting of a flat

tire, the system must be initialized for the cor-

rect tire inflation pressure.

Each time you correct the pressure in a

tire, or change a wheel or tire, the system

must be reinitialized.<

System limitations

The Flat Tire Monitor is unable to warn the driver

of sudden, severe tire damage caused by exter-

nal factors, nor can it identify the gradual loss of

pressure that will inevitably occur in all four tires

over a lengthy period of time.

In the following situations, the system could be

delayed or malfunction:

>System has not been initialized

>Driving on snowy or slippery road surface

>Performance-oriented style of driving: slip in

the drive wheels, high lateral acceleration

>Snow chains are attached

When the vehicle is driven with a space-saver

spare tire

*, page134, the Flat Tire Monitor can-

not function.

Initializing the system

The initialization is completed during driv-

ing, which can be interrupted at any time.

When driving resumes, the initialization is con-

tinued automatically.

Do not initialize the system if you are driving

with snow chains or a space-saver spare tire

*.<

1.Start the engine, but do not start driving.

2.Briefly press the button in the turn indicator

lever repeatedly until "SET/INFO" is dis-

played.

3.Press and hold the button until the display

changes.

Page 70 of 176

Technology for driving comfort and safety

68

Tire Pressure

Monitor TPM*

The concept

TPM checks the inflation pressures of the four

mounted tires. The system notifies you if there is

a significant loss of pressure in one or more tires.

Functional requirement

In order to assure the reliable reporting of a flat

tire, the system must be reset while all tire infla-

tion pressures are correct.

Always use wheels with TPM electronics. Other-

wise, the system may malfunction.

Each time a tire inflation pressure has

been corrected or a wheel or tire has been

changed, reset the system.<

System limitations

TPM cannot warn you in advance of sud-

den severe tire damage caused by outside

influences.<

The system does not work correctly if it has not

been reset; for example, a flat tire may be indi-

cated even though the tire inflation pressures

are correct.

The system is inactive and cannot indicate a flat

tire if a wheel without TPM electronics, such as a

compact spare wheel

*, has been mounted, or if

TPM is temporarily malfunctioning due to other

systems or devices using the same radio fre-

quency.

