light MINI COOPER 2003 Owner's Guide

[x] Cancel search | Manufacturer: MINI, Model Year: 2003, Model line: COOPER, Model: MINI COOPER 2003Pages: 148, PDF Size: 3.17 MB

Page 101 of 148

99

OVERVIEW REPAIRSOPERATIONCONTROLS DATA INDEX

CARING FOR YOUR VEHICLESuitable car-care products

Use the cleaning and car-care prod-

ucts available at your MINI Dealer.<

Washing your vehicle You can wash your new MINI from the out-

set in automatic car washes. Preference

should be for cloth car washes. If, due to

lack of availability, brush car washes must

be used, modern systems with soft brushes

should be given preference.

When using steam cleaners or high-

pressure cleaners, maintain sufficient

distance to the vehicle and do not exceed a

maximum temperature of 140 7 / 60 6.

If the jet is too close or the pressure is too

high, this can lead to damage or initial

damage that can develop into more serious

damage. Water that enters vehicle compo-

nents can lead to damage over the long

term.<

After washing the vehicle, apply the

brakes briefly to dry them, otherwise

water can reduce braking efficiency over

the short term and the brake rotors can cor-

rode.<

Switch the rain sensor off when pass-

ing through an automatic car wash,

see page 54. Failure to do so could result in

damage caused by undesired wiper activa-

tion.<

Rod antenna

If necessary, for example before

entering a car wash or a garage with

elevator ramp, remove the rod antenna.

To do so, grip the rod antenna at the base

and unscrew it from the antenna foot by

turning it to the left.<

Headlamps

When cleaning the headlamps,

please observe the following: do not

rub them dry, and never use abrasives or

strong solvents. Remove dirt and contami-

nation – such as insects – by soaking with

shampoo and then rinsing with plenty of

water. Always use a deicer spray to remove

accumulated ice and snow – never use a

scraper.<

Vehicle paintwork Regular care contributes greatly to driving

safety and value retention.

Environmental influences varying from one

region to the next can affect the vehicle

paintwork. Please base the frequency and

scope of car care on these various influ-

ences.Care of upholstery Depressions that come about on the uphol-

stery material of the seats in daily use can

be brushed out using a slightly damp brush

against the grain.

The fact that velour lays down is not a qual-

ity defect, but rather is inevitable in the

case of home textiles or clothing materials.

In the case of strong sunlight and longer

parking periods, cover the seats or all win-

dows to prevent discoloration.

ba.book Seite 99 Montag, 5. August 2002 8:09 20

ProCarManuals.com

Page 102 of 148

100

CARING FOR YOUR VEHICLECare of special parts >Light-alloy wheels

*:

Use wheel cleaner especially during the

winter months, but do not use any

aggressive, acidic, strong alkali or rough

cleansers or steam jets above 140 7 /

60 6. Observe the manufacturer's

instructions

>Chrome parts

* such as cooler grille, door

handles, etc.:

Especially if exposed to road salt, care-

fully clean these parts with plenty of

water and possibly with a shampoo addi-

tive.

For additional treatment, use chrome

polish

>Rubber parts:

Treat only with water or rubber care

products

Do not use silicon sprays or other

silicon-containing care products,

otherwise noise and damage could

occur.<

>Plastic parts, imitation leather surfaces,

headliner, lamp glass, covering glass for

the instrument cluster, as well as matt

black molded parts:

Clean with water and, if necessary, plas-

tic care products. Do not dampen seats

and the headliner.

Never use solvents such as lacquer thin-

ner, heavy-duty grease remover, fuel or

similar

>Wood paneling

*:

Please clean wood paneling and other

wood parts only with a damp cloth. Dry

off with a soft cloth

>Safety belts:

Only clean using mild soap, leaving the

belts fitted.

Do not dry clean, as the fabric can be

destroyed.

Always roll up safety belts only when dry.

Dirty safety belts prevent unrolling and

thus negatively affect safety>Floor carpets and floor mats

*:

If heavily soiled, clean using interior

cleaner. Floor mats can be removed to

allow the interior to be cleaned

>Wiper blades:

Clean with soapy water. Replace wiper

blades twice a year, before and after the

cold season. This is particularly impor-

tant on vehicles fitted with a rain sensor.

ba.book Seite 100 Montag, 5. August 2002 8:09 20

ProCarManuals.com

Page 104 of 148

102

OBD SOCKET The interface socket for onboard diagnos-

tics is located on the driver's side, behind a

cover located beneath the instrument

panel. The cover has the letters OBD on it.

