four wheel drive MINI Convertible 2009 Owner's Manual

[x] Cancel search | Manufacturer: MINI, Model Year: 2009, Model line: Convertible, Model: MINI Convertible 2009Pages: 176, PDF Size: 2.82 MB

Page 68 of 176

Technology for driving comfort and safety

66

>Engine responds more spontaneously to

movements of the accelerator.

>Steering response is more direct.

With automatic transmission:

>More rapid gear shifting in Sport program.

Activating the system

Press the SPORT button.

The LED lights up.

SPORT is briefly displayed in the tachometer.

Deactivating the system

>Press the SPORT button again.

>Switch off the engine.

Flat Tire Monitor FTM*

The concept

The Flat Tire Monitor detects pressure loss in a

tire by comparing the rotating speeds of the

individual tires while moving.

If a tire loses pressure, its rolling circumference

changes, and this in turn alters the speed of

rotation. This change is detected and is reported

as a flat tire.

Functional requirement

In order to assure the reliable reporting of a flat

tire, the system must be initialized for the cor-

rect tire inflation pressure.

Each time you correct the pressure in a

tire, or change a wheel or tire, the system

must be reinitialized.<

System limitations

The Flat Tire Monitor is unable to warn the driver

of sudden, severe tire damage caused by exter-

nal factors, nor can it identify the gradual loss of

pressure that will inevitably occur in all four tires

over a lengthy period of time.

In the following situations, the system could be

delayed or malfunction:

>System has not been initialized

>Driving on snowy or slippery road surface

>Performance-oriented style of driving: slip in

the drive wheels, high lateral acceleration

>Snow chains are attached

When the vehicle is driven with a space-saver

spare tire

*, page134, the Flat Tire Monitor can-

not function.

Initializing the system

The initialization is completed during driv-

ing, which can be interrupted at any time.

When driving resumes, the initialization is con-

tinued automatically.

Do not initialize the system if you are driving

with snow chains or a space-saver spare tire

*.<

1.Start the engine, but do not start driving.