Resetting the system

Each time a tire inflation pressure has

been corrected or a wheel or tire has been

changed, reset the system.<

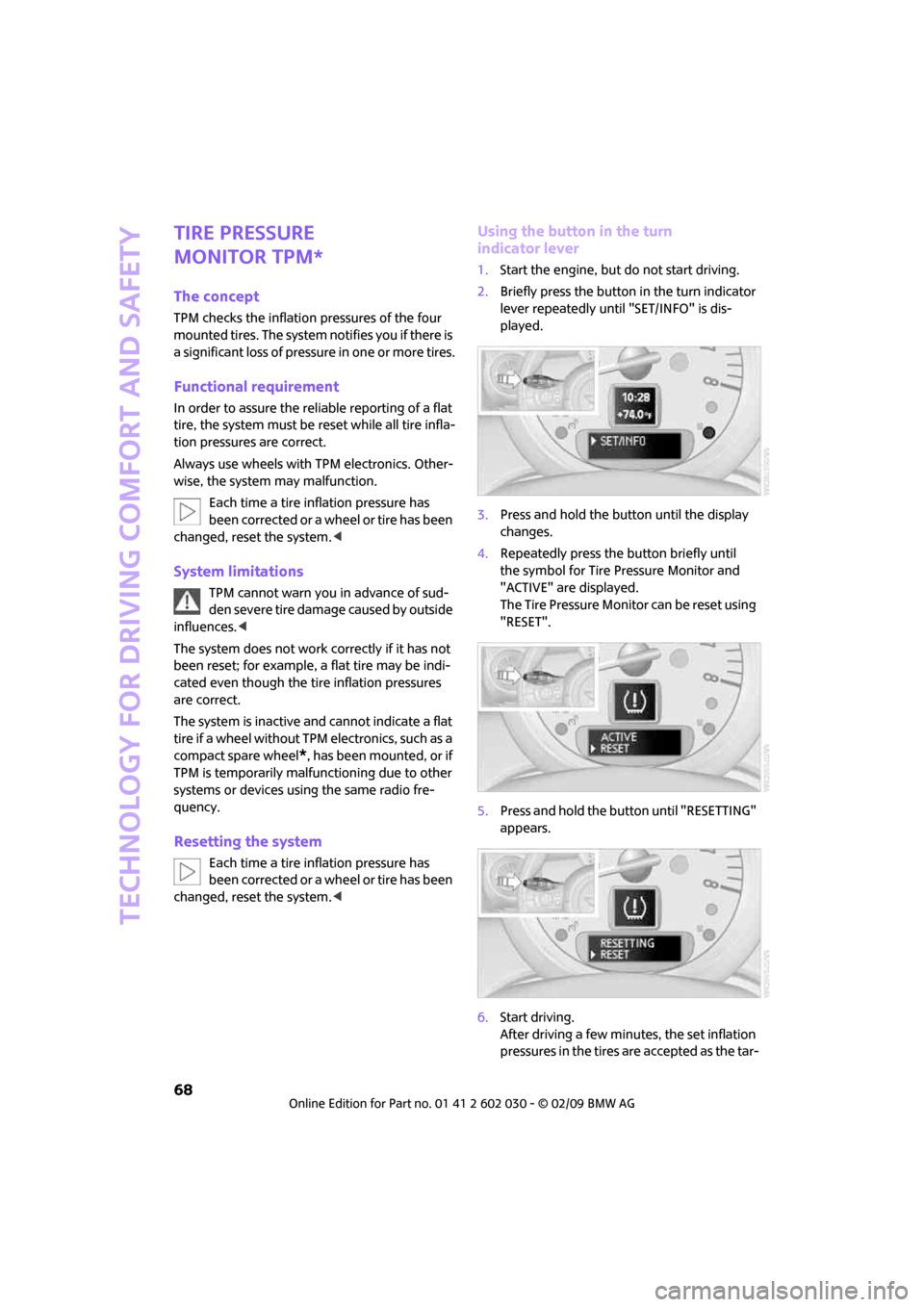

Using the button in the turn

indicator lever

1.Start the engine, but do not start driving.

2.Briefly press the button in the turn indicator

lever repeatedly until "SET/INFO" is dis-

played.

3.Press and hold the button until the display

changes.

4.Repeatedly press the button briefly until

the symbol for Tire Pressure Monitor and

"ACTIVE" are displayed.

The Tire Pressure Monitor can be reset using

"RESET".

5.Press and hold the button until "RESETTING"

appears.

6.Start driving.

After driving a few minutes, the set inflation

pressures in the tires are accepted as the tar-

Page 71 of 176

REFERENCEAT A GLANCE CONTROLS DRIVING TIPS MOBILITY

69

get values to be monitored. The system

reset is completed during your drive, and

can be interrupted at any time. When driving

resumes, the reset is continued automati-

cally. The indicator lamp goes out after the

system reset is completed.

Message for low tire inflation pressure

The warning lamps come on in yellow

and red. An acoustic signal also sounds.

There is a flat tire or substantial loss of

tire pressure.

1.Reduce speed and stop the vehicle with cau-

tion. Avoid sudden braking and steering

maneuvers.

2.Check whether your vehicle is equipped

with normal tires or Run-Flat Tires.

The symbol identifying Run-Flat Tires

is a circle with the letters RSC on the

sidewall, page114.<

Normal tires

1.Determine which tire is damaged.

If this cannot be determined, contact

your MINI Dealer.<

2.Repair the flat tire or change the damaged

tire, refer to page133.

Run-Flat Tires*

1.Cautiously reduce speed to below 50 mph/

80 km/h. Avoid sudden braking and steering

maneuvers. Do not exceed a speed of

50 mph/80 km/h.