The purpose of the OBD system is to ensure

proper operation of the emission control

system for the vehicle‘s lifetime. The sys-

tem monitors emission-related compo-

nents for deterioration and malfunction.

An illuminated lamp informs you of

the need for service, not of the

need to stop the vehicle.

However, the system should be checked by

your MINI Dealer at the earliest possible

opportunity.

Under certain conditions, the indicator will

blink or flash. This indicates a rather severe

level of engine misfire. When this occurs,

you should reduce speed and consult the

nearest MINI Dealer as soon as possible.

Severe engine misfire over only a short

period of time can seriously damage emis-

sion control components, especially the

catalytic converter.

Service Engine Soon warning lamp

for Canadian models.

When the filler cap is not properly

tightened, the OBD system can detect

the vapor leak and the indicator will light

up. If the filler cap is subsequently tight-

ened, the indicator lamp should go out

within a few days.<

ba.book Seite 102 Montag, 5. August 2002 8:09 20

ProCarManuals.com

Page 109 of 148

107

OVERVIEW REPAIRSOPERATION CONTROLS DATA INDEX

LAMPS AND BULBSProceed carefully when handling lamps and

bulbs. If you are not familiar with any of

the procedures, consult your MINI Dealer.

Do not touch the glass portion of a

new bulb with your bare hands since

even small amounts of impurities burn into

the surface and reduce the service life of

the bulb. Use a clean cloth, paper napkin, or

similar material, or hold the bulb by its

metallic base.<

Replacement bulbs are available from your

MINI Dealer.

Whenever working on the electrical

system, switch off the electrical

accessory you are working on or disconnect

the cable from the negative terminal of the

battery. Failure to do this could result in

short circuits.

To prevent injuries and damage, comply

with any instructions provided by the bulb

manufacturer.<

1Low beams H7 bulb, 55 Watts2High beamsH7 bulb, 55 Watts

The H7 bulb is pressurized. Therefore,

wear safety glasses and protective

gloves. If the lamp is damaged there is a

risk of injury.

1. Pull on the tab of the cover of the defec-

tive lamp and open it

2. Press the retaining wire lightly at the

eyelet and at the same time guide it out-

wards

3. Fold the retaining wire down

4. Remove the lamp holder and replace the

lamp

5. Reinsert the lamp holder in the correct

position

6. Fold the retaining wire back up and

catch in place. Ensure that it is placed in

the middle of the wire connector.Xenon lamps* The service life of these bulbs is very long

and the probability of a failure is very low,

provided that they are not switched on and

off an unusual number of times. If one of

these bulbs should nevertheless fail, it is

possible to continue driving with great cau-

tion using the fog lamps, provided traffic

laws in your area do not prohibit this.