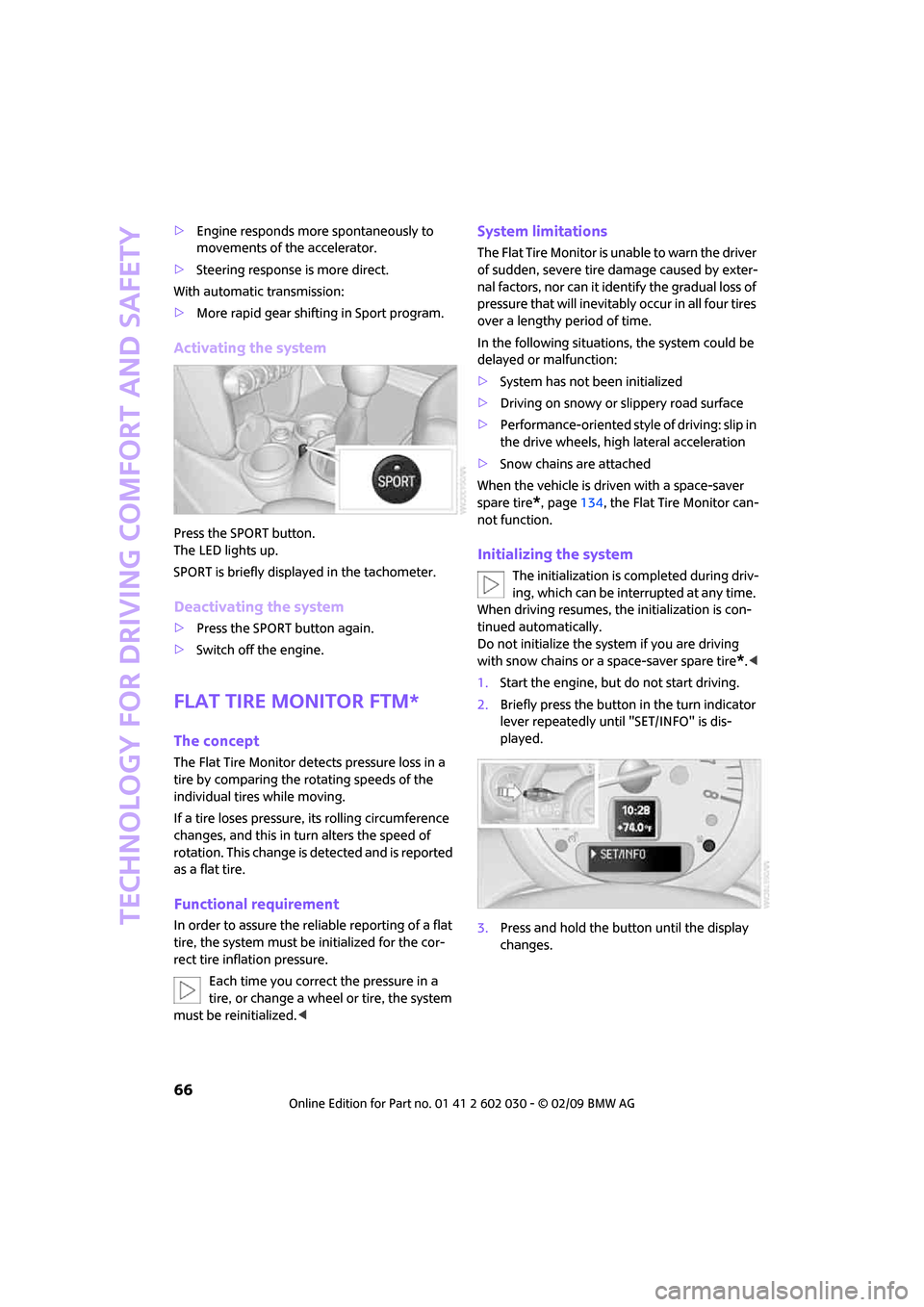

2.Briefly press the button in the turn indicator

lever repeatedly until "SET/INFO" is dis-

played.

3.Press and hold the button until the display

changes.

Page 133 of 176

REFERENCEAT A GLANCE CONTROLS DRIVING TIPS MOBILITY

131

>Tire change with space-saver spare tire,

page133

MINI Mobility System with onboard tool

kit and tire change set*

Follow the instructions on using the Mobil-

ity System found on the compressor and

the sealant bottle.<

Do not remove foreign bodies which have pen-

etrated the tire if possible.

Pull the sticker for the speed restriction off and

apply it to the steering wheel.

The Mobility System with onboard tool kit and

tire change set

* is located under the floor mat in

the cargo bay.

1Filling canister

2Hexagon wrench

*

3Vehicle jack*

4Wheel stud wrench

5Flat screwdriver/Phillips screwdriver,

towing eyelet

6Compressor

7Package with filling hose, valve remover,

valve insert and speed restriction label

Use of the Mobility System may be ineffec-

tive if the tire puncture measures approx.

1/8 in/4 mm or more. Contact the nearest MINI

Dealer if the tire cannot be made drivable with

the Mobility System.<

Liquid sealant

1Filling hose

2Filling canister

Filling

1.Shake the filling canister.

2.Screw the filling hose onto the filling

canister.

3.Unscrew the dust cap from the valve of the

defective tire.

4.Screw out the valve core with the valve

remover. The valve remover is located in a

package with the filling hose.

5.Remove the cap from the filling hose.

6.Push the filling hose onto the tire valve.

7.Hold the filling canister with the cap down

and squeeze.

8.Squeeze the entire contents of the canister

into the tire.

9.Remove the filling hose.

10.Screw the valve core into the tire valve with

the valve remover.

In the event of a lost or dirty valve core

you will find another valve core in the

package with the filling hose.

Remember that the liquid canister must be

replaced every four years if the equipment has

not been used.<

Compressor

Connector, cable and connection hose are

stored in the compressor housing.