Do not continue driving if the vehicle is

not equipped with Run-Flat Tires, oth-

erwise a serious accident could result.<

2.In the event of complete tire pressure loss,

0 psi/0 kPa, you can estimate the possible

distance for continued driving on the basis

of the following guidelines:

>With a light load:

1 to 2 persons without luggage:

approx. 155 miles/250 km

>With a medium load:

2 persons, cargo bay full, or 4 persons without luggage:

approx. 94 miles/150 km

>With a full load:

4 persons, load compartment full:

approx. 30 miles/50 km

Drive cautiously and do not exceed a

speed of 50 mph/80 km/h, otherwise an

accident may occur. In the event of pressure

loss, vehicle handling changes. This includes

reduced tracking stability in braking, extended

braking distance and altered natural steering

characteristics.

If unusual vibration or loud noises occur during

the journey, this may be an indication that the

damaged tire has finally failed. Reduce the vehi-

cle speed and stop as soon as possible. Other-

wise, sections of the tire may come loose and

cause accidents. Do not continue driving and

contact your MINI Dealer.<

Malfunction

The small warning lamp flashes in yel-

low and then lights up continuously; the

larger warning lamp comes on in yel-

low. No punctures can be detected.

This type of message is shown in the following

situations:

>If there is a malfunction.

Have the system checked.

>If a wheel without TPM electronics has been

mounted.

>If TPM is temporarily malfunctioning due to

other systems or devices using the same

radio frequency.

Message for unsuccessful system reset

Both warning lamps come on in yellow.

The system is not reset after a tire has

been changed, for example.

Check the tire inflation pressure and

reset the system, page68.

Page 117 of 176

REFERENCEAT A GLANCE CONTROLS DRIVING TIPS MOBILITY

115

Recommended tire brands

For each tire size, the manufacturer of your MINI

recommends certain tire brands. They are

marked with a clearly visible MINI designation

on the sidewall of the tire.

When properly used, these tires meet the high-

est standards in terms of safety and handling

characteristics.

Run-Flat Tires*

When mounting new tires or changing over from

summer to winter tires and vice versa, mount

Run-Flat Tires for your own safety. Keep in mind

that no space-saver spare tire is available in the

event of a flat. Your MINI Dealer will be glad to

advise you.

Special characteristics of winter tires

The manufacturer of MINI recommends the use

of winter tires on snowy roads or if temperatures

drop below 457/ +76. Although all-season

M+S tires provide better winter traction than

summer tires, they generally fail to provide the

same levels of cold-weather performance as

winter tires.

Pay attention to speed

Always comply with the speed limit for

the winter tires mounted on your car;

failure to do so could result in tire damage and

accidents.<

If the car is capable of speeds higher than that

permitted for the winter tires, a label stating the

maximum permitted speed for the mounted

tires must be displayed in your field of view.

Specialist tire dealers and your MINI Dealer can

supply these labels.

Storage

Always store wheels and tires in a cool, dry place

with as little exposure to light as possible.

Always protect tires against all contact with oil,

grease and fuels.

Do not exceed the maximum tire inflation pres-

sure indicated on the sidewall of the tire.

Swapping wheels among the axles

Depending on the individual use, front and rear

tires may exhibit different wear and tear.

In order to maintain an even wear and tear, the

wheels may be rotated between the axles. Your

MINI Dealer will be glad to advise you.

Always check the inflation pressure after the tire

rotation, if necessary change the pressure.

Snow chains*

Only certain types of fine-link snow chains have

been tested by the manufacturer of your MINI,

classified as road-safe and recommended. Con-

tact your MINI Dealer for more details.

Only attach snow chains in pairs to the front

wheels with the following tires.

>175/65 R 15 M+S

>175/60 R 16 M+S

John Cooper Works:

>185/50 R 17 86 H M+S XL RSC

Observe the manufacturer's instructions when

mounting snow chains. Do not exceed a speed

of 30 mph or 50 km/h.

Do not initialize the Flat Tire Monitor if

snow chains are mounted, otherwise the

instrument might issue an incorrect reading.