Because of the extremely high volt-

ages involved, any work on the xenon

lighting system should be carried out by

technically-qualified personnel only. Other-

wise, there is a risk of fatal injury.<

ba.book Seite 107 Montag, 5. August 2002 8:09 20

ProCarManuals.com

Page 115 of 148

113

OVERVIEW REPAIRSOPERATION CONTROLS DATA INDEX

CHANGING TIRES – MINI WITH SPACE-SAVER SPARE TIRE

*

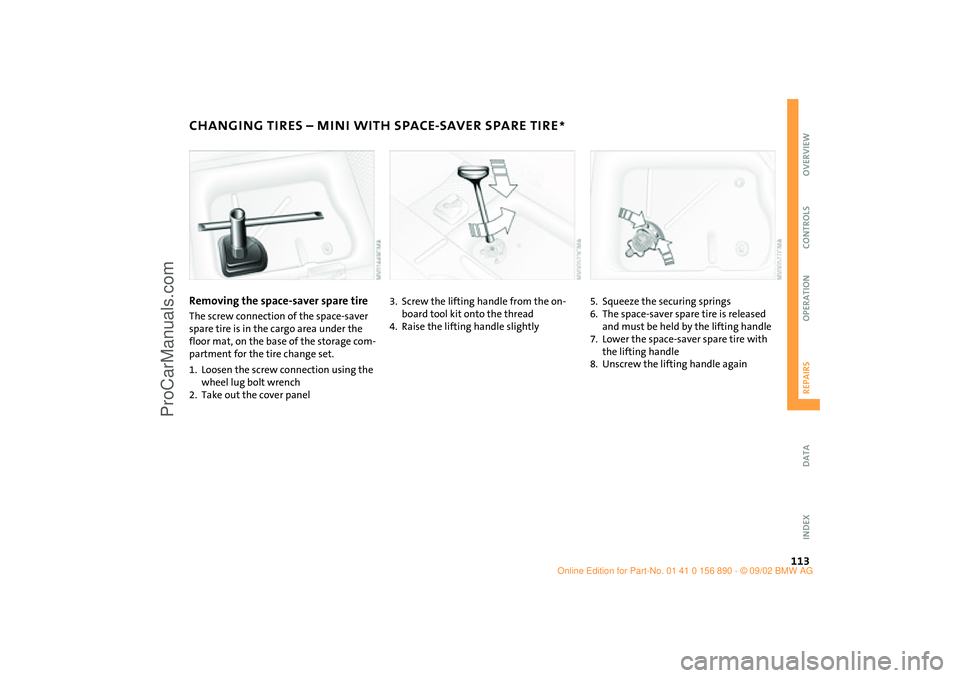

Removing the space-saver spare tire

The screw connection of the space-saver

spare tire is in the cargo area under the

floor mat, on the base of the storage com-

partment for the tire change set.

1. Loosen the screw connection using the

wheel lug bolt wrench

2. Take out the cover panel

3. Screw the lifting handle from the on-

board tool kit onto the thread

4. Raise the lifting handle slightly

5. Squeeze the securing springs

6. The space-saver spare tire is released

and must be held by the lifting handle

7. Lower the space-saver spare tire with

the lifting handle

8. Unscrew the lifting handle again

ba.book Seite 113 Montag, 5. August 2002 8:09 20

ProCarManuals.com

Page 118 of 148

116

FLAT TIRE– RUN FLAT TIRES

*

You will recognize Run Flat tires by a circu-

lar symbol containing the letters RSC on

the side of the tire.

Run Flat tires consist of self-contained tires

and special rims. The tire reinforcement

ensures that the tire retains some residual

safety in the event of pressure drop and

driving remains possible to a restricted

degree.

The reinforcement on the flanks of

the Run Flat tires means that it is usu-

ally not possible to detect an air loss from

outside.<

Flat tire The yellow indicator lamp in the instru-

ment cluster lights up to indicate a flat tire.

In addition, a gong sounds, see pages 17,

64.

1. Reduce vehicle speed carefully to under

50 mph / 80 km/h, avoiding hard brake

applications and steering maneuvers.

2. Do not exceed a speed of 50 mph /

80 km/h.

3. Identify damaged tires; check tire infla-

tion pressures on all four wheels at the

next opportunity, see page 85

4. Correct the tire inflation pressure if you

wish to continue your journey and this is

permitted, see next text section

5. Have damaged tires changed by your

MINI Dealer, see page 88.Your MINI Dealer has the information

needed for working with Run Flat

tires and is equipped with the necessary

special tools. They provide advice if you

wish to replace the tires on your MINI, or re-

equip from summer to winter tires or vice

versa, also see pages 85, 88, 89.<

For safety reasons, do not have a

damaged safety tire repaired.<

ba.book Seite 116 Montag, 5. August 2002 8:09 20

ProCarManuals.com

Page 120 of 148

118

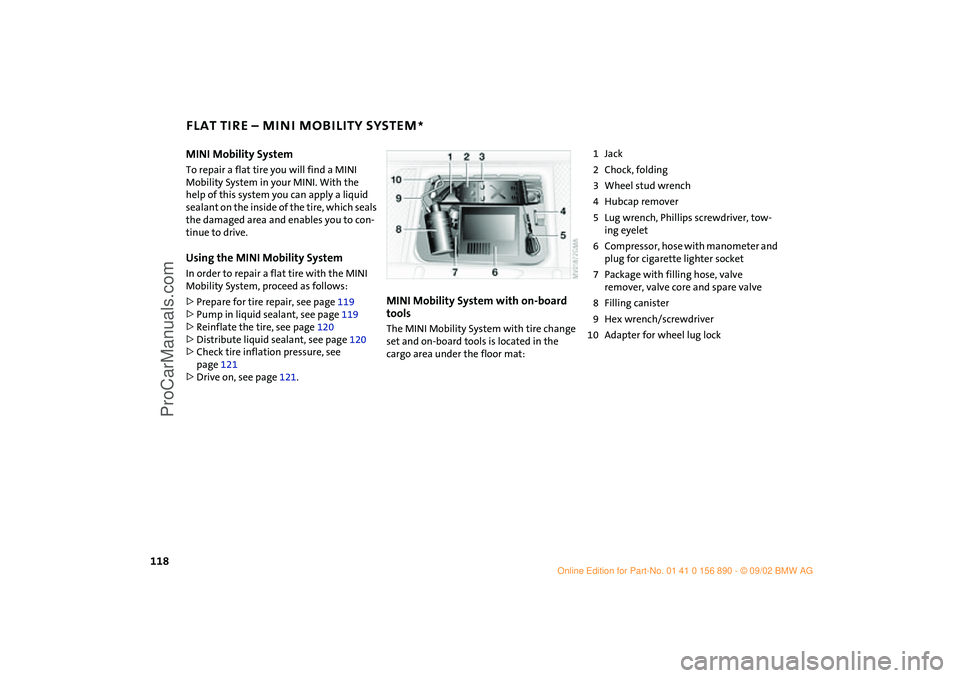

FLAT TIRE – MINI MOBILITY SYSTEM

*

MINI Mobility System

To repair a flat tire you will find a MINI

Mobility System in your MINI. With the

help of this system you can apply a liquid

sealant on the inside of the tire, which seals

the damaged area and enables you to con-

tinue to drive. Using the MINI Mobility SystemIn order to repair a flat tire with the MINI

Mobility System, proceed as follows:

>Prepare for tire repair, see page 119

>Pump in liquid sealant, see page 119

>Reinflate the tire, see page 120

>Distribute liquid sealant, see page 120

>Check tire inflation pressure, see

page 121

>Drive on, see page 121.

MINI Mobility System with on-board

toolsThe MINI Mobility System with tire change

set and on-board tools is located in the

cargo area under the floor mat:

1Jack

2Chock, folding

3Wheel stud wrench

4Hubcap remover

5Lug wrench, Phillips screwdriver, tow-

ing eyelet

6Compressor, hose with manometer and

plug for cigarette lighter socket

7Package with filling hose, valve

remover, valve core and spare valve

8Filling canister

9Hex wrench/screwdriver

10 Adapter for wheel lug lock

ba.book Seite 118 Montag, 5. August 2002 8:09 20

ProCarManuals.com

Page 122 of 148

120

FLAT TIRE – MINI MOBILITY SYSTEM

*

Reinflating the tire

1. Screw hose 1 with manometer onto the

tire valve

2. Connect plug 3 to the cigarette lighter

socket in the vehicle interior, see

page 73

3. Ignition key in position 1:

Turn on compressor 2

4. Pump up the tires to at least 26.1 psi /

180 kPa, but not to more than 36.2 psi /

250 kPa.

To check the current air pressure, shut

off the device for a short time

Do not run the compressor for

longer than 6 minutes, otherwise

the device will overheat and possibly be

damaged.<

If an air pressure of 26.1 psi /

180 kPa cannot be reached, drive

back and forth about 35 ft / 10 m so that

the liquid sealant is distributed in the

tire. Afterwards repeat the procedure.

If an air pressure of 26.1 psi / 180 kPa is

still not reached, the tire is too badly

damaged. Please contact the nearest

MINI Dealer.<

5. Turn off compressor 2

6. Unscrew hose 1 from the tire valve

7. Store the MINI Mobility System back in

the vehicle.

Distributing liquid sealantImmediately drive for 10 minutes, so that

the liquid sealant is uniformly distributed.

Do not exceed a speed of 40 mph /

60 km/h).

If possible do not drive at a speed lower

than 10 mph / 20 km/h. Stop at a suitable

location.<

ba.book Seite 120 Montag, 5. August 2002 8:09 20

ProCarManuals.com

Page 127 of 148

125

OVERVIEW REPAIRSOPERATION CONTROLS DATA INDEX

JUMP-STARTINGPreparing for jump-starting1. Check whether the battery of the sup-

port vehicle has 12 Volts and approxi-

mately the same capacity – measured in

Ah, printed on the battery

2. Switch off the engine of the support

vehicle

3. Switch off any electrical systems and

components in both vehicles – except

for the hazard warning flashers of the

support vehicle.