When driving with snow chains, it can be useful

to briefly deactivate the DSC or activate the DTC,

refer to page65.<

Page 133 of 176

REFERENCEAT A GLANCE CONTROLS DRIVING TIPS MOBILITY

131

>Tire change with space-saver spare tire,

page133

MINI Mobility System with onboard tool

kit and tire change set*

Follow the instructions on using the Mobil-

ity System found on the compressor and

the sealant bottle.<

Do not remove foreign bodies which have pen-

etrated the tire if possible.

Pull the sticker for the speed restriction off and

apply it to the steering wheel.

The Mobility System with onboard tool kit and

tire change set

* is located under the floor mat in

the cargo bay.

1Filling canister

2Hexagon wrench

*

3Vehicle jack*

4Wheel stud wrench

5Flat screwdriver/Phillips screwdriver,

towing eyelet

6Compressor

7Package with filling hose, valve remover,

valve insert and speed restriction label

Use of the Mobility System may be ineffec-

tive if the tire puncture measures approx.

1/8 in/4 mm or more. Contact the nearest MINI

Dealer if the tire cannot be made drivable with

the Mobility System.<

Liquid sealant

1Filling hose

2Filling canister

Filling

1.Shake the filling canister.

2.Screw the filling hose onto the filling

canister.

3.Unscrew the dust cap from the valve of the

defective tire.

4.Screw out the valve core with the valve

remover. The valve remover is located in a

package with the filling hose.

5.Remove the cap from the filling hose.

6.Push the filling hose onto the tire valve.

7.Hold the filling canister with the cap down

and squeeze.

8.Squeeze the entire contents of the canister

into the tire.

9.Remove the filling hose.

10.Screw the valve core into the tire valve with

the valve remover.

In the event of a lost or dirty valve core

you will find another valve core in the

package with the filling hose.

Remember that the liquid canister must be

replaced every four years if the equipment has

not been used.<

Compressor

Connector, cable and connection hose are

stored in the compressor housing.

Page 134 of 176

Replacing components

132

1Connector and cable for lighter socket

2Connection hose for connecting the com-

pressor and tire valve

3On/off switch

4Pressure gauge for indicating the tire infla-

tion pressure

5Release button for reducing the tire inflation

pressure

Reinflating the tire

1.Unscrew the dust cap from the tire valve of

the defective tire.

2.Screw connection hose2 onto the tire valve.

3.Insert connector 1 into the lighter socket in

the interior of the vehicle, page88.

4.Switch on the compressor using switch3.

5.Inflate the tire to at least 26 psi/180 kPa and

at most 36 psi/250 kPa.

To check the inflation pressure, switch off

the compressor briefly.

Do not run the compressor for longer

than 6 minutes, otherwise the device

will overheat and possibly be damaged.<

If an air pressure of 26 psi/180 kPa is not

reached:

1.Unscrew connection hose2 and drive the

vehicle forward and backward about 33 ft/

10 m to distribute the liquid sealant in the

tires evenly.

2.Repeat the procedure.

If an inflation pressure of 26 psi/180 kPa

still cannot be reached, the tire is too

heavily damaged. Please contact the nearest

MINI Dealer.<

Distributing liquid sealant

Immediately drive for approx. 10 minutes, so

that the liquid sealant is uniformly distributed.

Do not exceed speeds of 40 mph/

60 km/h.

If possible, do not drop below 10 mph/

20 km/h.<

Checking tire inflation pressure

1.After driving for approx. 10 minutes, pull

over at a suitable location.

2.Screw connection hose2 onto the tire valve.

3.Check the tire inflation pressure.

The tire pressure must be at least

18 psi/130 kPa. If it is not, do not con-

tinue driving.<

If a tire pressure of at least 18 psi/130 kPa is

displayed:

1.Switch on the compressor. Correct the tire

inflation pressure to the specified value,

page104.

2.Replace the tire as soon as possible.

Driving on

Do not exceed the permitted maximum

speed of 50 mph/80 km/h; doing so may

result in an accident.<

Replace the defective tire as soon as possible

and have the new wheel/tire assembly bal-

anced.

Have the Mobility System refilled.

Tire change set

When changing a tire, always observe the safety

measures and the procedure for changing tires

described below.

In case of a flat tire, the tire change set is

not needed due to the availability of the

Mobility System.<

Page 135 of 176

REFERENCEAT A GLANCE CONTROLS DRIVING TIPS MOBILITY

133

Changing wheels

Space-saver spare tire*

To change a space-saver spare tire, proceed

as follows:

>Remove the space-saver spare tire,

page133

>Prepare for tire change, page134

>Jack up vehicle, page134

>Mount space-saver spare tire, page135

>Tighten lug bolts, page135

>Drive with space-saver spare tire, page134

Tire change set for a space-saver

spare tire*

On vehicles with a space-saver spare tire, the

tire change set with onboard tools is stored

under the floor mat in the cargo bay.

1Chock, folding

2Hub cover remover

3Wheel stud wrench

4Vehicle jack

5Special wrench for removing the space-

saver spare tire

6Flat screwdriver/Phillips screwdriver

7Towing eyelet

8Lifting handle

The onboard tool kit includes a pouch with

a plastic bag in which you can place the dam-

aged wheel.

Removing the space-saver spare tire

The screw connection of the space-saver spare

tire is under the floor mat in the cargo bay, on the base of the storage compartment for the tire

change set.

1.Unscrew the screw connection with the spe-

cial wrench.

2.Take out the cover panel.

3.Screw the lifting handle from the onboard

tool kit onto the thread.

4.Raise the lifting handle slightly.

5.Squeeze the securing spring.

6.The space-saver spare tire is released and

must be held by the lifting handle.

7.Lower the space-saver spare tire with the

lifting handle.

8.Unscrew the lifting handle.

Page 136 of 176

Replacing components

134

9.Pull the space-saver spare tire underneath

the vehicle out towards the rear.

10.Position the space-saver spare tire with the

valve facing upward.

11.Unscrew the valve extension from the valve

of the space-saver spare tire.

12.Unscrew the dust cap from the extension

and place it on the valve of the space-saver

spare tire.

Due to its different dimensions, the dam-

aged wheel cannot be placed in the recess

for the space-saver spare tire.<

Driving with the space-saver spare tire

Drive cautiously and do not exceed a

speed of 50 mph/80 km/h. Changes may

occur in vehicle handling such as lower track sta-

bility during braking, longer braking distances

and changes in self-steering properties when

close to the handling limit. These properties are

more noticeable with winter tires.<

Only one space-saver spare tire may be

mounted at one time. Mount a wheel and

tire of the original size as soon as possible, to

avoid any safety risks.<

Check the tire inflation pressure at the ear-

liest opportunity and correct it if neces-

sary. Replace the defective tire as soon as possi-

ble and have the new wheel/tire assembly

balanced.<

Preparing for a tire change

Observe the safety precautions regarding

flat tires on page130.<

Additional safety measures when chang-

ing tires: Only change the tire when parked on a surface

that is level, firm and not slippery.

The vehicle or the jack could slip sideways on

soft or slippery support surfaces, such as snow,

ice, flagstones, etc.

Do not use a wooden block or similar object as a

support base for the jack, as this would prevent

it from extending to its full support height and

reduce its load-carrying capacity.

Do not lie under the vehicle or start the engine

when the vehicle is supported by the jack; other-

wise there is a risk of fatal injury.<

1.Place the foldable chock

* behind the front

wheel on the other side of the vehicle or in

front of the wheel if the vehicle is on an

incline. If the wheel is changed on a surface

with a more severe slope, take additional

precautions to secure the vehicle from

rolling.

2.Uncover the lug bolts if necessary.

If the wheel is equipped with a hub cover,

pry it off using the screwdriver from the tire

change kit.

3.Loosen the lug bolts by a half turn.

Jacking up the vehicle

The vehicle jack is designed for changing

wheels only. Do not attempt to raise

another vehicle model with it or to raise any load

of any kind. To do so could cause accidents and

personal injury.<

1.Place the jack at the jacking point closest to

the wheel.