>Do not disconnect the discharged bat-

tery from the vehicle electrical system

>Make certain that there is no contact

between the bodywork of the two

vehicles – short circuit hazard!

4. With the battery of the MINI COOPER,

remove the cover panel. To do so, press

both clips at the same time

or

with the MINI COOPER S, open the cover

of the positive terminal connection for

jump-starting

*, see arrow 1.

Connect the jumper cables

Adhere to the sequence also when

providing support for other vehicles;

failure to observe this procedure can lead

to sparks at the terminals and pose an

injury hazard.<

1. On the MINI COOPER S, the positive ter-

minal connection for jump-starting, see

arrow 1, functions as the positive bat-

tery terminal.

Make a connection with the "+" jumper

cable between the positive terminal of

the discharged battery and the positive

terminal of the support battery

2. Use the second, "–" jumper cable to set

up the connection between the negative

terminals of both vehicles.

To do so:

>Connect one terminal clamp to the

negative terminal and/or to an engine

or body ground of the support vehicle

>Connect the second terminal clamp to

the negative terminal of the battery

and/or to an engine or body ground of

the vehicle to be started. For the MINI,

see arrow 2.

Performing the jump-start1. Start the engine of the vehicle providing

the current and allow to run at a fast idle

speed for several minutes

2. Start the engine on the vehicle with the

discharged battery in the usual manner.

>If the first start attempt is not suc-

cessful, wait a few minutes before

another attempt in order to allow the

discharged battery to recharge

On the MINI:

Before disconnecting the jumper

cables, switch on the lighting, rear window

defroster and the highest blower speed as

well as the engine for at least approx.

10 seconds to prevent a voltage surge from

the regulator to the electrical systems and

components.<

3. Then disconnect the jumper cables in

the reverse order.

If necessary have the battery checked and

completely charged at a MINI Dealer.

ba.book Seite 125 Montag, 5. August 2002 8:09 20

ProCarManuals.com

Page 138 of 148

EVERYTHING FROM A TO Z

136

A

ABS (Antilock Brake

System)16,17,83

Accessories7,99

Activated-charcoal filter72

Adjusting

backrest35

steering wheel38

Air conditioner operation

air conditioning system68

automatic climate

control71

Air conditioning system67

Air distribution

air conditioning system68

automatic climate

control71,72

Air outlets, ventilation69

Air pressure85

Air recirculation68,71

Air supply

air conditioning system68

automatic climate

control71

Air vents69,72

Air, dry68

Air, drying71

Airbags16,33,40

Airing out69

Alarm system31

All-season tires89 Antenna99

Antifreeze96

Antilock Brake System

(ABS)16,17,83

Anti-theft system31

Aquaplaning, see

Hydroplaning81

ASC+T (Automatic Stability

Control plus

Traction)16,17,62

Ashtray73

AUTO Program, see Automatic

air distribution71

Auto washing99

Automatic

air distribution71

air supply71

cruise control56

Automatic car wash99

Automatic climate control70

Automatic Stability Control

plus Traction

(ASC+T)16,17,62

Average fuel consumption61

Average speed61

Axle loads132

B

Backrest, adjusting35

Backup lamps48

bulb replacement109 Bar, towing126

Battery124

charge current15

charging122

disposal122

maintenance122

Battery, remote control22

Belts33,38

Beverage holder73

Blower71

BMW6

Bonnet16,91

Bore130

Brake fluid level15,84,97

Brake hydraulic system15

Brake lamp

bulb replacement109

Brake pads80,84

Brake rotors80

Brake system80,84

brake fluid97

Brakes81,84

Braking system16

Breaking-in80

Bridging124

Bulb replacement

backup lamps109

brake lamp, center110

cargo area lamps111

footwell lamps111

front fog lamps108 front turn signal

indicators108

glove compartment

lamp111

interior lamps110

license plate lamp110

parking lamps108

reading lamps110

rear lamps109

side turn signal

indicators108

standing lamps108

tail lamps109

vanity mirror111

C

California Proposition

65 warning103

Capacity

fuel tank133

Car care99

Car wash99

Car-care products99

Care99

chrome parts100

floor mats100

imitation leather100

leather101

light-alloy wheels100

plastic parts100

rubber parts100

Hilfsrahmen für Querverweise

ba.book Seite 136 Montag, 5. August 2002 8:09 20

ProCarManuals.com